Горячая продажа серии XSG вращающаяся сушилка для мгновенного испарения маниоки

Спиновая флэш -сушилка серии XZG - это непрерывное сушильное оборудование, специально предназначенное для формы пирога, крем-паста, и вставьте материалы для вставки. Чистая тепловая среда входит в сушильную комнату от касательного направления и создает сильный ток воздушного воздуха, когда он находится в движении с мешалкой. Влажный материал добавляется в сушки в фиксированном количестве, и он будет измельчен и сухой при высокой скорости перемешивания. Верхняя часть сушки имеет классификацию размера частиц, Большие частицы будут остановлены классификатором, а тонкий порошок будет выброшен из центра кольца и собран циклоном сепаратора. Большие частицы вернутся в сушильную комнату и будут продолжать измельчать и сухие.

Описание

Серия XSG Вращающийся маниока вспышка испарение сушилка

Вращающаяся сушилка с мгновенным испарением маниоки ОПИСАНИЕ

Спиновая флэш -сушилка серии XZG - это непрерывное сушильное оборудование, специально предназначенное для формы пирога, крем-паста, и вставьте материалы для вставки. Чистая тепловая среда входит в сушильную комнату от касательного направления и создает сильный ток воздушного воздуха, когда он находится в движении с мешалкой. Влажный материал добавляется в сушки в фиксированном количестве, и он будет измельчен и сухой при высокой скорости перемешивания. Верхняя часть сушки имеет классификацию размера частиц, Большие частицы будут остановлены классификатором, а тонкий порошок будет выброшен из центра кольца и собран циклоном сепаратора. Большие частицы вернутся в сушильную комнату и будут продолжать измельчать и сухие.

Вращающаяся сушилка мгновенного испарения маниоки ОСОБЕННОСТИ

(1) Сырье обрабатывается путем резки., стрижка, дует, плавающий, и вращающийся, затем приобретают гранулированную форму и сильно разделяются; относительная скорость между твердой фазой и газовой фазой велика, это усиливает процесс теплообмена.

(2) Компактная конструкция и требуемая небольшая занимаемая площадь., и машина проста в управлении и обслуживании.

(3) Горячий воздух поступает в нижнюю часть машины и создает сильный вращающийся поток воздуха.; он может вымыть материал, прилипший к внутренней поверхности.

(4) Зона высокой температуры находится в нижней части машины., термочувствительное сырье не будет напрямую контактировать с нагревательной поверхностью. Как результат, проблемы карбонизации и изменения цвета могут быть решены.

(5) Сушилка работает под отрицательным или микроотрицательным давлением., нет необходимости в другой дробильной машине для измельчения сырья, и загрязнение обстоятельств не произойдет.

(6) В верхней сушильной камере установлены сегментирующее кольцо и ротационная насадка для контроля размера гранул и конечной влажности для обеспечения требуемой скорости содержания влаги и грануляции..

