喷雾干燥器设计使每个行业变得简单

工业喷雾干燥依赖于不同类型的喷雾干燥机, 包括单级, 两阶段, 和并行设计, 每个都使用独特的雾化方法. 了解喷雾干燥机设计可提高产品质量和工艺效率.

研究表明 优化喷雾干燥参数,例如入口空气温度或进料流量—减少工艺变异性并提高产量.

下表重点介绍了喷雾干燥系统设计的变化如何影响性能:

有了这些见解, 行业可以根据自己的需求选择合适类型的工业干燥机.

关键要点

不同的 喷雾干燥机设计 像单级的, 两阶段, 并流满足各种行业和产品需求.

根据进料类型和灵敏度选择正确的雾化方法可提高干燥效率和粉末质量.

喷雾干燥通过保持产品质量为许多行业提供支持, 增加产量, 并减少能源使用.

将干燥机设计和工艺参数与产品灵敏度和规模相匹配,确保一致性, 高品质粉末.

先进的技术和建模有助于优化喷雾干燥,以获得更好的性能和更安全的操作.

喷雾干燥技术

什么是喷雾干燥

喷雾干燥是将液体饲料转化为干粉的主要方法. 该过程使用专门的工业干燥机将液体雾化成细小的液滴. 加热的空气快速去除水分, 留下均匀的粉末颗粒. 操作员控制入口温度等参数, 雾化压力, 和气流以实现精确的除湿. 喷雾干燥提供了快速, 连续干燥过程, 使其成为大规模工业干燥的理想选择.

最近的进展推动了 喷雾干燥技术 向前.

这 喷雾干燥机市场达到美元 5.8 十亿 2024 预计将增长至美元 9.2 十亿 2033.

制造商现在集成先进的控制系统和自动化,以实现更好的过程控制.

纳米技术实现纳米颗粒和脂质体的喷雾干燥, 尤其是在制药领域.

耐腐蚀材料提高机器耐用性, 尤其是在食品加工领域.

定制允许在各种应用中专门生产粉末.

人工智能和机器学习支持预测性维护和实时监控.

节能机器和可再生能源解决可持续发展问题.

工业应用

喷雾干燥服务于广泛的工业领域. 在食品行业, 它保留了味道, 营养, 以及奶粉等产品的保质期, 咖啡, 和调味品. 制药公司依靠喷雾干燥机进行精确雾化和除湿, 确保抗生素的完整性, 蛋白质, 和疫苗. 化学品制造商使用喷雾干燥来制造具有受控粒径和高表面积的粉末, 对于催化剂和洗涤剂至关重要. 陶瓷生产商受益于用于铸造和涂层的均匀粉末颗粒.

工业领域 | 喷雾干燥改善了关键性能指标 | 具体改进 |

|---|---|---|

食物 & 奶制品 | 保质期, 营养保存, 风味保留, 干燥效率, 成本效益 | 保质期更长, 保留感官特性, 广泛应用于奶粉中, 婴幼儿配方奶粉, 咖啡, 汤粉 |

药品 | 产品质量一致性, 精准雾化, 生物活性完整性, 吞吐能力 | 保持抗生素的完整性, 蛋白质, 疫苗; 一致的粒径和稳定性 |

化学品 | 颗粒形态, 表面积, 孔隙率, 能源消耗优化 | 催化剂和洗涤剂生产受益于受控颗粒特性和能源效率 |

陶瓷 | 粒径均匀, 干燥效率, 吞吐量 | 由于均匀的颗粒,改进了铸造和涂层工艺 |

喷雾干燥可在工业环境中实现高产率. 例如, 医药喷雾干燥工艺已实现 产量高于 90% 跨多个批次 通过优化气体流量和温度. 这种效率凸显了价值 喷雾干燥机 在工业干燥中实现稳定的粉末生产和可靠的除湿.

