Bocal vs Atomizador Rotativo Qual opção de secador por spray é a melhor

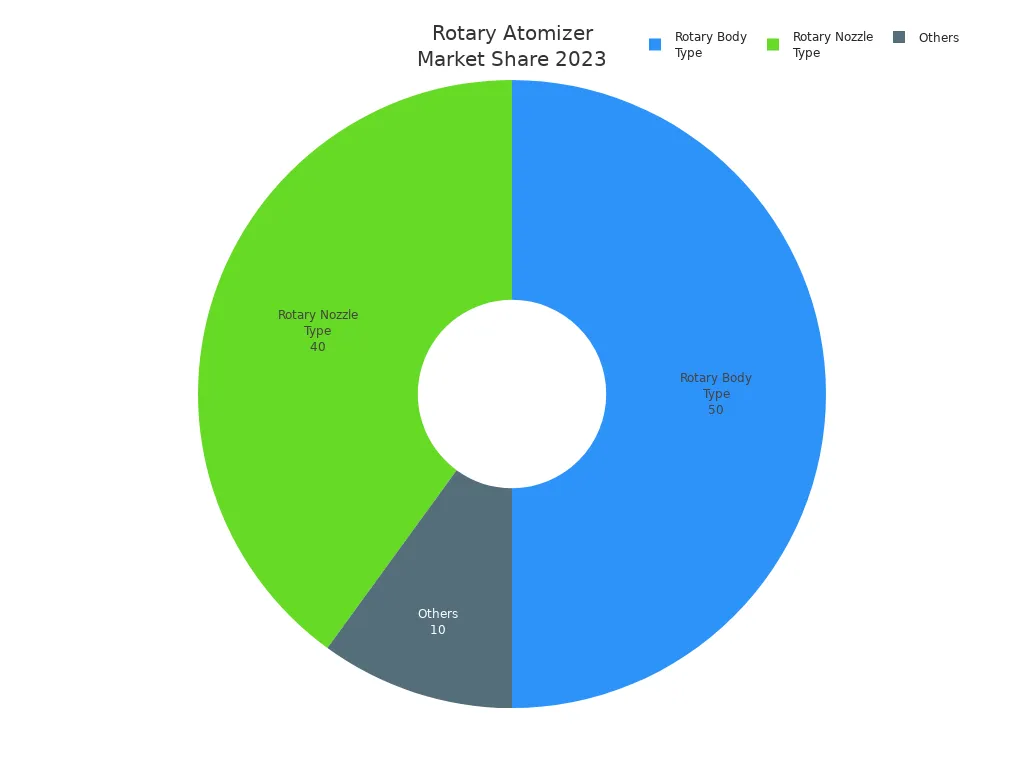

Choosing the best spray dryr atomiser depends on specific application needs. Nozzle atomisers dominate the global market, holding nearly 41.2% share due to their ability to produce free-flowing, coarser powders and flexible flow rates. Rotary atomisers, while currently smaller in market share, are growing rapidly because they handle high capacity and a broad range of products. Key decision factors include product type, required particle size, feed characteristics, maintenance requirements, and budget.

Each manufacturer should assess priorities and challenges before selecting an atomiser.

Takeaways -chave

Nozzle atomisers use high pressure to create fine droplets and work well with thick or sticky feeds, offering easy maintenance and energy savings.

Rotary atomisers spin liquid at high speeds to produce uniform droplets, ideal for large-scale production with lower viscosity feeds but require more energy and upkeep.

Choosing the right atomiser depends on feed type, tamanho de partícula desejado, production scale, and budget to ensure efficient drying and quality powder.

Both atomiser types allow control over droplet size, which affects powder flow, consistency, e qualidade do produto, so adjusting settings is key.

Following a clear selection checklist helps manufacturers match atomiser features to product needs, reducing trial-and-error and improving results.

Principais diferenças

Atomization Mechanism

Rotary atomisers and nozzle atomisers use different methods to create droplets in a spray dryer atomiser system.

Rotary atomisers use centrifugal force. A high-speed rotating disk, cup, or wheel spins the liquid feed. The liquid moves outward and forms droplets as it leaves the edge. This method produces droplets between 10 e 500 micrômetros.

Nozzle atomisers force the feed through a small opening under high pressure. The liquid breaks into droplets as it exits the orifice. Droplet sizes usually range from 10 para 400 micrômetros. Some nozzle atomisers use air to help break up the liquid.

Rotary atomisers rely on mechanical rotation, while nozzle atomisers depend on liquid pressure and orifice design. Each method affects droplet formation and the final powder properties.

Controle de tamanho de gota

Controlling droplet size is important for powder quality in spray drying. O size and distribution of droplets affect how the powder flows, packs, and dissolves.

Rotary atomisers adjust droplet size by changing the wheel speed, groove size, and feed rate. Higher speeds and taller vanes make smaller droplets. Thicker or stickier feeds create larger droplets.

