Showing 37–48 of 68 results

-

Product Keywords:Airflow DryerDescription:QG Series Pulse Air Flow Dryer is a large quantity production drier, it adopt instant drying principle, utilize hot air’s quick move to drive damp raw material and make it oats in the hot a ir, this can strengthen…

Product Keywords:Airflow DryerDescription:QG Series Pulse Air Flow Dryer is a large quantity production drier, it adopt instant drying principle, utilize hot air’s quick move to drive damp raw material and make it oats in the hot a ir, this can strengthen… -

SZG Series Conical Vacuum Dryer

Product Keywords:Double Cone Rotary Vacuum Dryer,Vacuum Dryer,Double Cone DryerDescription:Let heat source pass through the sealed Jacket The heat will be transmitted to raw material to be dried through inner shell,Under driving of power,the tank is rotated slowly and the raw material. -

High-Efficiency GFG Series acrylamide granules Fluidizing Dryer

Product Keywords:High-Efficiency Fluidizing Dryer,Fluidizing DryerDescription:Working Principle Purified and heated air is introduced from the bottom through suction fan and passed through the screen plate of raw material. In the work chamber, the state of fluidization is formed through stirring and negative…

-

Factory direct XF Series Fludizing Dryer for drying separated granule

Fluidizing drier is also called as fluidized-bed. It consists of air filter , heater ,fluidized-bed main machine, feeder , cyclone separator , cloth bag duster ,high-pressure centrifuge fan and operation table. Because the properties of raw materials exist dif ference, when equip the dust removing equipment, it should consider the practical need. It can select cyclone separator and cloth bag duster at the same time or one of them

-

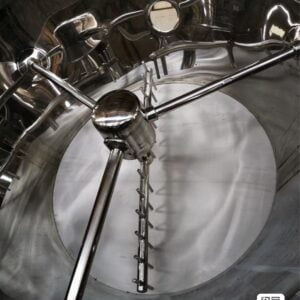

DZLG Single Conical Vacuum Dryer

Product Keywords:Single Conical Vacuum Dryer,Conical Vacuum Dryer

Description:Summary Verticalsingle-conical ribbon Mixer dryeris a multi-function fully enclosedvertical vacuum drying equipment integrating drying, crushing and powdermixing. Its drying efficiency is 3-5 times that of the “double cone rotaryvacuum dryer” of …

-

KJG Hollow Blade Dryer

Product Keywords:Hollow Blade Dryer,Blade DryerDescription:Applicable for drying or cooling of paste, particle, powder and slurry state of material, perform the process of drying, cooling, heating, sterilizing, reacting and combustion under low temperature. The special stirring and heating… -

China factory made CT Series 144 trays hot air circulating drying oven

144 trays hot air circulating drying oven adopts noise elimination and thermal stable axial flow fan and automatic temperature control system. The entire circulation system is enclosed to make that the heat efficiency of the drying oven increases from 3-7% of the traditional drying oven to 35-40% of the present one. The highest heat efficiency can be up to 50%. The successful design of CT-C hot air circulating oven makes that the hot air circulating drying oven in our country reach the advanced level in the world. It saves energy and increases the economic benefit. In 1990, the medical management bureau of the State issued the industry standard and the uniform type is RXH.

-

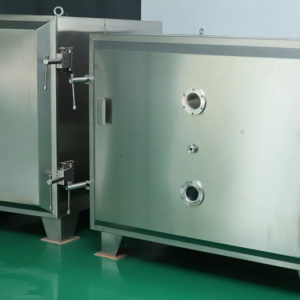

Hot Sale pharma industrial rotary drying machine FZG square static vacuum dryer

Product Keywords:Square Static Vacuum Dryer,Static Vacuum Dryer,Vacuum DryerDescription:Tt is well known that vacuum drying is to put raw material under the state of vacuum fo r heating and drying If use vacuum to pump air and humidity out,the dry speed will be faster. -

Energy Saving Dryer Powder Spray Drying

Energy Saving Dryer Powder Spray Drying Dryer Powder Spray Drying Product Overview Spray drying is the most widely used technology in liquid shaping and drying industry.Which is the most suitable for producing solid power or particle products from liquid material such as solution,emulsion,suspension and pumpable paste states.So if you want Particle size distribution,Residual moisture content,Bulk…

-

Factory Direct Sale Zpg Rotary Vacuum Rake Dryer

Factory Direct Sale Zpg Rotary Vacuum Rake Dryer is widely used in pharmaceutical industry, foodstuff industry, chemical industry and etc. Especially suitablefor the following materials:

1. Pulpiness, paste-like mixture or powder materials.

2.Thermal sensitive material which required to be dried at lower temperature.

3. Materials that are easy to oxidize or explode and the material that have strong irritative or toxic.

4.Materials that required recovering solvent. -

High speed Food Atomizer Centrifugal Spray Dryer

Food Atomizer Centrifugal Spray Dryer Food Atomizer Centrifugal Spray Dryer Product Overview Spray drying is the most widely used technology in liquid shaping and drying industry.Which is the most suitable for producing solid power or particle products from liquid material such as solution,emulsion,suspension and pumpable paste states.So if you want Particle size distribution,Residual moisture content,Bulk…

-

high efficiency Foodstuff Vacuum Drying Oven

high efficiency Foodstuff Vacuum Drying Oven FZG Vacuum Tray Dryer It is well known that vacuum drying is to put raw material under the state of vacuum for heating and drying. If use vacuum to pump air and humidity out, the dry speed will be faster. Note: If use condenser, the solvent in raw material…