不同类型的喷雾干燥机

喷雾干燥技术 提供多种干燥机设计,以满足各个工业领域的需求. 每种类型的干燥机都采用独特的方法将液体饲料转化为粉末. 干燥机的选择影响产品质量, 能源使用, 和流程效率. 了解不同类型的喷雾干燥机有助于行业选择适合其批量或连续生产需求的最佳系统.

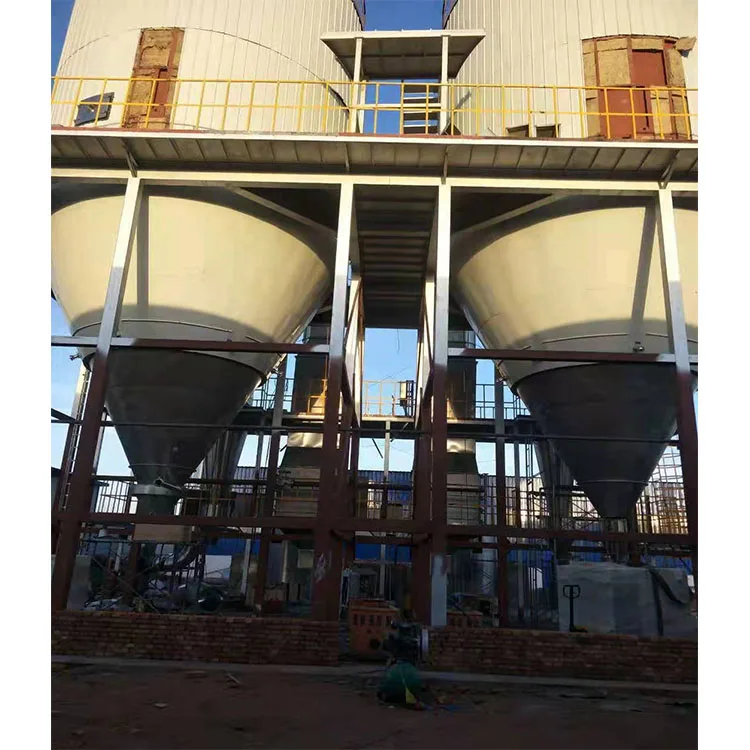

单级喷雾干燥机

单级喷雾干燥机 使用单程干燥工艺. 液体进料进入室并雾化成细小的液滴. 热空气流过腔室, 去除水分并形成粉末. 大多数单级干燥机需要高塔来提供足够的干燥时间. 旋转雾化器可以通过产生螺旋流来缩短容器, 改善较小空间内的干燥效果.

操作人员经常使用单级干燥机进行大规模, 连续生产食品, 化学品, 和陶瓷. 这些干燥机可处理大容量并快速生产干粉. 然而, 单级喷雾干燥机的设计可能会导致更多的粉尘和对颗粒尺寸的控制较少. 喷嘴位置 室内影响污垢和可操作性. 将喷嘴放置在腔室较低的位置可减少污垢并提高性能.

笔记: 单级干燥机最适合不需要严格控制粒度或结块的产品.

