Séchage par pulvérisation vs autres techniques de séchage 2025 Perspective

Le séchage est très important dans de nombreuses industries, Comme la nourriture et la médecine. Vous pourriez vous demander pourquoi la comparaison du séchage par pulvérisation à d'autres méthodes est important. Dans chaque sens a ses propres avantages, Mais le choix du meilleur affecte le coût, vitesse, et qualité du produit.

Par 2025, Les méthodes de séchage importeront encore plus. Pensez à ces changements dans l'industrie:

Utilisations de séchage des aliments 25% de l'énergie du monde, Donc, de meilleures méthodes sont nécessaires.

Les nouvelles idées se concentrent sur l'économie d'énergie et le fait d'être écologique.

La hausse des prix des combustibles fossiles fait que les industries utilisent des énergies renouvelables, comme le séchage solaire.

Ces raisons montrent pourquoi l'amélioration des méthodes de séchage est la clé pour l'avenir.

Principaux à retenir

Le séchage par pulvérisation fonctionne rapidement et bien, Idéal pour faire des poudres tout en gardant les nutriments.

Le séchage de gel garde le look et le goût des articles, Bon pour des choses délicates comme les vaccins et les fruits.

Le séchage de l'air est bon marché et facile mais plus lent, Mieux pour les petites tâches que les grandes usines.

Pensez à la consommation d'énergie et à la qualité des produits lors de la sélection d'un Méthode de séchage; Le séchage solaire est respectueux de l'environnement pour les petits emplois.

Découvrir nouveaux outils Comme l'IA et les systèmes d'économie de chaleur qui améliorent le séchage et aident l'environnement.

Aperçu des techniques de séchage

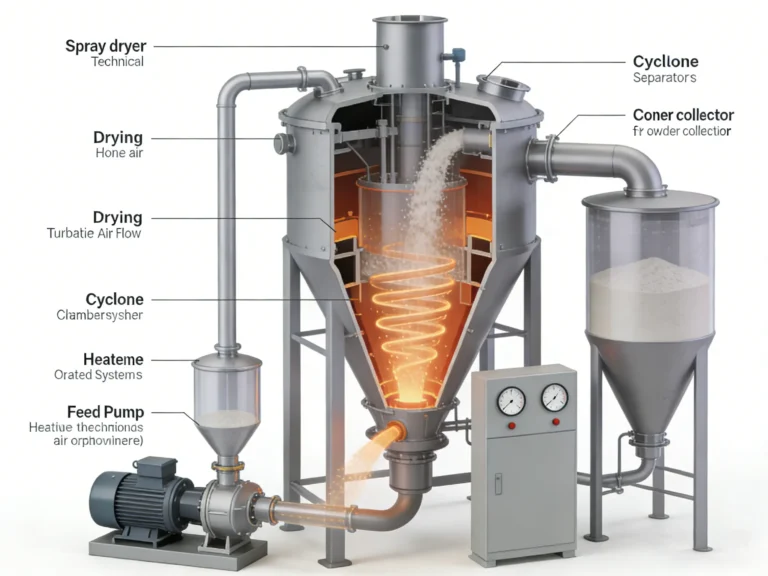

Séchage par pulvérisation: Comment ça marche

Le séchage par pulvérisation change les liquides en poudres. Il pulvérise liquide dans une chambre chaude. Le liquide se transforme en minuscules gouttes. Ceux-ci tombent secs rapidement à cause de la chaleur. Cette méthode maintient la qualité du produit. Industries comme la nourriture et la médecine Utilisez-le pour le lait en poudre et les médicaments.

Le séchage par pulvérisation fonctionne bien en fonction de certaines choses. Par exemple, La température de sortie est calculée à l'aide de cette formule:

$$ T_{texte{dehors}} = T_{texte{dans}} – fracter{{M_{texte{solde}} Temps partis( {1 – x_{texte{solides}} } droite) fois delta h_{texte{vapeur}} }}{{M_{texte{gaz}} fois C_{texte{p}} }} $$

Cela montre comment les débits et la chaleur affectent le séchage. Le séchage par pulvérisation est idéal pour les gros travaux. Il est rapide et économise de l'énergie.

