ZLG Series Good Quality Industry Salt Vibrating Fluidized Bed Dryer Machine

Vibrating Fluidized Bed Dryer Machine

Vibrating fluidized bed, is a new type of fluidized and efficient drying equipment suitable for drying granular and powdery materials. It has the advantages of easy operation, energy saving and environmental protection. The vibrating fluidized bed is a new type of equipment that has been gradually developed and expanded in the past decade, and is increasingly becoming the main model of drying equipment. The vibrating fluidized bed is a new drying device that applies specific required vibration sources to ordinary fluidized bed dryers. This vibration source can be divided into electric motor method, electromagnetic induction method, crankshaft or eccentric method, pneumatic or hydraulic method according to its excitation method.

Description

ZLG Series Good Quality Industry Salt Vibrating Fluidized Bed Dryer Machine

2. The vibration is created by motor. It is stable in operation and convenient in maintenance, low noise with long life span.

3. High efficiency, raw material is heated evenly with high efficiency and drying capacity is high. Compared with ordinary dryer, the energy can be saved about 30%.

4. It is good in regulation and wide in suitability. The thickness of raw material, moving speed and the amplitude can be adjusted.

5. It makes minimum damage to the surface of raw material. The equipment can be used for drying easy broken raw materials. The dryer also suitable for drying irregylar shape raw material.

6. The dryer adopt closed operation, protect raw material from cross-contamination, it is in continuous production

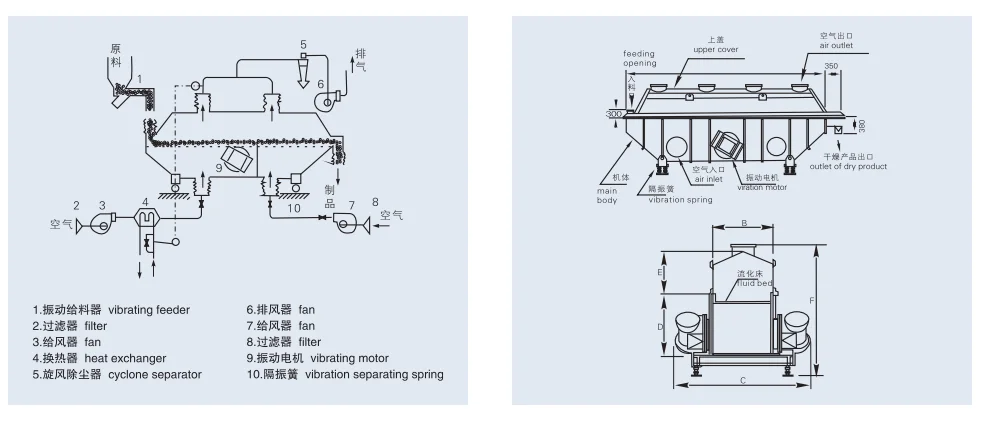

Principle of Breadcrumb / Crumb Vibration Fluid Bed Dryer

Raw material is fed into the dryer from the feeding end and moves forward continuously along under the function of vibration. The hot air penetrate fluid bed plate and dry damp raw material. Then the damp air is exhausted out through cyclone separator and dried raw material is discharged through discharge end.

| Model | Area of Fluidized-bed(㎡) | Inlet Air Temperature (℃) | Outlet Air Temperature (℃) | Evaporation Capacity(kg/h) | Vibration Motor | |

| Model | Power(kW) | |||||

| ZLG-3*0.3 | 0.9 | 70-140 | 40-70 | 20~35 | ZDS31-6 | 0.8*2 |

| ZLG-4.5*0.3 | 1.35 | 35~50 | ZDS31-6 | 0.8*2 | ||

| ZLG-4.5*0.45 | 2.025 | 50~70 | ZDS32-6 | 1.1*2 | ||

| ZLG-4.5*0.6 | 2.7 | 70~90 | ZDS32-6 | 1.1*2 | ||

| ZLG-6*0.45 | 2.7 | 80~100 | ZDS41-6 | 1.5*2 | ||

| ZLG-6*0.6 | 3.6 | 100~130 | ZDS41-6 | 1.5*2 | ||

| ZLG-6*0.75 | 4.5 | 120~170 | ZDS42-6 | 2.2*2 | ||

| ZLG-6*0.9 | 5.4 | 140~170 | ZDS42-6 | 2.2*2 | ||

| ZLG-7.5*0.6 | 4.5 | 130~150 | ZDS42-6 | 2.2*2 | ||

| ZLG-7.5*0.75 | 5.625 | 150~180 | ZDS51-6 | 3.0*2 | ||

| ZLG-7.5*0.9 | 6.75 | 160~210 | ZDS51-6 | 3.0*2 | ||

| ZLG-7.5*1.2 | 9 | 200~260 | ZDS51-6 | 3.7*2 | ||

Vibrating Fluidized Bed Dryer Machine Service before sell:

Vibrating Fluidized Bed Dryer Machine Service in sell:

Vibrating Fluidized Bed Dryer Machine Service after sell:

1.Can I use this machine to extract some raw materials?

Reviews

There are no reviews yet.