Comment fonctionne un sèche-laisseur dans des applications industrielles

Un séchoir par pulvérisation transforme un liquide en poudre sèche en le pulvérisant dans un courant d'air chaud. Vous voyez ce processus en action lorsque les industries doivent créer des produits comme le lait en poudre ou le café instantané rapidement et efficacement.. De nombreux secteurs s'appuient sur cette technologie, y compris:

Industrie chimique

Industrie de la céramique

Quand vous apprenez comment fonctionne un séchoir par pulvérisation, ou un sèche-linge par pulvérisation, comment ça marche, vous comprendrez pourquoi cela reste essentiel pour produire des poudres à partir de liquides à grande échelle.

Principaux à retenir

Un séchoir par pulvérisation transforme rapidement les liquides en poudres sèches en les pulvérisant dans de l'air chaud, ce qui le rend essentiel pour l'alimentation, médecine, et production chimique.

Le processus comprend la préparation de l'aliment liquide, en l'atomisant en minuscules gouttelettes, séchage à l'air chaud, évaporation rapide de l'humidité, et collecter la poudre efficacement.

Contrôler la taille des gouttelettes, température de séchage, et le flux d'air aide à produire des poudres de la bonne taille, forme, et l'humidité, protéger les ingrédients sensibles.

Le séchage par pulvérisation est rapide, séchage économique avec une qualité constante, mais nécessite un contrôle minutieux pour éviter des problèmes comme une poudre collante ou un séchage inégal.

Cette technologie prend en charge de nombreux produits comme le lait en poudre, café instantané, médicaments, et les détergents, rendre les poudres faciles à stocker, transport, et utiliser.

Qu'est-ce qu'un séchoir par pulvérisation?

Définition

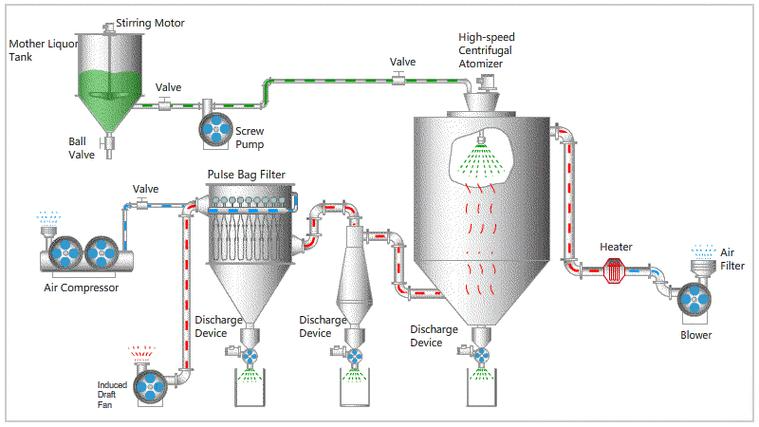

Un séchoir par pulvérisation est une machine qui vous aide à transformer un liquide en poudre sèche en quelques secondes seulement.. Vous commencez avec un aliment liquide, comme une solution ou une bouillie. Le séchoir par pulvérisation utilise une pompe pour déplacer ce liquide dans un atomiseur. L'atomiseur brise le liquide en minuscules gouttelettes, créant une fine brume. Ces gouttelettes pénètrent dans une grande chambre remplie d'air chaud ou de gaz, généralement chauffé à températures entre 200°C et 250°C. Quand les gouttelettes rencontrent l'air chaud, ils sèchent presque instantanément. L'eau ou tout autre liquide à l'intérieur des gouttelettes s'évapore, laissant derrière lui petit, particules sèches.

Vous trouverez plusieurs pièces importantes dans un séchoir par pulvérisation. Ceux-ci comprennent un aérotherme, un atomiseur (qui peut être une buse ou un disque tournant), une chambre de séchage, et un système pour récupérer la poudre sèche. Les ventilateurs déplacent l'air à travers le système, et des filtres spéciaux ou cyclones séparent la poudre de l'air. Le processus crée des poudres avec taille et forme contrôlées, souvent entre 1 et 50 micromètres. Ce contrôle vous aide à obtenir le type exact de poudre dont vous avez besoin pour votre produit.

Un séchoir par pulvérisation vous permet de produire des poudres sèches rapidement et avec une qualité constante, ce qui en fait un outil clé dans de nombreux secteurs.