Nozzle atomisers control droplet size with feed pressure, orifice diameter, and spray angle. Higher pressure and wider angles make smaller droplets. Larger orifices and thicker feeds produce bigger droplets.

A table below summarizes the main control factors:

Atomiser Type | Main Control Factors | Typical Droplet Size (μm) |

|---|---|---|

Rotary | Wheel speed, vane height, feed rate | 10–500 |

Nozzle | Pressure, orifice size, spray angle | 10–400 |

Droplet size control helps tailor the powder’s density, fluxo, and appearance. Both atomisers allow some adjustment, but nozzle atomisers often provide finer control for denser, free-flowing powders.

Feed Handling

The type of feed material influences which spray dryer atomiser works best.

Rotary atomisers handle a wide range of feed types, including those with higher solids or viscosity. They work well for large-scale production and can process feeds that might clog a nozzle.

Nozzle atomisers suit finer powders and high-viscosity feeds like fruit purees or slurries. They often appear in smaller or specialized batch operations.

Rotary atomisers excel with high-throughput and varied feeds, while nozzle atomisers shine with thick or sticky materials.

Maintenance Needs

Maintenance requirements differ between the two atomiser types.

Rotary atomisers have moving parts that need regular inspection and cleaning. Changes in feed or speed can cause deposits inside the drying chamber. Operators must monitor and adjust settings to prevent buildup.

Nozzle atomisers can clog, especially with thick or particulate-rich feeds. Cleaning or replacing nozzles is common. No entanto, they have fewer moving parts, which can reduce mechanical wear.

Operators should consider the ease of cleaning, downtime, and spare part costs when choosing an atomiser.

Energy and Cost

Energy use and operational costs play a big role in selecting a spray dryer atomiser.

Rotary atomisers require motors to spin the disk at high speeds. They use more energy but support higher production rates. Larger drying chambers may be needed for the bigger droplets they produce.

Nozzle atomisers use high-pressure pumps to force liquid through the orifice. They often use less energy and can be more cost-effective for smaller batches or when precise droplet control is needed.

Rotary atomisers suit high-capacity, continuous operations, while nozzle atomisers offer energy savings and lower costs for smaller or specialized runs.

Nozzle Atomiser Pros and Cons

Vantagens

Nozzle atomisers offer several operational and maintenance benefits in spray drying. Many manufacturers choose them for their efficiency and flexibility. Key advantages include:

Increased evaporative capacity, which allows more water to evaporate per hour.

Greater control over the atomisation process, leading to improved powder consistency.

Ability to dry slurries with solid content above 50%, which exceeds the limits of rotary atomisers.

Capability to handle a wide range of product types within the same spray dryer atomiser.

Introduction of new powder density parameters, moving beyond traditional disc adjustments.

No need for electric motors, hydraulic units, or complex mechanical parts such as bearings and belts.

Reduced formation of agglomerated residue on dryer walls due to non-vortex airflow.

Simple and cost-effective maintenance, as operators only need to replace internal nozzle components.

Enhanced drying capacity for hygroscopic products like sugar and fats.

Nozzle atomisers help companies achieve higher efficiency and lower maintenance complexity.

Desvantagens

Despite their strengths, nozzle atomisers present some challenges in daily operations:

Frequent clogging or damage, especially when processing thick or particulate-rich feeds.

Regular maintenance and cleaning required, which can lead to operational downtime.

Additional costs associated with maintenance and replacement parts.

Operators must plan for these issues to maintain consistent production.

Best Applications

Nozzle atomisers serve a broad range of industries and product types. Common applications include:

Food and beverage sectors, such as bakeries, lacticínios, and meat processing.

Sugar mills and cereal or snack production.

Chemical processing, including powders and specialty chemicals.

Mineração, building materials, and energy industries.

Pulp, paper, and tissue manufacturing.

Pharmaceutical manufacturing, steel, and metals.

Many industries rely on nozzle atomisers for their ability to handle diverse products and deliver reliable results.

Rotary Atomiser Pros and Cons

Vantagens

Rotary atomisers deliver several important benefits in spray drying operations. They create uniform droplets by spinning liquid at high speeds. This process results in powders with consistent particle size and shape. Operators can adjust the wheel speed to control droplet size, which helps meet strict product requirements. Rotary atomisers handle a wide range of feed rates and can process large volumes quickly. They work well with non-viscous fluids and allow for continuous production. Many manufacturers choose rotary atomisers for their flexibility and ability to produce high-quality powders at scale.

Rotary atomisers support efficient, large-scale spray drying where uniformity and throughput matter most.

Desvantagens

Rotary atomisers also present several challenges that operators must consider:

The high-speed rotating disc (7000-28000 rpm) requires a large equipment investment and leads to high energy consumption.

