Горячая Распродажа, сушилка для грануляции под давлением серии YPG для органических катализаторов

-

Сушилка для грануляции под давлением для органических катализаторов это своего рода устройство, которое может одновременно завершать сушку и гранулирование.. В соответствии с требованиями процесса, ты можешь регулировать давление, скорость потока жидкостного насоса материала и размер распылительного отверстия для получения необходимых сферических частиц в определенном соотношении размеров.

Описание

hot sale YPG Series Pressure Spray Granulation Dryer for Organic catalysts

Pressure Spray Granulation Dryer for Organic catalysts DESCRIPTION

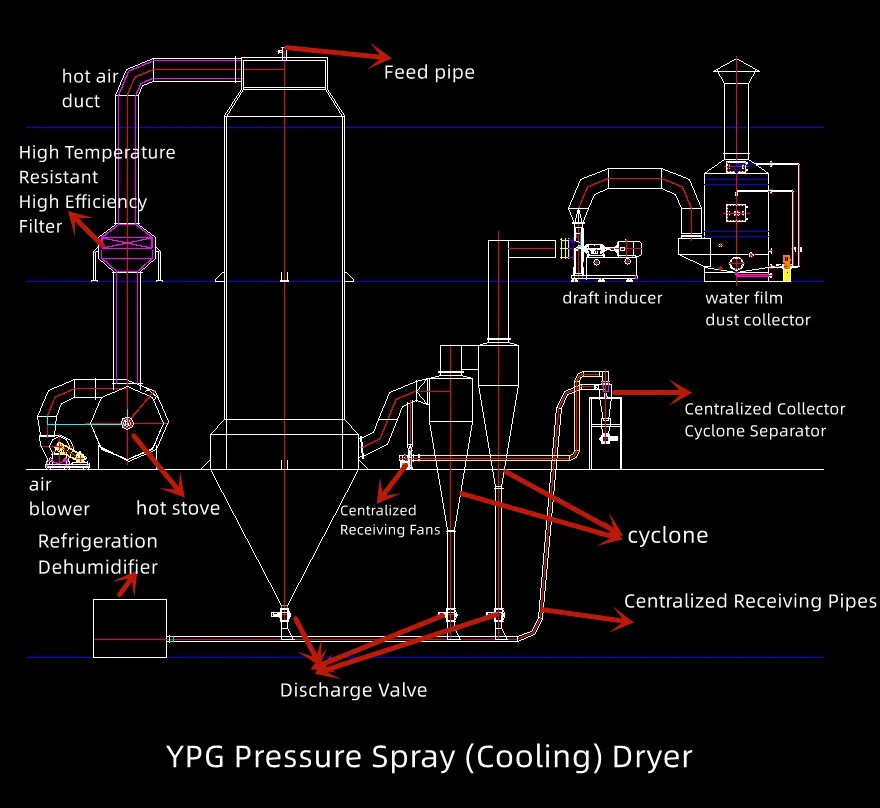

Спрей под давлением серии YPG (Застывать) Сушилка оснащена устройством, которое может одновременно выполнять сушку и гранулирование.. Давление распыления, Расход распыления и размер распылительного сопла насоса для жидкого материала можно регулировать в соответствии с требованиями и достигать определенного размера шариков гранул..Сушилка-грануляция под давлением для органических катализаторов ПРИНЦИП РАБОТЫ

Жидкий или пастообразный материал распыляется на небольшую каплю жидкости с помощью прижатого распылителя, который помогает вытягиваться под давлением мембранного насоса., и быстрое высыхание благодаря интенсивному теплообмену (10-90сек.).Most of the powder granules are collected from outlet of discharge at the bottom of the dryer.The wasted air and fine powder are separated by the cyclone, отработанный воздух выбрасывается вытяжным вентилятором, и мелкий порошок собирается в нижней части циклона. На выходе установлен пылесос второго класса.; поэтому, Скорость восстановления готовых гранул порошка может быть 96% к 98%.

Pressure Spray Granulation Dryer for Organic catalysts APPLICATION

Химическая индустрия: Sodium Fluoride (Калий ), Alkaline Dyestuff And Pigment,Dyestuff Intermediate, Mn3o4, Составное удобрение, Formic Silicic Acid, Катализатор, Sulphuric Acid Agent, Amino Acid,White Carbon, и так далее.

Пищевая промышленность: Fatty Milk Powder, Protein, Cocoa Milk Powder, Subsitute Milk Powder,Egg White (Yolk), Food And Plant,Oats,Chicken Juice, Кофе, Instant Dissoluble Tea ,Seasoning Meat,Protein ,Soybean,Peanut Protein, Hydrolysate, Sugar,Corn Syrup,Corn Starch,Glucose, Pectin,Malt Sugar, Sorbic Acid Potassium, и так далее.

Фармацевтическая индустрия: Chinese Traditional Medicines, Пестицид, Antibiotic, Medical Drinking Agent,и так далее.

Plastics and Resin: АБ, ABS Emulsion, Uric Acid Resin, Phenolic Aldehyde Resin, Urea-Formaldehyde Resin, Formaldehyde Resin, Polythene, Poly-Chloroprene, And etc.

Моет: Common Washing Powder,Advanced Washing Powder,Soap Powder, Soda Ash, Emulsifier, Brightening Agent, Orthophosphoric Acid, и так далее.

Ceramic: Aluminium Oxide, Ceramic Tile Material, MagnesiumOxide, Talcum, и так далее. Другой: Calmogastrin, Hime Chloride , Stearic Acid Agent, и так далее.

Pressure Spray Granulation Dryer for Organic catalysts FEATURES

1. Rapid drying speed.The surface area of the material will be enlarged greatly when liquid raw material is atomized and 95% – 98% of water can be evaporated instantly in the hot airflow. The drying time only need to take several seconds. This dryer is especially suitable for heating sen sitive material.

2. The finished product is ball granulewith uniform size. It’s fluidity and solubility are good. The quality and purity of the product is very high.

3. Depend on the characteristics of raw material, the dryer can use hot air to dry or use cool air to granulate.

4. Simple and stable operation. The control system is con venient which is easy to realize automatic operation.

Технические параметры

| Элемент \ Модель | Unit | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| water evapo- ration capacity |

кг | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| overall dimension (Φ×H) |

мм | 1600× 8900 |

2000× 11500 |

2400× 13500 | 2800× 14800 |

3200× 15400 |

3800× 1880 |

4600× 22500 |

| high-pressure pump pressure |

mPa | 2~10 | ||||||

| власть | КВт | 8.5 | 14 | 22 | 24 | 30 | 82 | 30 |

| inlet air температура |

оС | 140~350 | ||||||

| product water contents |

% | <5(可达0.5) | ||||||

| collection rate | % | >97 | ||||||

| electric heater | КВт | 75 | 120 | 150 | temperature is lower than 200,the parameters should be calculated |

|||

| электричество +пар |

Mpa+KW | 0.5+54 | 0.6+90 | 0.6+108 | according to the practical condition | |||

| печь с горячим воздухом | Kcal/h | 100000 | 150000 | 200000 | 300000 | 400000 | 500000 | 1200000 |

* Выше указано самое большое испарение..

Отзывы

Пока нет отзывов.