高速离心喷雾干燥机 速溶咖啡喷雾干燥机 奶粉喷雾干燥机

描述

高速离心喷雾干燥机 速溶咖啡喷雾干燥机 奶粉喷雾干燥机

LPG 离心喷雾干燥机 描述

喷雾干燥技术在液体成型技术和干燥行业中应用最广泛. 最适合生产粉末, 粒子, 或从溶液材料中阻止固体产物, 乳液, 固体状和可泵送的糊状状态. 所以, 当最终产品的粒度和分布发生变化时,喷雾干燥是最理想的技术之一, 它们的残余水含量, 饲养密度和颗粒形状均符合精度标准.

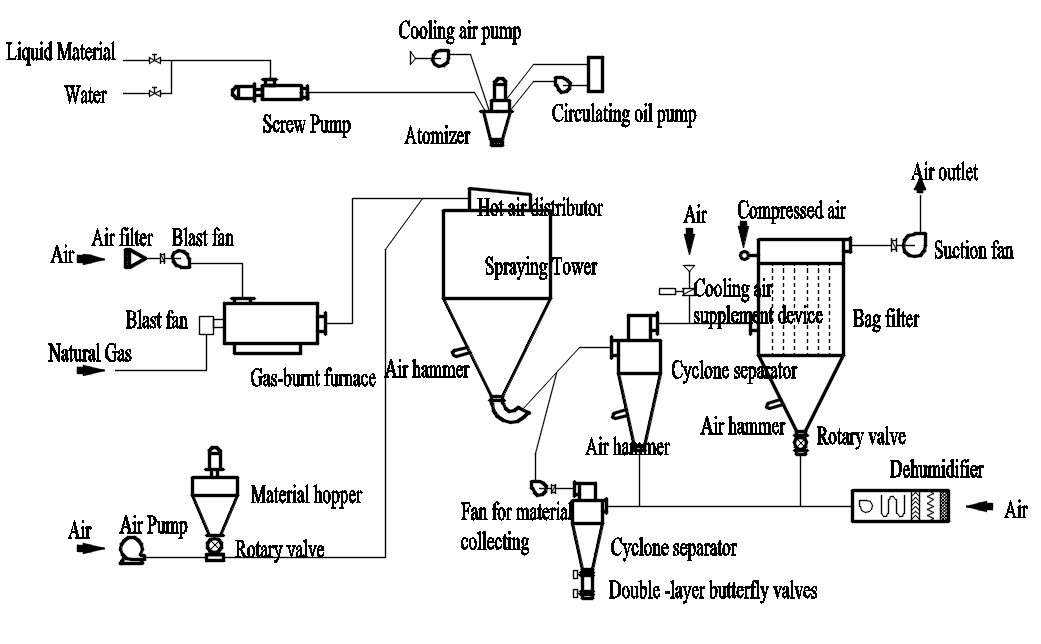

LPG离心喷雾干燥机工作原理

空气经过滤、加热后进入干燥机顶部的空气分配器. 热空气呈螺旋状均匀地进入干燥室. 当液体原料通过塔顶高速离心喷雾器时, 它会旋转并喷射成极细的雾状液珠. 原料与热空气接触瞬间干燥成成品. 成品由干燥塔底部和旋风分离器连续排出. 废气由鼓风机排出.

LPG离心喷雾干燥机特点

1.干燥速度快. 当液体原料雾化时, 材料的表面积将大大扩大. 95% – 98% 水份在热气流中瞬间蒸发,干燥仅需数秒. 该干燥机特别适用于热敏性物料的干燥.

2.均匀度, 流通能力 & 干燥机的溶解度非常好. 成品质量高、纯度高.

3.操作简单稳定, 方便的控制和调试, 轻松实现自动化操作.

4.生产工艺简单, 干燥机可以干燥含有液体的物料 40%-60%(90% 用于特殊材料) 水分立即变成粉末. 干燥后无需粉碎、筛分,操作环境清洁卫生, 还可避免干燥过程中粉末在空气中飞扬.