Sèche: Un look détaillé

Sèche, ou lyophilisation, enlève l'eau en congelant. Alors, il utilise un vide pour sécher le produit. Cela maintient la forme et les nutriments du produit. Il est utilisé pour les vaccins et les fruits secs. Le séchage du gel prend plus de temps et d'énergie que le séchage par pulvérisation.

Les scientifiques utilisent des modèles pour améliorer le sèche. Par exemple, Le graphique ci-dessous montre comment les réseaux de neurones prédisent les résultats de séchage de gel:

Le graphique prouve que l'apprentissage en profondeur aide à améliorer le sèche. Cela aide les industries à rendre le processus plus efficace.

Séchage à l'air: Bases et applications

Le séchage de l'air est un moyen simple de sécher les aliments. Il utilise de l'air chaud ou naturel pour éliminer l'eau. Cette méthode est utilisée pour les fruits, légumes, et les herbes. Vous pouvez le voir lors du séchage des vêtements ou de l'utilisation d'un déshydrateur alimentaire.

Le séchage de l'air fonctionne mieux avec les bonnes conditions. Par exemple, garder l'humidité à 0.2 à 0.3 LB Eau / LB Air sec aider. Mais le séchage à l'air est plus lent que le séchage par pulvérisation et lyoph. Cela le rend moins utile pour les grandes usines.

Séchage de convection: Points principaux

Le séchage à la convection est un moyen courant d'éliminer l'eau. Il utilise la chaleur de l'air ou du gaz pour sécher les articles. Cette méthode est populaire dans les industries de l'alimentation et de la médecine.

Ce séchage fonctionne bien avec de nombreux produits. Par exemple, Les pommes de séchage diminuent leur acidité et leurs niveaux de sucre. Il change également leur couleur en plus rouge et jaune. La texture devient plus douce et moins ferme que les pommes fraîches. Ces changements font que les aliments séchés ont le goût et se sentent uniques.

La température est très importante dans ce processus. La chaleur plus élevée rend le séchage plus rapidement. À 30 ° C, Le taux de séchage est de 4,4 × 10⁻¹⁰ m² / s. À 60 ° C, il augmente à 1,4 × 10⁻⁹ m² / s. La vitesse de l'élimination de l'eau pousse également avec la chaleur, de 3,7 × 10⁻¹⁰ m / s à 7,4 × 10⁻⁹ m / s. Cela montre comment la chaleur améliore le séchage.

La consommation d'énergie est un autre facteur clé. Ça prend 34 KJ / Mol of Energy pour commencer à sécher. Les réseaux de neurones aident à prédire comment le séchage change les produits. Cela aide les industries à améliorer le processus pour de meilleurs résultats.

Le séchage à la convection est flexible et efficace. Il fonctionne avec de nombreux matériaux, Le rendre utile pour différents besoins.

Analyse comparative des techniques de séchage

Avantages du séchage par pulvérisation

Le séchage par pulvérisation présente de nombreux avantages pour les industries. Il aide les médicaments mal solubles à se dissoudre mieux dans le corps. Cela se fait en les transformant en dispersions solides. Des particules plus petites sont fabriquées, qui se dissolvent plus rapidement en raison de leur plus grande surface.

Cette méthode est rapide et efficace. Les liquides se transforment en poudres en quelques minutes seulement. Cela fonctionne bien pour la production à grande échelle. Le séchage par pulvérisation garde les nutriments intacts et peut gérer différents produits comme le lait en poudre et les médicaments.

Aspect | Description |

|---|---|

Aide les médicaments mal solubles à se dissoudre mieux en créant des dispersions solides. | |

Impact de la taille des particules | Des particules plus petites se dissolvent plus rapidement en raison de la surface plus grande. |

Versatilité | Fonctionne pour de nombreux produits, y compris la nourriture et la médecine. |

Inconvénients du séchage par pulvérisation

Le séchage par pulvérisation a aussi des inconvénients. L'équipement est coûteux, et l'exécution utilise beaucoup d'énergie. Cela rend difficile pour les petites entreprises de se permettre.

