在喷雾干燥器设计计算中评估实验和计算方法

选择正确的方法进行喷雾干燥机设计计算很重要. 它影响流程的运作情况以及产品的质量. 科学家利用实验, 喜欢 实验统计设计, 了解流程变化如何影响产品.

基于模型的方法使用质量和能量平衡. 这些有助于减少所需的实验数量. 它们还使得更大规模地使用该方法变得更加容易.

仅使用统计方法可能不那么准确. 当一次生产更多产品时,这是一个更大的问题.

工艺参数 | 控制策略 / 范围 | 对产品质量的影响 / 效率 |

|---|---|---|

干燥气体出口温度 | 产品温度降低 5–20 °C 比出口 | 与产品特性的紧密联系 |

液滴尺寸控制 | 由原子化能量管理 | 干燥均匀, 产品形态一致 |

选择最佳方法使喷雾干燥机设计计算更可靠且可重复.

关键要点

实验方法给出真实数据. 该数据显示了喷雾干燥机的工作原理. 它还有助于使产品变得更好.

CFD 和热力学模型等计算模型可帮助工程师快速测试想法. 这些模型节省时间和资源.

使用实验数据和计算模型可以得到更好的结果 喷雾干燥机设计. 这些设计更准确, 可靠的, 并且易于扩展.

选择最佳方法取决于项目目标. 它还取决于您拥有什么以及产品需要什么. 这有助于使干燥工作顺利进行,而且成本不会太高.

将来, 人工智能, 数字双胞胎, 节能工具将有助于喷雾干燥. 这些趋势将使其变得更加智能, 更环保, 并且更加高效.

