hot sale YPG Series Pressure Spray Granulation Dryer for Organic catalysts

-

Pressure Spray Granulation Dryer for Organic catalysts is a kind of device which can finish drying and granulating at the same time. According to the process requirements, you can adjust the pressure, flow rate of the material liquid pump and the size of the spray hole to get the required spherical particles in a certain size ratio.

Description

hot sale YPG Series Pressure Spray Granulation Dryer for Organic catalysts

Pressure Spray Granulation Dryer for Organic catalysts DESCRIPTION

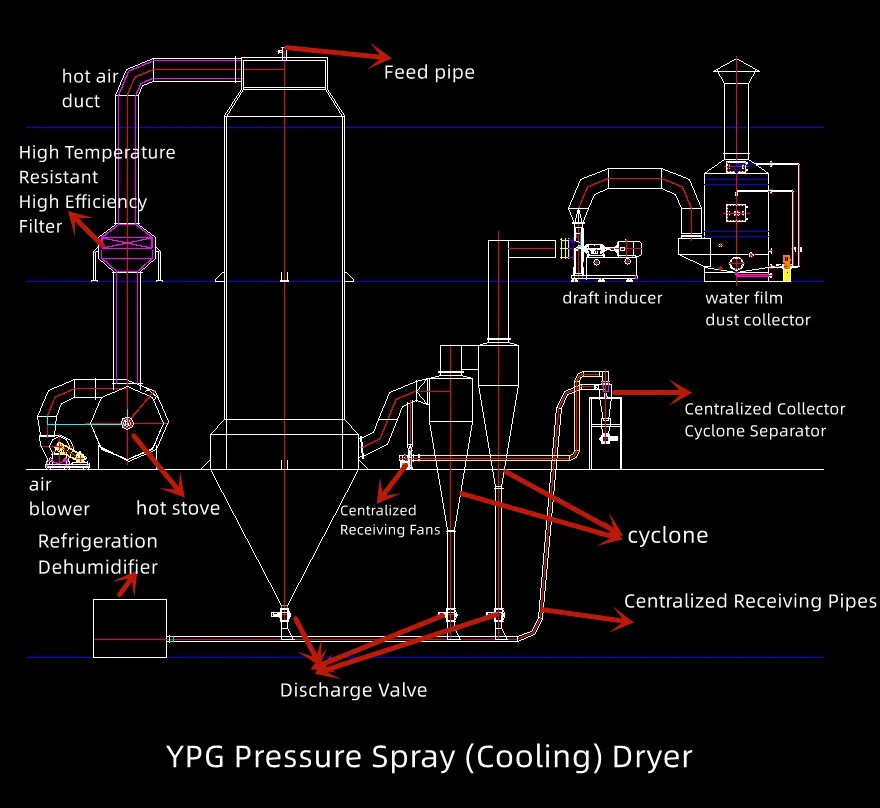

The YPG Series Pressure Type Spray (Congeal) Dryer has a device that can function drying and granulating together. The spraying pressure, spraying flow and the size of spray nozzle of the liquid material pump can be adjusted according to the requirements and the specific size of granule balls can be achieved.Pressure Spray Granulation Dryer for Organic catalysts WORKING PRINCIPLE

The liquid or paste raw material is sprayed into small liquid drop by pressed sprayer draw assistance from pressure of diaphram pump, and quickly drying through amply heat exchange (10-90sec.).Most of the powder granules are collected from outlet of discharge at the bottom of the dryer.The wasted air and fine powder are separated by the cyclone, the wasted air is exhaust from draft fan, and fine powder is collected at the bottom of cyclone. There is a second grade duster equipped at the outlet; therefore, the recovery rate of the finished powder granule can be 96% to 98%.

Pressure Spray Granulation Dryer for Organic catalysts APPLICATION

Chemical industry: Sodium Fluoride (Potassium ), Alkaline Dyestuff And Pigment,Dyestuff Intermediate, Mn3o4, Compound Fertilizer, Formic Silicic Acid, Catalyst, Sulphuric Acid Agent, Amino Acid,White Carbon, and etc.

Food Industry: Fatty Milk Powder, Protein, Cocoa Milk Powder, Subsitute Milk Powder,Egg White (Yolk), Food And Plant,Oats,Chicken Juice, Coffee, Instant Dissoluble Tea ,Seasoning Meat,Protein ,Soybean,Peanut Protein, Hydrolysate, Sugar,Corn Syrup,Corn Starch,Glucose, Pectin,Malt Sugar, Sorbic Acid Potassium, and etc.

Pharmaceutical Industry: Chinese Traditional Medicines, Pesticide, Antibiotic, Medical Drinking Agent,and etc.

Plastics and Resin: AB, ABS Emulsion, Uric Acid Resin, Phenolic Aldehyde Resin, Urea-Formaldehyde Resin, Formaldehyde Resin, Polythene, Poly-Chloroprene, And etc.

Detergent: Common Washing Powder,Advanced Washing Powder,Soap Powder, Soda Ash, Emulsifier, Brightening Agent, Orthophosphoric Acid, and etc.

Ceramic: Aluminium Oxide, Ceramic Tile Material, MagnesiumOxide, Talcum, and etc. Other: Calmogastrin, Hime Chloride , Stearic Acid Agent, and etc.

Pressure Spray Granulation Dryer for Organic catalysts FEATURES

1. Rapid drying speed.The surface area of the material will be enlarged greatly when liquid raw material is atomized and 95% – 98% of water can be evaporated instantly in the hot airflow. The drying time only need to take several seconds. This dryer is especially suitable for heating sen sitive material.

2. The finished product is ball granulewith uniform size. It’s fluidity and solubility are good. The quality and purity of the product is very high.

3. Depend on the characteristics of raw material, the dryer can use hot air to dry or use cool air to granulate.

4. Simple and stable operation. The control system is con venient which is easy to realize automatic operation.

Technical Parameter

| Item \ Model | Unit | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| water evapo- ration capacity |

kg | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| overall dimension (Φ×H) |

mm | 1600× 8900 |

2000× 11500 |

2400× 13500 | 2800× 14800 |

3200× 15400 |

3800× 1880 |

4600× 22500 |

| high-pressure pump pressure |

mPa | 2~10 | ||||||

| power | KW | 8.5 | 14 | 22 | 24 | 30 | 82 | 30 |

| inlet air temperature |

oC | 140~350 | ||||||

| product water contents |

% | <5(可达0.5) | ||||||

| collection rate | % | >97 | ||||||

| electric heater | KW | 75 | 120 | 150 | temperature is lower than 200,the parameters should be calculated |

|||

| electricity +steam |

Mpa+KW | 0.5+54 | 0.6+90 | 0.6+108 | according to the practical condition | |||

| hot air furnace | Kcal/h | 100000 | 150000 | 200000 | 300000 | 400000 | 500000 | 1200000 |

* The above is the largest evaporation.

Reviews

There are no reviews yet.