Le séchage de lit liquide et ses industries clés

Le séchage sur lit fluidisé vous permet de sécher les particules solides en faisant passer l'air vers le haut à travers un lit de matériau.. Ce processus soulève chaque particule, rendant le séchage rapide et uniforme. Vous constaterez que le séchage sur lit fluidisé a remplacé les anciennes méthodes de séchage dans de nombreuses usines.. Aujourd'hui, vous voyez le séchage sur lit fluidisé utilisé dans:

Médicaments

Transformation des aliments

Produits chimiques

Agriculture

Minéraux

Le marché mondial des systèmes de séchage à lit fluidisé se situe à $1.2 milliards dans 2024. Les experts s'attendent à ce qu'il atteigne $1.8 milliards 2033 car de plus en plus d'industries choisissent ces séchoirs pour de meilleurs résultats.

Principaux à retenir

Le séchage sur lit fluidisé utilise un flux d'air ascendant pour sécher les matériaux rapidement et uniformément., Le rendre idéal pour des industries comme les produits pharmaceutiques et la transformation des aliments.

Cette technologie offre des avantages tels qu'une qualité de produit améliorée, temps de séchage plus rapides, et des coûts énergétiques inférieurs par rapport aux méthodes de séchage traditionnelles.

Les composants clés des séchoirs à lit fluidisé comprennent un système d'alimentation en air, une plaque distributrice perforée, et un panneau de commande pour ajuster les paramètres.

Lors de la sélection d'un séchoir à lit fluidisé, considérer le type de matériau, capacité, efficacité énergétique, et les besoins en espace pour garantir des performances optimales.

Les progrès récents dans la technologie de séchage sur lit fluidisé se concentrent sur l’automatisation et l’efficacité énergétique, aider les industries à répondre à des demandes croissantes.

Bases du séchage sur lit fluidisé

Principe de fonctionnement

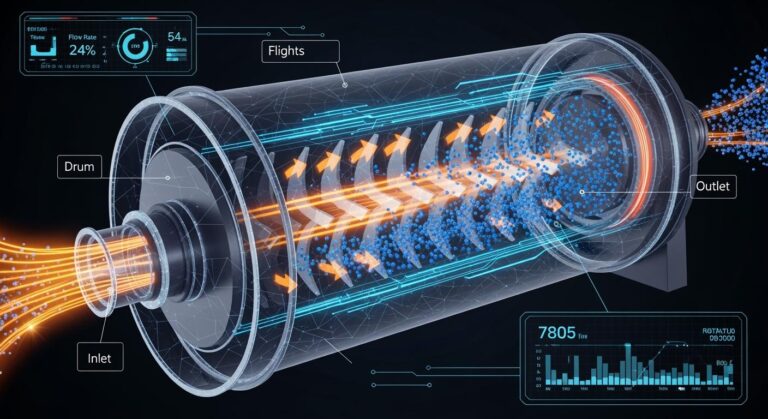

Vous considérez le séchage sur lit fluidisé comme une technologie intelligente qui utilise l’air pour sécher les matériaux.. Le processus de séchage commence lorsque l'air monte à travers un lit de particules solides.. L'air soulève chaque particule, les faisant flotter et se mélanger. Ce mouvement permet au processus de séchage de fonctionner rapidement et uniformément. Vous remarquez que la plaque distributrice perforée se trouve au bas du sèche-linge. La plaque répartit l'air afin que chaque particule reçoive la même quantité de flux d'air.. Cette technologie maintient la température stable et évite la surchauffe.

Conseil: La technologie de séchage par lit fluidisé fonctionne mieux lorsque vous devez sécher des matériaux sans les endommager. Vous bénéficiez d'un meilleur contrôle de l'humidité et de la température par rapport aux anciens processus de séchage industriels..

Principaux composants

Vous trouvez plusieurs pièces principales dans un séchoir à lit fluidisé. Chaque pièce joue un rôle clé dans la technologie:

Système d'alimentation en air: Pousse l'air dans le sèche-linge et contrôle la vitesse du flux d'air.

Plaque distributrice perforée: Répartit l'air uniformément sous le lit de particules.

Chambre de séchage: Retient le matériau et laisse le processus de séchage se dérouler.

Système de chauffage: Réchauffe l'air avant qu'il n'entre dans la chambre.

Panneau de contrôle: Vous permet d'ajuster les paramètres de température, flux d'air, et temps de séchage.

Composant | Fonction |

|---|---|

Système d'alimentation en air | Déplace l'air dans le sèche-linge |

Plaque perforée | Distribue l'air uniformément |

Chambre de séchage | Contient le matériau pour le processus de séchage |

Système de chauffage | Chauffe l'air pour un meilleur séchage |

Panneau de contrôle | Ajuste les paramètres technologiques |

Vous voyez que la technologie moderne rend ces séchoirs plus efficaces. Les nouveaux capteurs et l'automatisation vous aident à économiser de l'énergie et à améliorer la qualité des produits. Alors que de plus en plus d’industries investissent dans les technologies de pointe, le marché des séchoirs à lit fluidisé continue de croître. Vous bénéficiez d’un séchage plus rapide, des coûts inférieurs, et des produits plus sûrs.

Industries utilisant des séchoirs à lit fluidisé

Les séchoirs à lit fluidisé ont changé la façon dont vous abordez le séchage dans de nombreuses industries. Vous voyez ces séchoirs dans des endroits où la vitesse, qualité, et l'efficacité compte. Vous pouvez utiliser des séchoirs à lit fluidisé pour une large gamme d'applications. Chaque industrie a des besoins uniques, et les séchoirs à lit fluidisé répondent à ces besoins avec polyvalence.