范围和标准

主要方法概述

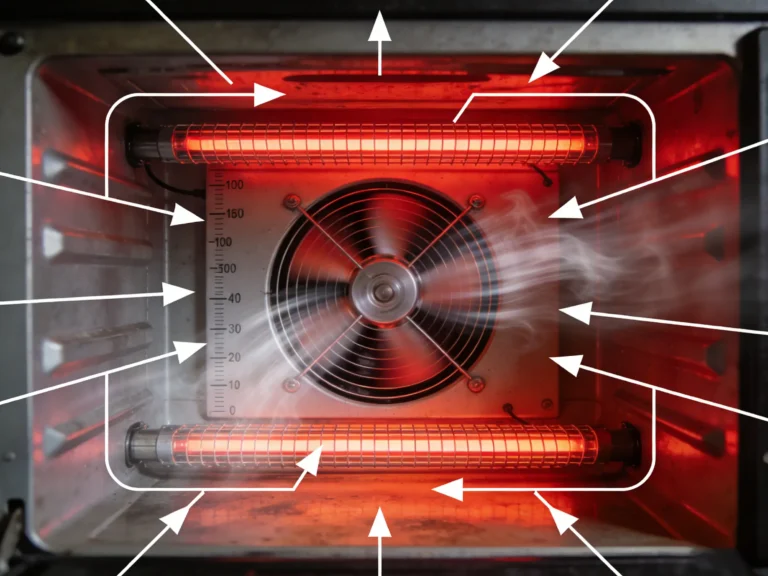

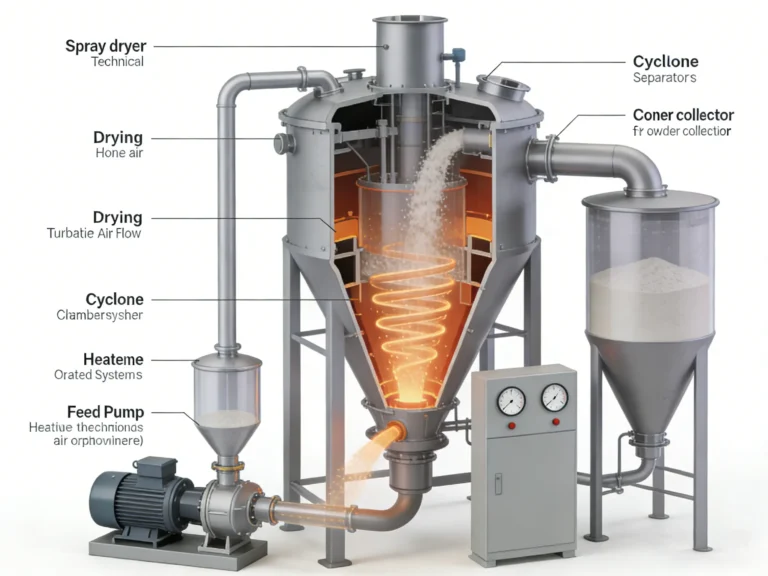

喷雾干燥机设计计算 使用两种主要类型的方法. 这些是实验和计算方法. 实验方法使用真实测量来观察干燥过程中事物的变化. 科学家在实验室中使用小型喷雾干燥器进行这些测试. 他们使用 皮托风速计和压力开关等工具. 这些工具检查干燥气体移动的速度以及气体流量. 他们还测量雾化气体压力. 这些工具提供的信息可以帮助科学家更好地了解干燥过程.

计算方法使用热力学模型等, 差价合约, 拉格朗日粒子追踪, 和 能量或火用分析. 热力学模型使用质量和能量平衡来猜测会发生什么, 比如出口温度. CFD 显示干燥机内部温度和速度的详细图片. 拉格朗日方法遵循每个液滴. 能量和火用分析着眼于过程的效率以及产生了多少熵. 研究表明,将这些方法与机器学习结合使用可以取得更好的结果并减少额外的实验. 科学家经常通过将模型与真实测试数据进行比较来检查他们的模型是否正确.

笔记: 每种方法都有自己的优点. 实验方法给出直接证明, 而计算模型可以让您快速测试许多想法并帮助改进流程.

评估指标

专家使用不同的方法来比较喷雾干燥机设计计算方法:

准确性: 人们使用诸如均方根误差之类的东西 (均方根误差), 平均绝对误差 (MAE), 和决定系数 (R²) 查看模型猜测与实际结果的接近程度. 例如, 出口温度的 RMSE 可以介于 2.15 K 和 14.91 K. R² 值可高达 0.99.

实用性: 了解方法的易用性很重要. CFD 需要大量时间和计算机能力. 热力学模型速度更快,需要的数据更少.

可扩展性: 一个好的方法应该适用于小型实验室测试和大型工厂. 设计空间的理念有助于控制流程并使其变得更大.

验证: 好的方法必须符合现实生活. 科学家使用试点测试和工厂数据来检查他们的模型是否正确.

这些要点可以帮助工程师选择最适合他们需求的方法.

实验方法

停留时间分布

工程师使用停留时间分布, 或RTD, 查看颗粒和气体在喷雾干燥器中停留的时间. RTD 帮助他们了解设计变化如何影响干燥和产品质量. 研究人员经常使用染料脉冲注射来跟踪颗粒的移动. 他们将数据与 CSTR-TIS 等模型进行匹配,以便更好地理解.

喷雾干燥机设计 | 颗粒与气体平均停留时间比 (不锈钢/不锈钢) | RTD 的传播 (n) | 主要观察结果 |

|---|---|---|---|

设计 1 & 2 | 13–18 | 更高的颗粒停留时间; 更多壁沉积 | |

设计 3 & 4 | 1.5–2.5 (3), 1.0–1.7 (4) | 5–8 | 较低的比率; 提高性能; 减少壁沉积 |

带有锥形室的新设计效果更好. 它们降低了墙的堆积并使 RTD 传播得更广. 这有助于再循环和干燥. RTD 测试还表明 CFD 模型是正确的.

