Как работают вибрирующие флюидированные сушилки для кроватей

A vibrating fluidized bed dryer dries materials by suspending particles on a stream of hot air while the machine vibrates. You see the vibration helping to keep particles moving, which lets the airflow reach every part of the material. This process gives you fast, равномерное высыхание, especially for powders and granules.

Industries that use this technology include:

Пищевая промышленность (largest market share)

Химикаты

Фармацевтика

Керамика

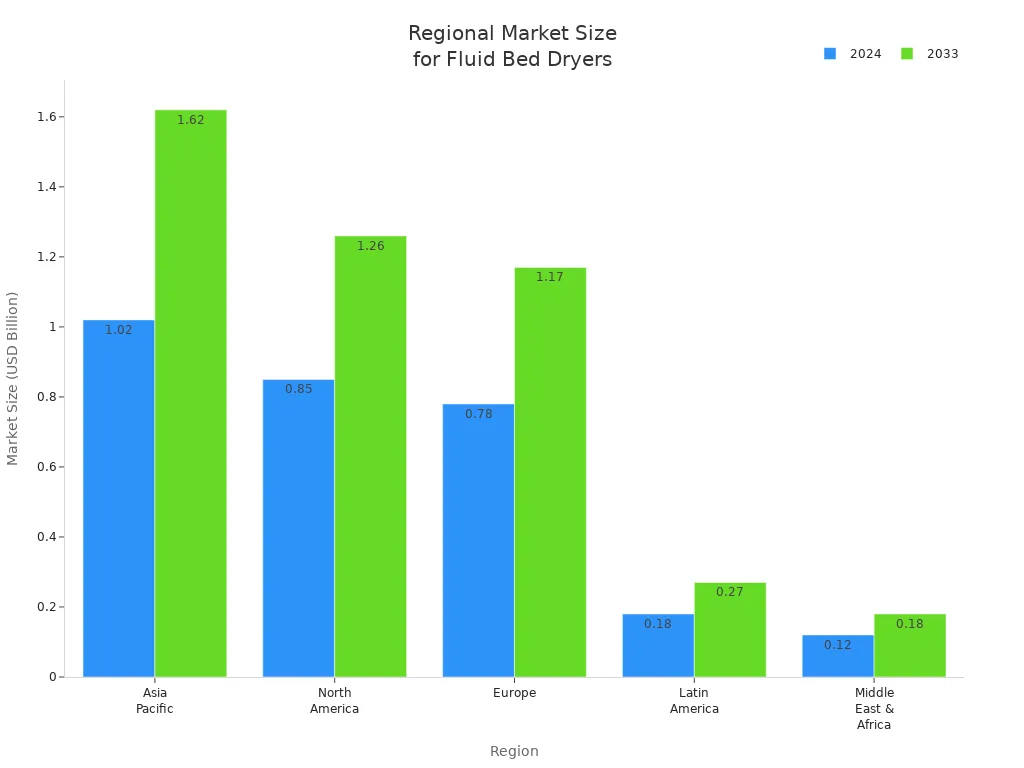

The global market for these dryers reached $750 million in 2024 and continues to grow as companies seek energy-efficient solutions.

Ключевые выводы

Vibrating fluidized bed dryers use hot air and vibration to dry powders and granules quickly and evenly.

Vibration keeps particles moving, preventing clumps and allowing hot air to reach every part of the material.

You can control temperature, расход воздуха, and vibration to match different materials and save energy.

These dryers work well in food, химический, and pharmaceutical industries for gentle, consistent drying.

Maintenance is easier with features like clean-in-place systems, and safety is ensured with dust collectors and sensors.

Vibrating Fluidized Bed Dryer Basics

Определение

You can think of a vibrating fluidized bed dryer as a special machine that dries small particles or powders. It uses both vibration and hot air to move and dry materials. The table below shows the main features of this dryer:

Аспект | Описание |

|---|---|

Тип сушилки | |

Material Bed Depth | Shallow (a few inches) |

Material Movement | Vibrating conveyor moves material with upward heated airflow |

Airflow Role | Hot air flows up through a perforated pan to dry material |

Material Flow Pattern | Plug flow, so first-in is first-out |

Particle Size Range | Handles particles from less than 50 microns up to about 1/2 дюйм |

Приложения | Еда, химикаты, фармацевтика, и многое другое |

Преимущества | Reduces channeling, works with many shapes, adjustable airflow, strong conveying force |

Ограничения | Needs more space than static dryers, more moving parts, temperature limits |

Эффективность сушки | Dries faster and uses less air than static dryers |

Обслуживание | More moving parts mean more maintenance |

Handling Wet Material | Very wet material may need mixing with dry material |

This design lets you dry many types of materials quickly and evenly.

