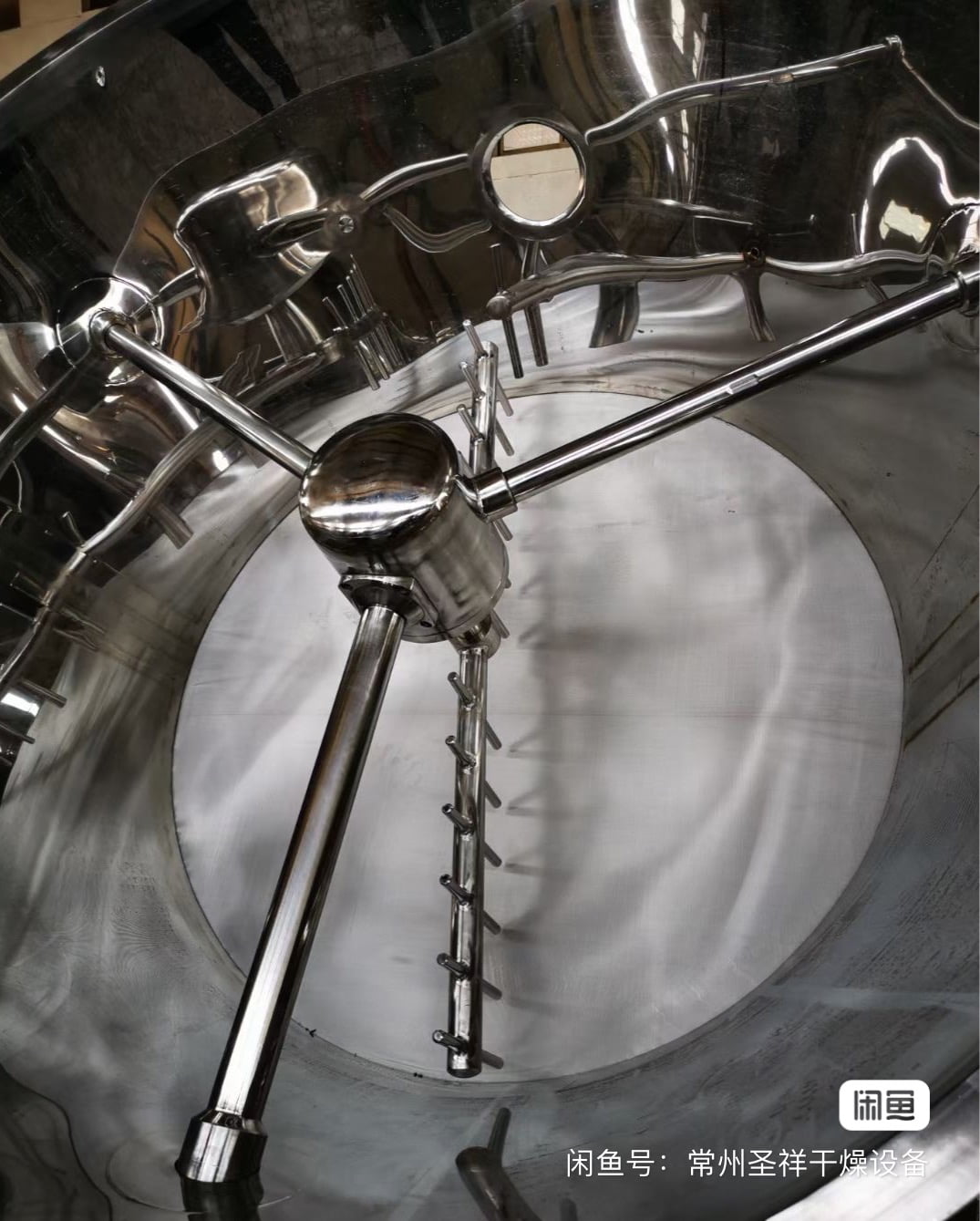

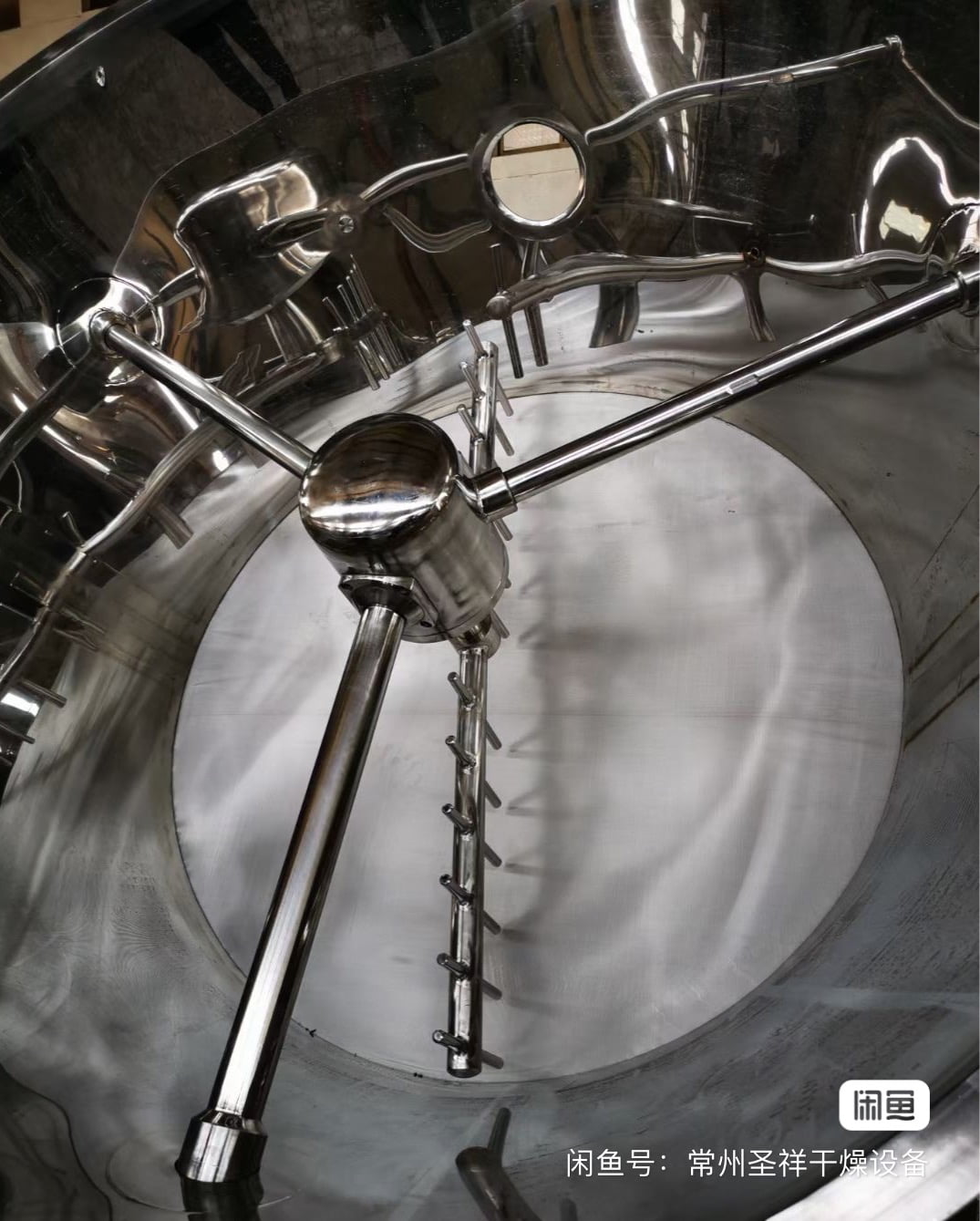

高效GFG系列丙烯酰胺颗粒沸腾干燥机

描述:工作原理 净化后的加热空气由吸风机从底部引入,穿过原料筛板. 在工作室里, 通过搅拌和负压形成流化状态……

描述

GFG Series High-Efficiency acrylamide Fluidizing Dryer

acrylamide Fluidizing Dryer Working Principle

Purified and heated air is introduced from the bottom through suction fan and passed through the screen plate of raw material. 在工作室里, the state of fluidization is formed through stirring and negative pressure. The moisture is evaporated and removed rapidly and the raw material is dried quickly

acrylamide Fluidizing Dryer Features

1. The structure of fluidization bed is of round so as to avoid dead corner.

2. Inside the hopper there is a stirring device in order to avoid agglomeration of raw material and forming canal of flow.

3. The granule is discharged through the method of turning over. 很方便也很齐全. 排出系统也可根据要求设计.

4. It is operated at he conditions of negative pressure and seal. 空气被过滤了. 因此操作简单,清洗方便. 是符合GMP要求的理想设备.

5. 干燥速度快、温度均匀. 干燥时间为 20-30 通常分钟.

丙烯酰胺流态化干燥机应用

1.螺杆挤出造粒, 摇摆制粒机和高速湿法混合制粒机的颗粒.

2.适用于制药行业湿块状或粉状原料的干燥, 食品, 喂养, 化学工业等领域.

3.大颗粒, 小块和粘合材料.

4.干燥过程中体积可能变化的物料.

评价

目前还没有评价