Роль порошкового оборудования в пищевой переработке: Примеры и истории успеха

Роль порошкового оборудования в пищевой переработке

Пищевая промышленность представляет собой обширный и разнообразный сектор, который в значительной степени зависит от порошкового оборудования для различных технологических операций.. От производства основных пищевых порошков, таких как мука и сухое молоко, до создания специальных пищевых ингредиентов и приправ., порошковое оборудование лежит в основе многих процессов производства пищевых продуктов.

В производстве муки, фрезерное оборудование является основным используемым порошковым оборудованием.. Для измельчения зерна, например пшеницы, обычно используются валковые и молотковые мельницы., кукуруза, и рис в мелкую муку. Валковые мельницы известны своей способностью производить муку с определенным гранулометрическим составом и желаемым качеством.. Например, в производстве хлебопекарной муки высшего качества, валковые мельницы можно отрегулировать для точного отделения отрубей и зародышей от эндосперма, в результате получается мука с отличными клейковинными свойствами.. Это приводит к лучшей обработке теста и, в конечном итоге,, превосходное качество хлеба.

Распылительная сушка — важнейший процесс порошкового оборудования в пищевой промышленности., специально для переработки жидких пищевых продуктов в порошки. Сухое молоко является ярким примером. В башне распылительной сушки, жидкое молоко распыляется на мелкие капли, а затем высушивается горячим воздухом.. Полученное сухое молоко имеет длительный срок хранения и удобно при хранении и транспортировке.. Этот процесс также позволяет добавлять питательные вещества и ароматизаторы во время процесса сушки., создание продуктов с добавленной стоимостью. Например, Производители детских смесей используют распылительную сушку для производства порошкообразного продукта, содержащего тщательно сбалансированную смесь белков., жиры, углеводы, витамины, и минералы.

Миксеры и блендеры используются для создания самых разнообразных пищевых продуктов.. При производстве смесей специй, например, различные специи и травы смешиваются в определенных пропорциях для достижения желаемого вкусового профиля.. Ленточный миксер можно использовать для получения однородной смеси порошкообразных специй, таких как корица., мускатный орех, и гвоздика. Эта однородная смесь необходима для обеспечения постоянного вкуса пищевых продуктов, таких как выпечка., соусы, и приправы.

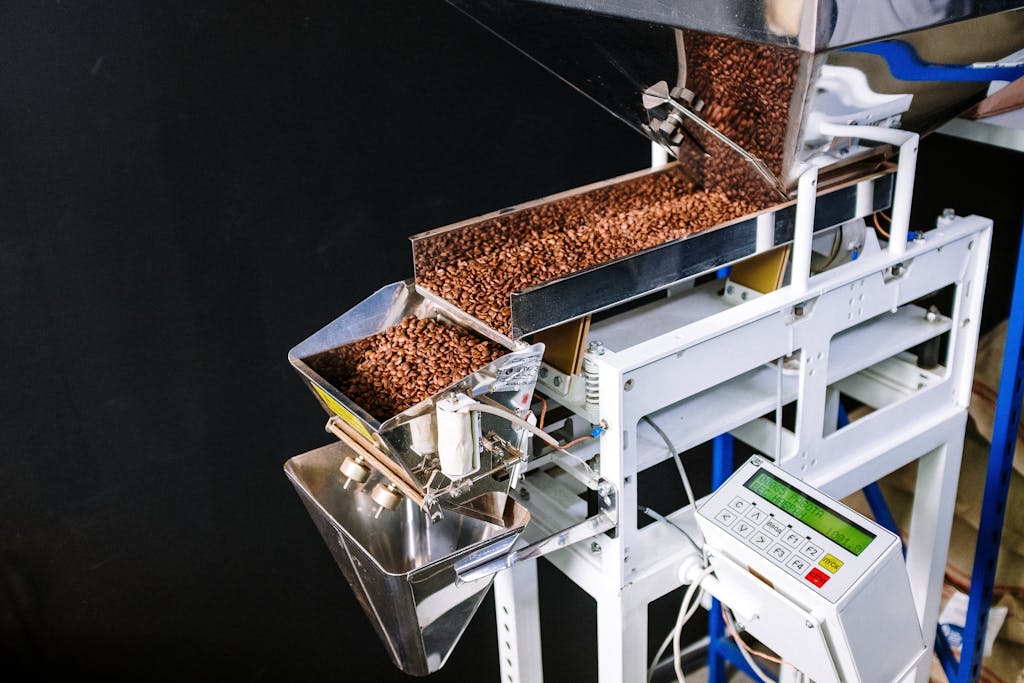

Еще одна история успеха связана с производством порошкообразного растворимого кофе.. Кофейные зерна сначала обжариваются, а затем измельчаются.. Затем молотый кофе экстрагируется горячей водой для получения концентрированной кофейной жидкости.. Затем эту жидкость сушат с использованием методов лиофилизации или распылительной сушки.. Сублимационная сушка предпочтительна для высококачественного растворимого кофе, поскольку она лучше сохраняет вкус и аромат кофе.. Полученный порошкообразный кофе можно быстро растворить в горячей воде., предоставление потребителям удобного и вкусного варианта кофе.

Роль порошкового оборудования в пищевой промышленности не только позволяет производить широкий ассортимент пищевых продуктов, но также способствует обеспечению безопасности и качества пищевых продуктов.. Путем точного контроля параметров обработки, таких как температура, размер частиц, и время смешивания, снижается риск микробного заражения и порчи продукции. Кроме того, порошковое оборудование позволяет стандартизировать пищевые продукты, обеспечение того, чтобы потребители получали стабильное качество и вкус каждый раз, когда они покупают определенный продукт питания. В заключение, порошковое оборудование является жизненно важным активом в пищевой промышленности., стимулирование инноваций и удовлетворение потребностей потребителей в удобном, высокое качество, и разнообразные продукты питания.