Factory Price Vibrating Dryer Machine Tea Leaf Fluidized Industry Salt Seed Fluid Bed

Description

Factory Price Vibrating Dryer Machine Tea Leaf Fluidized Industry Salt Seed Fluid Bed

1. Height of fluidizing chamber and dust collection is by requirement.

2. The vibration is created by motor. It is stable inoperation and convenient in maintenance, low noise with long life span.

3. High efficiency, raw material is heated evenly with high efficiency and drying capacity is high. Compared with ordinary dryer, the energy can be saved about 30%.

4. It is good in regulation and wide in suitability. The thickness of raw material, moving speed and the amplitude can be adjusted.

5. It makes minimum damage to the surface of raw material. The equipment can be used for drying easy broken raw materials. The dryer also suitable for drying irregylar shape raw material.

6. Vibrating Dryer Machine adopt closed operation, protect raw material from cross-contamination, it is in continuous production Principle of Breadcrumb / Crumb Vibration Fluid Bed Dryer Raw material is fed into the dryer from the feeding end and moves forward continuously along under the function of vibration. The hot air penetrate fluid bed plate and dry damp raw material. Then the damp air is exhausted out through cyclone separator and dried raw material is discharged through discharge end.

Project in China

Project in Turkey

Vibrating Dryer Machine Project in Africa

Vibrating Dryer Machine technical parameters

| Model | Area of Fluidized-bed(㎡) | Inlet Air Temperature (℃) | Outlet Air Temperature (℃) | Evaporation Capacity(kg/h) | Vibration Motor | |