物理测量

物理测量在喷雾干燥机设计的实验方法中非常重要. 科学家测量诸如温度之类的东西, 湿度, 以及来自烘干机的剩余水分. 他们使用热电偶等工具, 湿度传感器, 和压力开关. 这些数字帮助他们制作模型来显示烘干机中发生的情况. 例如, A 四级喷雾干燥机的动力学模型 使用良好的测试数据来找到重要的数字. 模型对温度和湿度的猜测与真实测试结果接近. 有关湿度和玻璃化转变温度的实验室数据使模型变得更好.

提示: 良好的物理测量可帮助工程师更改设置并使产品更加一致.

工业数据验证

检查工业数据可确保实验方法在现实生活中发挥作用. 测试用 中试喷雾干燥机和气相二氧化硅 显示测量的颗粒尺寸与模型猜测相匹配. 实验室流化床测试有助于设定干燥值, 就像传热和传质一样, 拟合温度和湿度数据. 这些数字有助于为大型干燥机进行良好的模拟和设计. 研究还检查了 使用真实食品烘干机的数据进行模型猜测. 模型猜测进料流量, 出口温度, 粒径, 而且干燥速度非常好. 这种强烈的匹配表明实验方法有助于 喷雾干燥机设计 计算可靠并有助于改进许多产品的流程.

计算方法

热力学模型

热力学模型帮助工程师猜测热量和质量如何在 喷雾干燥机. 这些模型使用气温等数字, 湿度, 以及空气流动的速度有多快. 工程师经常使用众所周知的传热和压降规则, 就像来自凯斯和伦敦的那些. 他们还使用有关污垢的测试数据, 这意味着奶粉会粘附在热交换器上. 这种粘附会改变热量的移动方式以及烘干机所需的能量.

工程师使用这些模型来了解设计变更如何影响烘干机的工作原理.

他们可以猜测烘干机将使用多少能源以及将生产多少产品.

热力学模型还有助于确定新设计是否可以省钱.

牛奶喷雾干燥机的真实示例表明这些模型可以猜测真实结果. 模型使用实数, 喜欢 排气温度和湿度, 与工厂里发生的事情相符. 这使得热力学模型成为喷雾干燥机设计计算的值得信赖的工具.

CFD 和拉格朗日方法

计算流体动力学, 或差价合约, 和拉格朗日方法详细显示了喷雾干燥器内部发生的情况. CFD 模型使用数学来显示空气和颗粒如何移动. 拉格朗日跟踪跟踪每个干燥的液滴.

工程师使用 欧拉-拉格朗日框架 模拟两相流.

他们求解空气的纳维-斯托克斯方程并跟踪液滴的传热和传质.

模型可以显示颗粒在室内停留的时间, 这对于热敏产品很重要.

CFD 预测气体流量, 干燥率, 以及颗粒落在干燥机内的位置.

CFD模型与测试数据吻合良好. 例如, 模型猜测如何改变墙壁条件, 例如隔热或冷却, 改变干燥和粉末回收. 传热传质之间的双向耦合使模型更好. CFD 还让工程师可以尝试新设计,而无需建造昂贵的测试干燥机.

