High Quality Ypg Pressure Spray Dryer Zirconium Oxide Spray Drying Machine Zirconium Oxide Dryer

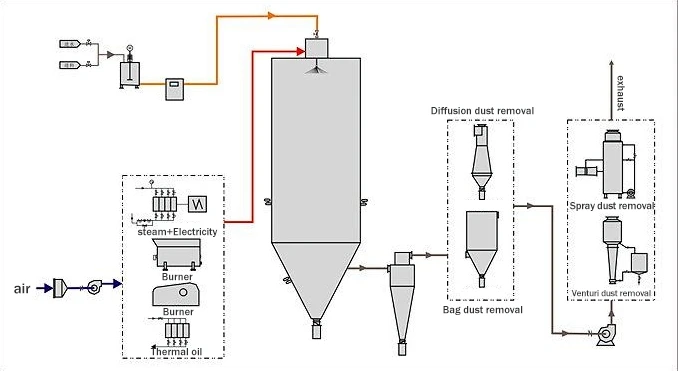

The YPG Series Pressure Type Spray (Congeal) Dryer has a device that can function drying and granulating together. The spraying pressure, spraying flow and the size of spray nozzle of the liquid material pump can be adjusted according to the requirements and the specific size of granule balls can be achieved.

Description

|

Pressure Spray Granule Drying |

||||||||

| Model | YPG-25 | YPG-50 | YPG-100 | YPG-150 | YPG-200 | YPG-300 | YPG-500 | YPG-1000-2000 |

| Evaporation Capacity(kg/h) | 25 | 50 | 100 | 150 | 200 | 300 | 500 |

The index depends on the practical situation |

| Overall Dimension(Φ*H)(mm) | 1300*7800 | 1800*9200 | 2400*11600 | 2600*14000 | 2800*15300 | 3200*17100 | 3800*19000 | |

| Power(kW) | 15 | 22 | 28 | 30 | 37 | 42 | 50 | |

| High-pressure Pump Pressure(Mpa) | It can be adjusted from 0.6 to 5 according to the material. In general, the pressure will be between 1 and 3 | |||||||

| Heating Resource | Electricity | Electricity+Steam | Electricity+Coal fuel (oil) hot air furnace | |||||

| Inlet Air Temperature(℃) | 300-350 | |||||||

| Product Water Contents | ≤5% | |||||||

| Material Restoration | >97% | |||||||

Foodstuff: amino acid and similar substance, flavoring, protein, starch, dairy products, extractive substance from coffee, fish powder,extractive substance from meat and so on

Ceramics: magnesium oxide, kaoline, all kinds of metallic oxide, dolomite and so on

Granulating through atomizing: all kings of fertilizer, aluminum oxide, ceramics powder, heavy metallic super hardness steel, chemical fertilizer, washing powder,and so on.

Zirconium Oxide Spray Drying Machine Service before sell:

Zirconium Oxide Spray Drying Machine Service in sell:

Zirconium Oxide Spray Drying Machine Service after sell:

1.Can I use this machine to extract some raw materials?

Additional information

| Model Number | YPG |

|---|---|

| Type | Spray Drying Equipment |

| Application | Chemicals Processing, Plastics Processing, Food Processing |

| Condition | New |

| Place of Origin | Jiangsu, China |

| Brand Name | CSTECH |

| Voltage | 110V-450V |

| Power | 15-50KW |

| Dimension(L*W*H) | according to the model |

| Key Selling Points | Long Service Life |

| Warranty | 2 years |

| Weight (KG) | 5000 |

| Applicable Industries | Manufacturing Plant, Food & Beverage Factory, Farms, Food Shop, Energy & Mining, Food & Beverage Shops |

| Showroom Location | None |

| Marketing Type | Hot Product 2022 |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 2 years |

| Core Components | Bearing, Pump, Gear, Motor, Gearbox, PLC, Engine, Pressure vessel, Other |

| Evaporation Capacity(kg/h) | Depends on the model |

| Heating Method | Electricity/Steam/Oil/Gas |

| Material | SUS304, SUS304L, SUS316, SUS316L, Ti, Other, SUS304 |

| Product name | Pressure Spray Granulation Drye |

| Model | YPG |

| Advantage | Environmental Protection |

| Installation | Under Technician's Guidance |

| Heating source | Electricity, Steam, coal fuel hot air furnace |

| Spare parts | Supply the whole lifetime |

| After-Sales Service Provided | Online support, Video technical support, Free spare parts, etc. |

| After Warranty Service | Video technical support, Online support, Spare parts |

| Certification | IS9001 |

Reviews

There are no reviews yet.