Secador de Fludização Série XF direto da fábrica para secagem de grânulos separados

O secador fluidizante também é chamado de leito fluidizado. Consiste em filtro de ar , aquecedor ,Máquina principal de leito fluidizado, alimentador , Separador de ciclone , Duster de bolsa de pano ,Fan de centrífuga de alta pressão e tabela de operação. Porque as propriedades das matérias -primas existem diferença, Ao equipar o equipamento de remoção de poeira, deve considerar a necessidade prática. Ele pode selecionar o separador de ciclones e o espanador de bolsa de pano ao mesmo tempo ou um deles

Descrição

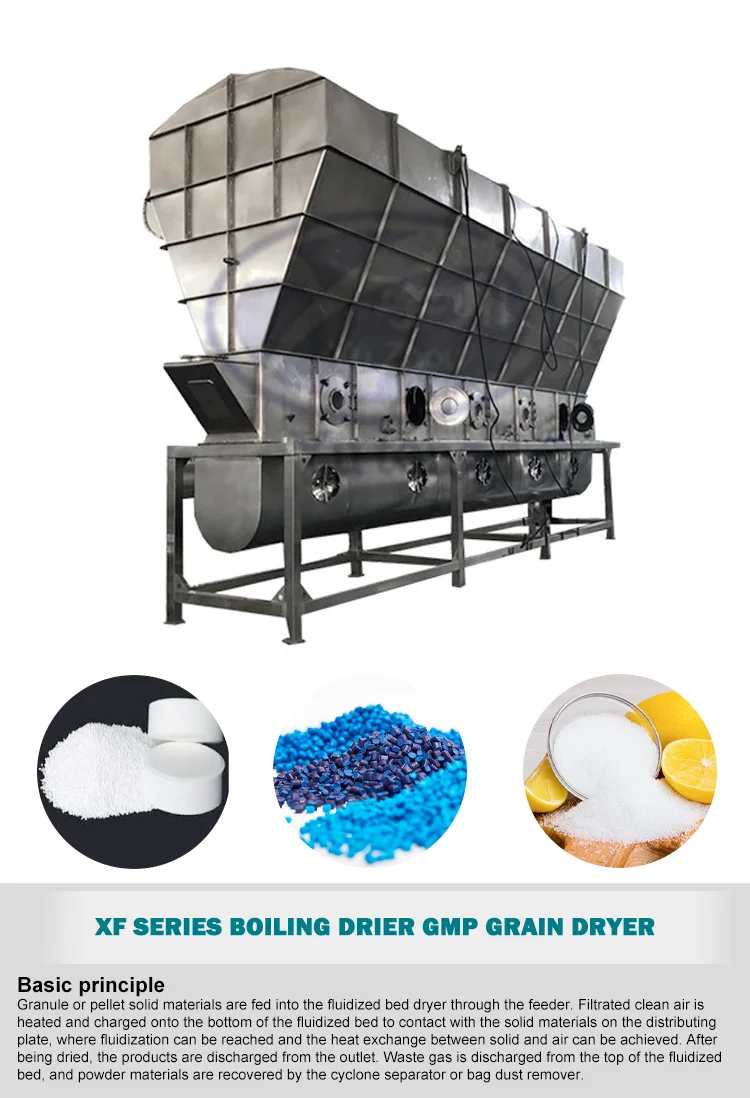

XF Series Fludizing Dryer for drying separated granule

XF Series Fludizing Dryer DESCRIPTION

The Boiling dryer is also call as fluidize-bed. Consiste em filtro de ar, aquecedor, Máquina principal de leito fluidizado, alimentador, Separador de ciclone, Duster de bolsa de pano, Fã de centrífuga de alta pressão, e tabela de operação. O coletor de poeira deve ser equipado de acordo com as propriedades das matérias -primas. Você pode usar separador de ciclone ou espanador de bolsa de pano de acordo com as características dos materiais, O separador de ciclone é usado principalmente para materiais de gravidade específicos e o espanador de saco de pano é usado principalmente para pó e materiais de grânulos pequenos. O dispositivo de alimentação de ar e o transportador de correia são opcionais. A fonte de calor pode usar vapor, eletricidade, Forno de ar quente conforme os requisitos do cliente.

