Showing 37–47 of 47 results

-

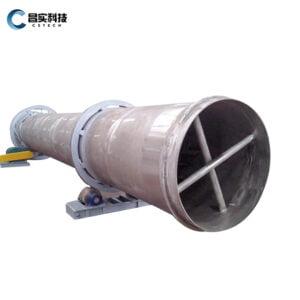

-300x300.jpg) Product Keywords:Rotary Drum Dryer,Rotary Dryer,Mining Drum DryerDescription:Wet material is loaded from one head of the dryer , and then it is stirred by the bafflers that is uniformly distributed in the barrel. Material is uniformly distributed and dispersed in the dryer , fully contact the hot air of parallel…

Product Keywords:Rotary Drum Dryer,Rotary Dryer,Mining Drum DryerDescription:Wet material is loaded from one head of the dryer , and then it is stirred by the bafflers that is uniformly distributed in the barrel. Material is uniformly distributed and dispersed in the dryer , fully contact the hot air of parallel… -

Good Price GMP Hot Air Circulating Oven For API Tray Dryer Industrial Drying Oven

Good Price GMP Hot Air Circulating Oven For API Tray Dryer Industrial Drying Oven 1.Options of heat source: steam, electricity, or far infrared, or both steamelectricity. 2. Hot Air Circulating Drying Oven Drying temperature: steam heating 50-130℃,Max.140℃. 3.Electricity and far infrared:50-300 ℃ .Automatic control system andcomputer control system on request.4.Commonly used steam pressure 0.2-0.8Mpa(2-8 bar). 5.For CT-C-I,electric heated, rated power consumption:15Kw,realconsumption:5-8Kw….

-

brand new design Industrial 24 trays hot air circulating drying oven

24 trays hot air circulating drying oven is a common type drying machine. Its application scope is wide, temperature is uniform, heat efficiency is high and operation is easy. It is suitable for heating, curing, drying and dehydration of materials and products in chemical, food, agricultural and sideline products, aquatic products, light industry, heavy industry and other industries. Such as API, traditional herbal, extract, powder, granule, drinking agent, packaging bottle, pigment, dye, vegetables, fruits and melons,

sausage, plastic resin, electrical components, baking paint, etc. -

High Speed Centrifugal Spray Dryer Instant Coffee Spray Dryer Milk Powder Spray Drying Machine

Product Keywords:High-Speed Centrifugal Spray Dryer,Centrifugal Spray Dryer,Spray DryerDescription:Spray drying is the technology most widely used in the liquid technology s haping and in the drying industry.The drying technology is most suitable for producing solid powder or particle products from liquid materials… -

High speed YPG Series Stainless Steel Detergent Pressure Nozzle Spray Dryer

High speed YPG Series Stainless Steel Detergent Pressure Nozzle Spray Dryer

YPG pressure spray dryer is suitable for solution, suspension, slurry, paste material, etc. Liquid material is atomized to small fog drops. And fog drops contact with hot air directly in the drying tower. Moisture content is evaporated instantly. So spray dryer features high efficiency, high mass transfer area, and short drying time, in general it is 5~30 seconds. Operating temperature can be adjusted according to actual situation, in general inlet air temperature is 150~500°C. And its automation control degree is control, environment solution environment can be solved. -

Hot sale XSG Series Revolving cassava flash vaporization dryer

XZG Series Spin Flash Dryer is continuous drying equipment specially designed for shaped cake, cream paste, and paste slurry materials. The clean heat medium goes into the drying room from the tangent direction and creates a strong rotary vortex air current when it’s in motion with the stirrer. The wet material is added to the drying room in a fixed quantity, and it will be crushed and dry under high speed stirring action. The top of the drying room has particle size classification, the big particles will be stopped by the classifier and the fine powder will be discharged from the center of the ring and collected by the cyclone separator. The big particles will return to the drying room and continue to be crushed and dry.

-

Centrifugal Spray Dryer With Dust Removal Device Atomizer Milk Powder Spray Dryer Price

Spray drying is the most widely used technology in liquid shaping and drying industry.Which is the most suitable for producing solid power or particle products from liquid material such as solution,emulsion,suspension and pumpable paste states.So if you want Particle size distribution,Residual moisture content,Bulk density and Particle shape must meet the precise standard,the spray drying is the best choice.

-

Atomizer Centrifugal Spray Spirulina Egg Liquid Dryer

Atomizer Centrifugal Spray Spirulina Egg Liquid Dryer Atomizer Centrifugal Spray Product Overview Spray drying is the most widely used technology in liquid shaping and drying industry.Which is the most suitable for producing solid power or particle products from liquid material such as solution,emulsion,suspension and pumpable paste states.So if you want Particle size distribution,Residual moisture content,Bulk…

-

Dryer Industrial Powder Spray Drying Machine

Industrial Powder Spray Drying Machine is the most widely used technology in liquid shaping and drying industry.Which is the most suitable for producing solid power or particle products from liquid material such as solution,emulsion,suspension and pumpable paste states.So if you want Particle size distribution,Residual moisture content,Bulk density and Particle shape must meet the precise standard,the spray drying is the best choice.

-

High Quality Dehydrator Machine Fruit Conveyor Hot Air Sea Fish Drying Machine Vegetable For Mesh Belt Dryer

The mesh belt dryer is a continuous production drying equipment. The main heating methods are electric heating, steam heating and hot air heating. The main principle is to spread the material evenly on the mesh belt. The mesh belt is made of 12-60 steel mesh belt, which is dragged by the transmission device to move back and forth in the dryer. The drying machine is discharged from the moisture exhaust hole to achieve the purpose of drying. The length of the box is composed of standard sections. In order to save space, the dryer can be made into a multi-layer type. 6-40m, effective width 0.6-3.0m.

-

Hot sale ZLG Series Rectilinear Vibrating Fludizing Dryer

Product Keywords:Vibration Fluidized Bed Dryer,Fluidized,Fluidized Bed DryerDescription:Raw mate rial is feed into the machine from equipment inlet and move forward continuously along with the horizontal direction under vibratory power. The hot air passes through fluidized-bed and exchange with raw materialsdamp…