流化的基本原理

当气体或液体以一定的速度向上通过细小的固体颗粒时,就会发生流化。 表现得像流体.

基本原理涉及流体的向上力平衡颗粒的重量, 使它们快速升起并混合.

当固体床膨胀时,您会看到流化状态 气泡形式, 很像沸水.

流化原理让您实现极佳的混合, 传热, 和化学反应.

许多行业依赖此流程来实现高效运营.

关键要点

当气体或液体向上穿过固体颗粒时发生流化, 使它们表现得像流体. 该过程增强了混合和传热.

了解影响流化的因素, 例如颗粒大小和密度, 有助于提高工业应用的效率.

流化床反应器因其能够有效混合固体和流体而广泛应用于化学制造和能源生产等行业.

使用流态化比传统方法具有优势, 包括对各种材料更好的湿度控制和更快的干燥时间.

监测温度和气流对于流化床的安全高效运行至关重要, 确保最佳性能.

基本原理

流化解释

通过观察气体或液体通过细小固体颗粒时的行为,您可以了解流化的基本原理. 基本原理是从流体向上运动开始. 这种运动产生了提升颗粒的力. 当向上的力与颗粒的重量相匹配时, 固体床开始膨胀. 你会看到气泡形成, 并且颗粒快速混合. 床的作用就像沸腾的液体.

颗粒床中初期不稳定的开始是在间隙中稳定的气体扩散之前,并且是由可以克服颗粒惯性的临界动量力引起的. 临界动量力由临界表观气体速度提供 Uc 以扩散临界质量通量的形式. 发现颗粒的第一次运动可以通过临界瞬态瑞利数来预测,该临界瞬态瑞利数由临界空塔速度等于最小流化速度确定, UMF. 发现初始流化的开始发生在 临界瞬态瑞利数 3.1, 这接近由自由表面界定的多孔介质中浮力对流的最低理论值.

需要关注影响基本原理的几个重要因素. 这些包括颗粒密度, 尺寸, 形状, 以及颗粒如何堆积在一起. 流体穿过床的方式也很重要. 您可以在下表中看到这些因素如何协同作用:

方面 | 发现 |

|---|---|

颗粒密度影响 | 颗粒密度越高,流化性能越差 在初始阶段. |

流体动力学 | 观察到对流体动力学的显着影响, 对高密度粒子的预测存在错误. |

流化阶段 | 确定了三个不同的流化阶段, 受粒度分布的影响. |

粒度分布 | 窄 PSD 带来更好的流动性和更低的最小流化速度 (U*mf). |

C 组颗粒 | 更宽的 PSD 导致更高的床膨胀并改善气固接触. |

纳米调制 | 提高 C 组粉末的流化质量, 表明规模和分布的重要性. |

您可以在流化过程中看到不同的行为,具体取决于颗粒的类型. 例如:

Geldart B/D颗粒容易形成气泡, 但床并没有扩大太多.

Geldart A 颗粒均匀膨胀, 这使得床更稳定.

气流过程中冲击波和连续波穿过床层, 展示基本原理如何实时工作.

流化的基本原理帮助您实现更好的混合和传热. 您可以在许多行业中使用此流程, 例如化学制造和能源生产.

两相理论

您可以探索 两相理论 更深入地了解流化的基本原理. 该理论认为床层包含两个主要相: 固体颗粒和流体 (气体或液体). 流体通过向上推动颗粒来支撑颗粒. 由于流体的阻力和浮力,颗粒移动并混合.

几何, 颗粒固体材料的物理和空气动力学特性都会影响流化的开始, 和特点, 流化床的行为和主要参数. 最重要的固体特性是: 粒子密度, 骨骼的 (真的) 密度, 堆积密度, 孔隙率, 平均当量粒径, 颗粒形状, 粒度分布, 和自由落体 (或终端) 速度.

