如何计算喷雾干燥机容量的分步指南

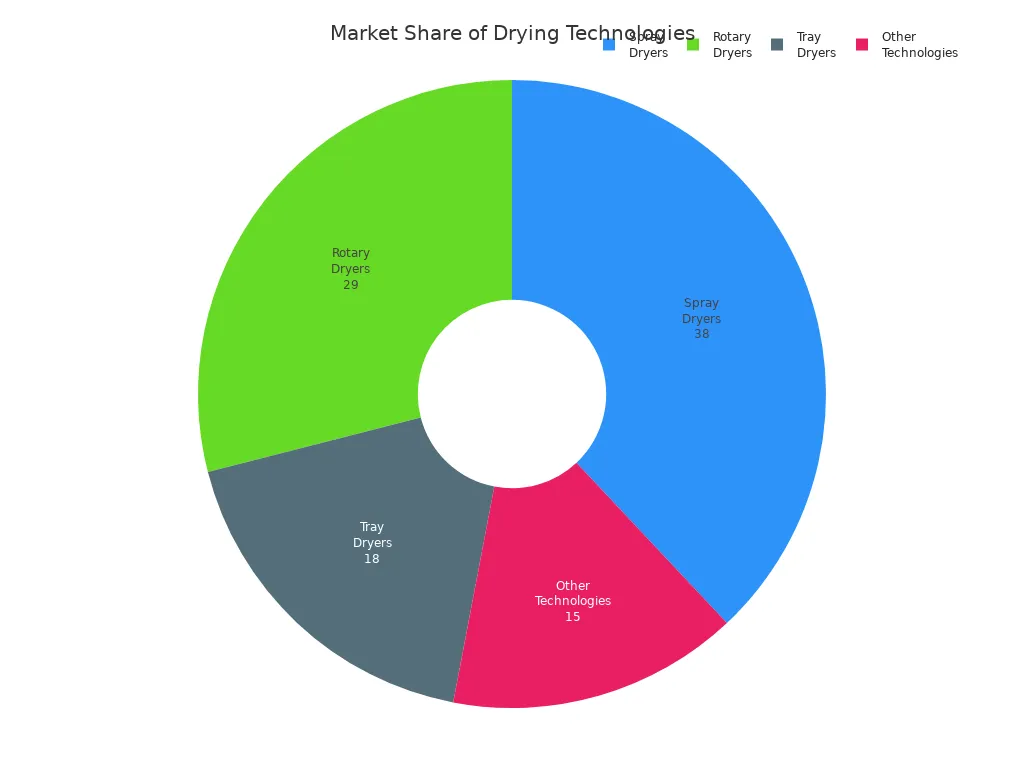

You need a clear process to calculate spray dryer capacity. Start by finding the moisture in your feed. 下一个, figure out how much water you must remove. Check the drying rate, look at thermal efficiency, and finally, calculate the capacity. Accurate data helps you get the right answer. Each parameter matters in spray dryer calculations. Spray dryers hold 38% of the industrial drying market, making them the most popular choice.

You will see a practical example and learn how to avoid common mistakes.

关键要点

Gather accurate data before starting calculations. Key data includes feed moisture, inlet and outlet temperatures, 和气流. Reliable data leads to better results.

Calculate the amount of water to evaporate using the moisture content before and after drying. This step is crucial for determining the dryer’s capacity.

Monitor drying rate factors like droplet size and airflow. Adjusting these can improve drying efficiency and product quality.

Assess thermal efficiency to maximize energy use. Higher efficiency means more drying with less energy, saving costs and increasing capacity.

Always include a safety margin in your calculations. This buffer helps manage unexpected changes and protects your process from errors.

Essential Data for Spray Dryer Calculations

Before you start spray dryer calculations, you need to gather some important data. Accurate measurements help you get reliable results. Each parameter affects the drying process and the final product. The table below shows the most critical data points you should collect:

Critical Data Points | 描述 |

|---|---|

Inlet and Outlet Temperatures | These temperatures help you determine drying efficiency and performance. |

Moisture Contributions | Includes moisture from air and combustion, which changes the drying process. |

Air Volume Measurement | Needed to calculate flow rates and keep the dryer working well. |

Water Contribution from Evaporation | Shows how much water you need to remove during drying. |

Drying-Gas Flow Rate | Influences the heat balance in the system. |

Feed Moisture Content

You must know how much water is in your feed before drying. Higher moisture content means you need more energy and time to dry the product. If the feed moisture changes, the final powder can have different sizes, 密度, 和溶解度. You can measure feed moisture by checking the soluble solids (like Brix), monitoring air humidity, or tracking temperature during drying.

提示: Keep feed moisture steady to get consistent product quality.