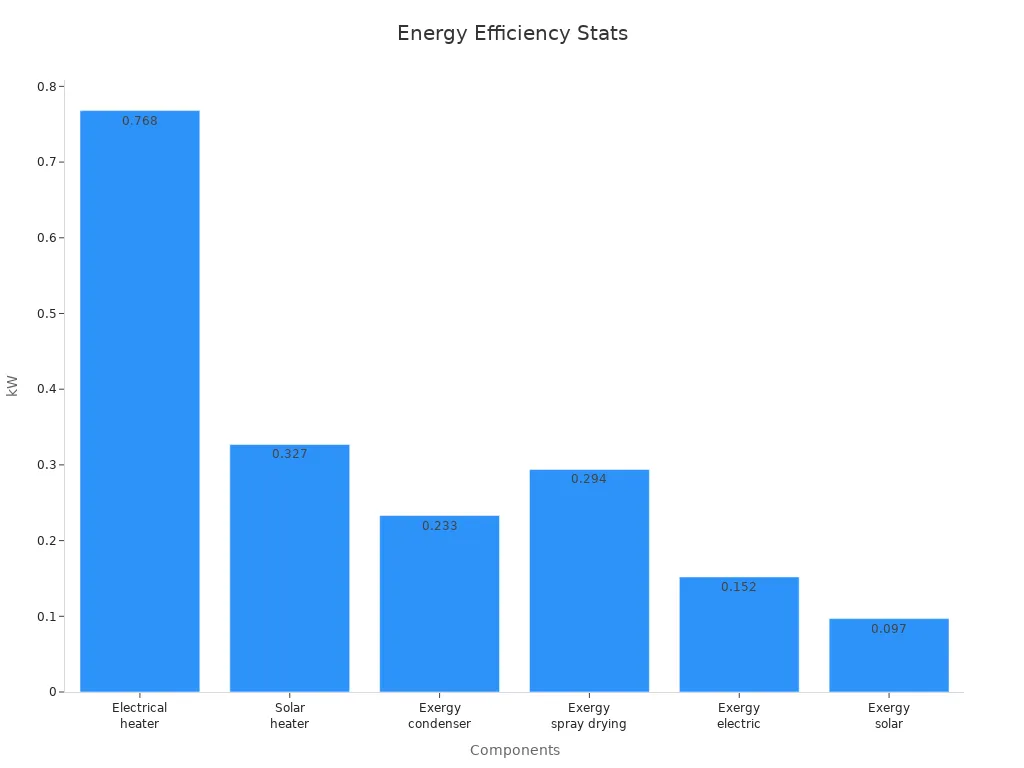

能源和火用分析

能源和 火用分析 帮助工程师找到喷雾干燥机浪费能源的地方. 能源分析显示烘干机使用了多少电力. 火用分析进一步显示能源浪费的地方以及如何解决它.

工程师使用这些方法来比较不同的干燥机设计.

火用分析指出烘干机的哪些部分浪费的能源最多.

更好的隔热或使用太阳能加热器等改进可以降低能源消耗.

范围 | 价值 | 描述 |

|---|---|---|

0.768 千瓦 | 电源供电 | |

太阳能空气能热水器耗电量 | 0.327 千瓦 | 太阳能供电 |

通过聚苯乙烯片材减少热损失 | 4.9→2.27 瓦·米⁻²·K⁻1 | 绝缘改善 |

减少电能输入比例 | 2.68→1.69 | 30% 太阳能贡献 |

冷凝器的最大火用改进 | 0.233 千瓦 | 最高火用破坏 |

干燥室火用的改进 | 0.294 千瓦 | 效率明显低下 |

电加热器火用的改进 | 0.152 千瓦 | 提高效率的空间 |

太阳能空气加热器火用的改进 | 0.097 千瓦 | 太阳能预热的潜在收益 |

火用分析为使喷雾干燥机更好地工作提供了清晰的思路. 这种方法可以帮助工程师在实际工厂中做出良好的设计选择并节省能源.

喷雾干燥机设计计算比较

准确性和可靠性

工程师在选择方法时需要准确性和可靠性 喷雾干燥机设计计算. 实验方法提供直接测量. 这些有助于检查模型是否正确并使结果值得信赖. 计算模型, 例如 CFD 和热力学模型, 猜测重要的事情,例如出口温度, 液滴尺寸, 和产品产量. 这些模型通常与真实测试数据吻合良好. 例如, 在制药过程中, 数据驱动模型高精度预测颗粒尺寸. 几乎所有 误差小于 2.5 千分尺, 这是在 10% 的允许范围内. 这意味着该模型可以代替实验室测试并帮助进行实时检查. 工程师可以相信这些模型包含重要的内容,例如喷嘴类型, 进料粘度, 和密度. 这使得它们适用于小型和大型项目.

笔记: 好的模型意味着更少的实验和更快的设计工作.