Цель

You use a vibrating fluidized bed dryer to reach several important goals:

Achieve fast and even drying for powders and granules.

Improve heat and mass transfer by keeping particles suspended in hot air.

Prevent clumping, so each particle dries the same way.

Save energy with high thermal efficiency.

Protect sensitive materials with gentle drying.

Handle large amounts of material for industrial production.

Improve product quality by making sure every batch dries the same.

Кончик: Если вы хотите сушить продукты, химикаты, или лекарство, this dryer gives you reliable results and saves energy.

Components

Воздушная система

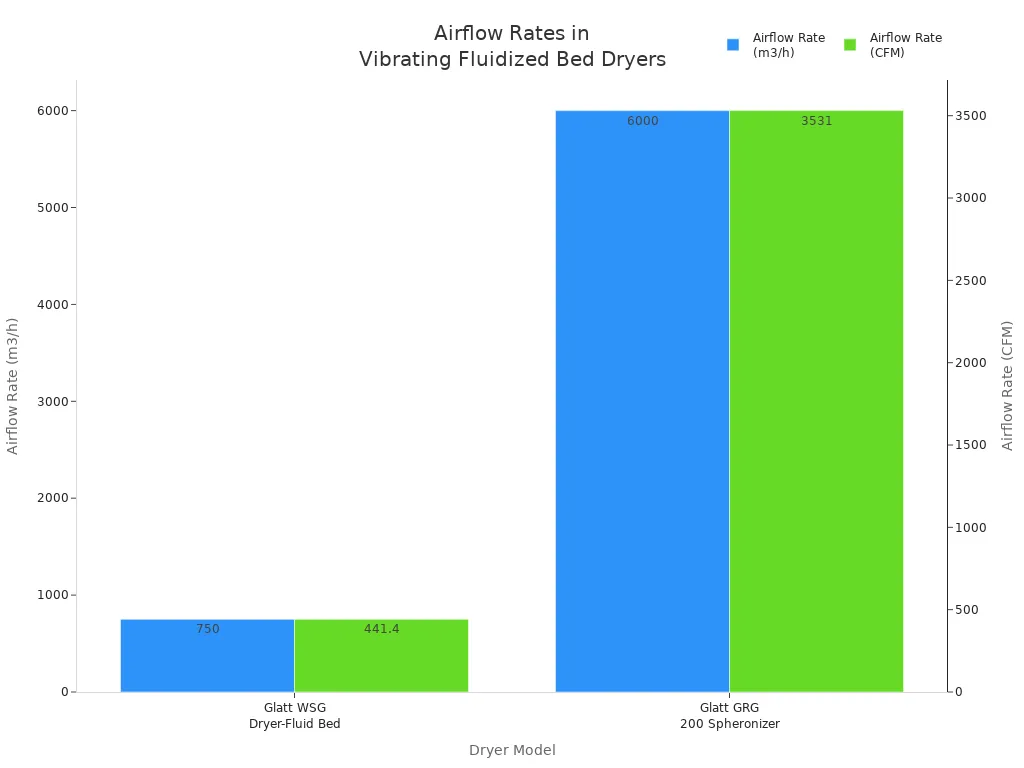

You rely on the air system to deliver heated, pressurized air through the bed of particles. This air lifts and separates the particles, making drying possible. Most systems use a perforated or porous plate to spread the air evenly. The airflow rate depends on the dryer model and your process needs. Например, the Glatt WSG model uses 750 m³/h of air at 3 бар, while the Glatt GRG 200 can reach 6,000 m³/h at 0.5 бар. You can see how airflow rates compare in the table below:

Dryer Model | Manufacturer | Air System Type | Скорость воздушного потока (м³/ч) | Скорость воздушного потока (CFM) | Operating Pressure (бар) | Примечания |

|---|---|---|---|---|---|---|

Glatt WSG Dryer-Fluid Bed | Glatt | Heated, pressurized air through perforated fluid bed with vibration | 750 | 441.4 | 3 | Batch operation, air heated to 70°C, uses compressed air at 3 бар |

Glatt GRG 200 Spheronizer | Glatt | Heated, pressurized air through perforated fluid bed | 6000 | 3531 | 0.5 | Batch operation, air heated to 60°C, lower pressure than WSG |

Niro Dryer-Fluid Bed | Niro | Continuous vibrating fluid bed with perforated fluid bed | Н/Д | Н/Д | Н/Д | Continuous operation, specific airflow rates not provided |

Witte Vibrating Fluid Bed Dryers | Witte | Heated air passed through porous conveying surface with vibration | Переменная (hundreds to thousands) | Н/Д | Н/Д | Airflow rates and sizes vary by application, product moisture, пропускная способность, температура |

Примечание: You can adjust the airflow to match your material and drying needs.