两级喷雾干燥机

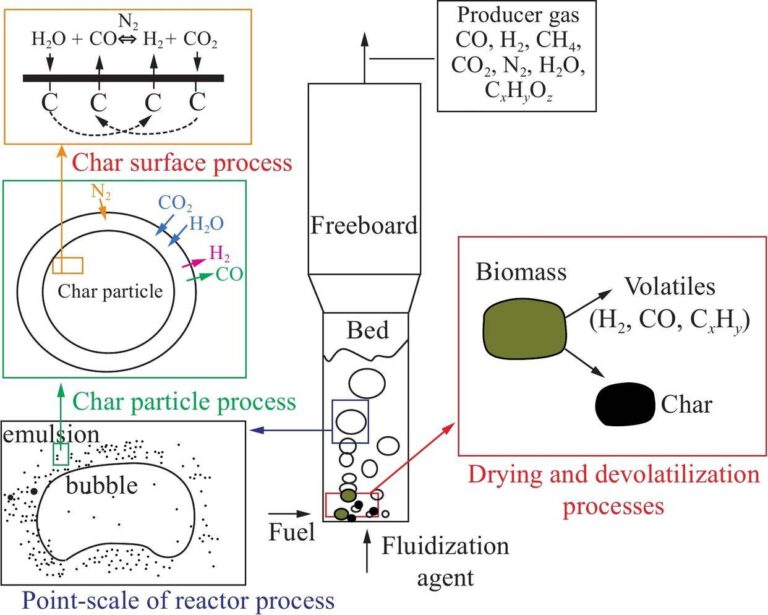

两级喷雾干燥机在干燥过程中添加了流化床. 第一阶段使用雾化室去除大部分水分. 第二阶段采用流化床, 在室内或室外, 完成干燥并冷却粉末. 这种设计通过减少灰尘和允许结块来提高产品质量.

两级干燥机适合需要更好地控制粉末特性的行业. 食品和乳制品生产商经常使用这些干燥机来干燥奶粉和速溶饮料. 两阶段过程支持批量和连续操作. 也降低了出口温度, 保护热敏产品.

并流喷雾干燥机

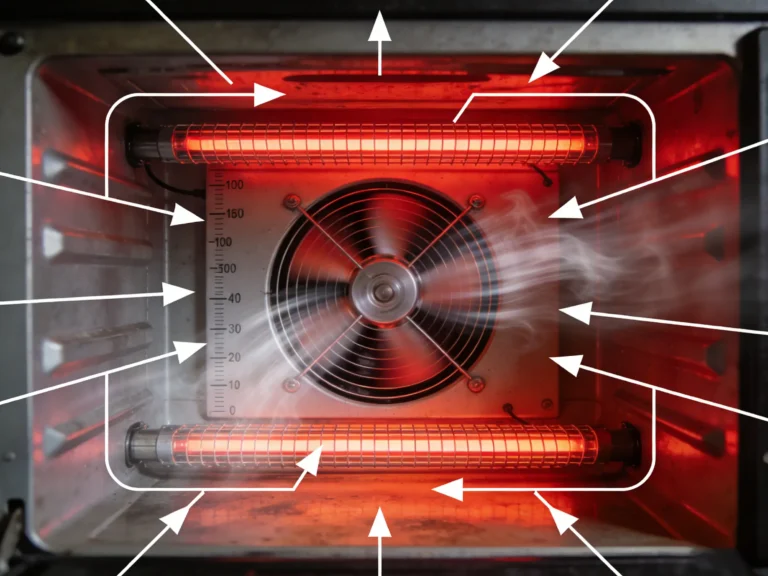

并流喷雾干燥机在干燥室顶部引入热空气和雾化进料. 空气和水滴同向运动. 这种设计创造了温和的干燥条件, 当最热的空气遇到最湿的水滴时. 随着粉末干燥温度下降, 保护敏感成分.

顺流干燥机非常适合需要小心处理的产品, 例如药品和食品香料. 这些干燥机支持连续生产并有助于保持产品质量. 并流流动降低了过热风险并保持粉末均匀.

逆流喷雾干燥机

逆流喷雾干燥机从干燥室底部送出热空气, 而雾化饲料则从顶部进入. 空气和水滴沿相反方向移动. 这种设计将最干燥的粉末暴露在最热的空气中, 可以提高干燥效率.

行业使用逆流干燥机来处理可以处理更高温度的产品. 化学品和陶瓷生产商经常选择这种设计来连续干燥坚固的粉末. 然而, 此方法可能不适合热敏材料, 当最终的粉末面对最热的空气时.

闭式循环喷雾干燥机

闭式循环喷雾干燥机在密封系统中运行. 代替空气, 这些干燥机使用惰性气体, 例如氮气, 干燥饲料. 系统回收气体并回收溶剂, 确保易燃或氧敏感产品的安全.