资源需求

选择喷雾干燥机设计计算方法时,资源需求很重要. 实验方法需要设备, 材料, 以及设置和收集数据的时间. 例如, 一项研究使用了 Büchi 迷你喷雾干燥机 进给速度 2 mL/min 和吸入速率 35 立方米/小时. 通过称重干粉并将其与放入的干材料进行比较来确定收率. 这些细节有助于工程师规划更大的生产.

下表显示了喷雾干燥的常见资源需求:

资源类别 | 数据 / 价值观 |

|---|---|

生产能力 | 中试规模: 1-5 公斤/小时水蒸发量 |

小批量生产: 5-50 公斤/小时水蒸发量 | |

中等产量: 50-250 公斤/小时水蒸发量 | |

大型工业: 250-4,000+ 公斤/小时水蒸发量 | |

能源消耗 | 通常 1.2-1.7 每蒸发一公斤水 kWh |

饲料特性 | 粘度高达 300 CP |

固体含量 1-50% | |

运营时间表 | 工程与设计: 2-3 月 |

设备制造: 3-8 月 | |

安装: 1-2 月 | |

调试和验证: 1-3 月 | |

产量提升: 1-2 月 | |

维护要求 | 每年维护费用: 3-5% 起始成本 |

雾化器: 500-1000 小时, 空气过滤器: 每月 | |

垫圈和密封件: 每三个月, 控制检查: 每年两次 |

计算方法, 像差价合约, 需要强大的计算机和专用软件. 但它们使用的物理材料更少,并且可以使设计过程更快. 工程师必须考虑这些需求并将其与他们的目标和预算相匹配.

可扩展性

可扩展性表明一种方法是否适用于小型实验室和大型工厂. 工程师通过检查模型猜测和不同尺寸的实际结果来测试这一点.

喷雾干燥完成 从 5 克至 400 克 使用三台机器: 步奇B-290, 方案 4M8Trix, 和流体空气. 这表明该过程对于不同的批量大小效果良好.

测试显示产品中残留的丙酮含量低于 1%, 证明所有尺寸均具有良好的干燥效果.

产品产量从 21% 结束 60% 更改入口温度和机器设置后.

机械和 CFD 模型猜测液滴尺寸, 干燥速度, 出口温度, 和产量. 这些猜测与真实数据吻合良好 (R² > 0.80).

旋风分离器适用于大于 18 千分尺, 使用良好的旋风分离器进行高收集.

CFD 模型有助于展示气体和液滴如何在大型干燥机中移动. 这帮助工程师解决了颗粒破碎和结块等问题.

改变干燥气体流量, 入口温度, 基于模型猜测的进料流量降低了壁的堆积并使扩大规模变得更容易.

在大型药厂, 模型预测颗粒尺寸 (dv50) 很好. 几乎所有错误都小于 2.5 千分尺, 这是在 10% 的允许范围内. 这证明先进的模型可以帮助大规模生产和实时质量检查. 工程师可以使用这些方法来设计和改进多种用途的喷雾干燥机.

建议

方法选择

根据您想要生产的产品选择正确的喷雾干燥机设计方法, 你有什么, 以及您的产品需要什么. 工程师可以使用分步计划来做好选择.

从小型喷雾干燥测试开始. 这有助于选择聚合物和药物量,同时使用更少的材料.

不要使用溶剂浇铸等旧方法. 这些方法并不复制真正的喷雾干燥,可能会给出错误的结果.

在产品制造的每个步骤中都使用实验室喷雾干燥. 这可以更好地进行猜测并减少额外的步骤.

尝试三步计划. 这可以使用 13 更少的材料和花费 12 时间少了几倍 比旧方法.

检查小批量是否与大批量一样. 混合和玻璃化转变温度等保持不变, 这样你就可以尽早改变事情.

使用 mDSC 等常见实验室工具, X射线衍射分析, 和产品生命周期管理. 大多数实验室都有这些, 他们为许多项目工作.

选择适合您极限的方法. 想想你有多少材料, 你需要多少时间, 以及您希望您的产品是什么样子.