您可以看到两相理论如何随着时间的推移而发展:

阶段 | 描述 | 时间段 |

|---|---|---|

1 | 20 世纪 40 年代初 | |

2 | 两相理论简介 | 20世纪50年代初 |

3 | 气泡流体动力学研究 | 20世纪60年代初 |

4 | 悬架结构的一般认识 | 世纪之交 |

两相理论可帮助您预测床的表现. 您可以看到床上的密集区域和稀疏区域. 流体和固相相互作用, 这导致不同的流动模式. 下表显示了科学家如何研究这些模式:

方面 | 细节 |

|---|---|

学习重点 | 密相循环流化床中的气固流动 (循环流化床) |

操作条件 | 空塔气速: 15.5 多发性硬化症; 固体助焊剂: 140 公斤/平方米; Geldart B 颗粒 (沙) |

主要发现 | 轴向固体浓度分布显示出稀区域和浓区域. 观察到的核心-环空结构和近壁返混. |

阻力模型 | 提出了基于 EMMS 模型的修正阻力系数并用于 CFD 模拟. |

验证方法 | 将实验结果与 CFD 模拟进行比较,以评估流动结构和压降. |

结论 | EMMS 阻力模型与实验数据表现出更好的一致性, 验证其在模拟中的使用. |

在两相理论中, 你会看到固相由液相支撑. 流化过程取决于流体提升和混合颗粒的程度. 您可以利用这一基本原理来改善反应器中的化学反应和传热.