But

Vous utilisez un séchoir par pulvérisation lorsque vous devez transformer efficacement un liquide en poudre. Les principaux objectifs comprennent:

Fabriquer des poudres fines à partir de liquides en une seule étape.

Contrôler la taille et l'humidité de chaque particule de poudre.

Protéger les produits sensibles à la chaleur des dommages pendant le séchage.

Créer des poudres de forme et de porosité uniformes.

Le séchage par pulvérisation fonctionne bien pour les produits qui doivent rester stables et faciles à manipuler, comme le lait en poudre, café instantané, ou un médicament. Vous pouvez également l’utiliser pour les produits chimiques et les matériaux avancés. Le processus vous aide à économiser du temps et de l’énergie, tout en vous offrant un produit répondant à des normes de qualité strictes. Le séchage par pulvérisation reste populaire car il vous offre flexibilité et contrôle., quel que soit le secteur dans lequel vous travaillez.

Processus de séchage par pulvérisation

Le séchage par pulvérisation est un moyen rapide et efficace de transformer un liquide en poudre sèche.. Vous pouvez voir comment un séchoir par pulvérisation fonctionne en suivant chaque étape du processus. Chaque étape joue un rôle clé pour garantir que vous obtenez une poudre de haute qualité, surtout lorsque vous travaillez avec des matériaux sensibles à la chaleur.

Préparation

Vous démarrez le processus de séchage par pulvérisation en préparant l'aliment. L'aliment doit être liquide, comme une solution, suspension, ou coller. Vous devez vous assurer que l'alimentation est homogène, pompable, et exempt d'impuretés. Parfois, toi concentrer l'aliment ou le filtrer pour éliminer les contaminants et augmenter la teneur en matières solides. Cette étape vous aide à améliorer l’efficacité du séchage et garantit que l’aliment est adapté à l’atomisation..

Préparer l'aliment sous forme liquide.

Concentrer ou filtrer les aliments pour augmenter les matières solides et éliminer les impuretés.

Les agents porteurs présents dans l'aliment aident à protéger les ingrédients sensibles, comme les saveurs, huiles, probiotiques, et vitamines, pendant le séchage.

Une bonne préparation des aliments vous donne une meilleure qualité de poudre et aide le séchoir par pulvérisation à fonctionner en douceur.

