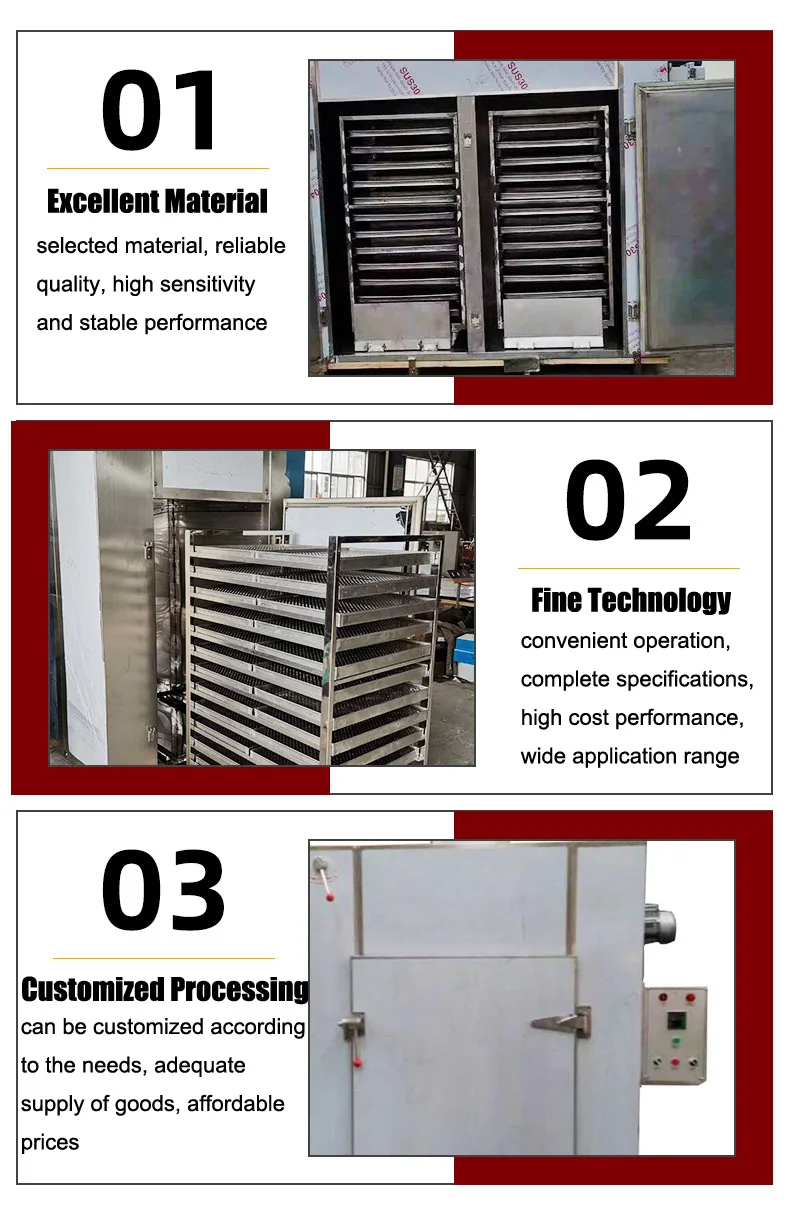

brand new design Industrial 24 trays hot air circulating drying oven

24 trays hot air circulating drying oven is a common type drying machine. Its application scope is wide, temperature is uniform, heat efficiency is high and operation is easy. It is suitable for heating, curing, drying and dehydration of materials and products in chemical, food, agricultural and sideline products, aquatic products, light industry, heavy industry and other industries. Such as API, traditional herbal, extract, powder, granule, drinking agent, packaging bottle, pigment, dye, vegetables, fruits and melons,

sausage, plastic resin, electrical components, baking paint, etc.

Description

sausage, plastic resin, electrical components, baking paint, etc.

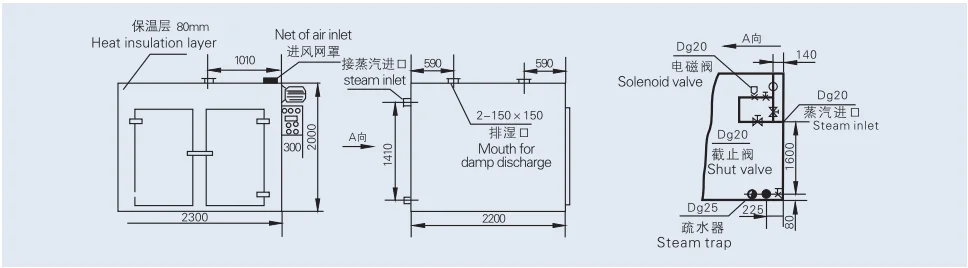

In drying process, fresh cold air is sucked into the drying chamber by the circulation fan and flows through the steam radiator or electrical heating tubes installed at the top to get required temperature. With the help of air distributor, the hot air evenly flows through each layer of trays for heat transfer and carries way the evaporated moisture. Most of the damp air flows back to the circulation fan for next drying circulation while part of the damp air is exhausted for energy saving. The drying process is batch type. When the drying is finished, open the chamber door and pull out the trolleys for unload the dried product.