Un autre problème est les changements de texture. Tandis que les nutriments restent intacts, La texture de certains produits pourrait être modifiée. Des particules plus petites peuvent également causer des problèmes de fabrication, comme un mauvais flux et moins de compressibilité.

Désavantage | Description |

|---|---|

Coût élevé | L'équipement est cher et utilise beaucoup d'énergie. |

Altération de la texture | Peut changer la texture de certains produits. |

Défis de fabrication | De petites particules peuvent entraîner de mauvais problèmes de débit et de compressibilité. |

Séchage de gel vs séchage par pulvérisation: Différences clés

Le sèche-liaison et le travail de séchage par pulvérisation travaillent différemment et ont des résultats uniques. Le séchage par pulvérisation est plus rapide, terminer en quelques minutes, tandis que le séchage du gel prend beaucoup plus de temps. Le séchage par pulvérisation utilise moins d'énergie, l'améliorer pour les emplois à grande échelle.

Le séchage du gel est idéal pour garder la texture, saveur, et arôme. Il est souvent utilisé pour les vaccins et les aliments spéciaux. Mais le séchage au gel coûte plus cher et a besoin d'outils spéciaux, qui limite son utilisation dans certaines industries.

Méthode | Avantages | Désavantage |

|---|---|---|

Séchage par pulvérisation | – Peut changer de texture | |

– Garde les nutriments intacts | – Coût élevé | |

– Fonctionne pour de nombreux produits | – Besoin d'un équipement spécial | |

Sèche | – Longue durée de conservation | – Coût élevé |

– Maintient la saveur et l'arôme | – Besoin d'un équipement spécial | |

– Préserve les nutriments et la texture | ||

– Facile à stocker et à déplacer |

Les deux méthodes ont des avantages et des inconvénients. Choisissez en fonction de vos besoins, comme le coût, type de produit, et la qualité.

Séchage à l'air vs séchage par pulvérisation: Pour les avantages et les inconvénients

Le séchage à l'air et le séchage par pulvérisation sont utilisés pour différentes tâches. Le séchage à l'air est une méthode ancienne et simple. Il utilise de l'air chaud ou naturel pour éliminer l'eau. Cela fonctionne bien pour le séchage des fruits, légumes, et les herbes. Il est bon marché et a besoin de petit équipement. Mais, Le séchage de l'air est lent et peut ne pas garder les nutriments ou la texture ainsi que le séchage par pulvérisation.

Le séchage par pulvérisation est plus rapide et plus moderne. Il transforme les liquides en poudres en les pulvérisant en chaleur. Cette méthode est idéale pour les gros travaux et maintient les nutriments meilleurs. Le séchage par pulvérisation est souvent utilisé dans les industries de l'alimentation et de la médecine. Cependant, il a des inconvénients. Les machines sont coûteuses, Et le processus utilise beaucoup d'énergie.

Lorsque vous comparez les deux, Le séchage de l'air est meilleur pour les petits travaux ou économiser de l'argent. Le séchage par pulvérisation est le meilleur pour les industries qui ont besoin de vitesse, qualité, et efficacité.

Conseil: Utilisez le séchage par pulvérisation pour les articles délicats comme le lait en poudre ou les médicaments. Pour sécher des fruits ou des herbes à la maison, Le séchage de l'air est plus facile.

Séchage de convection vs séchage par pulvérisation: Une comparaison

Le séchage à la convection et le séchage par pulvérisation sont différents dans les résultats et les résultats. Le séchage à la convection utilise de l'air chaud ou du gaz pour éliminer l'eau. Il fonctionne avec de nombreux matériaux comme la nourriture et la médecine. Cette méthode économise de l'énergie et gère de grandes quantités. Mais, il peut changer la texture et le goût des produits. Ce n'est pas bon pour les articles sensibles à la chaleur.

Le séchage par pulvérisation est meilleur pour garder en sécurité les produits sensibles à la chaleur. C'est plus rapide et fait même des poudres, Parfait pour les industries précises. Toujours, Le séchage par pulvérisation coûte plus cher et utilise plus d'énergie.