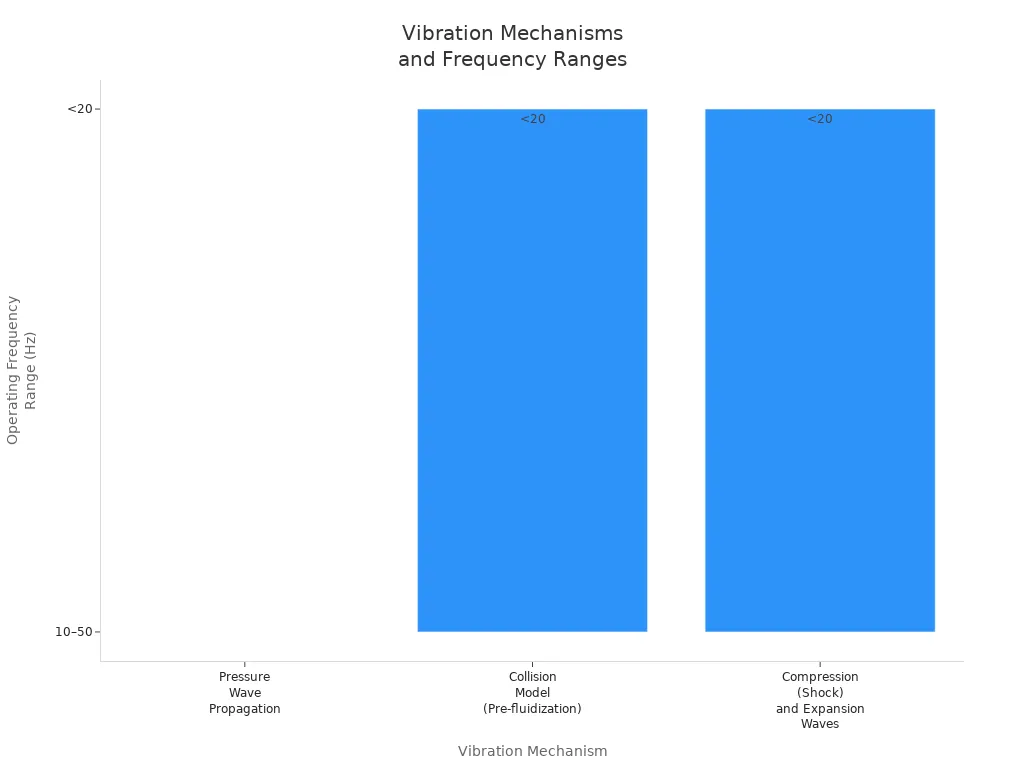

Vibration Mechanism

The vibration mechanism keeps particles moving and helps the air reach every part of the material. You find different types of vibration in these dryers. Some use pressure waves, while others use collision or compression waves. Most dryers operate between 10 и 50 Hz. Lower frequencies, below 20 Hz, work well for larger particles or heavy loads. The table below shows common vibration types and their frequency ranges:

Vibration Mechanism | Описание | Operating Frequency Range (Hz) |

|---|---|---|

Pressure Wave Propagation | Pressure waves from a vibrating base transfer energy through the bed. | 10–50 (commonly 10–25, ~30) |

Collision Model (Pre-fluidization) | Energy moves by collisions between the base and particles, then through particle collisions. | Below 20 |

Compression (Shock) and Expansion Waves | Pulsed gas flow and wave propagation across the bed at low frequency and high amplitude. | Below 20, amplitude > 10 мм |

Кончик: You can improve drying by setting the vibration amplitude around 3 мм.

Bed Structure

The bed structure holds the material and controls how air and particles move. You usually see a perforated or porous plate at the bottom. This plate spreads the air evenly and supports the material. The shape of the container also matters. Annular (ring-shaped) beds often give better results for uniform drying. The table below explains how different parts of the bed structure affect drying:

Bed Structure Element | Effect on Drying Efficiency and Uniformity |

|---|---|

Proper positioning ensures desired airflow and temperature, which controls airflow patterns and final product uniformity. | |

Product Container Shape | Different shapes affect particle holding and temperature/velocity distribution; annular designs often yield better results. |

Примечание: Good bed design helps you get even drying and high efficiency.