Atomisation

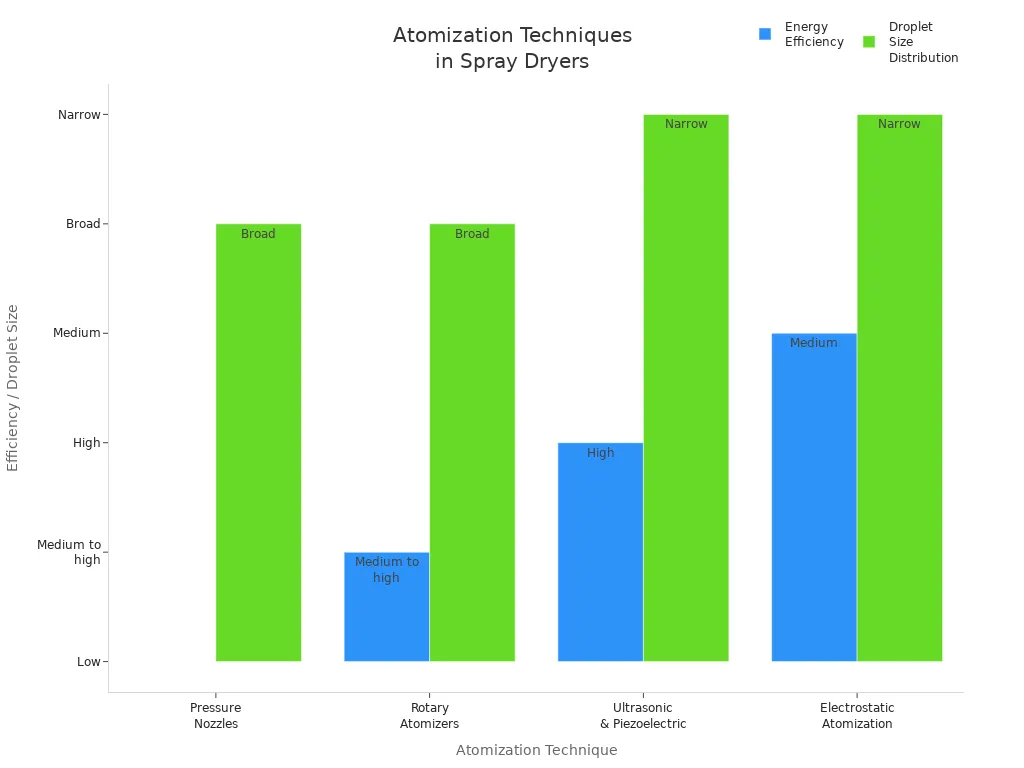

Suivant, vous atomisez l'alimentation liquide. L'atomisation brise le liquide en minuscules gouttelettes, créant une fine brume. Cette étape est cruciale car la taille des gouttelettes affecte la rapidité avec laquelle l'aliment sèche et à quoi ressemble la poudre finale. Vous pouvez utiliser différentes méthodes d'atomisation, comme les buses à pression, atomiseurs rotatifs, buses à ultrasons, ou atomisation électrostatique.

Distribution de la taille des gouttelettes | Efficacité énergétique | Gère les liquides visqueux | |

|---|---|---|---|

Buses à pression | Large | Faible | Limité |

Atomiseurs rotatifs | Large | Moyen | Bien |

Buses à ultrasons | Étroit | Haut | Approprié |

Buses piézoélectriques | Étroit | Haut | Approprié |

Électrostatique | Étroit | Moyen | Approprié |

La plupart des gouttelettes vont de 5 à 20 micromètres en diamètre, mais la taille peut varier en fonction de l'équipement et des réglages. Les plus petites gouttelettes sèchent plus rapidement et vous aident à protéger les produits sensibles à la chaleur.

Chambre de séchage

Après atomisation, les gouttelettes entrent dans la chambre de séchage. Ici, vous introduisez un courant d'air chaud ou de gaz. Le la température à l'intérieur de la chambre varie généralement de 105°C à 200°C, mais vous pouvez utiliser des températures plus basses (jusqu'à 60°C) pour systèmes à vide. Le flux d’air est soigneusement contrôlé, souvent vers 1.5 mètres cubes par minute, et la température reste précise à ±1°C. Ce contrôle vous aide à protéger les matériaux sensibles à la chaleur contre les dommages.

L'air chaud rencontre les gouttelettes et démarre le processus de séchage. La conception de la chambre garantit que l'air le plus chaud touche en premier les gouttelettes les plus humides., ce qui évite la surchauffe des particules déjà séchées.

Évaporation

À l'intérieur de la chambre, une évaporation rapide se produit. Les minuscules gouttelettes ont une grande surface, ainsi l'humidité s'évapore rapidement lorsqu'elle rencontre l'air chaud. Ce séchage rapide est important pour les produits qui peuvent se décomposer ou perdre en qualité s'ils sont exposés trop longtemps à la chaleur..

L'évaporation rapide raccourcit le temps de séchage et réduit l'exposition à la chaleur.

Le processus préserve la qualité, activité biologique, et valeur nutritionnelle des ingrédients sensibles.

Flux d'air à co-courant (où l'air et les gouttelettes se déplacent dans la même direction) aide à éviter la surchauffe.

L'évaporation rapide est l'une des raisons pour lesquelles le séchage par pulvérisation fonctionne si bien pour les aliments, médicaments, et autres produits délicats.

Collection

Enfin, vous récupérez la poudre sèche de l'air. Les méthodes de collecte les plus courantes sont les séparateurs cycloniques et les filtres à manches..

Les séparateurs cycloniques utilisent la force centrifuge pour séparer la poudre de l'air.

Les filtres à manches piègent toutes les particules fines restantes avant de libérer de l'air propre.

Méthode de collecte | Description |

|---|---|

Utilise la force centrifuge pour séparer la poudre séchée de l'air évacué; la poudre s'accumule au fond. | |

Filtre à manches | Élimine les particules de poudre restantes en faisant passer l'air évacué à travers des sacs filtrants, libérer de l'air pur. |

Utilisation combinée | Les grands séchoirs par pulvérisation utilisent souvent à la fois des séparateurs cycloniques et des filtres à manches en tissu pour une collecte efficace de la poudre.. |

Recyclage des amendes | Les fines particules séparées par des cyclones ou des filtres à manches peuvent être recyclées dans la chambre de séchage ou dans les lits fluidisés pour contrôler l'agglomération et améliorer la qualité de la poudre.. |

Vous pouvez vous attendre à récupérer plus de 80% de votre produit dans le premier lot, et avec un bon contrôle des processus, les rendements peuvent atteindre plus 90%. De la poudre peut adhérer aux parois de la chambre, mais vous pouvez le récupérer avec des étapes supplémentaires si nécessaire.