XF Series Fludizing Dryer APPLICATION

This dryer is widely used for medicines, chemical raw materials, alimento, grain processing, alimentar, e etc.. Example applicable materials such as raw medicine, comprimido, Chinese medicine, health care products, drinks, alimentar, resina, citric acid and other powders. The suitable drying diameter of raw material is 0.1~6mm. The best drying diameter of raw material will be 0.5~3mm.

XF Series Fludizing Dryer WORKING PRINCIPLE

The granular solid material is fed to fluidized bed dryer by the feeder. The blower will blows the filtered clean hot air heated into the fluidized bed at the bottom of the distribution plate and fluidization to gas-solid heat and mass exchange to heat the solid material. The dried material is discharged from the discharge outlet. The exhaust gas is discharged from the top of the fluidized bed and the solid power will be collected by the cyclone separator or cloth bag duster.

XF Series Fludizing Dryer Installation Instructions

1.All equipment should be placed flat, fixed with foot screws, the components of a good seal.

2.Fan can be placed in the outdoor or indoor self silencer. Layout can be adjusted as appropriate depending on the circumstances.

XF Series Fludizing Dryer TECHNICAL PARAMETERS

| Model and specifications Technical Parameters |

XF0.25-1 (Original XF10) |

XF0.25-2 (Original XF20) |

XF0.25-3 (Original XF30) |

XF0.25-6 | XF0.3-2 | XF0.3-4 | XF0.3-6 | XF0.3-8 | XF0.3-10 | XF0.4-4 | XF0.4-6 |

| Area of bed layer (eu2) | 0.25 | 0.5 | 1.0 | 1.5 | 0.6 | 1.2 | 1.8 | 2.4 | 3.0 | 1.6 | 2.4 |

| Capacidade de secagem (kg h2O/h) | 10-15 | 20-25 | 30-45 | 52-75 | -30 | 42-60 | 63-90 | 84-120 | 105-150 | 56-80 | 84 |

| Power of fan (kw) | 5.5 | 7.5 | 15 | 22 | 7.5 | 18.5 | 30 | 37 | 48 | 30 | 37 |

| Temperature of air in (óC) | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 |

| Temperature of air in (óC) | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 |

| Overall dimensions(main machine) L × W × H. (eu) | 1×0.6 ×3.35 |

2×0.6 ×3.35 |

4×0.6 ×3.35 |

6×0.6 ×3.35 |

2×0.70 ×3.4 |

4×0.7 ×3.4 |

6×0.7 ×3.4 |

8×0.7 ×3.4 |

10×0.7 ×3.4 |

4×1 ×3.58 |

6×1 ×3.58 |

| Occupied area (eu2) | 18 | 25 | 35 | 40 | 25 | 38 | 45 | 56 | 70 | 18 | 56 |

| Model and specifications Technical Parameters |

XF0.4-8 | XF0.4-10 | XF0.4-12 | XF0.5-4 (Original XF50) |

XF0.5-6 | XF0.5-8 | XF0,5-10 | XF0.5-12 | XF0.5-14 | XF0.5-16 | XF0.5-18 |

| Area of bed layer (eu2) | 3.2 | 4.0 | 4.8 | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | 7.0 | 8.0 | 9.0 |

| Capacidade de secagem (kg h2O/h) | 112-160 | 140-200 | 168-240 | 70-100 | 140-200 | 140-200 | 175-250 | 210-300 | 245-350 | 280-400 | 315-450 |

| Power of fan (kw) | 44 | 66 | 66 | 30 | 66 | 66 | 90 | 90 | 150 | 150 | 165 |

| Temperature of air in (óC) | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 |

| Temperature of air in (óC) | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 |

| Overall dimensions(main machine) L × W × H.(eu) | 8×1 ×3.58 |

10×1 ×3.58 |

12×1.2 ×4.1 |

4×1.2 ×4.1 |

8×1.2 ×4.1 |

8×1.2 ×4.1 |

10×1.2 ×4.1 |

12×1.2 ×4.1 |

14×1.2 ×4.1 |

16×1.2 ×4.1 |

18×1.2 ×4.1 |

| Occupied area (eu2) | 74 | 82 | 96 | 50 | 70 | 82 | 100 | 140 | 180 | 225 | 268 |

Observação:

1.A forma de alimentação tem: a.star feeding b.combining star feeding air conveyor c.belt conveying d.decided by customer;

2.Automatic production can be realized.3.Besides the model above mentioned,the special model can also be designed and manufactured as request.4.According different raw material,the power of fan will be differ.

Avaliações

Ainda não existem avaliações.