What is a Spray Dryer and How does a spray dryer work?

What is a Spray Dryer and How does a spray dryer work?

A spray dryer is a rapid drying method that transforms a liquid or slurry into a dry powder using hot gas. This technique is particularly advantageous for heat-sensitive products like foods and medicines. JSCSTech specializes in supplying spray dryers to diverse industries, including food processing and pharmaceuticals.

What is a Spray Dryer?

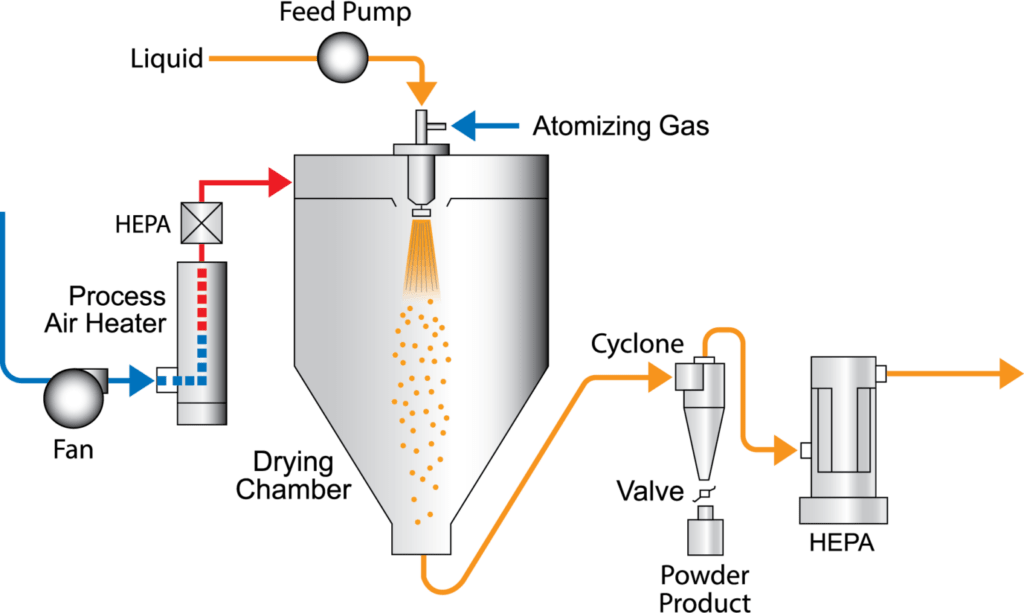

A spray dryer separates solute as a solid and solvent as vapor, collecting the material in a drum or cyclone. A nozzle sprays the liquid input stream into a hot vapor stream, causing it to evaporate. As droplets evaporate, the nozzle maximizes heat transfer, resulting in the formation of solids. High-pressure single-fluid and two-fluid nozzles are primary for drying.

Compared to alternative drying methods, a spray dryer operates more efficiently, simplifying the process and converting a solution into dried powder in a single step, ultimately enhancing profit margins.

In pharmaceutical production, spray drying facilitates the creation of Amorphous Solid Dispensation by evenly dispersing Active Pharmaceutical Ingredients into a polymer matrix. This process boosts drug dispersion by elevating the energy level of active chemicals, aiding their effective distribution in the body.

How does a Spray Dryer Work?

The spray drying process comprises five key stages, irrespective of the factory’s sophistication:

- Wet Process:

Materials intended for drying exist in a liquid state before entering the spray dryer. The pre-spray drier procedure prepares the materials for successful spray drying, optimizing yield. - Atomization:

Atomizing the liquid influx into tiny droplets ensures rapid drying, significantly increasing particle surface for effective humidity escape. - Contact between the dry substance and the air:

Heated air efficiently dries sprayed droplets, enhancing moisture absorption and particle drying in the spray chamber. The air can be blown co-currently from the top of the tower or counter-currently from the bottom. Co-current is advantageous in spray drying as higher-temperature air contacts the particles with the highest humidity first, preventing overheating. - Drying:

Drying in the spray chamber follows particle movement, gradually removing moisture through mass and heat transfer with surrounding air. - Solids Separation:

Collecting the dried particles is crucial. Cyclones often perform these separations, equipped with filters to enhance effectiveness. The powder is gathered in the spray dryer’s bottom and pneumatically delivered to a cyclone for separation from the air. The drying chamber directs the air to another cyclone, separating any fines, and returning them to the main product stream. Humid air is typically rejected, but in specific cases, it can be utilized for pre-heating due to its retained heat.

JSCSTech offers cutting-edge technology in evaporators, crystallizers, spray dryers, distillation systems, solvent recovery systems, and heat exchangers. Contact us today for exceptional processing equipment across various industries.