提示: 工程师还应该考虑能源使用, 他们能赚多少钱, 以及机器的使用寿命有多长. 例如, 选择喷雾干燥机 30% 大 如果您以后想赚更多,可以提供帮助. 进料粘度及其处理热量等材料可帮助您选择合适的雾化器和雾化室. 钱也很重要, 比如机器的成本是多少以及需要多长时间才能还清.

组合方法

结合使用实验和计算方法通常最适合喷雾干燥机设计. 工程师使用两者来检查模型, 做出更好的设计, 并猜测产品功能.

CFD 模拟和测试数据 在一起可以显示颗粒粘附或聚集的位置. 这有助于找到最佳喷嘴并使产品更加均匀.

测试结果, 例如液滴大小和干燥, 帮助确保数学模型正确. 然后这些模型猜测变化如何影响颗粒尺寸, 密度, 和水分.

使用 简单和详细的模型 让工程师研究诸如砌墙之类的困难问题. 出口温度和湿度的测试数据有助于检查这些模型.

将计算机猜测和实际结果结合在一起有助于做出更好的设计, 扩大规模, 并运行喷雾干燥机.

笔记: 使用这两种方式可以帮助工程师做出更好的选择, 控制过程, 并在生产更多产品时避免错误.

未来趋势

随着新技术和想法的出现,喷雾干燥机的设计不断变化. 一些趋势正在塑造接下来的趋势.

人工智能和机器学习有助于控制流程并在问题发生之前解决问题. 这些工具可以 减少惊喜停留最多 45%.

数字孪生促进发展 30-40% 快点. 他们帮助设计和运行测试.

热回收系统可以节省 25-35% 能量的, 使喷雾干燥使用更少的电力.

闭合水循环可减少用水量 90%, 这对地球有好处.

更小的模块化机器可以节省 40-60% 空间并方便以后添加更多空间.

新材料, 如特殊合金, 帮助机器持续 40-50% 更长.

混合技术, 如超声波喷雾干燥, 用途 15-20% 更少的能源并生产更好的产品.

特别想法, 如无菌和纳米喷雾干燥, 帮助提供药物和食物.

金钱事实表明,大多数新系统都能收回成本 2-4 几年,因为他们的成本更低,生产出更好的产品.

未来将会有智能, 闭环, 和区块链系统. 这些将使喷雾干燥变得更环保、更智能.

工程师应不断了解这些趋势,以保持领先地位并确保他们的喷雾干燥机设计是最新的.

工程师发现使用实验和计算方法有助于喷雾干燥机的设计. 实验数据证明结果是否正确. 计算模型让工程师快速尝试新想法. 团队应该选择适合他们的项目和他们拥有的东西的方法. 结合使用这两种方法通常会产生更好的结果. 将来, 研究可能着眼于更智能的控制和节省更多能源.

常问问题

实验方法和计算方法之间的主要区别是什么?

实验方法使用实验室或飞行员的真实测量结果 喷雾干燥机. 计算方法使用数学模型和计算机程序来猜测结果. 这两种方法都可以帮助工程师制造出更好的喷雾干燥机, 但各有各的长处.

为什么工程师将实验和计算方法结合起来?

工程师使用两者来获得更准确的答案. 实验数据检查模型是否正确. 计算机工具让他们快速尝试许多想法. 使用两者有助于做出更好的设计并减少错误.

CFD 如何帮助喷雾干燥机设计?

差价合约, 或计算流体动力学, 显示空气和水滴如何在烘干机内移动. 工程师使用 CFD 来发现问题, 测试新想法, 无需建造大量测试干燥机即可使产品变得更好.

哪些因素影响设计方法的选择?

工程师思考项目目标, 他们有什么, 产品需要什么, 以及他们有多少时间. 他们还关注能源使用情况, 设备尺寸, 和成本. 最好的方法取决于这些事情.

喷雾干燥机模型可以预测产品质量吗?

是的. 许多模型可以猜测重要的事情,例如颗粒大小, 水分, 和产量. 工程师利用这些猜测来控制质量并使干燥过程更好.