The equipment design is complex and occupies a large area in the facility.

Atomiser and powder recovery devices come with high costs.

High air consumption increases the power needs of blowers and recovery systems.

The system shows low thermal efficiency and uses more heat than other options.

Operators must weigh these factors when selecting a spray dryer atomiser for their process.

Best Applications

Rotary atomisers find their best use in industries that need uniform and fine particle size from non-viscous fluids. Typical applications include:

Food and dairy production, such as maltodextrin and food encapsulation.

Pharmaceutical and nutraceutical manufacturing, including antibiotics, penicillin, enzimas, and whey proteins.

Chemical processing, where moisture reduction and product quality are critical.

The growing demand in pharmaceutical, comida, and chemical sectors continues to drive the use of rotary atomisers in modern spray drying equipment.

Product Quality Impact

Distribuição de Tamanho de Partícula

The choice between nozzle and rotary atomisers shapes the tamanho de partícula, morfologia, and density of spray-dried powders. Rotary atomisers usually create larger particles, while nozzle atomisers—especially two-fluid types—produce finer particles. Operators can adjust atomisation conditions to influence droplet size and drying kinetics, which directly affect the final powder. Por exemplo, two-fluid nozzles often yield particles smaller than 10 μm, while pressure nozzles generate particles from 10 para 100 μm. Rotary atomisers typically produce a broader range of particle sizes.

Particle Size Metric | |

|---|---|

D10 (10% smaller) | 5 para 50 |

D50 (Median) | 20 para 150 |

D90 (90% smaller) | 50 para 250 |

Nozzle geometry and process settings play a major role in determining these ranges. Matching droplet size does not always guarantee matching particle size, so operators must consider the complex interactions during drying.

Powder Flow and Consistency

Spray drying aims to produce powders with uniform particle size, high flowability, and reliable dispersibility. The atomisation step, whether by nozzle or rotary atomiser, transforms the liquid feed into fine droplets. This step sets the stage for consistent drying and final product quality. Nozzle and rotary atomisers both influence bulk density and porosity, which impact powder flow and handling. Advances in atomiser technology now allow for better control over droplet size and distribution, leading to improved product consistency and process efficiency.

Consistent powder flow and uniformity help manufacturers achieve reliable downstream processing and packaging.

Sensitive Ingredients

Many industries process sensitive ingredients, such as vitamins, enzimas, or probiotics. The atomiser choice affects how well these ingredients survive the drying process. Nozzle atomisers, with their precise droplet control, often suit products that require gentle handling. Rotary atomisers, which operate at high speeds, may expose ingredients to more heat and shear. Operators must match the atomiser type to the sensitivity of the product to protect quality and functionality.

Selecting the right atomiser ensures that sensitive ingredients retain their activity and value in the final powder.

Choosing a Spray Dryer Atomiser

Decision Checklist

Selecting the right spray dryer atomiser involves a series of clear steps. Each step helps manufacturers align equipment choice with product and process requirements. Here is a practical checklist to guide the decision:

Define the target droplet size based on the desired particle size and solids content of the final powder.

Evaluate atomiser geometry, feed properties (como viscosidade e tensão superficial), and atomisation parameters like nozzle pressure.

Choose pressure nozzles for robust, scalable operation, especially with viscous or film-forming solutions.

Consult scientific correlations that link droplet size, feed properties, and nozzle geometry to narrow down initial options.

Test droplet size using model solutions that match the actual feed’s viscosity and surface tension.

Characterize selected nozzles by measuring pressure drop and particle size at different flow rates to finalize the nozzle and operating pressure.

Integrate these steps into a process-development plan that includes formulation screening, process constraints, thermodynamic design, and drying kinetics.

Following this checklist ensures a systematic approach to atomiser selection, reducing trial-and-error and supporting consistent product quality.

Matching to Product Needs

Matching the atomiser type to product characteristics is essential for optimal spray drying results. Operators should consider several key factors:

Feed viscosity: Lower viscosity feeds atomize more easily and produce finer particles.

Feed solids content: Higher solids help maintain droplet size and reduce solvent exposure.

Atomiser speed and pressure: These settings influence droplet and final particle size.

Nozzle geometry and size: These shape the droplets and affect powder properties.

Taxa de alimentação: Higher rates increase droplet and particle size.

Drying conditions: Inlet and outlet temperatures, as well as humidity, impact drying rate and powder quality.

Pressure nozzles: Best for viscous feeds (50-100 mPas) at pressures between 20-200 bar, offering robust and scalable performance.

O table below summarizes how product characteristics align with each atomiser type:

Product Characteristic / Parâmetro | Atomizador Rotativo | Atomizador de bico de pressão |

|---|---|---|

Tamanho da gota | Very fine, uniforme | Larger, less uniform |

Particle Size Control | Consistent, fine | Controlled, larger |

Suitable Feed Viscosity | Lower viscosity | Higher viscosity, film-forming |

Robustness and Scalability | Moderate | Alto, preferred for viscous feeds |

Application Benefit | Uniform powders for dissolution | Controlled size for specific needs |

Operators should match atomiser type and settings to the physical and chemical properties of their product for the best spray drying performance.