Facteurs clés à considérer

Coût et efficacité énergétique

Lorsque vous choisissez une méthode de séchage, Coût et consommation d'énergie. Séchage par pulvérisation est idéal pour les gros travaux mais a besoin de beaucoup d'énergie. Il nécessite également des machines coûteuses. Sèche utilise encore plus d'énergie car cela prend plus de temps. Séchage à l'air et séchage de convection sont moins chers mais peuvent ne pas donner la même qualité.

Séchage solaire est une option pour les petites tâches pour les petites tâches. Par exemple, Un séchoir solaire coûte 42 037,45 ₹ chaque année. Il se paie dans 1.6 ans pour les courges de bouteille et 2 ans pour les tomates. Cela en fait un bon choix pour sécher les fruits et légumes. Les séchoirs de convection naturels sont également efficaces, avec 61.78% efficacité exergétique. Ces chiffres montrent pourquoi les méthodes d'économie d'énergie sont importantes dans 2025.

Impact sur la qualité du produit

Garder les nutriments et la saveur est essentiel lors du choix d'une méthode de séchage. Sèche est le meilleur pour garder la texture, couleur, et nutriments. Par exemple, Les articles lyophilisés restent vert clair et ressemblent à des fraîches. Séchage par pulvérisation Garde également bien les nutriments, Le rendre idéal pour les médicaments et les aliments en poudre.

D'autre part, séchage à l'air et séchage du soleil peut assombrir les couleurs et changer les textures. Le séchage du soleil économise de l'énergie mais peut provoquer des formes inégales et moins de nutriments. Séchage au micro-ondes est plus rapide mais peut endommager la structure cellulaire. La méthode de séchage que vous choisissez affecte la conservation des nutriments et des saveurs, ce qui est important pour les clients satisfaits.

Teneur en humidité | Couleur de biomasse | Description de la morphologie cellulaire | Consommation d'énergie (kWh / kg) | |

|---|---|---|---|---|

Sèche | Faible | Vert clair | Comme les cellules fraîches (10 μm) | 45.75 |

Séchage à l'air | Faible | Vert foncé | Taille normale, moins de vésicules | N / A |

Séchage du soleil | Le plus bas | Orange | Forme inégale, taille plus petite | 0.01–0.1 |

Séchage au micro-ondes | Le plus élevé | Vert foncé | Cellules plus petites, Pas de vésicules | 26.2–34.9 |

Applications spécifiques à l'industrie

Différentes industries Besoin de méthodes de séchage différentes. Séchage par pulvérisation est populaire dans la nourriture et la médecine car il fait des poudres de tailles exactes et de niveaux d'humidité. Il est particulièrement utile pour les médicaments où les nutriments et les ingrédients actifs doivent rester intacts.

Séchoirs rotatifs sont utilisés dans l'exploitation minière pour sécher de grandes quantités de matériaux. Sèche-linge sont éconergétiques et secs uniformément, les rendre communs dans la nourriture et la médecine. Le Sèche-linge en deux étapes, avec sur 48% part de marché, offre un meilleur contrôle. Cela fonctionne bien pour les produits chimiques, produits de beauté, et boissons. Sa production élevée et ses économies d'énergie en font un choix de premier plan pour les industries qui ont besoin d'options abordables.

Conseil: Pensez aux besoins de votre industrie, comme le type de produit et la taille du travail, Avant de choisir une méthode de séchage.

Considérations environnementales et de durabilité

Avez-vous réfléchi à la façon dont le séchage affecte l'environnement? Dans 2025, Les industries visent à économiser de l'énergie et à réduire les émissions de carbone. Ils veulent également conserver des produits de haute qualité. Choisir le droit Méthode de séchage Aide à atteindre ces objectifs.

Différentes méthodes de séchage ont un impact sur l'environnement de manière unique. Séchage par pulvérisation utilise beaucoup d'énergie mais est rapide pour les gros travaux. Sèche prend encore plus d'énergie car c'est plus lent. Séchage à l'air et séchage de convection utiliser moins d'énergie mais peut ne pas garder les nutriments ou la qualité également.