闭式循环干燥机适用于处理溶剂或需要防止氧化的行业. 制药和化学品制造商使用这些干燥机进行批量和连续生产. 闭环设计提高了安全性并允许溶剂回收, 减少对环境的影响.

提示: 闭式循环喷雾干燥机设计非常适合在工业环境中处理危险或有价值的溶剂.

组合喷雾干燥机

组合喷雾干燥机融合了不同设计的特点. 例如, 干燥机可以使用并流和逆流气流,或者将喷雾干燥与其他干燥方法结合起来. 这些系统为复杂产品提供了灵活性.

当标准设计不能满足行业需求时,行业会使用组合式干燥机. 这些干燥机可以处理特殊粉末, 例如具有独特粒径或水分要求的颗粒. 组合式干燥机支持间歇式和连续式工艺, 使它们适合研究和定制生产.

干燥机类型 | 主要特点 | 典型用途 |

|---|---|---|

单级 | 一次干燥, 高塔 | 食物, 化学品, 陶瓷 |

两级 | 流化床添加, 降尘 | 奶制品, 速溶饮料, 结块 |

并流 | 温和干燥, 同向流 | 药品, 口味 |

逆流 | 高效率, 逆流 | 化学品, 陶瓷 |

闭式循环 | 惰性气体, 溶剂回收 | 药品, 溶剂 |

组合 | 混合设计, 操作灵活 | 定制粉末, 右&D |

喷雾干燥机设计 选择影响能源使用和产品质量. 回收废气 可以提高能源效率, 特别适用于高固体含量饲料. 对回收空气进行除湿可提高其温度并降低加热所需的能量. 这些步骤增加了水分蒸发的驱动力,使喷雾干燥更加高效.

经营者必须考虑饲料的类型, 所需的粉末特性, 在不同类型的喷雾干燥机中进行选择时的安全需求. 每种设计都支持批量和连续生产, 允许行业将其流程与产品相匹配.