Desired Product Moisture

Set a target for how dry you want your final product. This value helps you decide how much water to remove. If you do not reach the right moisture level, your product may spoil or not dissolve well.

Inlet and Outlet Air Temperatures

Inlet and outlet temperatures control how fast water leaves the product. High inlet temperatures can dry faster but may hurt product quality. The right balance keeps your powder stable and safe for storage.

Changes in these temperatures affect the powder’s moisture and how well it stores.

Managing these temperatures helps you avoid sticky or clumpy powders.

Airflow and Humidity

You need to measure airflow and humidity to control drying. Use tools like hot-wire anemometers or chilled mirror hygrometers for best results. Good airflow keeps the drying even and helps you reach your target moisture.

笔记: Accurate airflow and humidity readings make your spray dryer calculations more precise.

Step-by-Step Spray Dryer Calculations

Spray dryer calculations follow a logical order. Each step builds on the last. You need to move through each stage carefully to get an accurate result.

Calculate Water to Evaporate

Start by finding out how much water you need to remove from your feed. This step forms the base for all other spray dryer calculations. You use the moisture content before and after drying to find the amount of water to evaporate.

Here is a table that shows the formulas you need:

Formula for Amount of Evaporated Water |

|---|

1. Material weight after drying (公斤/小时) = (1 – moisture content before drying) × [Material weight before drying (公斤/小时)] ÷ (1 – moisture content after drying) |

2. Material weight before drying (公斤/小时) = (1 – moisture content after drying) × [Material weight after drying (公斤/小时)] ÷ (1 – moisture content before drying) |

3. Amount of evaporated water (公斤/小时) = [Material weight before drying (公斤/小时)] – [Material weight after drying (公斤/小时)] |

The initial feed moisture content changes how much water you need to evaporate. If your feed has high moisture, you need less energy to remove water. If the feed has low moisture, you need more energy. The table below shows this relationship:

Moisture Content Level | Energy Required for Evaporation | Activation Energy Relationship |

|---|---|---|

高的 | Less energy needed | Minimum energy required |

低的 | More energy needed | Energy increases with less water present |

提示: Always measure your feed moisture and product moisture carefully. Small errors can lead to big mistakes in your spray dryer calculations.

Determine Drying Rate

The drying rate tells you how fast water leaves your product. Many factors affect this rate. You need to know these to make your spray dryer calculations accurate.

因素 | 描述 |

|---|---|

液滴尺寸 | Larger droplets take longer to dry. Variation in size leads to uneven drying. |

雾化压力 | Higher pressure makes smaller droplets. This improves drying rate, but too much pressure can cause wear. |

Drying Air Temperature | Higher temperatures speed up evaporation. Very high temperatures can damage sensitive products. |

风量 | High airflow helps mass transfer. Too much airflow can cause dust and incomplete drying. |

Humidity of Drying Air | High humidity slows down evaporation. |

居住时间 | Short time means incomplete drying. Long time can over-dry the product. |

You can adjust these factors to control the drying rate. 例如, you can increase the air temperature or change the atomization pressure.

Assess Thermal Efficiency

Thermal efficiency shows how well your spray dryer uses energy. You want to get the most drying with the least energy. Several methods help you improve thermal efficiency:

Use energy recovery systems, like air-to-air heat exchangers. These can boost energy efficiency by up to 34%.

Optimize process settings, such as solid concentration and inlet air temperature. Small changes can make a big difference.

Try new atomization techniques. Monodisperse atomization lets you spray thicker fluids and saves energy.

笔记: Improving thermal efficiency not only saves energy but also increases your spray dryer’s capacity.

Final Capacity Calculation

Now you can calculate the final capacity of your spray dryer. This step brings together all your earlier work. You use the amount of water to evaporate, the drying rate, and the thermal efficiency.

Higher processing temperatures increase heat flow and boost capacity.

Lower water content in your feed saves energy and improves performance.

Drying air with low humidity lets your spray dryer work better. High humidity limits how much water you can remove.

You need to check each parameter. If you change one, it affects the others. 例如, if you raise the air temperature, you may dry faster, but you must watch product quality. If you lower the humidity, you can increase capacity, but you may need to adjust other settings.

记住: Each step in spray dryer calculations depends on the last. Always double-check your numbers before moving to the next step.

Example of Spray Dryer Calculations

Sample Data and Assumptions

You need sample data before you start spray dryer calculations. Here are some common assumptions you might use:

你 assume all liquid in the feed will evaporate inside the spray dryer.

You consider the relative humidity of the drying air. This helps you predict how much water will actually evaporate.

You adjust the amount of evaporated liquid based on the humidity. This prevents you from making unrealistic predictions.