La nature en une seule étape du séchage par pulvérisation le rend efficace et fiable pour la production à grande échelle.

En comprenant chaque étape, vous voyez comment le séchoir par pulvérisation fonctionne pour transformer rapidement les liquides en poudres, sans risque, et de haute qualité.

séchoir par pulvérisation comment ça marche

Présentation étape par étape

Vous pouvez comprendre le fonctionnement du séchoir par pulvérisation en examinant chaque étape du processus.. Chaque étape joue un rôle dans la transformation de votre aliment liquide en poudre sèche. Voici un clair, aperçu étape par étape:

Préparation des aliments: Vous commencez par préparer votre aliment liquide. Ajuster la concentration, viscosité, et la température afin que l'aliment réponde aux exigences du séchage par pulvérisation.

Atomisation: Vous utilisez un atomiseur pour briser le liquide en fines gouttelettes. Cette étape contrôle la taille des particules et la vitesse à laquelle elles sèchent..

Contact gouttelette-air: Les gouttelettes entrent dans la chambre de séchage et rencontrent de l'air chaud. Ce contact déclenche le transfert de chaleur et de masse nécessaire au séchage.

Évaporation de l'humidité: L'air chaud provoque une évaporation rapide de l'humidité des gouttelettes. La grande surface de chaque gouttelette contribue à accélérer ce processus.

Formation de particules: Alors que l'humidité s'en va, les solides dans les gouttelettes forment des particules de poudre. Ceux-ci peuvent être solides, creux, ou même poreux, en fonction de vos paramètres.

Séparation des particules: Les particules séchées se séparent de l'air à l'aide de dispositifs comme des cyclones ou des filtres.

Collection de produits: Vous récupérez la poudre finale. Parfois, vous le traitez davantage en l'agglomérant ou en l'emballant.

Lorsque vous suivez ces étapes, vous voyez comment le séchoir par pulvérisation fonctionne pour créer des poudres de manière efficace et de haute qualité.

Facteurs clés

Plusieurs facteurs clés affecter la façon dont le séchoir par pulvérisation fonctionne dans votre opération. Prêter attention à ces points vous aide à obtenir la meilleure qualité et cohérence du produit.:

Température de séchage, y compris la température de l'air entrant et sortant de la chambre, a un grand impact sur la qualité de votre produit.

L'humidité du gaz de séchage modifie l'humidité laissée dans votre poudre et peut affecter la façon dont les particules collent ensemble..

Taille des gouttelettes, que vous contrôlez pendant l'atomisation, décide de la taille et de la qualité finales des particules.

La vitesse d'alimentation et les modifications des propriétés de votre flux peuvent rendre votre produit plus ou moins cohérent..

Problèmes mécaniques, tels que des fuites de buses ou des dommages, peut modifier le motif de pulvérisation et causer des problèmes de taille des particules.

Le cyclone ou le filtre que vous utilisez pour la collecte de la poudre affecte la taille et la qualité de votre poudre., surtout si vous souhaitez des particules fines ou fragiles.

Systèmes de surveillance et de contrôle, comme les capteurs de température et de pression, vous aider à maintenir le processus stable et lié à la qualité du produit.

Surveillance en temps réel, comme mesurer la taille des particules pendant le séchage, vous permet de détecter les problèmes rapidement et de vous adapter rapidement.

Une approche basée sur les risques vous aide à vous concentrer sur les points les plus importants pour maintenir la cohérence et la haute qualité de votre produit..

Conseil: Vous pouvez améliorer vos résultats en vérifiant souvent ces facteurs et en utilisant des systèmes de contrôle pour que votre séchoir par pulvérisation continue de fonctionner au mieux..

