Understanding the Working Principle of Industrial Flash Dryers

In the realm of industrial drying processes, efficiency and speed are critical for optimizing production. Flash dryers stand out as a rapid drying solution for various particulate materials, making them indispensable in industries such as food processing, pharmaceuticals, chemicals, and minerals. This article delves into the working principle of industrial flash dryers, their advantages, and their applications across different sectors.

What is a Flash Dryer?

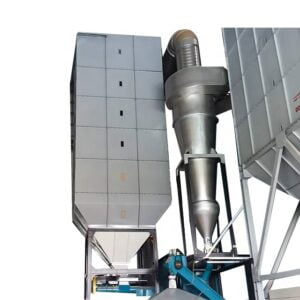

A flash dryer is a specialized piece of equipment designed to quickly and efficiently reduce moisture content in materials like powders, granules, and flakes. The technology is engineered to ensure that moisture is evaporated almost instantaneously, thereby enhancing productivity and minimizing thermal degradation of heat-sensitive materials.

Working Principle of Industrial Flash Dryers

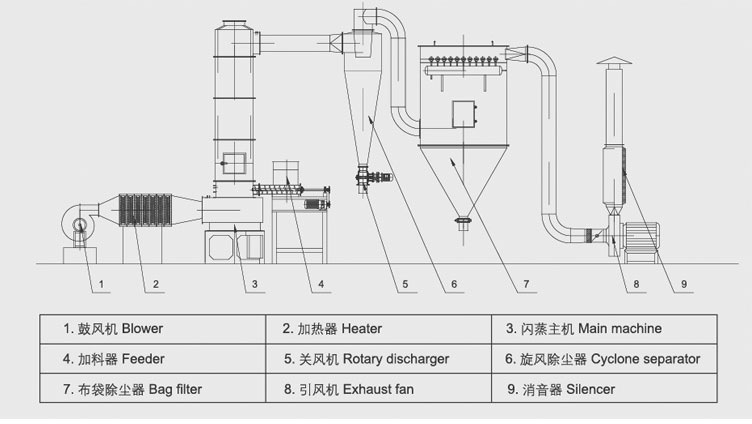

The operation of a flash dryer can be broken down into several key steps:

Material Feeding: The drying process begins with a feeder that introduces the wet material into the flash dryer. This controlled flow is essential for maintaining consistent drying conditions.

Introduction of Hot Air: Inside the drying chamber, a high-velocity stream of hot air is introduced, typically generated from gas burners, steam, or electric heaters. The high temperature of the air is crucial for rapid moisture evaporation.

Rapid Drying Process: As the wet material comes into contact with the hot air stream, the moisture evaporates almost instantaneously. The combination of high temperature and velocity accelerates the drying process while minimizing the risk of damaging the material.

Separation and Collection: The dried material, now consisting of fine particles, is carried along with the air stream to a cyclone separator or bag filter. This component efficiently separates the dry particles from the air, allowing for easy collection for further processing or packaging.

Exhaust Air Management: An exhaust fan expels the moisture-laden air from the system, ensuring a continuous flow of fresh air and maintaining optimal drying conditions.

Advantages of Flash Dryers

Understanding the working principle of flash dryers reveals several key advantages:

Rapid Drying: Flash dryers can complete the drying process in seconds, significantly reducing production times and increasing throughput.

Energy Efficiency: The efficient heat transfer in flash dryers results in lower operational costs, making them an economical choice for large-scale drying.

Versatility: These dryers are capable of handling a wide range of materials, from fine powders to larger granules, making them suitable for various applications.

Compact Design: Their small footprint allows for easy integration into existing production lines, requiring minimal modifications to current setups.

Applications of Industrial Flash Dryers

Industrial flash dryers are utilized across numerous industries, including:

Pharmaceuticals: For drying sensitive compounds and active ingredients.

Food Processing: Essential for drying products like starch, fish meal, and distiller’s grains.

Chemical Manufacturing: Used for drying various chemical powders and resins.

Mineral Processing: Effective in drying mineral powders and coal.

Why Choose jscstech for Flash Dryers?

jscstech is recognized as a leading manufacturer of flash dryers, providing tailored solutions to meet the unique needs of various industries. Here’s why jscstech is the preferred choice:

Customized Solutions: jscstech understands that different industries have specific requirements and offers tailored drying solutions for optimal performance.

Quality Assurance: Their flash dryers adhere to the highest quality standards, ensuring reliable and consistent performance.

Expert Support: jscstech provides comprehensive support, from installation to maintenance, facilitating smooth operations.

Continuous Innovation: The company invests in ongoing research and development to incorporate the latest advancements in drying technology.

Conclusion

Flash dryers are a vital component in the industrial drying landscape, providing rapid and efficient moisture removal for a variety of materials. By understanding the working principle and advantages of flash dryers, industries can make informed decisions that enhance their production processes. Trust in jscstech for high-performance, reliable, and innovative drying solutions tailored to your specific needs. For more information or inquiries, reach out to jscstech’s expert team today.