Qual é o princípio de um secador de leito fluidizado

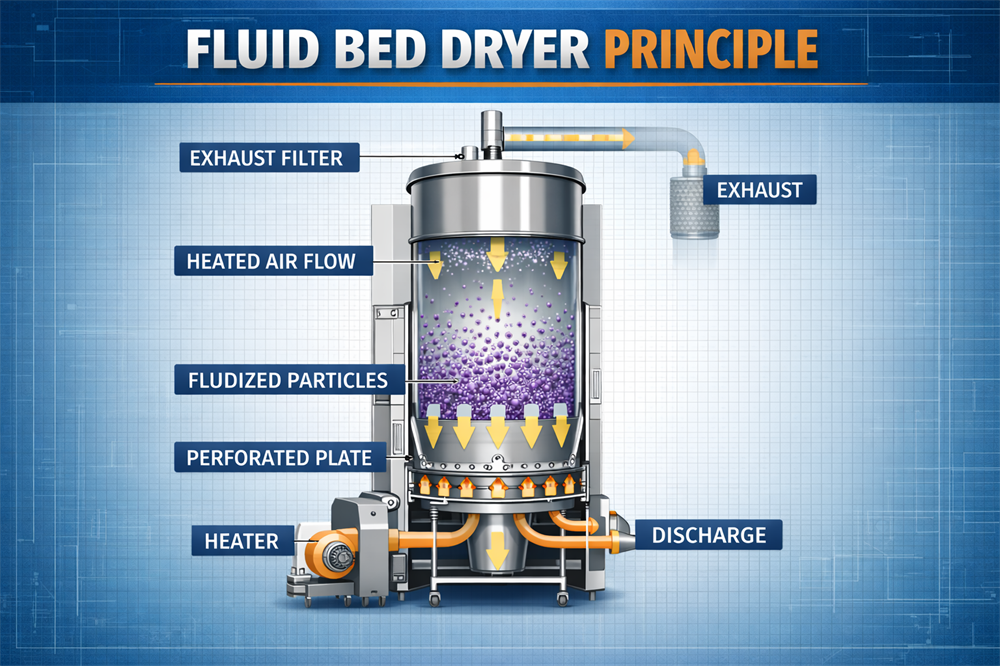

You can observe the fluid bed dryer principle in action as solid pieces are lifted and moved around in hot air. This process allows each piece to float, ensuring that heat and air can reach all sides for rapid and uniform drying. The principles of fluidization, transferência de calor, and moisture removal work together to maintain product quality and preserve nutrients. Companies utilizing fluid bed dryers often achieve drying times that are cut in half while eliminating uneven drying. This makes them an excellent choice for achieving optimal drying results.

The system distributes heat and air uniformly, preventing any items from becoming too dry or insufficiently dried.

Takeaways -chave

Secadores de leito fluidizado blow hot air to move and mix particles. This helps dry them evenly and stops them from sticking together. – It is important to control the heat and air speed. This makes drying work well and keeps the product good. – These dryers use less energy and dry things faster. They are great for many industries, como comida e remédios. – A good perforated plate spreads air better. This helps dry things well and stops blockages. – Fluid bed dryers can be used for many materials. They give steady results in different uses.

Fluid Bed Dryer Principle

Fluidization Process

You can watch how a fluid bed dryer works when solid particles move like a liquid. Hot air lifts the particles and keeps them floating. This is called fluidization. When gas or liquid goes through the particles, they act like a fluid. This movement helps things dry faster and better.

Fluidization means solid particles float in a fluid-like way.

Gas or liquid moves through the particles and mixes them.

The upward gas stream makes the particles move, which helps heat and mass spread.

You get better drying because every particle touches the hot air. This helps remove moisture quickly. The fluidized bed dryer uses this mixing to dry things evenly.

Role of Hot Air and Perforated Plate

Hot air is very important in a fluid bed dryer. You need the right speed for the air to lift and mix the particles. When hot air goes up fast enough, it makes a fluidized bed. The air pushes up harder than gravity, so the particles float and move.

The perforated plate is at the bottom of the dryer. Isto spreads air evenly under the particles.

The perforated plate spreads air evenly for good fluidization.

Its design stops clogging and saves energy.

The special holes help heat and mass move, so every particle gets the same treatment.

Dica: A good perforated plate helps you dry things well and evenly.

Uniform Particle Movement

You get even movement of particles with a fluid bed dryer. The dryer keeps particles floating in hot air. Each particle moves and mixes with others. This stops problems like overdrying or uneven moisture.

Fluidized bed dryers dry things more evenly than other dryers. The moving particles do not stick together. You get fast and mesmo secando, which keeps products good. The fluidized bed makes sure every particle gets the same heat and air.

Observação: Even movement in a fluid bed dryer helps you keep product quality and stops clumping.

Heat Transfer in Fluidized Bed Dryer

How Heat Is Supplied

Heated air is used in a fluidized bed dryer. The air comes from the bottom and goes up. It passes through a screen or perforated plate. O hot air covers each wet particle. This helps the particles dry fast. You can heat the air with electricity, natural gas, óleo, or steam. The energy source depends on your facility and product.

Heat moves when hot air touches the solid particles. Good contact between air and solids gives high transferência de calor. Heat also moves between the particles and the dryer walls. The heat exchanger design and bed features change how well heat moves.

Dica: Pick the best energy source and make sure air flows evenly for better efficiency.

Tamanho de partícula, forma, and density affect heat speed.

Air speed and dryer design also help with efficiency.

Temperature and Airflow Control

You must control temperature and airflow for good drying. Higher temperatures dry things faster. But do not overheat your product. More airflow removes moisture quickly. You need to balance it to keep quality.