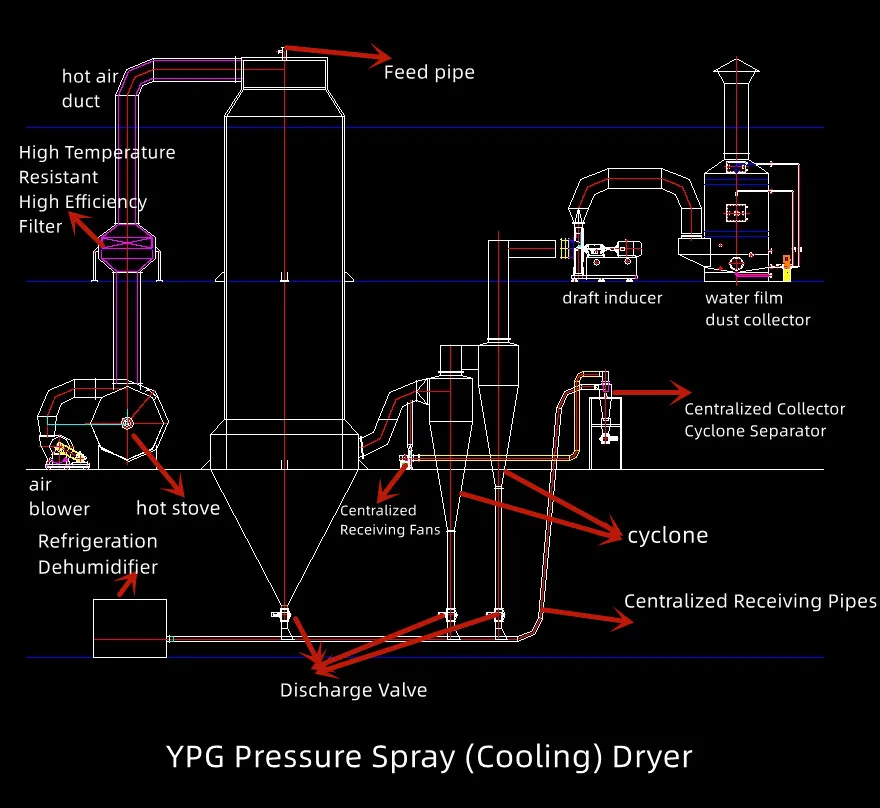

喷雾干燥机设计中的雾化方法

喷雾干燥机的性能在很大程度上取决于雾化方法的选择. 雾化将液体进料分解成细小的液滴, 增加表面积以快速去除水分. 正确的雾化技术确保高效干燥, 一致的粉末质量, 和最佳能源利用. 三种主要雾化方法在工业中占主导地位 喷雾干燥机设计: 旋转雾化器, 压力喷嘴雾化器, 和二流体喷嘴雾化器.

旋转雾化器

旋转雾化器使用高速旋转的盘或轮将液体向外抛出, 形成细小液滴喷雾. 这种雾化方法可以很好地处理粘性或多组分液体. 操作员经常选择旋转雾化器进行大规模生产,因为它们可以产生均匀的液滴尺寸, 这导致粉末颗粒一致并有效去除水分.

旋转雾化器适合化工和乳制品等行业, 进料粘度变化且均匀性至关重要的情况.

压力喷嘴雾化器

压力喷嘴雾化器迫使液体在高压下通过小孔, 创建喷雾. 这种雾化方法产生一系列尺寸的液滴, 可以通过改变压力或喷嘴设计来调节. 压力喷嘴雾化器最适用于低至中等粘度的进料.

CFD 模拟 揭示压力喷嘴雾化器产生独特的流动模式和温度分布.

操作员可以根据特定粉末特性和除湿需求微调液滴尺寸.

这种方法通常会导致更高的传热强度和高效的干燥.

压力喷嘴雾化器常见于食品和制药行业, 精确控制粉末特性至关重要的场合.

二液喷嘴雾化器

双流体喷嘴雾化器将液体进料与压缩空气或气体混合, 将其分解成水滴. 这种雾化方法非常适合热敏饲料或稀释饲料. 添加的空气有助于产生非常细小的液滴, 加速去除水分并产生小粒径粉末.

双流体喷嘴雾化器为实验室规模或特种产品提供灵活性.

它们允许操作员通过改变空气与液体的比率来调整雾化能量.

此方法支持温和干燥, 保护敏感成分.

行业使用双流体喷嘴雾化器进行制药, 口味, 和特种化学品.

选择正确的雾化方法取决于进料粘度, 所需粉末尺寸, 和行业要求. 每种雾化技术都会塑造喷雾图案, 干燥效率, 和最终产品质量.

按应用分类的工业干燥机类型

食品工业

食品工业广泛依赖喷雾干燥. 乳制品生产商使用喷雾干燥机生产奶粉, 婴幼儿配方奶粉, 和咖啡粉. 这些产品需要温和干燥以保留营养成分和风味. 喷嘴雾化干燥机和离心干燥机可以很好地处理热敏性食品. 运营商选择这些 工业干燥机的类型 因其能够批量生产自由流动的粉末. 食品干燥也受益于节能设计, 这有助于降低运营成本. 亚太地区在新型喷雾干燥机安装方面处于领先地位, 受加工食品和饮料需求的推动.

桌子: 喷雾干燥在食品和制药行业中的比较

因素 | 食品加工业 | 医药制造行业 |

|---|---|---|

关键应用 | 奶粉, 蛋粉, 咖啡粉 | 蜜蜂, 疫苗, 生物制剂 |

市场份额 (烘干机) | 离心喷雾干燥机: 45.2% (2024) | |

产品优点 | 批量生产, 纹理保存 | 精确, 稳定, 生物利用度 |

医药行业

药品制造依靠喷雾干燥来生产具有精确粒径和稳定性的粉末. 离心喷雾干燥机在该领域占据主导地位, 支持活性药物成分的生产 (蜜蜂), 疫苗, 和生物制品. 这些干燥机可确保粉末均匀并保护敏感化合物. 业界重视先进的干燥技术,因为它能够保持生物利用度和产品完整性. 亚太地区药品喷雾干燥领域呈现强劲增长, 反映了生物制剂和先进药物制剂的全球崛起.