Discharge

You remove the dried product through a discharge system at the end of the bed. This system can be a simple chute or a controlled valve. You can adjust the discharge rate to match your process speed. This step ensures you get a steady flow of dried material, ready for packaging or further processing.

How a Vibrating Fluidized Bed Dryer Works

Подача материала

You start the drying process by feeding your material into the vibrating fluidized bed dryer. You can use a screw feeder, conveyor belt, or even manual loading, depending on your setup. The feeder spreads the material evenly onto the bed. This even distribution is important because it helps every particle get the same chance to dry. The vibration of the dryer body helps move the material forward and supports the start of fluidization. You can adjust the feeding rate to match your production needs.

Кончик: A steady, uniform feed keeps the drying process stable and prevents clumping at the start.

Fluidization by Airflow

Once the material enters the dryer, hot air flows upward through a perforated plate at the bottom of the bed. This air comes from a blower or supply fan and is heated to the right temperature for your product. The air lifts the particles, making them float and move freely. This floating state is called “fluidization.” You control the air temperature and humidity to match your material. Например, you might use air at 70°C to 120°C for fertilizers, or lower temperatures for sensitive products. The perforated plate spreads the air evenly, so every particle gets the same amount of heat.

The air system also includes filters and dust collectors to keep the process clean and safe.

You can adjust the airflow to change how much the particles move and how fast they dry.

Vibration Effects

Vibration is what makes this dryer special. The vibrating motor shakes the bed, causing the particles to jump and move in random directions. This movement keeps the particles from sticking together or settling in one spot. You get better mixing, which means the hot air can reach every surface of every particle. Vibration also helps prevent dead zones and clumps, so you avoid uneven drying. The combination of vibration and airflow turns the material from a static pile into a dynamic, moving layer. This dynamic state improves both heat and mass transfer, making drying faster and more uniform.

Vibration reduces friction between particles, so they move smoothly across the bed.

The gentle shaking protects delicate materials from breaking apart.

Процесс сушки

As the particles float and move, the hot air removes moisture from them. The heat from the air transfers to the wet material, causing water to evaporate. The moving particles expose new surfaces to the air all the time, поэтому высыхание происходит быстро и равномерно. You can control the temperature and humidity of the air to fit your product. Например, you might start with lower temperatures for very wet materials and increase the heat as drying continues. The control system lets you adjust fan speeds, давление воздуха, and vibration strength to get the best results.

Примечание: The dryer collects dust and fine particles using cyclone separators and filters, keeping the air clean before it leaves the system.

Product Movement

The vibration not only mixes the particles but also moves them forward along the bed. As the material travels, it spends enough time in the hot air to dry completely. The horizontal movement prevents particles from staying in one place too long or escaping too soon. This steady flow keeps the bed depth even and ensures that every batch dries the same way. At the end of the bed, the dried product leaves through a discharge spout or valve. You can adjust the discharge rate to match your process speed.

The horizontal transport avoids dead zones and blow-through, so you get uniform drying.

The system recovers dust and keeps the environment safe.

In summary, the vibrating fluidized bed dryer uses a careful balance of feeding, расход воздуха, vibration, and movement to turn wet material into a dry, uniform product. You get fast, efficient drying with less risk of clumping or uneven results.

Features and Advantages

Энергоэффективность

You can achieve impressive energy savings with a vibrating fluidized bed dryer. The vibratory motion improves heat transfer and keeps particles moving, so you use less drying air. This system dries materials faster than conventional dryers. You also get нежное обращение, which protects your product and keeps moisture levels even. When you operate near the system’s natural frequency, you can boost energy efficiency by 5% к 15%. The dryer uses less energy while still giving you high drying rates and quality results. You can control the air temperature and vibration to match your needs, which helps you avoid wasting energy.

Кончик: Lower drying temperatures and the right vibration settings can help you save even more energy.

Process Control

You have strong control over the drying process. Real-time monitoring lets you adjust temperature, расход воздуха, и влажность as needed. Vibration helps you move even tough materials, so you avoid hot spots and uneven drying. You can use zoning to create different drying stages in one machine. Adjusting the vibration angle lets you control how long the material stays in the dryer. Plug flow design ensures that the first material in is the first out, so you get consistent results every time.

You prevent under-drying or over-drying by adjusting settings on the fly.

Consistent drying improves product quality and safety.

