Understanding Fluid Bed Dryers: How They Work for Drying Applications

How does a fluid bed dryer work for drying applications?

Fluid bed dryers are widely used in various industries for drying granular materials, powders, and even some delicate products. This technology has gained popularity due to its efficiency, uniformity, and ability to handle a diverse range of materials. In this article, we will explore the working principles of fluid bed dryers, their advantages, and their applications.

What is a Fluid Bed Dryer?

A fluid bed dryer is a type of drying equipment that utilizes a stream of hot air to suspend and dry particles. The process involves creating a fluidized state in which the material behaves like a liquid, allowing for efficient heat and mass transfer. This method is particularly effective for drying bulk materials, such as pharmaceuticals, food products, and chemicals.

How Does a Fluid Bed Dryer Work?

The operation of a fluid bed dryer can be broken down into several key steps:

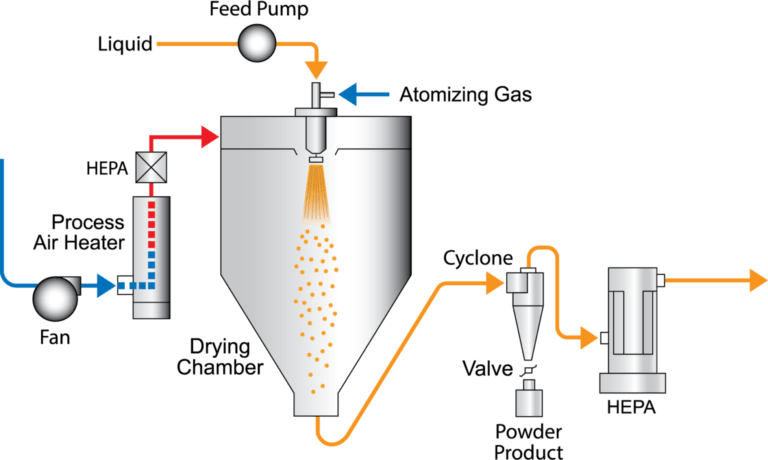

- Material Loading: The process begins with the loading of the material into the drying chamber, which is typically a cylindrical or rectangular container. The material is spread evenly across a perforated plate or mesh screen at the bottom of the chamber.

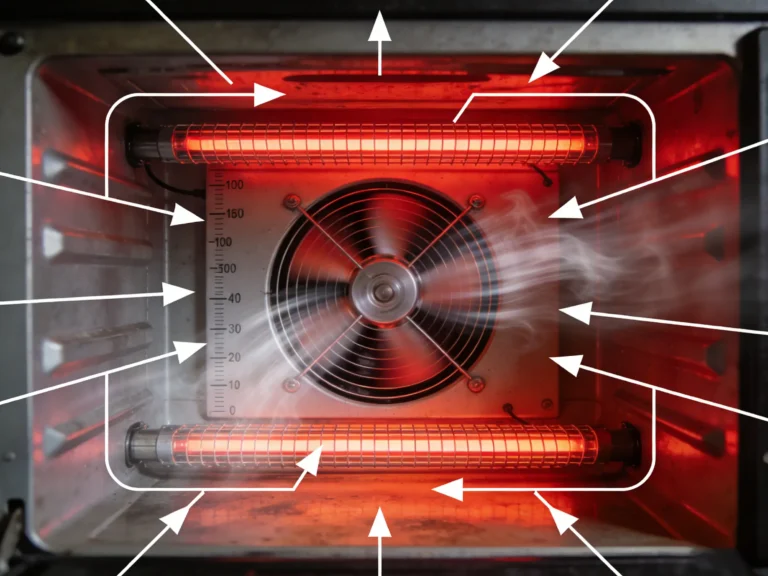

- Airflow Initiation: Once the material is loaded, a blower or fan draws ambient air through the perforated plate. This air is then heated to the desired temperature, usually between 40°C to 100°C, depending on the material being dried.

- Fluidization: As the hot air passes through the perforations, it creates an upward flow that lifts and suspends the particles in the chamber. This state is known as fluidization. The particles are agitated and uniformly distributed, ensuring even exposure to the hot air.

- Drying Process: The heat from the air evaporates moisture from the surface of the particles. As the moisture evaporates, it is carried away by the airflow, maintaining a consistent drying environment. The residence time, or the amount of time the material spends in the dryer, can be adjusted by controlling the airflow and the temperature.

- Particle Collection: Once the drying process is complete, the dried material is collected at the bottom of the chamber. The airflow can be adjusted to ensure that only the dried particles remain, while any airborne moisture or fines are removed through a cyclone separator or filter.

- Cooling (if necessary): In some applications, a cooling phase is integrated into the process. This involves introducing cooler air to lower the temperature of the dried product before it is discharged, preventing any thermal degradation.

Advantages of Fluid Bed Dryers

Fluid bed dryers offer several benefits that make them an attractive choice for drying applications:

- Uniform Drying: The fluidization of particles ensures that all surfaces are exposed to hot air, resulting in consistent moisture removal and uniform product quality.

- Efficiency: Fluid bed dryers typically have shorter drying times compared to other methods, leading to increased productivity.

- Scalability: These systems can be easily scaled up or down to accommodate different batch sizes, making them versatile for various production needs.

- Energy Savings: The efficient heat transfer in fluid bed dryers can lead to lower energy consumption compared to conventional drying methods.

- Gentle Handling: Fluid bed dryers are suitable for fragile materials, as the gentle agitation minimizes the risk of damage.

Applications of Fluid Bed Dryers

Fluid bed dryers are utilized across a range of industries, including:

- Pharmaceuticals: For drying granules, powders, and active pharmaceutical ingredients (APIs) while maintaining product integrity.

- Food Industry: For drying ingredients like herbs, spices, and instant coffee, ensuring flavor and nutritional content are preserved.

- Chemicals: For drying various chemical powders and granules used in manufacturing processes.

- Agriculture: For drying seeds, fertilizers, and animal feeds, enhancing shelf life and usability.

Conclusion

Fluid bed dryers are a powerful and efficient solution for drying a variety of materials across multiple industries. Their ability to provide uniform drying, energy efficiency, and gentle handling makes them a preferred choice for manufacturers looking to optimize their production processes. By understanding how fluid bed dryers work, businesses can harness this technology to achieve high-quality drying results.