流化床

流化床的工作原理

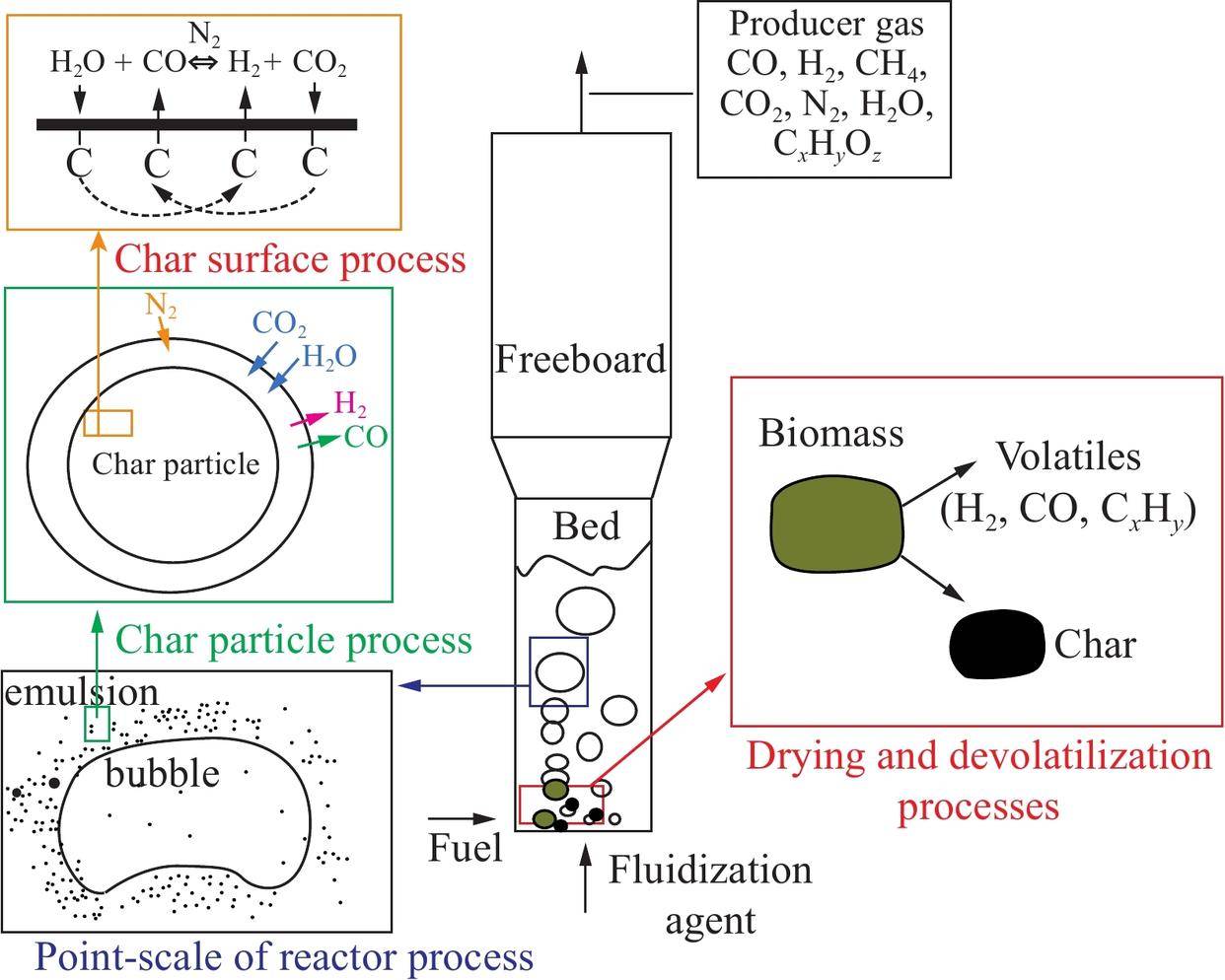

通过观察从固体颗粒床下方引入空气或液体时发生的情况,您可以了解流化床的运行方式. 向上的气流将颗粒提升, 使它们移动和混合. 这种运动创建了一个动态系统,其中粒子的行为几乎像液体. 随着流体速度的变化,您会注意到不同的流动状态. 下表显示了床位如何随每种方案而变化:

流量类型 | 描述 |

|---|---|

固定床 | 粒子静止且未流态化的初始状态. |

鼓泡流化 | 床内形成气泡, 和粒子的相互作用更加活跃. |

段击流化 | 出现大气泡, 造成颗粒的不规则运动. |

湍流流化 | 水流变得汹涌澎湃, 并且颗粒快速混合. |

稀相传输 | 颗粒分散在气相中, 和浓度下降. |

快速流化 | 床就像流体一样, 具有强烈的气体和粒子相互作用. |

段塞流/气泡流 | 段塞和气泡同时存在, 创造混合运动. |

无气泡密相流 | 床保持密集, 并且气体流量仍然很低. |

填充床流量 | 颗粒紧密堆积, 并且流体运动最小. |

你可以 使用气体喷射将固体颗粒悬浮在连续液相中. 液体从顶部进入并逆气流运动. 气体分配器的设计让液体从底部排出,而不会带走颗粒. 这种机制允许您在连续流动反应器中使用细小或低密度的颗粒.

当您从粉末床下方引入空气时,会发生均匀混合. 空气提升并搅动颗粒, 将致密粉末变成流体状. 您可以将液体粘合溶液喷洒到流态化颗粒上,以帮助颗粒生长并改善混合.

主要特点

您会发现流化床的几个独特特征. 下表强调了这些重要方面:

主要特点 | 描述 |

|---|---|

高表面积接触 | 每个床体积中的流体和颗粒之间都有很大的接触面积. |

高相对速度 | 与彼此相比,流体和颗粒移动得更快. |

混合 | 颗粒在整个床上充分混合. |

碰撞 | 粒子之间以及与墙壁之间频繁发生碰撞. |

你需要考虑 建造流化床时的设计因素. 颗粒尺寸分布影响您需要的空气流量. 圆形颗粒的行为与椭圆形颗粒不同, 这会改变干燥均匀性. 堆积密度影响流化所需的最小速度并有助于防止材料损失. 比热告诉您加热颗粒需要多少能量. 脆弱的颗粒可能需要温和的流化以避免破碎. 化学成分可能会导致粘性或热敏性等问题. 入口空气温度必须与颗粒可以处理的温度相匹配. 空气流速控制流化状态和传热. 保留时间取决于气流和堰高度, 帮助您达到合适的湿度水平.

温度和压力也会影响流化床的工作方式. 气泡运动控制较低温度下的流动结构. 在较高温度下, 粒子粘在一起的方式变得更加重要. 超高温度增加颗粒间力, 这可以改变粒子的行为.

流化床反应器

工业应用

您可以在许多行业中找到流化床反应器. 这些反应器可帮助您更有效地处理化学反应和材料加工. 你看到它们用于炼油, 化学生产, 和能源生产. 这些反应器的设计可让您快速混合固体和液体, 这改善了流程.