LPG离心喷雾干燥机应用

化学工业: 氟化钠 (钾), 碱性染料 & 颜料, 染料中间体, 肥料, 甲酸硅酸, 催化剂, 硫酸剂, 氨基酸, 白炭黑, 等等.

塑料树脂: AB, ABS乳液, 脲醛树脂, 酚醛树脂, 脲醛树脂, 聚乙烯, 聚氯乙烯, 等等.

食品工业: 富含脂质的牛奶, 腋下蛋白质, 可可奶粉, 代乳品, 狩猎血粉, 蛋白 (黄色的), 鸡汁, 咖啡, 速溶茶, 调味肉, 蛋白质, 大豆, 花生蛋白, 水解物, 等等.

糖: 玉米糖浆, 玉米淀粉, 葡萄糖, 果胶, 麦芽糖, 山梨酸钾, 等等.

LPG离心喷雾干燥机技术参数

| 方面 / 模型 | 5 | 25 | 50 | 150 | 200-2000 |

| 入口温度°C | 140-350 自动控制 | ||||

| 出口温度°C | 80-90 | ||||

| 最大限度. 蒸发量 (公斤/小时) | 5 | 25 | 50 | 150 | 200-2000 |

| 雾化方式 | 压缩空气驱动 | 机械驱动 | |||

| 革命 (转速) | 25000 | 18000 | 18000 | 15000 | 8000-15000 |

| 革命 (转速) 雾化盘直径 (毫米) |

50 | 120 | 120 | 150 | 180-240 |

| 热源 | 电 | 蒸汽+电力 | 蒸汽+电力, 油, 石油燃料, 热风炉 | ||

| 最大限度. 加热功率 (千瓦) | 9 | 36 | 72 | 99 | |

| 外形尺寸(长×宽×高)(米) | 1.8×0.93×2.2 | 3×2.7×4.26 | 3.5×3.5×4.8 | 5.5×4×7 | 视实际情况而定 |

| 干粉还原率 (%) | ≥95 | ||||

笔记: 水份蒸发量与原料特性及进、出风温度有关. 当出口空气温度为90℃时, 水份蒸发曲线见上表 (仅供参考). 产品是否经过新技术改进或更新, 相关参数也会相应改变!

注意订购

◎液体名称及性质: 固体含量(或含水量), 粘度 , 表面张力和PH值.

◎干粉密度允许残留水分含量, 粒径, 和允许的最高温度.

◎输出: 每日轮班时间 .

◎可供应能源: 蒸汽压力, 正确用电 , 煤的燃料, 石油和天然气 .

◎控制要求: 是否应控制进、出口温度.

◎收粉要求: 是否需要使用布袋过滤器以及废气的环境要求 .

◎其他特殊要求.

LPG离心喷雾干燥机技术参数

| 尺寸 | A | 乙 | C | D | E1 | E2 | F | G | H | 我 |

| 液化石油气-25 | 1290 | 3410 | 4260 | 1800 | 1200 | 1200 | 1000 | 1700 | 1300 | 1550 |

| 液化石油气-50 | 1730 | 4245 | 5100 | 2133 | 1640 | 1640 | 1250 | 1750 | 1800 | 1600 |

| 液化石油气-100 | 2500 | 5300 | 6000 | 2560 | 2100 | 2100 | 1750 | 1930 | 2600 | 1780 |

| 液化石油气-150 | 2800 | 6000 | 7000 | 2860 | 2180 | 2180 | 1970 | 2080 | 3050 | 1960 |

| 液化石油气-200 | 2800 | 6600 | 7300 | 3200 | 2300 | 2300 | 2210 | 2250 | 3050 | 2100 |

| 液化石油气-300 | 2800 | 8000 | 8700 | 3700 | 2800 | 2800 | 2520 | 2400 | 3040 | 2250 |

评价

目前还没有评价