Parâmetro | Descrição |

|---|---|

Temperatura | Higher temperatures dry faster, but do not go above the product’s limit. |

Fluxo de ar | More airflow dries better, but keep product quality in mind. |

Control humidity for best drying and good product quality. |

Gas speed and movement inside the dryer mix the particles. This helps heat move better. High temperatures make more drying air. This speeds up drying. If you control these things well, you save energy and lower costs.

Fator | Impact on Drying Quality and Speed |

|---|---|

Gas Speed | Good mixing and heat transfer for fast drying. |

Mechanical Movement | Better mixing, less dust, and more product. |

Temperature Range | High temperatures give more drying air. |

Eficiência Energética | Lower costs and better sustainability. |

Observação: Control temperature and airflow carefully to keep product quality and get the best efficiency.

Moisture Removal Mechanism

Evaporation and Airflow

Moisture leaves the particles when hot air moves through them. Primeiro, the dryer warms up the particles. Então, water starts to leave at a steady speed. Mais tarde, drying slows down as the particles get drier. During the steady stage, the air takes water from the wet particles. How fast things dry depends on how much water the air can hold, the air’s heat, and how humid it is. Hotter air can hold more water, but you must keep the heat safe for your product.

The size of the particle’s surface also changes how fast they dry. In a fluidized bed dryer, the particles move and mix all the time. This lets each piece touch the hot air. Because of this, things dry quickly and evenly. You can change the air and heat to get the right dryness without hurting your product.

Hot air goes up and lifts the particles.

The air grabs water and takes it away.

You get even drying and fast results.

Dica: Change the air and heat to fit your product and reach the right dryness fast.

Preventing Clumping

You do not want the particles to stick together. In a fluidized bed dryer, the particles keep moving all the time. The air pushes up and makes them float like a liquid. This stops them from sticking and making lumps. When the particles stay apart, water leaves evenly and drying is steady.

Beneficiar | How It Helps You |

|---|---|

No clumping | Keeps product quality high |

Even particle movement | Ensures uniform drying |

Fast drying time | Improves productivity |

You can trust the fluidized bed dryer to dry things smoothly. Its design stops lumps and helps you get the right dryness in every batch.

Observação: When particles keep moving, they do not stick together. This helps you get a better product at the end.

Working of Fluidized Bed Dryer in Industry

Applications for Powders and Granules

Fluidized bed dryers are very helpful for powders and granules. Many industries use them for different materials. Você pode dry drugs and vitamins for making tablets and capsules. Chemical companies use them for powders, pigmentos, and detergents. Food makers use them for mixes, sabores, and instant foods. They also work for crystals, mining stuff, and recycled powders.

These dryers mix and dry things evenly.

This is important for making granules.

You can use them in chemical, comida, laticínio, and other industries.

Benefits for Productivity and Quality

Fluidized bed dryers give you many good results. The air lifts the materials and helps heat move fast. This makes drying quick and saves energy. You can dry things that flow easily. Gentle drying keeps the product safe and gives steady results.

Here is a table that shows how fluid bed dryers work compared to other dryers:

Tipo de secador | Tempo de secagem | Eficiência Energética |

|---|---|---|

Fluid Bed Dryer | Uses less energy than hot air ovens | |

Fluid Bed Processor | 15 – 40 minutes | Saves more energy than tray dryers |

General Fluid Bed Drier | Short cycles | Good heat transfer, less energy used |

Fluid bed dryers work faster and use less energy. This helps you make more products and keep them high quality.

Operational Considerations

You need to check some things when using these dryers. Make sure the materials are the same size for even drying. Keep the dryer clean so air moves well. Watch the temperature and air speed. New control systems help you change settings quickly.

Sometimes you may have problems like uneven drying or high energy use. You can fix these by picking special designs and using recirculation. Closed systems also help. Jiangsu Changshi Technology makes advanced fluidized bed dryers. They have over 20 years of experience. You get custom machines, good quality, and help for drying in many industries. Their dryers help you work well and get good results every time.

Fluid bed dryers use fluidization, transferência de calor, and moisture removal. These help dry things fast and evenly. You can pick the best dryer for your needs. This also helps you make more products. The table below shows why fluid bed dryers are important:

Key Takeaway | Descrição |

|---|---|

Eficiência | Dries things quickly and saves energy |

Uniformidade | Makes drying even for better quality |

Versatilidade | Works for many materials and industries |

If you know these ideas, you can make your drying better and get good results every time.

Perguntas frequentes

What is a fluid bed dryer?

A fluid bed dryer dries powders and granules. The machine lifts the particles using hot air. This makes drying fast and even. Many industries use fluid bed dryers because they work well.

How does the fluidizing medium work in a fluid bed dryer?

Hot air moves up through a perforated plate. The particles float and mix together. This helps each particle dry the same way. The fluidizing medium keeps things moving and stops clumps.

Why should you choose a fluid bed dryer for your process?

Fluid bed dryers dry things quickly and keep quality high. The hot air helps stop uneven moisture. You save time and energy. Many companies use them for powders, grânulos, and crystals.

Can you use different fluidizing mediums in a fluid bed dryer?

You can use air, nitrogen, or other gases in a fluid bed dryer. The choice depends on your product and safety rules. Fluid bed dryers work with many mediums for different materials.

What makes a fluid bed dryer better than other dryers?

Fluid bed dryers dry things evenly because the air lifts and mixes particles. They work faster than tray or oven dryers. You see less clumping and better quality. Fluid bed dryers fit many industries and materials.