喷雾器如何在工业应用中起作用

您可以在工业应用中使用喷雾干燥机将液体饲料一步变成干粉或颗粒. 该过程利用热风和雾化进行快速干燥. 许多行业选择这种方法是因为它提供效率和产品一致性.

喷雾干燥机占 38% 的市场份额 适用于全球生产的工业粉末.

技术 | 能源消耗 | 运营成本 |

|---|---|---|

喷雾干燥 | 适度的能源消耗 | 降低运营成本 |

冷冻干燥 | 能耗高 | 4-8 比喷雾干燥高数倍 |

如果您想了解喷雾干燥机的功能, 您就会明白为什么这项技术脱颖而出.

关键要点

喷雾干燥有效地将液体饲料转化为干粉, 在工业应用中节省时间和能源.

仔细的进料制备和雾化对于实现一致的粉末质量和所需的粒度至关重要.

喷雾干燥可精确控制产品特性, 使其成为食品和制药等行业的理想选择.

该过程是可扩展的, 允许企业在不改变方法的情况下从小批量发展到大批量生产.

使用喷雾干燥可以提高产品稳定性和保质期, 使其成为各行业的宝贵选择.

喷雾干燥机的工作原理: 过程

了解喷雾干燥机 como funciona 如何帮助您了解为什么这项技术在工业中如此受欢迎. 您可以将流程分解为 五个主要步骤. 每个步骤在将液体饲料变成干饲料的过程中都起着关键作用, 可用粉末.

饲料准备

首先准备饲料. 这意味着确保您的材料处于液体状态并准备好雾化. 进料可以包括多种类型的材料, 例如:

催化剂

颜料

洗涤剂

动物饲料

肥料

农药

重组蛋白

疫苗

电动汽车电池正极和负极材料

您需要将成分溶解或悬浮在溶液中. 该制剂的质量影响最终粉末. 重要参数包括干燥空气的温度, 空气和饲料的流量, 以及雾化所用的压力. 例如, 较高的泵速会产生较大的颗粒, 而较高的干燥温度也会增加颗粒尺寸.

提示: 精心准备饲料可确保您从喷雾干燥机 como funciona 工艺中获得一致的结果.

雾化和喷嘴

下一个, 你转向雾化. 这里, 您使用喷嘴或雾化器将液体进料分解成微小的液滴. 此步骤增加表面积, 这有助于水滴快速干燥. 喷嘴的设计非常重要. 它控制液滴的大小和均匀性, 这会影响最终粉末的质量.

您可以选择多种雾化技术:

雾化技术 | 优点 | 应用领域 |

|---|---|---|

旋转雾化 | 处理高粘度液体, 产生均匀的颗粒 | 食物 (牛奶粉, 咖啡奶精), 化学品 |

压力雾化 | 很好, 均匀的液滴, 节能 | 药品, 精细化工粉体 |

二流体 (气动) 雾化 | 产生非常细小的液滴, 精确控制 | 药品, 化妆品 |

超声波雾化 | 温和的, 产生非常细小的液滴 | 药品, 电子产品 |

喷嘴设计也会影响粒度分布. 如果您想要特定的质感或品质, 您必须选择正确的喷嘴并调整其设置.

热风接触

一旦出现水滴, 您将它们引入干燥室内的热空气. 该空气的温度通常范围为 100入口处 °C 至 300°C 出口温度为 50°C 至 100°C. 热空气迅速蒸发水滴中的水分.

进气温度: 180–200°C

出口空气温度: 80–100°C

空气的速度和温度会影响液滴的干燥速度以及最终粉末的外观. 您需要控制这些设置才能从喷雾干燥机 como funciona 工艺中获得最佳结果.

干燥和粉末形成

当水滴遇到热空气时, 他们迅速失去水分. 干燥过程发生在 三个主要阶段:

阶段 | 描述 |

|---|---|

雾化 | 饲料变成细小的水滴, 增加表面积和干燥速度. |

蒸发 | 热空气加热液滴, 导致液体快速蒸发. |

颗粒形成 | 当液体离开时固体聚集在一起, 形成固体颗粒. |

您可以使用以下方法控制水分含量 先进系统. 这些系统可帮助您保持最终粉末干燥但又不会太干燥. 如果你控制好湿度, 避免结块或干燥不均匀等问题.

笔记: 颗粒的形成方式取决于许多因素, 包括温度, 空气速度, 和进给速度. 您可能需要进行试验才能找到适合您产品的最佳设置.