Les experts utilisent des outils pour mesurer la durabilité. Le Indice de durabilité (ET) montre à quel point l'énergie est utilisée. Le Facteur d'impact environnemental (Eif) mesure les dommages causés par la perte d'énergie. Les nombres EIF inférieurs signifient une meilleure durabilité. Les autres outils incluent le Ratio d'énergie des déchets (Nous sommes) pour les déchets d'énergie et Potentiel d'amélioration (IP) Pour les idées d'économie d'énergie.

Voici un tableau comparant les données environnementales pour les méthodes de séchage:

Métrique | Cas 1 | Cas 2 | Cas 3 |

|---|---|---|---|

Période de récupération de l'énergie (années) | 3.09 | 2.49 | 1.82 |

Émissions annuelles de CO2 (kg / an) | 137.37 | 136.48 | 132.69 |

Potentiel d'atténuation du CO2 (tonnes / an) | 81.85 | 83.93 | 83.97 |

Ces chiffres montrent que l'économie d'énergie abaisse les émissions et le temps de récupération. Par exemple, Le séchage solaire a moins d'impact et un remboursement plus rapide que les méthodes plus anciennes.

Garder les nutriments fait également partie de la durabilité. Sèche Garde mieux les nutriments mais utilise plus d'énergie. Séchage par pulvérisation équilibre la consommation d'énergie et la préservation des nutriments, le rendre populaire dans la nourriture et la médecine. Séchage à l'air et séchage de convection utiliser moins d'énergie mais peut perdre plus de nutriments.

Conseil: Choisissez une méthode de séchage qui permet d'économiser de l'énergie, garde les nutriments, Et correspond à vos besoins.

Tendances futures des technologies de séchage

Nouvelles idées en séchage par pulvérisation

Le séchage par pulvérisation s'améliore avec la nouvelle technologie. CFD Aide à comprendre comment l'air se déplace dans les chambres de pulvérisation. Cela facilite la définition des meilleures conditions de séchage. Il aide également à maintenir mieux les nutriments et la qualité des produits. Des études montrent que l'évolution des formes de la chambre et la baisse de la pression peuvent économiser de l'énergie. Ces idées aident les industries à fabriquer plus de produits tout en utilisant moins de puissance.

Une autre idée cool est le séchage à plusieurs étapes. Il protège les articles sensibles à la chaleur comme la nourriture et les médicaments. Le sèche-lèvre de pulvérisation devient également populaire. Il mélange le séchage par pulvérisation et le sèchet pour maintenir la texture et les nutriments.

Les outils intelligents font désormais partie du séchage par pulvérisation. Les sécheuses Wi-Fi et les applications téléphoniques facilitent le contrôle. Ces outils économisent de l'énergie et fonctionnent plus rapidement. Ils répondent également au besoin de solutions écologiques.

Améliorations du séchage de congé

Le séchage du gel s'est amélioré récemment. Ajout NaCl aux produits abaissent humidité à sous 1%. Cela rencontre OMS Règles pour garder les articles stables. OMS Les études montrent que ces produits ont des pores ouverts. Cela aide l'eau à partir plus rapidement et maintient l'humidité bas.

Automation est un grand changement dans le séchage de gel. Les machines réglaient désormais les paramètres par eux-mêmes. Cela rend les résultats plus cohérents et réduit les erreurs. Nouveau idées d'économie d'énergie Coupe également les coûts tout en gardant une qualité de haute qualité.

Nouvelles méthodes de séchage dans 2025

Dans 2025, Les méthodes de séchage deviennent plus intelligentes. IA aide à améliorer le séchage en définissant les meilleures conditions. Les outils d'IA vérifient rapidement les données pour contrôler l'humidité et la consommation d'énergie.

Économiser de l'énergie est très important. Les systèmes de séchage à énergie solaire deviennent populaires. Ils utilisent l'énergie du soleil et sont parfaits pour les petits travaux.