| Model | Power(kW) | |||||

| ZLG-3*0.3 | 0.9 | 70-140 | 40-70 | 20~35 | ZDS31-6 | 0.8*2 |

| ZLG-4.5*0.3 | 1.35 | 35~50 | ZDS31-6 | 0.8*2 | ||

| ZLG-4.5*0.45 | 2.025 | 50~70 | ZDS32-6 | 1.1*2 | ||

| ZLG-4.5*0.6 | 2.7 | 70~90 | ZDS32-6 | 1.1*2 | ||

| ZLG-6*0.45 | 2.7 | 80~100 | ZDS41-6 | 1.5*2 | ||

| ZLG-6*0.6 | 3.6 | 100~130 | ZDS41-6 | 1.5*2 | ||

| ZLG-6*0.75 | 4.5 | 120~170 | ZDS42-6 | 2.2*2 | ||

| ZLG-6*0.9 | 5.4 | 140~170 | ZDS42-6 | 2.2*2 | ||

| ZLG-7.5*0.6 | 4.5 | 130~150 | ZDS42-6 | 2.2*2 | ||

| ZLG-7.5*0.75 | 5.625 | 150~180 | ZDS51-6 | 3.0*2 | ||

| ZLG-7.5*0.9 | 6.75 | 160~210 | ZDS51-6 | 3.0*2 | ||

| ZLG-7.5*1.2 | 9 | 200~260 | ZDS51-6 | 3.7*2 | ||

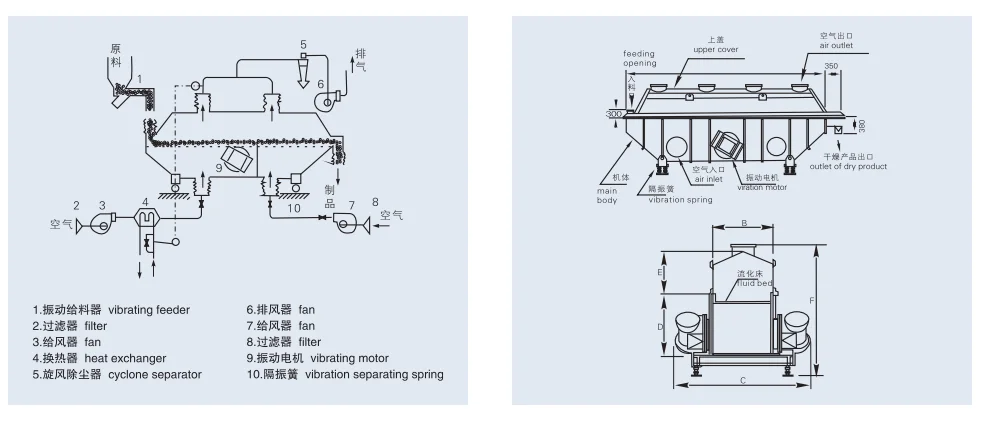

Vibrating Dryer Machine flow chart

Jiangsu Changshi Drying Technology Co., Ltd specializes in design, production and development of mixer, dryer, crusher, granulator, vibrating screen, dust collector and conveyor. The company has modern standard workshop buildings, engineering and technical personnel with medium and senior titles, more than 10 sets of processing equipment.The specialty provides complete set of powder equipment and solutions. In accordance with the GMP certification standard, the whole process of service is provided.

Vibrating Dryer Machine Service before sell:

—-Provide relative technical data for help equipment selection—-Running pilot test—-Offering advice for equipment selection, material analysis—-Provide flow chart, basic drawing—-Provide technical design

Vibrating Dryer Machine Service in sell:

—-Provide factory layout according to contract—-Manufacturing ordered equipment according to the related standard—-A presentation report of manufacturing situation will be offered every 15days—-Tracking and supervising in whole manufacturing and transporting period according to the contract requirement—-Photo of wooden case will be offered, wooden case with standard shipping marks.—-Photo of freight loading will be offered.—-A record of detailed delivery list will be offered—-A record of detailed freight loading list will be offered—-All of wooden case will be marked serial number, all of attachments will be marked serial number, convenient for client’s clearing

Vibrating Dryer Machine Service after sell:

—-Send service engineer for help instruct installation.—-Send service engineer for running test at site and training the operator—-Help client for maintenance and repair—-Provide one year spare part—-Quality warranty for two years after sell

1.Can I use this machine to extract some raw materials?

Yes, in order to help you better, we suggest you provide the name of the raw material you want to process. 2.Can I use my own raw materials for extraction test? Yes, of course. We can do extraction tests and send videos and test reports for your reference. 3.Do you have OEM service? Do you provide parts? Yes, we will, as long as you provide us with your drawings and detailed requirements. 4.How can we visit your factory? You can fly to Changzhou airport, or if you arrive in Shanghai, you can tell us your specific location. We will arrange a driver to pick you up. 5.How to transport equipment? We usually choose sea transportation. Laboratory models can be shipped by air according to customer requirements. 6.What is the voltage of the equipment? The equipment voltage is 110V~380V, the specification can be customized according to the voltage standard of the country where your equipment is used.

Additional information

| Model Number | ZLG |

|---|---|

| Type | Vibrating Fluidized Bed Dryer |

| Application | Chemicals Processing, Plastics Processing, Food Processing |

| Condition | New |

| Place of Origin | Jiangsu, China |

| Brand Name | CSTECH |

| Voltage | 110V-480V (TBD) |

| Power | 5.5KW-155KW |

| Dimension(L*W*H) | 3*0.3*1.2m-10-2*3m |

| Key Selling Points | Long Service Life |

| Warranty | 2 years |

| Weight (KG) | 3500 |

| Applicable Industries | Manufacturing Plant, Food & Beverage Factory, Farms, Food Shop, Energy & Mining, Food & Beverage Shops |

| Showroom Location | None |

| Marketing Type | Hot Product 2022 |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 2 years |

| Core Components | Motor, Other, PLC, Engine |

| Evaporation Capacity(kg/h) | 180 |

| Heating Method | Steam/Electric/Gas/Diesel |

| Material | SUS304, SUS304L, SUS316, SUS316L, Ti, Other |

| Product name | Vibrating Fluidized Bed Dryer |

| Color | Customized Color |

| Drying Temperature | 50-250℃ |

| Evaporation Capacity | 1.5L-1000L |

| Way to Discharge | Manual/ Pneumatic / Electrical |

| Drying Efficiency | 50-75% |

| Special Design | Corrosive / Explosive / Wall Adhesive |

| After Warranty Service | Video technical support |

| Installation | Engineer Guide |

| Certification | ISO9001 |

Reviews

There are no reviews yet.