Let’s say you want to dry a dairy feedstock. You have 50 liters of liquid feed per hour. The feed has 45% 水分. You want the final product to have 4% 水分. The inlet air temperature is 180°C. The outlet air temperature is 90°C. The airflow is 400 公斤/小时. The relative humidity is 10%.

Calculation Walkthrough

You can follow these steps to calculate the spray dryer capacity:

Find the amount of water to evaporate:

Water to evaporate = (进给速度) × (Initial moisture – 最终水分)

Water to evaporate = 50 L/h × (0.45 – 0.04) = 20.5 L/h

Check the drying rate:

Drying rate depends on air temperature, 空气流动, 和湿度.

Higher air temperature and lower humidity help you dry faster.

Assess thermal efficiency:

If you use energy recovery, you can save energy and increase capacity.

Calculate final capacity:

Medium-sized spray dryers can process between 10 和 100 升每小时.

Your result fits within this range.

提示: Always compare your results with manufacturer specifications. This helps you spot errors early.

Capacity Result

Your calculated capacity matches what most medium-scale spray dryers can handle. You can check your numbers against supplier data using the table below:

范围 | |

|---|---|

Total Solids Percentage | Should match as specified by the user |

Primary Air Temperature | Must align with user specifications |

空气流动 (公斤/小时) | Should not differ significantly |

Absolute Humidity | Must match as specified by the user |

Exhaust Air Temperature | Should be similar across suppliers |

Exhaust Airflow (公斤/小时) | Can be up to 30% higher than primary air |

Exhaust Relative Humidity | Should be closely compared between suppliers |

Gas Retention Time (GRT) | Big differences may mean calculation errors |

You can use this example to guide your own spray dryer calculations. Always check your data and compare with supplier specs for best results.

Common Mistakes and Pro Tips

Data Accuracy Issues

You need accurate data for every step of your spray dryer calculation. Small mistakes in measuring feed moisture or air temperature can lead to big errors in your final results. If you use outdated or estimated values, you may overestimate or underestimate your dryer’s capacity. Always use calibrated instruments and double-check your numbers.

提示: Record all measurements in a logbook. This helps you spot trends and catch errors early.

Applying Safety Margins

You should always include a safety margin in your calculations. This extra buffer helps you handle unexpected changes in feed properties or process conditions. 例如:

A 10% oversizing of your calculated minimum capacity gives you room for error.

You may need to process up to 11% more material than planned if your dryer is less efficient than expected.

By adding a safety margin, you protect your process from sudden changes and avoid costly downtime.

Equipment Limitations

Spray dryers have limits that you must consider during calculations. If you ignore these, you risk poor product quality or equipment failure. Common limitations include:

Inconsistent process parameters can cause uneven drying.

High-viscosity liquids may not dry well.

Thermally sensitive substances can degrade during drying.

Energy use is high, which raises costs.

Some materials need extra filtration to meet safety rules.

Seasonal humidity changes can slow drying and cause clumping.

笔记: Always check your material’s properties and your dryer’s specifications before starting a new process.

Pro Tips for Optimization

You can improve your calculations and process by using modern tools and methods. The table below shows some helpful strategies:

Strategy Type | 描述 |

|---|---|

热力学模型 | Use these to understand how droplets dry and to set better process targets. |

Computer Simulations | Predict and optimize your dryer’s performance with digital models. |

Small-Scale Experiments | Test your process on a small scale to confirm your calculations. |

Digital optimization tools help you improve efficiency and reduce environmental impact. New digital approaches make it easier to manage and adjust your spray drying process for better results.

You now know the key steps to calculate spray dryer capacity.

Gather accurate data

Calculate water to evaporate

Check the drying rate

Assess thermal efficiency

Find the final capacity

Always double-check your numbers. 如果您感到不确定, ask an expert or read the equipment manual. Use this guide for your own calculations. Careful work helps you get the best results every time.

常问问题

What is the most important data for spray dryer calculations?

You need accurate feed moisture and product moisture data. These numbers help you find how much water you must remove. Inlet and outlet air temperatures also matter. Always check your airflow and humidity readings.

How do you measure feed moisture content?

You can use a moisture analyzer or a drying oven. Some people use a refractometer for liquids. Always use the same method for each batch to keep results consistent.

Why does thermal efficiency affect spray dryer capacity?

Thermal efficiency shows how well your dryer uses energy. High efficiency means you dry more product with less energy. You save money and increase capacity when you improve efficiency.

Can you use any material in a spray dryer?

不. Some materials do not dry well or may burn. You should check if your material can handle high temperatures and fast drying. Always read the equipment manual.

What happens if you skip the safety margin in your calculations?

Skipping the safety margin can cause problems. You may overload your dryer or get poor product quality. Always add a safety margin to protect your process.