热销YPG系列有机催化剂压力喷雾造粒干燥机

-

有机催化剂压力喷雾造粒干燥机 是一种能同时完成干燥和制粒的设备. 根据工艺要求, 你可以调节压力, 料液泵的流量和喷孔的大小,以一定的尺寸比得到所需的球形颗粒.

描述

热销售YPG系列压力喷雾剂颗粒干燥机的有机催化剂

用于有机催化剂描述的压力喷雾剂颗粒干燥机

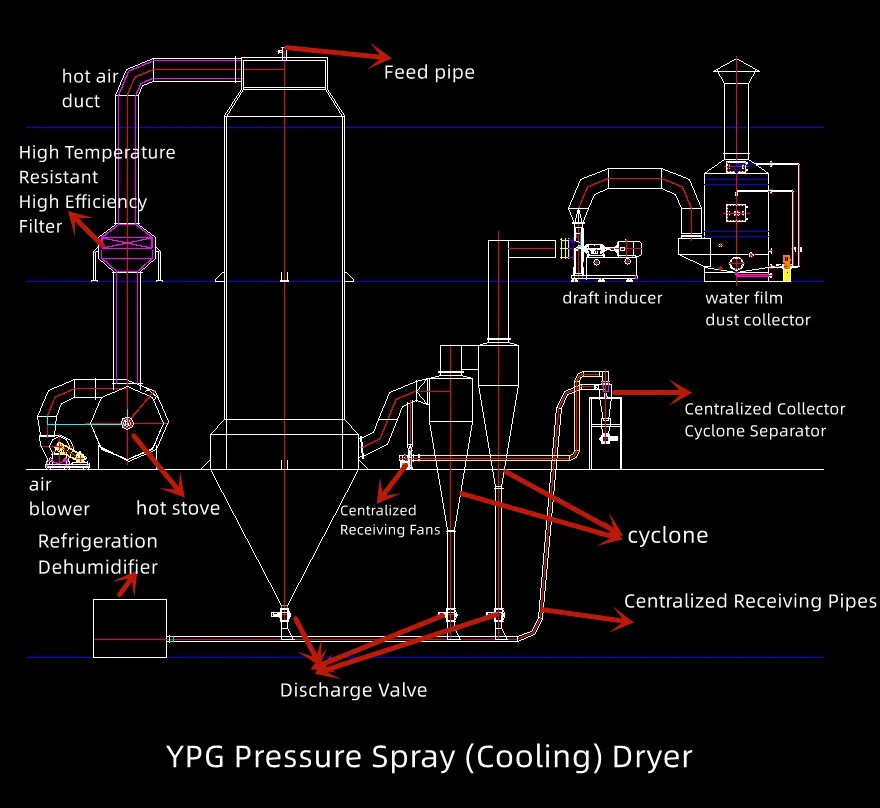

YPG系列压力式喷雾器 (凝) 干燥机具有干燥和制粒一体的装置. 喷涂压力, 液料泵的喷雾流量和喷嘴尺寸可根据需要调节,可达到颗粒球的具体尺寸.用于有机催化剂的压力喷雾剂颗粒干燥机工作原理

液体或糊状物质被压式喷雾器喷涂到小液滴中, 并通过热交换快速干燥 (10-90秒).大多数粉末颗粒是从干燥机底部排放的出口收集的.浪费的空气和细粉被旋风分离, 浪费的空气是草稿风扇的排气, 并在旋风的底部收集细粉. 插座有一个二年级的duster; 所以, 成品粉末颗粒的回收率可以是 96% 到 98%.

用于有机催化剂施用的压力喷雾剂颗粒干衣机

化学工业: 氟化钠 (钾 ), 碱性染料和颜料,染料中间, MN3O4, 复合肥, 甲酸硅酸, 催化剂, 硫酸剂, 氨基酸,白碳, 等等.

食品工业: 脂肪奶粉, 蛋白质, 可可奶粉, 牛奶粉,蛋白 (蛋黄), 食物和植物,燕麦,鸡汁, 咖啡, 即时溶解茶 ,调味肉,蛋白质 ,大豆,花生蛋白, 水解剂, 糖,玉米糖浆,玉米淀粉,葡萄糖, 果胶,麦芽糖, 山刺酸钾, 等等.

医药行业: 中国传统药物, 农药, 抗生素, 医疗饮酒剂,等等.

塑料和树脂: AB, ABS乳液, 尿酸树脂, 酚醛树脂, 尿素 - 甲醛树脂, 甲醛树脂, 聚乙烯, 聚氯丁烯, 等等.

洗涤剂: 普通洗衣粉,先进的洗衣粉,肥皂粉, 纯碱, 乳化剂, 亮剂, 正磷酸, 等等.

陶瓷制品: 氧化铝, 陶瓷瓷砖材料, 镁氧化物, 滑石粉, 等等. 其他: Calmogastrin, 山氯化物 , 硬脂酸剂, 等等.

用于有机催化剂特征的压力喷雾剂颗粒烘干机

1. 快速干燥速度。当液体原材料被雾化并且 95% – 98% 可以在热气流中立即蒸发水的水. 干燥时间只需要几秒钟. 该干衣机特别适合加热Sen Sitive材料.

2. 成品是球颗粒均匀尺寸. 它的流动性和溶解度很好. 产品的质量和纯度很高.

3. 取决于原材料的特征, 干衣机可以使用热空气干燥或使用凉爽的空气颗粒.

4. 操作简单稳定. 控制系统是Con venient,很容易实现自动操作.

技术参数

| 物品 \ 模型 | 单元 | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| 水蒸发- 配给容量 |

公斤 | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| 总体维度 (φ×h) |

毫米 | 1600× 8900 |

2000× 11500 |

2400× 13500 | 2800× 14800 |

3200× 15400 |

3800× 1880 |

4600× 22500 |

| 高压 泵压力 |

MPA | 2〜10 | ||||||

| 力量 | 千瓦 | 8.5 | 14 | 22 | 24 | 30 | 82 | 30 |

| 入口空气 温度 |

哦C | 140~350 | ||||||

| 产品水 内容 |

% | <5(可达0.5) | ||||||

| 收集率 | % | >97 | ||||||

| 电加热器 | 千瓦 | 75 | 120 | 150 | 温度低于200, 应计算参数 |

|||

| 电 +蒸汽 |

MPA + KW | 0.5+54 | 0.6+90 | 0.6+108 | 根据实际条件 | |||

| 热风炉 | kcal/h | 100000 | 150000 | 200000 | 300000 | 400000 | 500000 | 1200000 |

* 以上为最大蒸发量.

评价

目前还没有评价