Вращающаяся сушилка с мгновенным испарением маниоки ПРИНЦИП РАБОТЫ

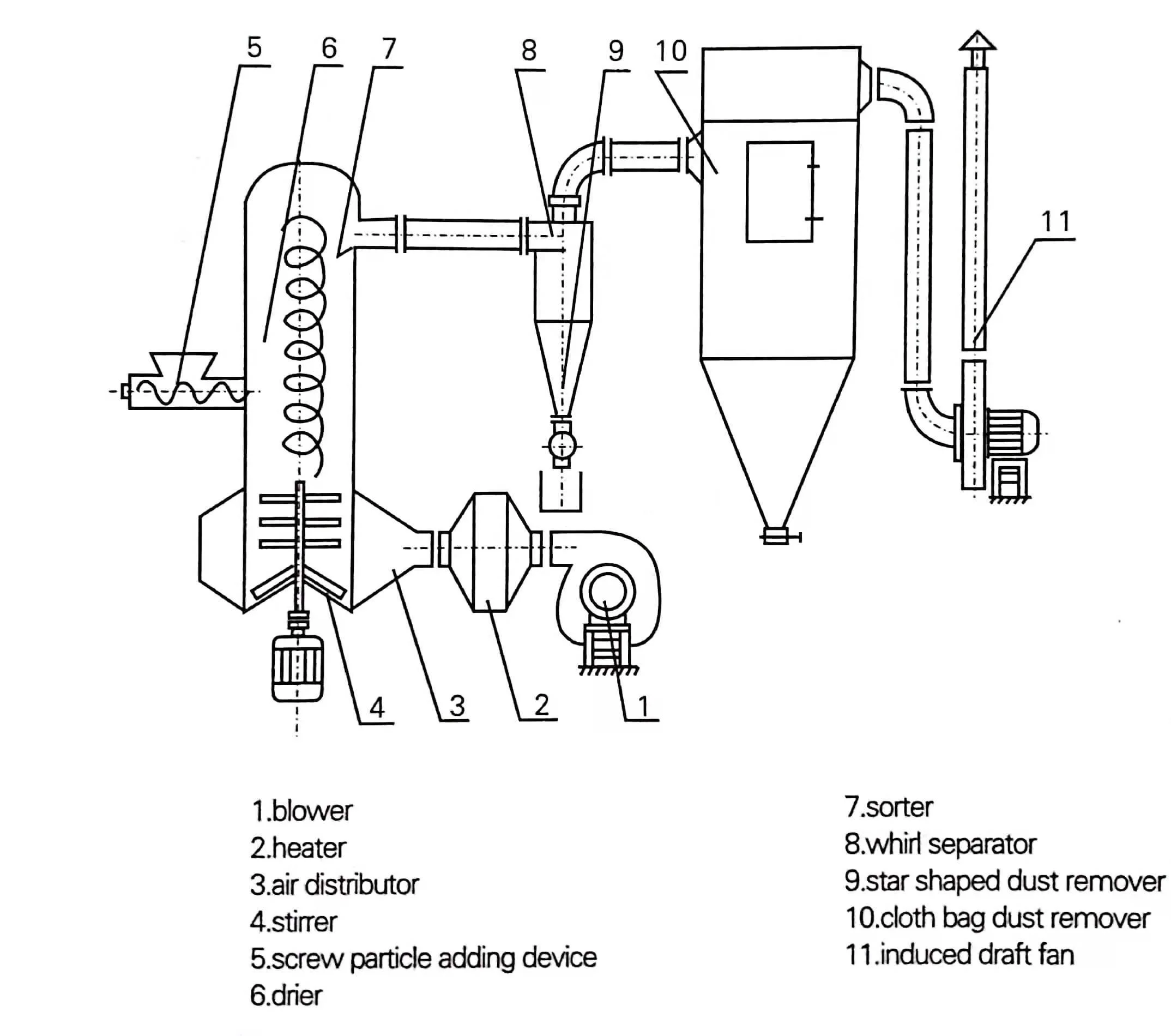

Горячий воздух поступает в нижнюю часть сушилки по касательной.. Под приводом мешалки, образуется мощное вращающееся ветровое поле. Материалы в пастообразном состоянии поступают в сушилку через шнековый питатель.. Под мощной функцией перемешивающих лопастей при высокоскоростном вращении, материалы распределяются по функции забастовки, сила трения и сдвига. Материалы состояния торта будут разбиты и полностью контактируют с горячим воздухом, а материалы нагреваются и высушиваются.. Обезвоженные материалы будут подниматься вверх вместе с потоком горячего воздуха.. Ступенчатые кольца остановят и удержат крупные частицы.. Мелкие частицы будут выгружаться из сушилки из центра машины, а материал будет собираться циклонным сепаратором пылесборника.. Влажные или крупные частицы будут отбрасываться к стене под действием центробежной силы, и материалы снова будут измельчены после падения на дно..

