Showing 61–72 of 88 results

-

Product Keywords:Hollow Blade Dryer,Blade DryerDescription:Applicable for drying or cooling of paste, particle, powder and slurry state of material, perform the process of drying, cooling, heating, sterilizing, reacting and combustion under low temperature. The special stirring and heating…

Product Keywords:Hollow Blade Dryer,Blade DryerDescription:Applicable for drying or cooling of paste, particle, powder and slurry state of material, perform the process of drying, cooling, heating, sterilizing, reacting and combustion under low temperature. The special stirring and heating… -

China factory made CT Series 144 trays hot air circulating drying oven

144 trays hot air circulating drying oven adopts noise elimination and thermal stable axial flow fan and automatic temperature control system. The entire circulation system is enclosed to make that the heat efficiency of the drying oven increases from 3-7% of the traditional drying oven to 35-40% of the present one. The highest heat efficiency can be up to 50%. The successful design of CT-C hot air circulating oven makes that the hot air circulating drying oven in our country reach the advanced level in the world. It saves energy and increases the economic benefit. In 1990, the medical management bureau of the State issued the industry standard and the uniform type is RXH.

-

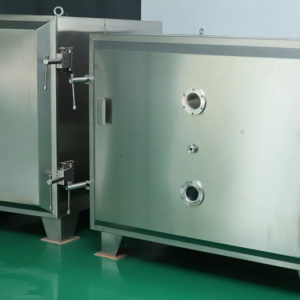

Hot Sale pharma industrial rotary drying machine FZG square static vacuum dryer

Product Keywords:Square Static Vacuum Dryer,Static Vacuum Dryer,Vacuum DryerDescription:Tt is well known that vacuum drying is to put raw material under the state of vacuum fo r heating and drying If use vacuum to pump air and humidity out,the dry speed will be faster. -

Energy Saving Dryer Powder Spray Drying

Energy Saving Dryer Powder Spray Drying Dryer Powder Spray Drying Product Overview Spray drying is the most widely used technology in liquid shaping and drying industry.Which is the most suitable for producing solid power or particle products from liquid material such as solution,emulsion,suspension and pumpable paste states.So if you want Particle size distribution,Residual moisture content,Bulk…

-

Factory Direct Sale Zpg Rotary Vacuum Rake Dryer

Factory Direct Sale Zpg Rotary Vacuum Rake Dryer is widely used in pharmaceutical industry, foodstuff industry, chemical industry and etc. Especially suitablefor the following materials:

1. Pulpiness, paste-like mixture or powder materials.

2.Thermal sensitive material which required to be dried at lower temperature.

3. Materials that are easy to oxidize or explode and the material that have strong irritative or toxic.

4.Materials that required recovering solvent. -

High speed Food Atomizer Centrifugal Spray Dryer

Food Atomizer Centrifugal Spray Dryer Food Atomizer Centrifugal Spray Dryer Product Overview Spray drying is the most widely used technology in liquid shaping and drying industry.Which is the most suitable for producing solid power or particle products from liquid material such as solution,emulsion,suspension and pumpable paste states.So if you want Particle size distribution,Residual moisture content,Bulk…

-

high efficiency Foodstuff Vacuum Drying Oven

high efficiency Foodstuff Vacuum Drying Oven FZG Vacuum Tray Dryer It is well known that vacuum drying is to put raw material under the state of vacuum for heating and drying. If use vacuum to pump air and humidity out, the dry speed will be faster. Note: If use condenser, the solvent in raw material…

-

High Efficiency Drying Machine Custom Atomizer Drier Granule Granulator Protein Pressure Nozzle Spray Dryer

YPG Protein Pressure Nozzle Spray Dryer is suitable for solution, suspension, slurry, paste material, etc. Liquid material is atomized to small fog drops. And fog drops contact with hot air directly in the drying tower. Moisture content is evaporated instantly. So spray dryer features high efficiency, high mass transfer area, and short drying time, in general it is 5~30 seconds. Operating temperature can be adjusted according to actual situation, in general inlet air temperature is 150~500°C. And its automation control degree is control, environment solution environment can be solved.

-

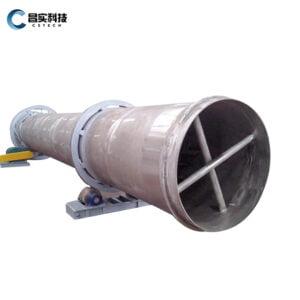

Industrial Coal Clay Slime Cement Rotary Drying Equipment Sludge 3 Rotary Drum Dryer Machine Slag Sand Ore Dryer

3 Rotary Drum Dryer Machine Slag Sand Ore Dryer

3 Rotary Drum Dryer Machine Slag Sand Ore Dryer is widely used to dry materials in industries like cement, mine, construction, chemical, food, compound fertilizer, etc. Thermocouples are installed in feeding and discharging units to control temperature. Temperature change of the dryer also canbe indicated by the thermometer, which is convenient for temperature control inside the dryer ( it is usually 250-350℃).

-

New Customized OEM Factory CE Standard Hollow Paddle Blade Rotary Stirring Drying Machine

ZPG Rotary Vacuum Rake Dryer(Rotary Stirring Drying Machine) is widely used in pharmaceutical industry, foodstuff industry, chemical industry and etc. Especially suitablefor the following materials:

1. Pulpiness, paste-like mixture or powder materials.

2.Thermal sensitive material which required to be dried at lower temperature.

3. Materials that are easy to oxidize or explode and the material that have strong irritative or toxic.

4.Materials that required recovering solvent. -

-300x300.jpg)

HZG Series Mining Drum Dryer For Sludge Mud Powder Drying Equipment Sludge Mud Rotating Dryer

Product Keywords:Rotary Drum Dryer,Rotary Dryer,Mining Drum DryerDescription:Wet material is loaded from one head of the dryer , and then it is stirred by the bafflers that is uniformly distributed in the barrel. Material is uniformly distributed and dispersed in the dryer , fully contact the hot air of parallel… -

Good Price GMP Hot Air Circulating Oven For API Tray Dryer Industrial Drying Oven

Good Price GMP Hot Air Circulating Oven For API Tray Dryer Industrial Drying Oven 1.Options of heat source: steam, electricity, or far infrared, or both steamelectricity. 2. Hot Air Circulating Drying Oven Drying temperature: steam heating 50-130℃,Max.140℃. 3.Electricity and far infrared:50-300 ℃ .Automatic control system andcomputer control system on request.4.Commonly used steam pressure 0.2-0.8Mpa(2-8 bar). 5.For CT-C-I,electric heated, rated power consumption:15Kw,realconsumption:5-8Kw….