Gérer les plus gros travaux est également un objectif. Les nouvelles méthodes peuvent sécher plus d'articles sans perdre de qualité. Ceci est utile pour les industries de l'alimentation et de la médecine. Ces nouvelles idées changeront la façon dont le séchage est fait à l'avenir.

Durabilité et efficacité énergétique dans le séchage

La durabilité et l'énergie d'économie sont très importantes aujourd'hui. Différentes méthodes de séchage utilisent l'énergie de différentes manières. Choisir le bon économise des ressources et maintient les produits du bien.

Le séchage solaire devient de plus en plus populaire. Il utilise l'énergie du soleil au lieu de combustibles fossiles. Par exemple, Les séchoirs solaires peuvent sécher les fruits et légumes à bas prix. Cette méthode réduit la pollution et économise de l'argent.

L'amélioration des anciens systèmes aide également l'environnement. Les outils intelligents comme l'IA peuvent ajuster instantanément les paramètres de séchage. Ces outils arrêtent les déchets d'énergie et améliorent le séchage. Par exemple, L'IA peut dire combien de temps un produit doit sécher, Économiser de l'énergie supplémentaire.

Les systèmes de récupération de chaleur sont une autre excellente idée. Ils collectent la chaleur du séchage et l'utilisent à nouveau. Cela réduit la consommation d'énergie et économise de l'argent pour les industries.

Conseil: Choisissez des méthodes de séchage qui permettent d'économiser de l'énergie et de maintenir la qualité élevée. Aider la planète aide également votre entreprise à se développer.

Dans 2025, Économiser de l'énergie dans le séchage n'est pas seulement intelligent - il est nécessaire. L'utilisation de meilleures méthodes aide la Terre et répond aux besoins de l'industrie.

Le séchage par pulvérisation est rapide et fonctionne bien pour les gros travaux. Il garde les nutriments tout en étant efficace. Le séchage du gel est plus lent mais maintient la texture et dure plus longtemps. La sélection entre eux dépend du coût, énergie, et les besoins de qualité.

De nouvelles idées de séchage s'améliorent. Le séchage solaire utilise le soleil pour économiser de l'énergie. Les outils d'IA aident à rendre le séchage plus intelligent et plus efficace. Ces changements visent à économiser de l'énergie et à garder les produits frais plus longtemps.

FAQ

Ce qui rend le séchage par pulvérisation meilleur que les autres méthodes?

Séchage par pulvérisation est beaucoup plus rapide que d'autres façons. Il transforme les liquides en poudres en quelques minutes seulement. Cela le rend idéal pour faire rapidement de grandes quantités. Il donne également une qualité constante, ce qui est important pour les industries de l'alimentation et de la médecine.

Le lyoph?

Oui, Le sèche-ligodie conserve les nutriments, texture, et la saveur très bien. Il gèle d'abord les articles, les aider à rester près de leur état d'origine. C'est pourquoi c'est génial pour des choses délicates comme les fruits, légumes, et vaccins.

Le séchage à l'air est-il moins cher que le séchage par pulvérisation?

Le séchage à l'air coûte moins cher car il utilise des outils simples et de l'air chaud. Mais cela prend plus de temps et peut ne pas garder les nutriments aussi. Le séchage par pulvérisation coûte plus cher mais fonctionne plus vite et maintient une meilleure qualité.

Le séchage solaire peut-il remplacer les méthodes plus anciennes?

Le séchage solaire est bon pour les petits travaux comme le séchage des fruits ou les herbes. Il utilise l'énergie du soleil, ce qui économise de l'argent et aide l'environnement. Mais ce n'est pas aussi bon pour les grandes tâches industrielles que le séchage par pulvérisation ou lyophilisation.

Quelle méthode de séchage permet d'économiser le plus d'énergie?

Le séchage à l'air et le séchage solaire utilisent la moindre énergie. Le séchage par pulvérisation et le sèche-ligodie ont besoin de plus d'énergie mais donnent de meilleurs résultats. Choisissez une méthode en fonction de vos besoins, comme le coût, consommation d'énergie, et la qualité.

Conseil: Pensez à votre produit et à votre budget avant de choisir une méthode de séchage.

Un Commentaire