Универсальность

A vibrating fluidized bed dryer works with many types of materials. Ты можешь dry powders, гранулы, fibers, and even small particles. This dryer is common in the food, химический, and pharmaceutical industries. You can handle grains, cereals, фрукты, полимеры, and catalysts. If you need to dry materials with different particle sizes, you can adjust the vibration and airflow. You should check the moisture content before drying, since too much moisture can cause problems like bed stall. Breaking up large lumps before drying helps you get better results.

Material Type | Example Products | Промышленность |

|---|---|---|

Powders/Granules | Фармацевтика, зерна | Pharma, Еда |

Fibers | Cellulose, plant fibers | Химикаты, Еда |

Small Particles | Катализаторы, полимеры | Химикаты |

Обслуживание

You will find maintenance easier with a vibrating fluidized bed dryer, especially if you use a circular design. These dryers often have features like internal vibration cancellation, clean-in-place nozzles, and removable hoods. You can clean and set up the dryer quickly, which reduces downtime. You do not need to worry about belt tension or cleaning under belts, as you would with belt dryers. The risk of dust explosions is lower, and you avoid problems like uneven drying or burning. If you use a rectangular unit, you may need more time for cleaning, but overall, maintenance is simpler than with many other drying systems.

Примечание: Regular cleaning and inspection help you keep your dryer running smoothly and safely.

Приложения

Пищевая промышленность

You often see these dryers in food processing plants. They help you dry products like соль, молочный порошок, панировочные сухари, potato granules, powdered sauces, instant foods, soybeans, rice, специи, nuts, and cheese. The table below shows some common food products and the benefits you get from using this drying method:

Food Products Dried | Преимущества |

|---|---|

Salt, Milk Powder, Bread Crumbs, Potato Granules, Powdered Sauces, Instant Foods, Soybeans, Rice, Специи, Nuts, Cheese | – Consistent drying |

Multi-zone dryers let you control temperature and airflow in each zone. Вы можете сушить, roast, sterilize, and cool in one system. This setup protects fragile foods and keeps quality high.

Chemicals and Pharmaceuticals

You use these dryers to handle chemicals and pharmaceutical products with high moisture or poor flow. Vibration keeps materials from sticking together and helps you dry sticky or hard-to-move powders. The table below explains how these dryers work in these industries:

Аспект | Описание |

|---|---|

Use Case | |

Vibration Mechanism | Uses controlled vibration for gentle movement |

Heating Methods | Direct or indirect heating, heat recovery, high-temp heat pumps |

Process Control | Vibration controls drying time and mixing |

Преимущества | Even drying, экономия энергии, improved product handling |

You can monitor moisture with advanced sensors. This helps you keep every batch safe and consistent. You also save energy because the system uses less air and lower pressure.

Other Uses

You find these dryers in many other industries. They help you dry minerals, удобрения, пластмассы, моющие средства, and even pet food. You can use them for cooling, roasting, or sterilizing as well. The gentle movement and even airflow protect delicate materials and prevent dust problems.

You can dry a wide range of particle sizes.

You can combine several steps, like drying and cooling, in one machine.

You get reliable results for both bulk and specialty products.

Кончик: If you need to dry sensitive or fragile materials, this technology gives you control and efficiency.

You achieve efficient drying by following clear steps: feed your material, use hot air to fluidize particles, apply vibration for even movement, and collect the dried product. Vibration and airflow work together to give you uniform results and protect product quality.

Key benefits include:

Easy cleaning and maintenance

Precise control for consistent drying

Versatility for many materials

As demand grows in food, химический, and pharmaceutical industries, you can trust this method for reliable, high-quality drying.

Часто задаваемые вопросы

What materials can you dry in a vibrating fluidized bed dryer?

Можно сушить порошки, гранулы, кристаллы, and small particles. Common products include salt, сахар, зерна, химикаты, and pharmaceuticals. This dryer works well for materials that flow easily and do not stick together.

How does vibration improve the drying process?

Vibration keeps particles moving. You get better mixing and avoid clumping. The hot air reaches every surface, so drying happens faster and more evenly. You also reduce the risk of dead zones.

Can you adjust the drying temperature and airflow?

Да, you can control both temperature and airflow. This helps you match the drying process to your material. You protect sensitive products and save energy by using only what you need.

Is cleaning and maintenance easy?

You will find cleaning and maintenance simple. Many dryers have removable parts and clean-in-place systems. Regular checks keep your dryer running safely and efficiently.

What safety features do these dryers have?

Most dryers include dust collectors, filters, and explosion vents. You protect your workplace from dust and overheating. Sensors help you monitor temperature and airflow for safe operation.