以下是 流化床反应器的主要类型 你可能会遇到:

反应器类型 | 描述 |

|---|---|

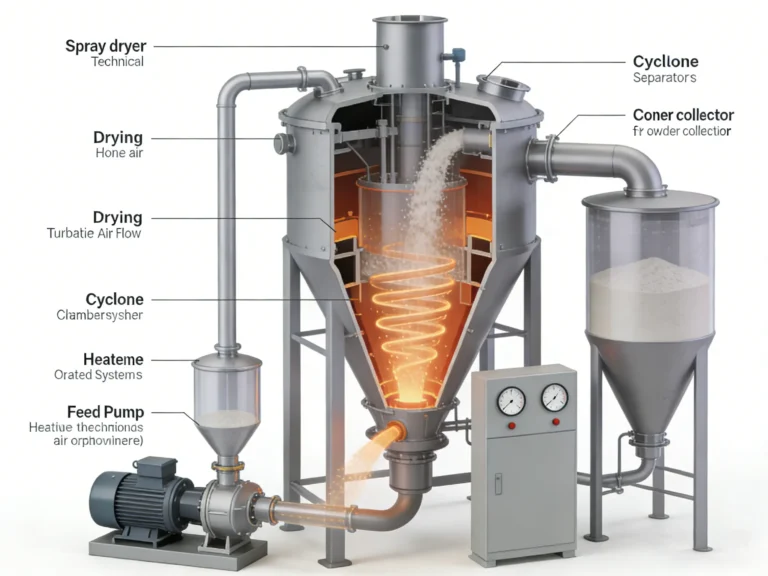

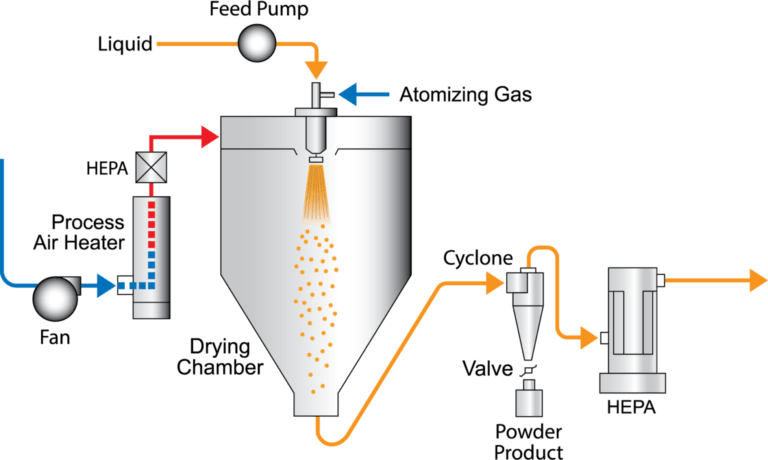

疯牛病 (鼓泡流化床) | 带有反应器柱的简单设计, 分销商, 生物质螺旋喂料系统, 和旋风分离器用于去除细颗粒. |

循环流化床 (循环流化床) | 由反应柱组成, 多个旋风分离器, 和生物质螺旋喂料系统; 捕获并再循环粗颗粒和细颗粒. |

气流床 | 使用高气体速度保持颗粒悬浮. |

流化床反应器在多个方面发挥着关键作用 工业应用:

应用类型 | 描述 |

|---|---|

石油和化学加工 | 用于连续投料和生产生物油. |

丙烯腈的合成 | 用于生产丙烯腈. |

催化裂化 | 用于石化工业的催化过程. |

传热 | 高效传热,床层温度均匀. |

您还在药品制造中看到这些反应器. 它们可以帮助您干燥粉末, 衣片, 并混合配料. 流化床反应器市场持续增长. 在 2024, 市场达到美元 3.5 十亿. 专家预计这将 升为美元 5.9 十亿 2033, 并以稳定的速度增长.

好处

流化床反应器提供许多 工业流程的优势. 您可以获得更好的混合和更快的反应. 该设计让您轻松控制温度和物料流动. 您可以使用这些反应器进行化学合成, 减少污染, 和材料加工.

优点/应用 | 描述 |

|---|---|

化学合成 | 用于合成聚乙烯、聚丙烯等关键塑料, 并生产单体. |

减少污染 | 通过使用吸附剂捕获硫来减少污染并在较低温度下运行. |

材料和传热 | 促进高效涂层, 药品干燥, 和食品的快速冷冻. |

您注意到流化床中的传热和传质速率非常高 高于固定床反应器. 这使得它们非常适合需要高效传热和传质的反应. 您可以维护 温度分布均匀, 这有助于传热. 该技术还允许您经常再生催化剂而无需停止过程.

流化床反应器帮助您提高药品制造中的产品质量. 您可以干燥并均匀地涂覆药粉. 您还可以减少污染和能源使用, 这对环境和您的业务都有好处.