粉末系列

干燥后, 你需要收集粉末. 大多数喷雾干燥机使用旋风分离器或类似装置. 该设备将干粉从废气中分离出来. 您还可以使用更高的塔或部分真空来帮助减少产品损失并提高效率.

方法 | 描述 | 应用领域 |

|---|---|---|

喷雾干燥 | 雾化液体饲料, 用热风吹干, 有效收集粉末 | 大规模, 连续生产 |

滚筒干燥 | 将浆料涂在滚筒上, 在热表面上干燥 | 各种浆料 |

冷冻干燥 | 冻结和升华水 | 精美的, 高孔隙率物质 |

托盘干燥 | 将液体涂在托盘上, 用热风吹干 | 批量处理 |

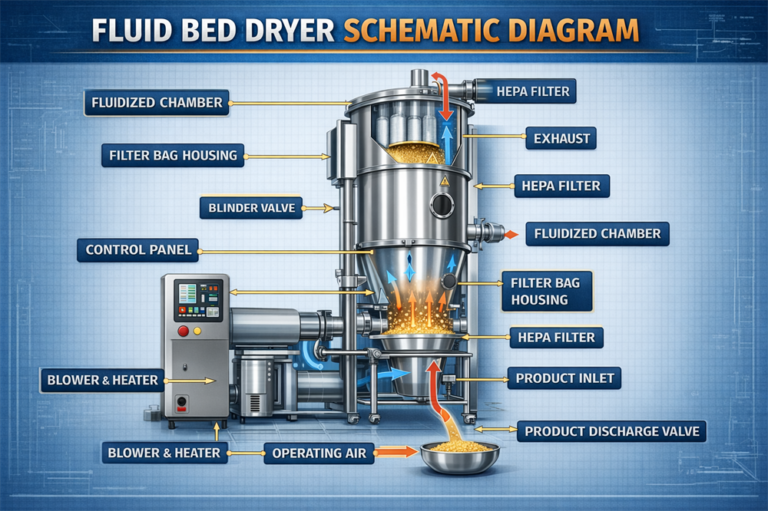

流化床干燥 | 在流化床中轻轻干燥粉末 | 热敏材料 |

真空干燥 | 在真空下去除水分 | 敏感材料 |

你想要 最大限度地减少产品损失 收集期间. 使用更高的喷雾干燥塔或应用部分真空可以帮助您回收更多粉末并保持高品质.

按照以下步骤操作, 您可以看到喷雾干燥机在真实工业环境中的功能. 每个阶段, 从饲料制备到粉末收集, 在高效生产高质量粉末方面发挥着至关重要的作用.

喷雾干燥的优点

喷雾干燥为工业生产提供了几个重要的好处. 当您使用喷雾干燥机时, 您获得速度优势, 产品质量, 和可扩展性. 这些优势可帮助您高效、经济地生产高质量粉末.

速度和效率

您可以通过喷雾干燥将液体快速干燥成粉末. 该过程使用热空气和雾化在几秒钟内去除水分. 与传统方法相比,这种快速干燥意味着您可以节省时间和能源. 喷雾干燥还可以有效利用能源, 这有助于降低您的运营成本.

益处 | 描述 |

|---|---|

快速处理大量, 节约能源并减少对防腐剂的需求. | |

易于存储 | 生产易于储存和运输的粉末, 降低成本并支持可持续性. |

提示: 喷雾干燥可帮助您保持生产线快速运转, 这样您就可以毫不拖延地满足高需求.

产品质量控制

使用喷雾干燥时,您可以精确控制最终产品. 雾化步骤可让您调整液滴大小, 这会改变粉末的大小和质地. 您还可以控制温度和进料速度,以保护敏感成分免受过多热量的影响.

雾化让您控制颗粒大小和干燥速度.

仔细的进料速率管理会影响粉末特性.

监控过程参数确保结果一致.

先进设备可实时调整质量.

您可以使用摄像头和传感器来观察问题, 确保您的粉末始终符合您的标准. 这种控制水平对于食品和制药等行业非常重要, 安全性和一致性最重要的地方.

可扩展性

喷雾干燥适用于小型和大型生产运行. 您可以从实验室规模的设备开始,然后升级到每天处理大量材料的商业系统. 这种灵活性意味着您可以在不改变流程的情况下发展业务.

喷雾干燥技术可让您控制颗粒大小, 形状, 和水分含量.