Composants clés

Atomiseur

L'atomiseur est le cœur de votre atomiseur. Il brise votre alimentation liquide en minuscules gouttelettes, qui sèche ensuite en poudre. Vous pouvez choisir parmi différents types d'atomiseurs, chacun avec ses propres atouts. Le le tableau ci-dessous montre les principaux types et leurs avantages:

Type d'atomiseur | Avantage(s) |

|---|---|

Atomiseurs à buse | Produire des particules de plus petite taille |

Atomiseurs à disque rotatif | Convient pour manipuler des aliments plus épais |

Quand tu régler la vitesse de l'atomiseur, vous contrôlez la taille des gouttelettes. Des vitesses plus élevées créent des gouttelettes plus petites. Ces petites gouttelettes sèchent plus rapidement et forment des poudres de formes différentes, comme des particules creuses ou poreuses. Si vous ralentissez l'atomiseur, vous obtenez des gouttelettes plus grosses, qui sèchent plus lentement et peuvent modifier la texture de votre poudre. En changeant la vitesse de l'atomiseur, vous pouvez affiner la taille du produit final, forme, et la densité.

Conseil: Utilisez le bon atomiseur et la bonne vitesse pour répondre aux besoins de votre produit et obtenez la meilleure qualité de poudre.

Chambre de séchage

La chambre de séchage est l'endroit où vos gouttelettes rencontrent l'air chaud et se transforment en poudre. Vous trouverez plusieurs modèles, comme le co-courant, contre-courant, et chambres à flux mixtes. La plupart des chambres ont une grande, corps rond avec un fond en forme de cône. Le le rapport hauteur/diamètre varie généralement de 1:1 à 5:1. L'acier inoxydable est courant pour les aliments et les médicaments, tandis que les alliages spéciaux fonctionnent mieux pour les produits chimiques agressifs. À l'intérieur, les déflecteurs et les guides aident l'air à circuler en douceur. Isolation, souvent 100 à 200 mm d'épaisseur, garde la chaleur à l'intérieur. Les surfaces lisses facilitent le nettoyage et empêchent la poudre de coller. Vous pouvez également voir des fonctionnalités telles que des panneaux de secours contre les explosions, lunettes de vue, et systèmes de nettoyage sur place.

Note: Une bonne conception de la chambre vous aide à éviter que la poudre ne colle aux parois et à garder votre produit en sécurité et au sec.

Système pneumatique

Le le système d'air contrôle la température et l'humidité à l'intérieur de votre séchoir par pulvérisation. L'air sec est important car une humidité élevée peut faire coller la poudre et réduire votre rendement.. Les déshumidificateurs éliminent l'humidité de l'air avant qu'elle n'entre dans la chambre. Les radiateurs réchauffent ensuite l’air à la bonne température. Les ventilateurs poussent et aspirent l'air à travers le système, en gardant un débit constant et un léger vide. Vous pouvez ajuster la température de l'air ou le débit d'alimentation pour maintenir les conditions de séchage stables. Ce contrôle minutieux vous aide à produire une poudre avec la bonne humidité et la bonne texture à chaque fois..

Les déshumidificateurs améliorent la qualité de la poudre et réduisent la consommation d'énergie.

L'air sec continu maintient un séchage rapide et empêche l'agglutination.

Un bon contrôle de l'air prolonge la durée de conservation de votre poudre.

Système de collecte

Après séchage, tu dois récupérer ta poudre. Les systèmes les plus courants sont séparateurs cycloniques et filtres à manches. Les séparateurs cycloniques font tourner l’air, utiliser la force centrifuge pour extraire la poudre. Ils fonctionnent bien pour les particules fines et nécessitent peu d'entretien. Les filtres à manches capturent des particules encore plus petites, en vous assurant de ne pas perdre de produit précieux. Les deux systèmes permettent à l'air pur de s'échapper tout en protégeant votre poudre.. Cette configuration vous aide à obtenir un rendement élevé et une qualité de poudre constante.

Souviens-toi: De bons systèmes de collecte vous aident à économiser le produit et à assurer le bon fonctionnement de votre séchoir par pulvérisation.