比较

传统方法

当您使用传统方法处理细小固体时, 你经常面临很多挑战. 这些方法包括自由固体飞溅, 定向注气, 重击, 和固体夹带. 每种方法都有自己的 运输率和能源效率. 您可以在下表中看到差异:

方法 | 传输率 (公斤/平方米·秒) | 能源效率 |

|---|---|---|

自由固体飞溅 | 5 × 10⁻²–2 × 10³ | 最高 |

定向气体喷射 | 1.9–4.3 m/s | 中间的 |

重击 | 不适用 | 中间的 |

受限固体飞溅 | 不适用 | 最低 |

固体夹带 | 不适用 | 最低 |

您可能会注意到这些方法并不总是提供高效率, 特别是当您需要控制水分或实现均匀混合时. 传统系统常常难以清除小垃圾, 这会堵塞泵并导致浮渣堆积. 重的碎片可能会损坏设备, 所以你需要额外的筛查设备. 当您处理高固体负载时, 您必须使用细筛和研磨机去除碎片. 这些步骤降低了整体效率并且难以控制湿度水平.

局限性 | 对运营的影响 |

|---|---|

导致泵堵塞和消化池浮渣堆积. | |

重碎片造成的损坏 | 需要额外的筛选装置以防止设备过载. |

无法处理高固体负载 | 需要细筛和研磨机,以便在高固体含量情况下有效去除碎片. |

流态化的优点

当您使用流态化时, 与传统方法相比,您可以获得多种优势. 流化的工作原理让您实现更高的混合效率, 传热, 和湿度控制. 您可以加工多种材料, 从谷物和香料到化学品和药品, 无需改变您的设备. 这种灵活性意味着您可以干燥不同水分含量的产品并达到更快的干燥时间.

流化床干燥适用于多种食品, 比如谷物, 零食, 和香料.

您可以在不同行业使用相同的设备, 包括药品和化学品.

工作原理允许您处理各种水分含量的物料, 显示出极大的操作灵活性.

您还可以获得更好的过程控制和混合. 流态化工作原理, 尤其是与振动相结合时, 减少细颗粒之间的强力. 这使得即使是最小的颗粒也更容易混合和流化. 您可以实现更均匀的除湿以及更高的干燥和加工效率.

振动流化 打破团块并改善混合.

您可以处理传统方法难以处理的细小颗粒.

该过程为您提供更多控制权, 带来更高的效率和更均匀的水分含量.

提示: 当您需要快速均匀地干燥产品时, 流化使您的干燥时间更快,并帮助您以更少的能量达到所需的湿度水平.

您已经了解到流化将固体颗粒转变为类似流体的状态, 这可以帮助你混合, 热, 并更有效地处理材料. 流化床和反应器在许多行业中发挥着关键作用. 下表显示了一些重要的好处:

应用领域 | 好处 |

|---|---|

增强太阳能发电厂储能系统的充电和放电. | |

工业流程 | 提高各种工业应用中的传热传质效率. |

高温储能 | 提高显热和相变储能系统的功率输出. |

新型流态化方法研究, 喜欢 流化床芬顿技术, 可以帮助您更好地处理废水并减少污染. 您可以探索这些进步来改进您自己的工作或学习.

常问问题

流态化在工业上有什么用途?

您使用流化来改善混合, 烘干, 和化学反应. 许多行业依靠这一过程来提高能源效率和产品质量. 你经常在食物中看到它, 化学, 和药品制造.

如何控制流化床?

您可以通过调节气体或液体的流量来控制流化床. 这可以让您管理温度, mixing, 和粒子运动. 良好的控制可帮助您取得更好的结果并保持能源效率.

为什么流化可以提高能源效率?

流化提高了能源效率,因为它增加了颗粒和流体之间的接触. 您可以获得更快的传热和更好的混合. 这意味着您可以使用更少的能量来达到相同的结果.

可以对小颗粒使用流化吗?

是的, 您可以对小颗粒使用流化. 您可能需要特殊设备来控制过程. 这有助于您避免颗粒损失并保持稳定运行.

使用流化床时应遵循哪些安全提示?

您应该密切监测温度和压力. 始终控制气流以防止过热或堵塞. 定期检查可确保您的系统安全高效.