您可以从小批量扩大到大批量,同时保持高产品质量.

该过程是连续的, 因此您可以以适中的成本快速大量生产.

如果您想了解喷雾干燥机为您的企业提供的功能, 请记住,它支持增长并帮助您避免扩大规模期间的浪费.

喷雾干燥机在工业中的应用

食品和饮料

你看 喷雾干燥用于许多食品和饮料产品 你享受每一天. 喷雾干燥机具有快速将液体食品变成粉末的功能, 这有助于保持风味和营养. 你会发现这个过程:

速溶咖啡和茶粉

水果和蔬菜粉

调味品和香料

蛋白粉和营养补充剂

喷雾干燥成分化妆品 关于 5% 到 8% 所有食品和饮料产品. 这种方法可以帮助您更轻松地储存和运输食物. 下表显示喷雾干燥如何影响食品粉末:

方面 | 发现 |

|---|---|

营养品质 | |

微生物污染 | 较低的水分活度可降低污染风险. |

贮存 | 干粉比新鲜食品保质期更长. |

提示: 在喷雾干燥过程中封装香料和脂肪有助于延长保质期并保持食物新鲜.

药品

您在药品中使用喷雾干燥从液体药物中制造粉末. 此过程可帮助您控制药物颗粒的大小和形状. 您可以制作片剂粉末, 胶囊, 甚至吸入药物. 一些好处包括:

用热敏药物生产稳定的粉末

制造在体内更好溶解的口服药物

减少药物开发所需的时间

喷雾干燥可以保护敏感成分并提高药物的药效. 您还可以用它来使药物更容易储存和运输.

化学品和材料

您在化学工业中发现喷雾干燥用于制造催化剂, 颜料, 和染料. 该过程的工作原理是将原材料喷射到热空气中, 几秒钟内就可以干燥它们. 您可以调整工艺以获得适合您产品的粒径和稳定性. 常见用途包括:

制造低水分粉末以更好地储存

形成均匀的颗粒以更好地混合产品

提高化学粉末的稳定性和处理能力

方面 | 益处 |

|---|---|

水分含量 | 较低的湿度意味着更安全, 更持久的粉末 |

粒度分布 | 均匀的尺寸有助于混合和稳定性 |

您可以看到喷雾干燥机如何在这些行业中发挥作用,使产品更安全, 更稳定, 并且更容易使用.

您现在了解喷雾干燥机如何利用雾化和热空气将液体变成粉末. 这个过程给你 快干, 均匀颗粒, 和更好的保质期. 了解喷雾干燥如何为各行业增加价值:

优点 | 应用领域 |

|---|---|

快速干燥过程 | 食物: 牛奶, 咖啡 |

粒径均匀 | 药品: 片剂粉末 |

延长保质期 | 化学品: 颜料, 聚合物 |

可定制参数 | 陶瓷: 均匀的粉末 |

高效率 |

喷雾干燥还为您的产品提供了更多的控制力和稳定性.

实用优势 | 描述 |

|---|---|

改进的控制 | 您可以根据需要精确塑造您的产品. |

增强产品稳定性 | 粉末在运输和储存过程中保持安全. |

增加生物利用度 | 药物在您的身体中发挥更好的作用. |

掩味 | 您可以隐藏食物或药物中不需要的味道. |

修改版本 | 有些药物释放缓慢,效果更持久. |

新趋势聚焦 可持续发展和智能技术. 如果你想要高效, 高品质粉末, 喷雾干燥可能是您工艺的正确选择.

常问问题

喷雾干燥机可以使用哪些类型的液体?

您可以使用解决方案, 悬浮液, 或乳液. 常见的例子包括牛奶, 汁, 化学品, 和药物混合物. 液体必须易于流动并含有要干燥的材料.

如何控制粉体的粒径?

您调整喷嘴类型, 进给率, 和气温. 较小的液滴可形成更细的粉末. 较大的液滴产生较大的颗粒. 仔细控制为您提供所需的尺寸.

喷雾干燥对于热敏产品安全吗?

是的, 您可以通过使用较低的气温和快速干燥来保护热敏成分. 这个方法可以帮助你保留维生素, 口味, 和药物稳定.

如何清洁喷雾干燥机?

您可以通过用水或清洁溶液冲洗喷雾干燥机来清洁它. 一些系统使用自动清洁. 定期清洁可确保您的产品安全并防止污染.