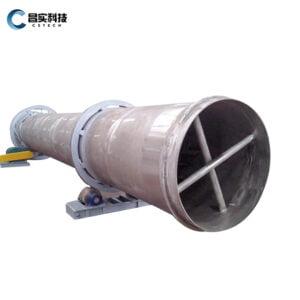

Industrial Coal Clay Slime Cement Rotary Drying Equipment Sludge 3 Rotary Drum Dryer Machine Slag Sand Ore Dryer

3 Rotary Drum Dryer Machine Slag Sand Ore Dryer

3 Rotary Drum Dryer Machine Slag Sand Ore Dryer is widely used to dry materials in industries like cement, mine, construction, chemical, food, compound fertilizer, etc. Thermocouples are installed in feeding and discharging units to control temperature. Temperature change of the dryer also canbe indicated by the thermometer, which is convenient for temperature control inside the dryer ( it is usually 250-350℃).

Description

3 Rotary Drum Dryer Machine Slag Sand Ore Dryer is widely used to dry materials in industries like cement, mine, construction, chemical, food, compound fertilizer, etc. Thermocouples are installed in feeding and discharging units to control temperature. Temperature change of the dryer also canbe indicated by the thermometer, which is convenient for temperature control inside the dryer ( it is usually 250-350℃).

| Rotation Drum Dryer | ||||||

| Item(m) | Productive Capacity(T/h) | Rotating Speed(r/min) | Motor power(kW) | Install angle(°) | Humidity of Final Material(%) | |

| Φ1.0×5.0 | 0.5~1.2 | 1月19日 | 4 | 3~5 | ≤1.5% | 90000 |

| Φ1.2×6~10 | 1.5~3 | 5.5 | 100000-170000 | |||

| Φ1.5×12~18 | 3~5.5 | 15 | 200000-350000 | |||

| Φ1.8×12~18 | 5~6.5 | 18.5 | 220000-400000 | |||

| Φ2.2×12~22 | 7~12 | 22 | 310000-680000 | |||

| Φ2.4X15~20 | 9~15 | 30 | 350000-820000 | |||

| Φ3.0×25 | 16 | 55 | 1000000 | |||

| Applications | ||||||

| Item | Direct heating clockwise way | Direct heating clockwise way | Direct heating counterclockwise way | Direct heating counterclockwise way | Compound heating | Compound heating |

| Raw Material | Ore | HP Vesicant | Slag of blast furnace | Ammonium sulphate | Phosphorus fertlizer | Coal |

| Amount to be Treated(kg/h) | 1000 | 466 | 15000 | 20000 | 12000 | 5000 |

| Primary Humidity(%) | 30 | 13 | 6 | 1.5 | 5 | 6.5 |

| Final Humidity(%) | 15 | 0.3 | 1 | 0.1 | 0.1 | 0.1 |

| Average Diameter(mm) | 6.5 | 0.05 | 4.7 | 0.5~0.7 | 0.5 | 5 |

| Material Stacking Weight(kg/m³) | 770 | 800 | 1890 | 1100 | 1500 | 750 |

| Amount of Hotair(m³/kg) | 39000 | 5400 | 10750 | 9800 | 6500 | 16000 |

| Inlet Air Temperature (℃) | 600 | 165 | 500 | 180 | 650 | 570 |

| Outlet Temperature(℃) | 42 | 100 | 70 | 80 | 75 | |

| Heating Resource | Gas | Steam, electricity | Heavy oil | Coal fuel hotair furnace | Heavy oil | Heavy oil |

| Charging Factor | 6.3 | 7 | 7.5 | 7.8 | 18 | |

| Rotating Speed(rpm) | 4 | 4 | 3.5 | 3 | 4 | 2 |

| Gradient(m/m) | 0.04 | 0.005 | 0.03 | 0.05 | 0.05 | 0.043 |

| Quanity of Stirring-up Rake | 12 | 24 | 12 | 22 | Outer of inner cylinder 8, inner of outer cylinder 16 | Outer of inner cylinder 6, inner of outer cylinder 12 |

| Drum Diamete(m) | 2 | 1.5 | 2 | 2.3 | Outer of inner cylinder 2, inner of outer cylinder 0.84 | Outer of inner cylinder 2.4, inner of outer cylinder 0.95 |

| Drum Length(m) | 20 | 12 | 17 | 15 | 10 | 16 |

| Driving Power(kW) | 22 | 7.5 | 15 | 11 | 11 | 15 |

3 Rotary Drum Dryer Machine Slag Sand Ore Dryer Service before sell:

3 Rotary Drum Dryer Machine Slag Sand Ore Dryer Service in sell:

3 Rotary Drum Dryer Machine Slag Sand Ore Dryer Service after sell:

1.Can I use this machine to extract some raw materials?

Additional information

| Model Number | HZG |

|---|---|

| Type | Drum Drying Equipment |

| Application | Chemicals Processing, Plastics Processing, Food Processing |

| Condition | New |

| Place of Origin | Jiangsu, China |

| Brand Name | CSTECH |

| Voltage | 110V-480V (TBD) |

| Power | 4KW-55KW |

| Dimension(L*W*H) | D1.0m*5.0m–D3.0m*25m |

| Key Selling Points | High Productivity |

| Warranty | 2 years |

| Weight (KG) | 15000 |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Energy & Mining, Other |

| Showroom Location | None |

| Marketing Type | Hot Product 2022 |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 2 years |

| Core Components | Bearing, Pump, Gear, Motor, Gearbox, Other, PLC, Engine |

| Evaporation Capacity(kg/h) | 5000 |

| Heating Method | Gas/Steam/Oil/Coal fuel hotair furnace Heating |

| Material | SUS304, SUS304L, SUS316, SUS316L, Ti, Other |

| Product Name | Rotary Drum Dryer |

| Evaporation Capacity | 50L-10000L |

| Drying Temperature | 120-500℃ |

| Way to Discharge | Manual/ Pneumatic / Electrical |

| Drying Efficiency | 50% |

| Way to Control | Touch Screen/Button/Remote |

| Special Design | SCorrosive / Heavy Duty / Chamber Adhesive |

| Weight | 2250KGS-60000KGS |

| After-sales Service Provided | Free spare parts |

| Certification | ISO9001 |

-300x300.jpg)

Reviews

There are no reviews yet.