1.Options of heat source: steam, electricity, or far infrared, or both steamelectricity.

| 24 trays hot air circulating drying oven | |||||||||

|

Industry Standard Models

|

Model

|

Drying

Capacity/batch

(kg)

|

Power

(kW)

|

Steam to be

consumed

(kg/h)

|

Heat Dissipation Area(㎡)

|

Air volume

(㎡/h)

|

Baking Trays

|

Overall Dimensions

(L*W*H)(mm)

|

Baking Car (set)

|

|

RXH-5-C

|

CT-C-0

|

25

|

0.45

|

9

|

10

|

3400

|

8

|

1400*1200*1600

|

1

|

|

RXH-14-C

|

CT-C-I

|

100

|

0.45

|

18

|

20

|

3450

|

48

|

2300*1200*2000

|

2

|

|

RXH-27-C

|

CT-C-II

|

200

|

0.9

|

36

|

40

|

6900

|

96

|

2300*2200*2000

|

4

|

|

RXH-41-C

|

CT-C-III

|

300

|

1.35

|

54

|

80

|

10350

|

144

|

2300*3220*2000

|

6

|

|

RXH-54-C

|

CT-C-IV

|

400

|

1.8

|

72

|

100

|

13800

|

192

|

4450*2200*2000

|

8

|

|

RXH-25-A

|

High-efficiency high-temperature far-infrared sterilization oven, power matching according to temperature requirements.

|

1200*1000*1600

|

24 trays hot air circulating drying oven Service before sell:

24 trays hot air circulating drying oven Service in sell:

24 trays hot air circulating drying oven Service after sell:

1.Can I use this machine to extract some raw materials?

Additional information

| Model Number | CT-C |

|---|---|

| Type | Tray Dryer |

| Application | Chemicals Processing, Plastics Processing, Food Processing |

| Condition | New |

| Place of Origin | Jiangsu, China |

| Brand Name | CSTECH |

| Voltage | 110V-380v |

| Power | 0.45kw-1.8kw |

| Dimension(L*W*H) | 1400*1200*1600-1200*1000*1600 |

| Key Selling Points | Easy to Operate |

| Warranty | 2 years |

| Weight (KG) | 2000 |

| Applicable Industries | Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Retail, Food Shop, Energy & Mining, Food & Beverage Shops, Other |

| Showroom Location | None |

| Marketing Type | Hot Product 2022 |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 2 years |

| Core Components | Motor, PLC, Other |

| Evaporation Capacity(kg/h) | 1-300 |

| Heating Method | Steam/Electricity/Far Infraded/Both Steam&Electricity |

| Material | SUS304, SUS304L, SUS316, SUS316L, Ti, Other |

| Product name | CT-C hot air circulating drying oven |

| Color | Silver |

| Advantage | Energy Saving |

| Capacity | 25-400KG/Batch |

| Temperature | 50-300℃ |

| Baking Car | 1-8sets |

| Tray Quantity | 8-192PCS |

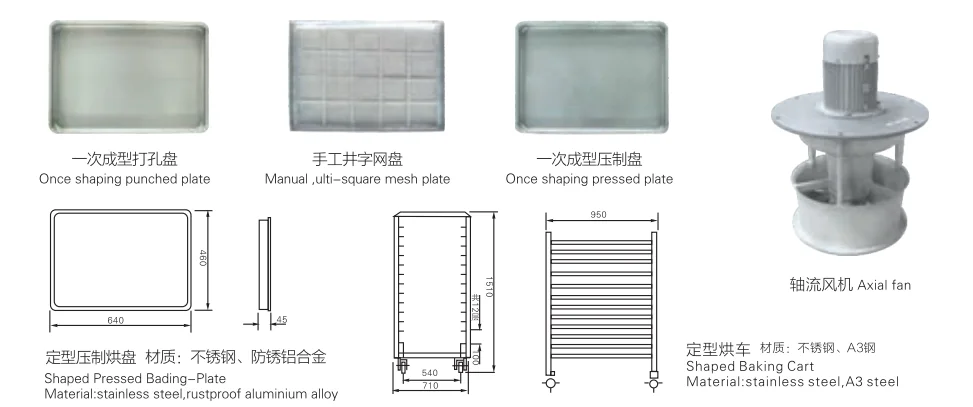

| Tray Size | 460*640*45mm/Customizable |

| Feature | Wide range of applications |

| Certification | ISO9001 |

Reviews

There are no reviews yet.