Applications

Industrie alimentaire

Le séchage par pulvérisation est utilisé dans de nombreux aliments que vous mangez quotidiennement.. Ce processus vous aide à transformer des liquides en poudres rapidement et en toute sécurité. Vous pouvez trouver des produits séchés par pulvérisation dans votre cuisine et votre épicerie. Quelques exemples courants incluent:

Café instantané

Lait en poudre

Préparation pour nourrissons

Ingrédients alimentaires

Nutraceutiques

Vitamines

Séchage par pulvérisation élimine l'humidité de la nourriture, ce qui vous aide à conserver ces poudres pendant longtemps sans les abîmer. Vous obtenez également des poudres qui se dissoudre facilement dans l'eau, ce qui les rend parfaits pour les boissons et les mélanges. Le processus vous permet contrôler la taille et la forme de chaque particule, donc tu deviens doux, poudres fluides. Vous pouvez protéger les nutriments et les arômes sensibles car le séchage par pulvérisation utilise de courtes bouffées de chaleur.. Cela signifie que les vitamines et les probiotiques restent actifs et frais.

Conseil: Le séchage par pulvérisation est idéal pour les aliments qui nécessitent une longue durée de conservation et un mélange rapide, comme les soupes instantanées et les boissons en poudre.

Médicaments

Vous comptez sur le séchage par pulvérisation pour fabriquer de nombreux médicaments modernes. Le processus vous aide à créer des poudres pour comprimés, gélules, et inhalateurs. Vous pouvez utiliser le séchage par pulvérisation pour améliorer la façon dont votre corps absorbe certains médicaments., surtout ceux qui ne se dissolvent pas facilement dans l'eau. Voici quelques produits pharmaceutiques fabriqués par séchage par pulvérisation:

Dispersions solides amorphes pour une meilleure absorption des médicaments

Médicaments inhalables comme l'insuline en poudre

Microcapsules pour médicaments à libération contrôlée

Formulations au goût masqué

Le séchage par pulvérisation protège les médicaments sensibles à la chaleur en les exposant à la chaleur pendant une courte période seulement. Vous pouvez également contrôler la taille et la forme des particules, ce qui vous aide à fabriquer des médicaments qui agissent plus rapidement et durent plus longtemps. Le processus est rapide et peut être étendu pour grande production, ce qui en fait un favori de l'industrie pharmaceutique.

Type de produit | Pourquoi utiliser le séchage par pulvérisation? |

|---|---|

Médicaments inhalables | Séchage doux, contrôle précis des particules |

Gélules à libération contrôlée | Taille constante, protège les principes actifs |

Comprimés au goût masqué | Meilleure saveur, expérience patient améliorée |

Produits chimiques

On trouve le séchage par pulvérisation dans l'industrie chimique pour fabriquer des poudres aux propriétés particulières.. Ce processus vous aide à créer des produits comme:

Pigments

Catalyseurs

Pesticides

Le séchage par pulvérisation vous permet de contrôler la taille et la forme de chaque particule. Vous pouvez réaliser des poudres uniformes et faciles à manipuler. Pour les catalyseurs, le séchage par pulvérisation crée des particules poreuses, ce qui augmente leur activité. Le procédé permet également de stériliser les produits à l'air chaud, les rendant plus sûrs à utiliser. Vous pouvez produire rapidement de grandes quantités de poudre, ce qui vous aide à répondre à la forte demande sur le marché chimique.

Note: Le séchage par pulvérisation est parfait pour les produits chimiques qui doivent rester stables, se dissoudre rapidement, ou avoir une taille de particule spécifique pour leur travail.

Avantages et défis

Avantages

Le séchage par pulvérisation vous offre de nombreux avantages dans les applications industrielles. Vous pouvez sécher des liquides en poudres rapidement et efficacement. Cette méthode fonctionne bien pour la production à grande échelle. Vous obtenez une qualité de produit constante et une taille de particule uniforme. Le séchage par pulvérisation vous aide également à prolonger la durée de conservation de vos produits en éliminant l'humidité.. Vous pouvez utiliser ce procédé pour la nourriture, médicaments, et produits chimiques.

Voici une comparaison des méthodes de séchage courantes:

Méthode de séchage | Efficacité | Rétention des nutriments | Consommation d'énergie | Coût |

|---|---|---|---|---|

Séchage par pulvérisation | Haut | Modéré | Modéré | Modéré |

Sèche | Faible | Haut | Haut | Haut |

Séchage à l'air | Modéré | Faible | Faible | Faible |

Vous trouverez plus de séchage par pulvérisation rentable que la lyophilisation. Cela consomme moins d’énergie et prend moins de temps. Vous pouvez facilement augmenter la production. De nombreuses industries choisissent le séchage par pulvérisation car il équilibre la vitesse, coût, et qualité du produit. Vous bénéficiez également d’une efficacité opérationnelle améliorée et d’une réduction des déchets. Les séchoirs par pulvérisation modernes utilisent des fonctionnalités d'économie d'énergie, comme la récupération de chaleur, pour réduire encore plus les coûts.

