New arrival low price china supplied FG Series Vertical Fluid Bed Dryer

Features of FG Series Vertical Fluidized Dryer

Because of powder granulating, the flow property is improved and the dust is reduced.

Showing 25–36 of 88 results

Because of powder granulating, the flow property is improved and the dust is reduced.

Granulator Drying Equipment for Powders

The Powder Granule In Fluid Bed Appears In The State Of Fluidization. It Is Preheated And Mixed With Clean And Heated Air. At The Same Time The Solution Of Adhesive Is Sprayed Into The Container. It Makes The Particles Become Granulating That Contains Adhesive. Being Of Unceasing Dry Through Hot Air, The Moisture In The Granulating Is Evaporated. The Process Is Carried Out Continuously. Finally It Forms Ideal, Uniform And Porous Granules.

Hollow paddle Dryer (Sludge Drying Machine)

is a horizontal stirring and heat conduction type Drying Equipment that can work continuously. Its stirring blade is like ship paddle, so it is called paddle dryer. In foreign countries, it is also called slot dryer or stirring dryer.

Hollow paddle dryer is successfully used in foodstuff, chemical, petrochemical, dyestuff, industry sludge fields, etc. The characters of heat transfer, cooling, and stirring make the machine can achieve the following operation: Calcination (low temperature), cooling, drying (solvent recovery), heating (melting), reaction and sterilization. Stirring paddle is heat transfer surface as well, it makes the unit efficient heat transfer area larger, and handling time is reduced. Heat transfer surface of wedge type has slef-cleaning function. Compress—expand stirring function makes the material mixed uniformly. Material makes piston flow movement along the axial direction, in the axial direction interval, the temperature, humidity and mixedness gradient is very low.

YK Swing Granulator is the special granulator that can make damp powder pass through screen and granulate particles under the reaction of clockwise and counterclockwise rotating of cylinder. In addition, it can make the agglomeration powder into the needed size particles. The material contact area is made of stainless. It’s easy to clean, simple operation and low energy consumption

YPG Series Organic Catalysts Granulation pressure spray Drying machine : Spray drying process is the widest used in the liquid forming process and in drying industry. The drying technology is most suitable for powder, particle products from materials, such as,solution, emulsion, SC and pumpable paste states material. For this reason, when the particle size and distribution of the final product, their residual water contents, the stacking density and particle shape must meet the precision standard, spray drying process is one of the most desired processes.

Vibrating Fluidized Bed Dryer Machine

Vibrating fluidized bed, is a new type of fluidized and efficient drying equipment suitable for drying granular and powdery materials. It has the advantages of easy operation, energy saving and environmental protection. The vibrating fluidized bed is a new type of equipment that has been gradually developed and expanded in the past decade, and is increasingly becoming the main model of drying equipment. The vibrating fluidized bed is a new drying device that applies specific required vibration sources to ordinary fluidized bed dryers. This vibration source can be divided into electric motor method, electromagnetic induction method, crankshaft or eccentric method, pneumatic or hydraulic method according to its excitation method.

XSG series rotary flash dryer (Silicon Carbide Flash Evaporation Dryer) is a new type of drying equipment developed by our factory on the basis of introducing and absorbing advanced foreign technology. The machine has advanced technology, reasonable design, compact structure, wide application range, large production capacity, good product quality, high efficiency, and energy saving. Drying, crushing, and screening are completed at one time in one device, eliminating environmental pollution, and the performance of the whole machine reaches International advanced technology level.

Banana Hot Air Circulating Oven is suitable for the material and product hot solidification and dry de-watering in the pharmaceutical, chemical, food, farming, side-product, aquatic product, light industries, heavy industries and others industries. Such as: raw material medicine, crude drug, prepared herbal medicine of Chinese traditional medicine, plaster, powder, particle, drinking agent, pill, packing bottle, pigment, dyestuff, de-watering vegetable, dried fruit piece, sausage, plastics, resin, electric component, baking varnish and etc

XSG Chlortetracycline Flash Vaporization Dryer is widely used for drying materials such as paste, cake shape, powder, granules material, etc. It is a new type high drying efficiency and low energy consumption equipment that researched and developed by our company.

