Showing 13–24 of 88 results

-

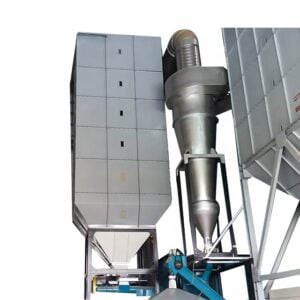

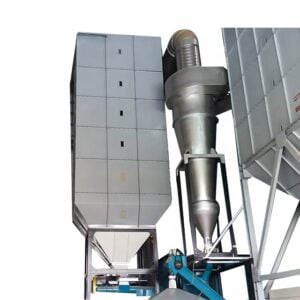

Glyphosate Flash Evaporation Dryer(Spin Flash Dryer) is a continuous Drying Equipment specially designed for shaped cake, cream paste, paste slurry materials. Clean heat medium goes into the drying room from the tangent direction, form a strong rotary vortex air current together with mechanical mixer. Wet material has been added to the drying room in a fix quantity, and stir in the vortex of air currents were crushed under dry. Drying room at the top with particle size classification, the fine powder discharged from the top of the tower from the back of the separator to collect the product into larger particles return to the drying room, continue to be crushed, and dried.

-

Sludge Stirring Blade Mixer Mud Hollow Paddle Dryer

KJG Hollow Blade dryer is a kind of contacting dryer. There is jacket on the body of dryer, hollow blade strongly welded on two hollow shafts, filling heating medium (could be hot water, steam or thermal oil) in them, wet raw material is heated, dried as well as driven forward by two shafts. It could be consisted of one to four shafts, whole operation will be finished in closed or partial closed environment.

-

Continuous Rotary Plate Dryer for chemical powder is a kind of high efficiency conducting and continuous drying equipment. Its unique structure and operating principle provide advantages of high heat efficiency , low energy consumption, less occupying area, simple configuration, easy operation and control as well as good operating environment etc. It is widely used in drying process in the fields of chemical,agricultural chemicals, foodstuff, fodder,process of agricultural and by-products etc., and is well received by various industries.

-

Sludge Drying Machine(Hollow blade paddle Dryer )is a thermal conduction and low-speed agitation type dryer. Installation of the jacket, which is equipped with hollow shaft and hollow tube leaves, the heat carrier into the wet material from the mixing paddle to complete processing of the tank, mixing blades heat the surface of the heat exchange, the raw material depletion.

-

Hollow Blade Paddle (Hollow blade paddle Dryer )

is a thermal conduction and low-speed agitation type dryer. Installation of the jacket, which is equipped with hollow shaft and hollow tube leaves, the heat carrier into the wet material from the mixing paddle to complete processing of the tank, mixing blades heat the surface of the heat exchange, the raw material depletion.

-

Seasoning Flavouring Granules Drying Equipment(FG series fluid bed dryer )is the special equipment used extensively in the pharmaceutical industries to reduce the moisture content of pharmaceutical powder and granules. By using powder granulation. Allpack fluid bed dryers can be used to improve the liquidity and thinner dust.

-

Silicon Dioxide Flash Evaporation Dryer(Spin Flash Dryer) is a continuous Drying Equipment specially designed for shaped cake, cream paste, paste slurry materials. Clean heat medium goes into the drying room from the tangent direction, form a strong rotary vortex air current together with mechanical mixer. Wet material has been added to the drying room in a fix quantity, and stir in the vortex of air currents were crushed under dry. Drying room at the top with particle size classification, the fine powder discharged from the top of the tower from the back of the separator to collect the product into larger particles return to the drying room, continue to be crushed, and dried.

-

Continuous Rotary Plate Dryer for Lithium Carbonate is a kind of high efficiency conducting and continuous drying equipment. Its unique structure and operating principle provide advantages of high heat efficiency , low energy consumption, less occupying area, simple configuration, easy operation and control as well as good operating environment etc.

-

PLG series Continuous Plate Dryer (Lithium carbonate dryer) is a kind of high efficiency conducting and continuous Drying Equipment. Its unique structure and operating principle provide advantages of high heat efficiency , low energy consumption, less occupying area, simple configuration, easy operation and control as well as good operating environment etc.

-

Dyes Pressure Spray Dyer

This unit is a kind of device which can finish drying and granulating at the same time. According to the process requirements, you can adjust the pressure, flow rate of the material liquid pump and the size of the spray hole to get the required spherical particles in a certain size ratio.

-

The spin flash dryer is widely used in the dispersion and drying of granular, powdery, paste-like, and filter cake-like false agglomerates in the chemical, building materials, food, feed, and other industries. The flash dryer has the advantages of small occupied areas, low energy consumption, high thermal efficiency, and continuous mass production. The flash dryer body is provided with a rotary cutting device, and the dry material is subjected to shearing, rotating, collision, friction, etc., so that the material is pulverized and refined, and is highly dispersed, thereby achieving the effect of efficiency and rapidly evaporating water.

-

Features of FG Series Vertical Fluidized Dryer

Because of powder granulating, the flow property is improved and the dust is reduced.

Because of powder granulating, its solving property is improved.

The mixing, granulating and drying could be completed in one machine.

Being adapted anti static filter bag, the operation is safe.

There is explosion releasing hole to keep the people’s security when explosion.

The equipment has no dead corner, easy for feeding, discharging and clean. It could meet the requirement of GMP.