Venda quente Série YPG Secador de granulação por spray de pressão para catalisadores orgânicos

-

Secador de granulação por spray de pressão para catalisadores orgânicos é um tipo de dispositivo que pode terminar a secagem e granulação ao mesmo tempo. De acordo com os requisitos do processo, você pode ajustar a pressão, taxa de fluxo da bomba de líquido do material e o tamanho do orifício de pulverização para obter as partículas esféricas necessárias em uma determinada proporção de tamanho.

Descrição

Hot Sale YPG Series Spray Spray Granulation Secador para catalisadores orgânicos

Secador de granulação por spray de pressão para catalisadores orgânicos Descrição

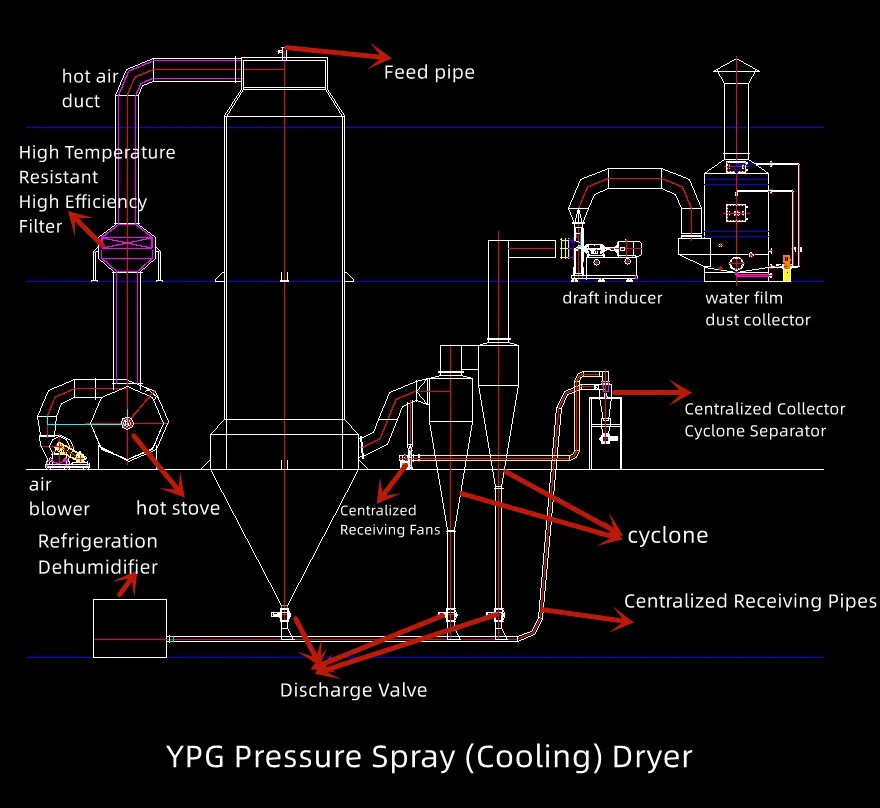

O spray tipo pressão da série YPG (Congelar) O secador possui um dispositivo que pode funcionar secando e granulando juntos. A pressão de pulverização, o fluxo de pulverização e o tamanho do bico de pulverização da bomba de material líquido podem ser ajustados de acordo com os requisitos e o tamanho específico das bolas granuladas pode ser alcançado.Secador de granulação por spray de pressão para catalisadores orgânicos Princípio de trabalho

A matéria -prima líquida ou de pasta é pulverizada em uma pequena queda de líquido por pulverizador pressionado, desenho de assistência da pressão da bomba diaframa, e secar rapidamente através da troca de calor amplamente (10-90Sec.).A maioria dos grânulos de pó é coletada a partir da saída da descarga no fundo do secador.O ar desperdiçado e o pó fino são separados pelo ciclone, O ar desperdiçado é exaustão do ventilador de draft, e o pó fino é coletado na parte inferior do ciclone. Há um espanador de segunda série equipado na saída; portanto, A taxa de recuperação do grânulo de pó acabado pode ser 96% para 98%.

Secador de granulação por spray de pressão para catalisadores orgânicos aplicação

Indústria química: Fluoreto de sódio (Potássio ), Corante alcalino e pigmento,Intermediário de corante, Mn3o4, Fertilizante Composto, Ácido silícico fórmico, Catalisador, Agente de ácido sulfúrico, Aminoácido,Carbono branco, e etc..

Indústria alimentícia: Leite em pó gordo, Proteína, Leite de cacau em pó, Substituto de leite em pó,Ovo branco (Gema), Comida e planta,Aveia,Suco de frango, Café, Chá dissolúvel instantâneo ,Carne de tempero,Proteína ,Soja,Proteína de amendoim, Hidrolisando, Açúcar,Xarope de milho,Amido de milho,Glicose, Pectina,Açúcar de malte, Potássio do ácido sorbico, e etc..

Indústria farmacêutica: Medicamentos tradicionais chineses, Pesticida, Antibiótico, Agente de bebida médica,e etc..

Plásticos e resina: AB, Emulsão ABS, Resina do ácido úrico, Resina fenólica de aldeído, Resina de uréia-formaldeído, Resina de formaldeído, Polieteno, Poli-cloropreno, E etc..

Detergente: Pó comum em pó,Avançado em pó,Sabão em pó, Refrigerante, Emulsificante, Agente de iluminação, Ácido ortofosfórico, e etc..

Cerâmica: Óxido de alumínio, Material de ladrilhos de cerâmica, Magnésioxido, Talco, e etc.. Outro: Calmogastrin, Cloreto de hime , Agente de ácido esteárico, e etc..

Secador de granulação por spray de pressão para catalisadores orgânicos

1. Velocidade de secagem rápida. 95% – 98% de água pode ser evaporado instantaneamente no fluxo de ar quente. O tempo de secagem só precisa levar vários segundos. Este secador é especialmente adequado para aquecer o material da sen.

2. O produto acabado é o tamanho uniforme da bola Granulewith. Sua fluidez e solubilidade são boas. A qualidade e pureza do produto são muito altas.

3. Dependem das características da matéria -prima, O secador pode usar ar quente para secar ou usar ar frio para granular.

4. Operação simples e estável. O sistema de controle é conveniente, fácil de realizar operação automática.

Parâmetro técnico

| Item \ Modelo | Unidade | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| Evapo de água- capacidade de ração |

kg | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| dimensão geral (Φ × h) |

milímetros | 1600× 8900 |

2000× 11500 |

2400× 13500 | 2800× 14800 |

3200× 15400 |

3800× 1880 |

4600× 22500 |

| de alta pressão pressão da bomba |

MPA | 2~ 10 | ||||||

| poder | KW | 8.5 | 14 | 22 | 24 | 30 | 82 | 30 |

| ar de entrada temperatura |

óC | 140~ 350 | ||||||

| água do produto conteúdo |

% | < 5(Até 0,5) | ||||||

| taxa de cobrança | % | > 97 | ||||||

| aquecedor elétrico | KW | 75 | 120 | 150 | A temperatura é menor que 200, o Os parâmetros devem ser calculados |

|||

| eletricidade +vapor |

MPA + KW | 0.5+54 | 0.6+90 | 0.6+108 | De acordo com a condição prática | |||

| forno de ar quente | Kcal/h | 100000 | 150000 | 200000 | 300000 | 400000 | 500000 | 1200000 |

* O acima é a maior evaporação.

Avaliações

Ainda não existem avaliações.