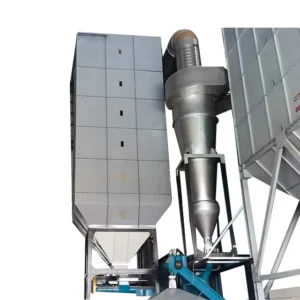

Sodium Chloride Horizontal Fluid Bed Dryer is also call as fluidize-bed. It consists of air filter, heater, fluidized-bed main machine, feeder, cyclone separator, cloth bag duster, high-pressure centrifuge fan, and operation table. The dust collector shall be equipped according to the properties of raw materials. You can use cyclone separator or cloth bag duster according to the materials characteristics, the cyclone separator is mainly used for high specific gravity materials and the cloth bag duster is mainly used for powder and small granule materials. The air feeding device and belt conveyor is optional. The heat source can use steam, electricity, hot air furnace as per customer requirements.

Factory Direct Sale Plastic Peanut Oil Liquid Laundry Silk Pepper Manure Mango Spin Screen Protein Feed Flash Evaporation Dryer XSG Series Spin Flash Dryer XSG Spin Flash Dryer is widely used for drying materials such as paste, cake shape, powder, granules material, etc. It is a new type high drying efficiency and low energy consumption…

Sodium Sulfate Vibrating Fluidized Bed Dryer Applicable Materials

Boric Acid, Borax, Dihydroxybenzene, Malic Acid, Maleic Acid, Monosodium Glutamate, Oxalate, Potassium, Permanganate, Sesame, Pentaerythritol, HPAM, Hypha Protein, Sodium Sulfate, Sodium Borate, Plastic Archon, Catalyst, Baking Soda, Detergent, Quartz Sand, Bean Pulp, Edible Sugar, Refine Salt, Bean, Seeds, Mining Slag, Activated Clay, Compound Fertilizer, and etc.

Choosing Jiangsu Changshi Technology means choosing a seasoned partner with a wide range of products, customization capabilities, and a dedicated team to support you at every step.

Tailored drying solutions to match your specific project requirements.

Dedicated sales, technology, and after-sales teams ensuring seamless service.

Reliable, high-performance drying machines meeting stringent industry standards.

Actively seeking and incorporating customer feedback allows us to adapt and improve, ensuring that our products not only meet but exceed customer expectations in terms of quality and performance

Our company has paid attention to the pre-sales and after-sales service to customers for many years, to provide users with satisfactory solutions, high-quality products, perfect after-sales, is our consistent commitment to win the satisfaction of every customer.

Embracing customer feedback as a valuable resource, we use it to drive continuous improvement in our products and services, ensuring an ever-evolving customer-centric approach.

“Jiangsu Changshi Technology not only listens but acts on customer feedback promptly. Their commitment to improvement is evident in the enhanced quality and performance of their products.”

“The feedback loop with Jiangsu Changshi Technology is truly collaborative. They value our insights and work towards addressing any concerns, creating a partnership that feels more like a shared journey towards excellence.”

“Their receptiveness to feedback sets them apart. It’s not just about delivering a product; it’s about creating an experience, and they make sure the customer’s voice is not only heard but incorporated into their ongoing innovations.”

Yes, in order to help you better, we suggest you provide the name of the raw material you want to process.

Yes, of course. We can do extraction tests and send videos and test reports for your reference.

Yes, we will, as long as you provide us with your drawings and detailed requirements.

You can fly to Changzhou airport, or if you arrive in Shanghai, you can tell us your specific location. We will arrange a driver to pick you up.

We usually choose sea transportation. Laboratory models can be shipped by air according to customer requirements.

The equipment voltage is 110V~380V, the specification can be customized according to the voltage standard of the country where your equipment is used.

Our company has paid attention to the pre-sales and after-sales service to customers for many years, to provide users with satisfactory solutions, high-quality products, perfect after-sales, is our consistent commitment to win the satisfaction of every customer.