Вращающаяся сушилка мгновенного испарения маниоки ПРИМЕНИМЫЕ МАТЕРИАЛЫ

Органика: Атразин (Пестициды), Кадмий лаурат, Бензойная кислота, Гермицид, оксалат натрия, Ацетат целлюлозы, Органические пигменты, и так далее. Красители: Антрахинон, Черный оксид железа, Пигменты индиго, Масляная кислота, Гидроксид Титана, Сульфид цинка, Промежуточные соединения азокрасителей, и так далее. Неорганический: Бура, Карбонат кальция, Гидроксид, Медный купорос, оксид железа, Карбонат бария, Триоксид сурьмы, Гидроксиды металлов, Соли тяжелых металлов, Синтетический криолит, и так далее. Еда: Я протеин, Желатинизированный крахмал, Лиз, Пшеничный сахар, Пшеничный крахмал, и так далее.

Вращающаяся сушилка мгновенного испарения маниоки ТЕХНИЧЕСКИЕ ПАРАМЕТРЫ

| Элемент \ Модель | XSG-2 | XSG-4 | XSG-6 | XSG-8 | XSG-10 | XSG-12 | XSG-16 | XSG-20 |

| Диаметр башни (мм) | 200 | 400 | 600 | 800 | 1000 | 1200 | 1600 | 2000 |

| Количество воздуха (М3/час) | 350-500 | 1150-2000 | 2450-4500 | 4450-7550 | 7000-12500 | 10000-20000 | 18000-36000 | 28200-56500 |

| Испарение воды (кг/ч) | 12-17 | 40-70 | 80-150 | 150-250 | 230-4250 | 300-600 | 600-1000 | 1000-1500 |

| Общая мощность (кВт) | 10 | 20 | 40 | 65 | 85 | 105 | 150 | 230 |

| Макс. Высота оборудования (м) | 4.0 | 4.8 | 5.8 | 6.5 | 7.1 | 7.8 | 8.8 | 10.1 |

| Занимаемая площадь (м2) | 15 | 20 | 28 | 35 | 40 | 52 | 80 | 150 |

Примечание:

1. Количество испаряемой влаги рассчитывается при температуре на входе l80.оC и температура на выходе 180°С.оC, а температура на выходе 180оС;

2. Помимо вышеперечисленных моделей, специальная спецификация также может быть сделана по запросу;

3. Вышеупомянутая оснащенная мощность является стандартной.. Мощность также может быть уменьшена в соответствии с практическими условиями..

Пример сырья & Характеристики (на базе модели XZG-6)

| Элемент \ Сырье | Стеаратовая кислота | Гидроксид алюминия | Карбонат цинка | Моносультап | ТМТД | ДСД Кислота |

Красный оксид железа | Сурьма Диоксид |

Медистый Хлористый |

Белый углерод черный |

| Температура воздуха на входе (оС) | 150 | 180 | 150 | 120 | 140 | 150 | 200 | 180 | 200 | 280 |

| Первичная влага (%) | 80 | 55 | 80 | 30 | 65 | 60 | 60 | 45 | 30 | 85 |

| Конечная влажность (%) | 0.5 | 1.5 | 1.0 | 1.0 | 0.5 | 0.5 | 0.5 | 1.0 | 3.0 | 5.0 |

| Практическая производительность сушки (кг/ч) | 140-160 | 250-280 | 130-170 | 80-110 | 80-120 | 80-120 | 300-350 | 280-320 | 290-310 | 250-300 |

| Элемент \ Сырье | ЗДК ускорение ЗДК |

Масло растворимый чернила |

Заменять Цинк манганат |

Фталок- вроде краситель |

Кальций цитрат |

сверхтонкий кальций карбонат |

суспензия уход агент |

Натрий изоцианурат диоксид |

Натрий изоцианурат триоксид |

| Температура воздуха на входе (оС) | 150 | 150 | 120 | 150 | 140 | 160 | 200 | 180 | 150 |

| Первичная влага (%) | 60 | 45 | 30 | 55 | 40 | 70 | 75 | 25 | 30 |

| Конечная влажность (%) | 0.5 | 2.0 | 1.0 | 1.0 | 1.0 | 1.5 | 5.0 | 0.2-2 | 1.0 |

| Практическая производительность сушки (кг/ч) | 80-110 | 350-380 | 120-150 | 160-180 | 300-350 | 430-470 | 290-310 | 80-120 | 90-150 |

Отзывы

Пока нет отзывов.