Conseil: Le séchage par pulvérisation vous aide à produire des poudres dont l'humidité et la taille sont contrôlées, faciliter le stockage de vos produits, transport, et utiliser.

Limites

Le séchage par pulvérisation s'accompagne également de certains défis. Vous devez contrôler soigneusement le processus pour éviter les problèmes. Si les gouttelettes ne sèchent pas assez vite, vous pouvez voir des dépôts collants sur les parois de la chambre. Une mauvaise atomisation peut entraîner un séchage inégal et une qualité inférieure du produit. Quelques matériaux, comme les polymères de haut poids moléculaire ou les aliments très collants, ne fonctionnent pas bien dans les séchoirs par pulvérisation.

Les défis courants incluent:

Un séchage rapide est nécessaire pour empêcher la poudre humide de coller.

Une atomisation uniforme est requise pour un séchage efficace.

Les séchoirs par pulvérisation à petite échelle peuvent ne pas éliminer tous les solvants.

Certains aliments ne peuvent pas être atomisés ou peuvent obstruer le système.

Les produits qui fondent aux températures de séchage nécessitent des ajustements spéciaux.

Vous pourriez également être confronté à des coûts d’énergie plus élevés, entretien, et nettoyage. La formation des opérateurs et la conformité réglementaire augmentent vos dépenses. Dans les produits pharmaceutiques, des installations et une expertise limitées peuvent ralentir le développement. Produits sensibles, comme les produits biologiques, besoin de soins supplémentaires pour éviter les dommages pendant le séchage.

Note: Vous pouvez surmonter de nombreuses limitations en choisissant le bon équipement, optimisation des paramètres de processus, et bien former votre équipe.

Vous comprenez maintenant comment un séchoir par pulvérisation transforme un liquide en poudre par atomisation., air chaud, et une collecte soignée. Les séchoirs par pulvérisation vous aident à préparer des aliments, médecine, et produits chimiques de manière sûre et efficace. Quand vous choisissez un séchoir par pulvérisation, tu devrais:

1. Définissez vos besoins en produits et votre type de matériau. 2. Vérifier l'efficacité du séchage et le contrôle de la taille des particules. 3. Planifiez une croissance future et un nettoyage facile.

Nouvelles tendances comme l'IA et les conceptions respectueuses de l'environnement façonnera l’avenir du séchage par pulvérisation. Pour les projets complexes, vous voudrez peut-être parler avec un expert ou explorer plus de ressources.

FAQ

Quels produits pouvez-vous fabriquer avec un séchoir par pulvérisation?

Vous pouvez faire du lait en poudre, café instantané, lait maternisé pour bébé, oeufs en poudre, médicaments, détergents, et même certains produits chimiques. Les séchoirs par pulvérisation vous aident à transformer de nombreux liquides en poudres sèches pour un stockage et un transport faciles.

Comment nettoyer un séchoir par pulvérisation?

Vous nettoyez un séchoir par pulvérisation en le rinçant avec de l'eau ou des solutions de nettoyage spéciales. Certaines machines disposent de systèmes de nettoyage automatiques. Vous devez éliminer toute poudre et résidu pour garder vos produits sûrs et de haute qualité..

Pourquoi la taille des particules est-elle importante dans le séchage par pulvérisation?

La taille des particules affecte la façon dont votre poudre se dissout, flux, et magasins. Les particules plus petites se dissolvent plus rapidement. Les plus gros peuvent mieux circuler. Vous contrôlez la taille en modifiant les paramètres de l'atomiseur et les propriétés d'alimentation.

Le séchage par pulvérisation est-il sans danger pour les produits sensibles à la chaleur?

Oui! Le séchage par pulvérisation utilise de courtes bouffées de chaleur. Ce processus rapide protège les vitamines, les saveurs, et des médicaments contre les dommages. Vous pouvez sécher en toute sécurité de nombreux ingrédients sensibles sans perdre en qualité.