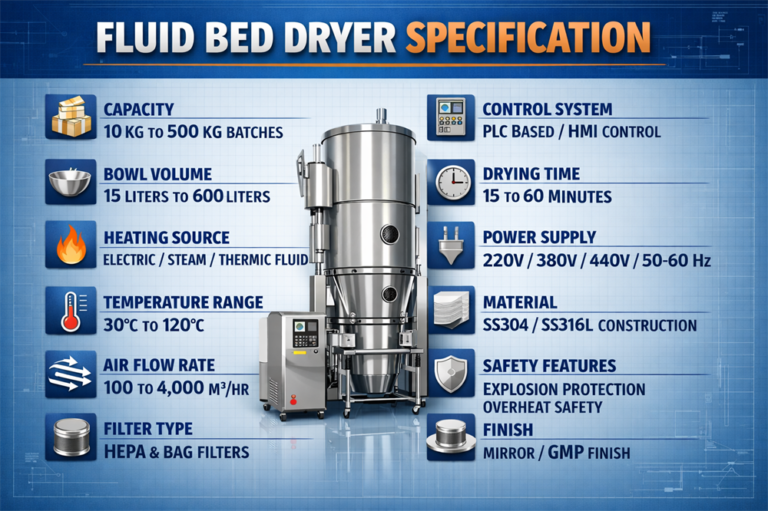

3 Principais especificações do secador de leito fluidizado que você precisa

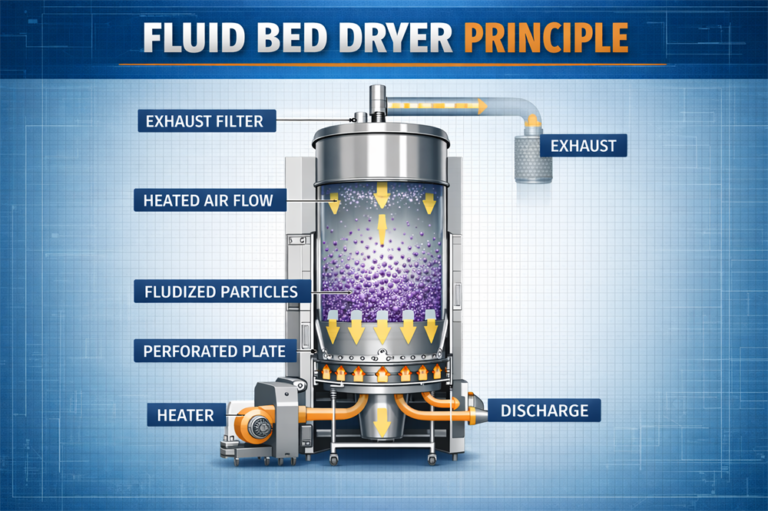

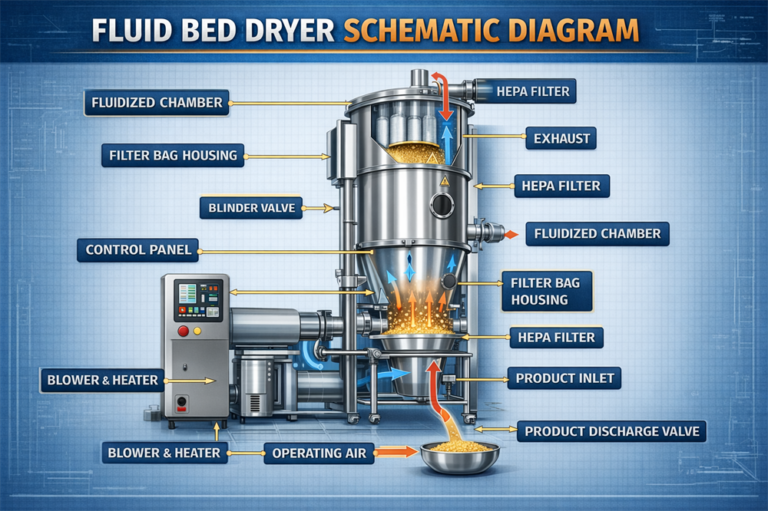

Entenda as especificações do secador de leito fluidizado: fluxo de ar, controle de temperatura, e tamanho do lote para desempenho de secagem ideal e qualidade consistente do produto.