Maintenance and Budget

Maintenance and budget considerations play a major role in atomiser selection. Pressure nozzles offer a cost-effective solution with simple design and lower maintenance needs. They are easy to clean and have fewer moving parts, which reduces both operational costs and downtime. Initial costs for pressure nozzles typically range from $50 para $500.

Rotary disk atomisers, por outro lado, require a higher initial investment, geralmente entre $2,000 e $5,000. Their complex mechanical systems need regular lubrication, inspection, and cleaning. Operators must check mounts and connections monthly, clean external surfaces quarterly, and inspect internal passages annually. Replacing worn components is necessary as recommended by the manufacturer. These factors lead to higher ongoing maintenance costs and more frequent service interruptions.

Manufacturers should weigh the initial purchase price and ongoing maintenance demands against their production goals and budget. Choosing the right spray dryer atomiser helps balance performance, reliability, and cost-efficiency.

Industry Examples

Food and Dairy

Food and dairy manufacturers rely on spray drying to create powders with stable shelf life and easy handling. Nozzle atomisers often appear in milk powder production, where they help achieve consistent particle size and moisture content. These atomisers can handle viscous feeds like concentrated milk or fruit purees. Rotary atomisers also play a role, especially in large-scale operations that require high throughput. Operators select the atomiser based on the product’s viscosity, desired powder texture, e escala de produção. Por exemplo, café instantâneo, whey protein, and baby formula producers often choose the atomiser that best matches their quality standards and process needs.

Food and dairy companies value atomisers that deliver uniform powders and support efficient, hygienic cleaning.

Produtos farmacêuticos

Pharmaceutical companies must protect sensitive ingredients during spray drying. The atomiser choice directly affects product quality and safety. Companies consider several factors when selecting between nozzle and rotary atomisers:

Manufacturing scale and target particle size guide the decision.

Rotary disk atomisers and pressurised nozzles suit large-scale production with bigger particles.

Two-fluid or ultrasonic nozzles work best for small batches or finer particles.

Atomisation conditions and nozzle design control droplet size distribution.

Droplet size management helps maintain product quality and reduces thermal stress on sensitive drugs.

The atomiser type shapes initial droplet size, which influences final particle characteristics and heat exposure.

Pharmaceutical manufacturers use these guidelines to ensure that spray-dried drugs remain effective and safe for patients.

Produtos Químicos

Chemical producers often process complex, viscous, or multicomponent liquids. Rotary atomisers excel in these environments. Researchers have studied the internal flow and atomisation mechanisms of rotary atomisers in chemical spray drying. They use advanced tools like phase Doppler measurements to analyze droplet size and velocity. These studies help operators predict and control drop size distribution, which is vital for product quality. Semi-empirical models based on jet thickness and atomisation mechanisms guide process optimization. This research highlights the importance of rotary atomisers for handling challenging chemical feeds and achieving consistent powder properties.

Chemical plants benefit from rotary atomisers’ ability to process tough feeds and deliver reliable results.

Choosing the right spray dryer atomiser depends on process needs and product characteristics.

Evaluate fluid properties, spray pattern, drop size, and mechanical complexity.

Rotary atomisers offer adjustable drop size but require higher investment.

Nozzle types provide flexibility for different viscosities and operational reliability.

Manufacturers should use the checklist to match atomiser type with product goals. Consulting a spray drying expert or arranging a trial can help optimize results. Aligning atomiser choice with process control, cleaning needs, e qualidade do produto ensures efficient, scalable production.

Perguntas frequentes

What is the main difference between nozzle and rotary atomisers?

Nozzle atomisers use high pressure to force liquid through a small opening. Rotary atomisers spin liquid at high speed to create droplets. Each method affects droplet size and powder quality.

Which atomiser is easier to maintain?

Nozzle atomisers have fewer moving parts. Operators can clean or replace nozzles quickly. Rotary atomisers need more regular inspection and cleaning because of their complex design.

Can both atomisers handle thick or sticky feeds?

Rotary atomisers process a wide range of feed types, including some thick liquids. Nozzle atomisers work best with high-viscosity or sticky feeds, such as fruit purees or slurries.

How does atomiser choice affect energy use?

Nozzle atomisers use less energy because they rely on pressure, not motors. Rotary atomisers need more power to spin the disk at high speeds, which increases energy costs.

Which industries use spray dryer atomisers most?

Comida, laticínio, farmacêutico, and chemical industries use spray dryer atomisers. Each sector selects the atomiser type based on product needs, feed properties, e escala de produção.