化学工业

化学品制造商使用喷雾干燥来制造洗涤剂粉末, 催化剂, 和颜料. 这些应用需要能够处理高温和不同饲料特性的工业干燥机. 逆流和闭式循环喷雾干燥机通常服务于该领域. 操作员选择这些类型的工业干燥机是因为它们的效率和回收溶剂的能力. 所得粉末具有可控的粒径和高表面积, 这对于化学反应和产品性能至关重要.

其他工业用途

喷雾干燥支持许多其他工业干燥需求. 陶瓷生产商依靠喷雾干燥机生产用于铸造和涂层的均匀粉末. 该工艺确保颗粒尺寸一致, 从而提高产品质量. 组合干燥机为研究和定制粉末生产提供灵活性. 饮料制造商使用喷雾干燥生产速溶饮料粉, 确保快速溶解和较长的保质期. 每个应用都受益于根据产品要求匹配正确的干燥器和雾化方法.

提示: 选择正确的喷雾干燥机设计和雾化方法可提高所有工业应用的效率和产品质量.

选择正确的喷雾干燥机设计

关键选择因素

选择正确的 喷雾干燥机设计 需要仔细评估几个因素. 产品敏感性是首要问题. 有些粉末在高温下会降解, 因此操作员必须设置最高入口和出口温度以保护产品质量. 生产规模也很重要. 批量操作适合小批量生产或研究, 而连续系统可处理大容量和稳定的输出. 饲料特性, 例如粘度和固体含量, 影响雾化和干燥过程. 操作员还必须考虑所需的除湿水平以及精确控制粉末特性的需要.

提示: 始终将干燥过程与产品的热敏感性和生产规模相匹配,以获得最佳效果.

基于模型的方法有助于定义批量和连续喷雾干燥的操作空间. 该方法使用质量和能量平衡来预测出口条件, 减少昂贵实验的需要. 操作员可以绘制多元图表,以可视化进料速率或温度的变化如何影响粉末质量.

根据产品需求匹配干燥机

使干燥机设计符合行业要求,确保高效除湿和稳定的产品质量. 下表总结了 指导这一过程的关键基准:

基准 / 范围 | 描述 / 角色 |

|---|---|

最小特定干燥比 | 确保批量和连续运行有足够的吞吐量和流程效率. |

最高出口温度 (输出) | 保护产品密度并防止热降解. |

最高入口温度 (锡) | 避免粘在干燥机入口处, 对于批量和连续模式都至关重要. |

最低出口温度 (输出) | 防止粘性颗粒并确保干燥过程中的良好产量. |

出口相对饱和度 (%RS_输出) | 控制干燥完整性和收集率. |

关键工艺参数 (关键PP) | 包括进给率, 气体流量, 和温度; 与质量和能量平衡的联系. |

基于模型的方法论 | 使用基于物理的计算来定义安全高效的操作空间. |

间歇式喷雾干燥机 为小规模或特种产品提供灵活性. 连续喷雾干燥机提供高通量和均匀性, 使它们成为大规模制造的理想选择. 运营商应选择符合其产品需求的系统, 考虑粉末尺寸等因素, 除湿, 和对热的敏感性. 干燥机类型和工艺参数的正确调整可带来可靠的结果, 跨行业的高品质粉末.

现实世界的工业例子

食品加工

喷雾干燥在食品工业中发挥着至关重要的作用. 工业烘干机将液态奶转化为奶粉, 储存良好且溶解迅速. 许多食品公司使用单级干燥机来处理大批量牛奶, 咖啡, 和蛋制品. 这些干燥机有助于保存营养和风味. 运营商还使用两级干燥机来制作速溶饮料和粉末饮料. 该过程产生一种自由流动的粉末,很容易与水混合. 食品制造商依靠喷雾干燥来满足高需求并保持质量. 现代干燥机使用先进的控制装置来保持粉末特性一致.

药品

制药公司依靠喷雾干燥来制造药物粉末. 工业干燥机可处理小型实验室批次和大型商业运行. 运营商使用 旋转和双流体喷嘴雾化器 控制颗粒大小和流动性. 氮气常作为干燥气体以保护敏感药物. 喷雾干燥有助于生产吸入器粉末和难溶性药物. 工程师使用 计算流体动力学 (差价合约) 模拟干燥过程并预测粉末质量. 他们将模拟结果与真实的干燥机数据进行比较,以提高性能. 新的实验室规模干燥机现在生产的粉末具有与大型工业干燥机相似的特性, 降低扩大规模期间的风险.

粒径和粉末流量取决于雾化器类型和固体浓度.

工艺建模工具有助于优化喷雾干燥并确保产品质量.

化学品和洗涤剂

化工厂使用喷雾干燥来制造洗涤剂和催化剂的粉末. 工业干燥机必须能够承受高温和不同的进料类型. 逆流式和闭式循环干燥机在该领域很常见. 操作员选择这些干燥机是因为它们能够回收溶剂和控制粉末尺寸. 喷雾干燥产生高表面积的粉末, 改善化学反应. 工程师使用过程模拟来设置最佳干燥器条件. 这种方法有助于保持工业环境的安全性和效率.

陶瓷和颜料

陶瓷和颜料生产商依靠喷雾干燥来生产均匀的粉末. 工业干燥机确保每个颗粒都具有适合铸造和涂层的尺寸. 组合干燥机为定制粉末和研究项目提供了灵活性. 操作员调整干燥机设置以满足每种产品的需求. 喷雾干燥支持小型和大规模生产. 该工艺有助于陶瓷和颜料实现高质量和一致的颜色.

提示: 为每种应用匹配正确的工业干燥机和喷雾干燥方法可以提高粉末质量和工艺效率.

工业喷雾干燥机有多种类型, 比如单级, 两阶段, 并流, 和闭式循环. 旋转式等雾化方式, 压力喷嘴, 和双流体喷嘴有助于塑造最终粉末. 了解喷雾干燥机设计可帮助工业操作员提高产品质量和效率. 统计模型, 包括方差分析和回归, 表明喷雾干燥参数的变化对工业过程结果有很大影响. 这些发现有助于工业团队选择最适合其需求的设计. 工业用户应审查他们的产品目标, 咨询专家, 探索新的研究以保持工业喷雾干燥的领先地位.

方差分析和回归模型揭示了喷雾干燥参数对 工业产品质量.

强 F 值和低 p 值 确认这些因素在工业环境中的重要性.

可靠的模型拟合和信噪比支持自信的工业决策.

对于那些感兴趣的人 工业喷雾干燥, 行业期刊和技术指南提供了有价值的后续步骤.

常问问题

喷雾干燥相对于其他干燥方法的主要优点是什么?

喷雾干燥产生均匀的粉末 迅速地. 它适用于热敏产品. 操作员可以控制颗粒大小和水分含量. 该方法支持许多行业的大规模生产.

操作人员如何选择合适的雾化方式?

操作员根据进料粘度选择雾化方法, 所需粉末尺寸, 和产品敏感性. 旋转雾化器适合粘性饲料. 压力喷嘴适用于低粘度液体. 双流体喷嘴可处理热敏或稀释饲料.

喷雾干燥机可以处理危险材料吗?

是的. 闭式循环喷雾干燥机使用氮气等惰性气体. 这种设计可防止氧化并回收溶剂. 化学和制药行业使用这些干燥机来安全处理易燃或敏感材料.

喷雾干燥机需要哪些维护?

任务 | 频率 |

|---|---|

清洁雾化器 | 日常的 |

检查密封件 | 每周 |

检查过滤器 | 每周 |

校准传感器 | 每月 |

定期保养 保持系统高效并延长设备寿命.