Médicaments

Vous trouvez des séchoirs à lit fluidisé dans la fabrication pharmaceutique. Ces séchoirs vous aident à sécher les poudres, granulés, et tablettes. Vous les utilisez dans des systèmes de granulation pour vous assurer que chaque lot a la bonne teneur en humidité. Les séchoirs à lit fluidisé vous offrent un séchage uniforme, ce qui vous aide à maintenir une qualité de produit élevée. Vous pouvez contrôler la température et le débit d'air, vous évitez ainsi d'endommager les ingrédients sensibles. Vous remplacez les anciens séchoirs à plateaux par des séchoirs à lit fluidisé parce que vous souhaitez un séchage plus rapide et de meilleurs résultats..

Applications courantes dans le secteur pharmaceutique:

Séchage des principes actifs pharmaceutiques (Apis)

Préparation de granulés pour la production de comprimés

Granulés d'enrobage et de séchage

Note: Les séchoirs à lit fluidisé vous aident à respecter des normes strictes de sécurité et de qualité dans la fabrication pharmaceutique.

Préparation des aliments

Vous utilisez des séchoirs à lit fluidisé dans les applications de transformation des aliments pour améliorer la durée de conservation et la sécurité des produits.. Ces séchoirs vous permettent de sécher les fruits, légumes, grains, et des collations rapidement. Vous obtenez une élimination uniforme de l'humidité, ce qui vous aide à conserver la saveur et la texture. Les séchoirs à lit fluidisé remplacent les fours traditionnels et les séchoirs à bande dans de nombreuses applications de l'industrie alimentaire. Vous les choisissez parce qu'ils économisent de l'énergie et réduisent le temps de séchage.

Applications agroalimentaires:

Sécher les céréales du petit-déjeuner et les snacks

Éliminer l'humidité des épices et des herbes

Transformation de soupes instantanées et de boissons en poudre

Produit alimentaire | Application | Avantage |

|---|---|---|

Fruits/Légumes | Élimination de l'humidité | Durée de conservation plus longue |

Grains | Séchage avant emballage | Empêche la détérioration |

Épices/Herbes | Séchage uniforme | Maintient la saveur et l'arôme |

Produits chimiques

Vous voyez des séchoirs à lit fluidisé dans les applications de l'industrie chimique car vous avez besoin d'un contrôle précis du séchage.. Ces séchoirs manipulent des poudres, cristaux, et granules. Vous les utilisez pour sécher les détergents, catalyseurs, et pigments. Les séchoirs à lit fluidisé vous aident à éviter l’agglutination et la surchauffe. Vous remplacez les séchoirs rotatifs et à tambour par des séchoirs à lit fluidisé pour une meilleure efficacité.

Applications clés en chimie:

Poudres détergentes siccatives

Traitement des pigments et des colorants

Traitement des catalyseurs et des résines

Conseil: Les séchoirs à lit fluidisé vous permettent d'ajuster le débit d'air et la température pour différents produits chimiques, ce qui les rend très polyvalents.

Agriculture

Vous utilisez des séchoirs à lit fluidisé en agriculture pour traiter les graines, grains, et granulation d'engrais. Ces séchoirs vous aident à sécher les cultures rapidement après la récolte. Vous obtenez des niveaux d’humidité constants, ce qui vous aide à conserver les produits plus longtemps. Les séchoirs à lit fluidisé remplacent le séchage au soleil et les séchoirs à silo car vous souhaitez des résultats plus rapides et plus sûrs..

Applications agricoles:

Séchage des grains et graines récoltés

Transformation des granulés d'aliments pour animaux

Granulation d'engrais pour un meilleur rendement des cultures

Produit agricole | Application | Avantage |

|---|---|---|

Céréales/Graines | Séchage après récolte | Empêche la moisissure |

Alimentation animale | Séchage des pellets | Améliore la nutrition |

Engrais | Séchage des granulations | Stimule la croissance des cultures |

Minéraux

Vous trouvez des séchoirs à lit fluidisé dans le traitement des minéraux. Ces séchoirs vous aident à sécher le sable, argile, calcaire, et minerais. Vous les utilisez pour préparer des minéraux en vue d'un traitement ultérieur ou d'un emballage.. Les séchoirs à lit fluidisé vous offrent un séchage uniforme, ce qui vous aide à éviter le gaspillage. Vous remplacez les séchoirs à tunnel et rotatifs par des séchoirs à lit fluidisé parce que vous souhaitez un meilleur contrôle et une consommation d'énergie réduite..

Applications minérales:

Sable de séchage pour la construction

Traitement de l'argile pour la céramique

Préparation des minerais pour la fusion

Bloquer le devis: Les séchoirs à lit fluidisé vous offrent une flexibilité pour différents types et tailles de minéraux.

Vous voyez que les séchoirs à lit fluidisé ont remplacé de nombreux séchoirs traditionnels dans tous les secteurs.. Vous bénéficiez d’un séchage plus rapide, meilleure qualité du produit, et des coûts énergétiques réduits. Les séchoirs à lit fluidisé vous offrent la polyvalence nécessaire pour gérer de nombreuses applications, des produits pharmaceutiques aux minéraux.

Avantages et défis des séchoirs à lit fluidisé

Avantages

Vous bénéficiez de nombreux avantages lorsque vous utilisez des séchoirs à lit fluidisé dans votre ligne de traitement. Ces séchoirs vous offrent un séchage efficace car l'air chaud se déplace autour de chaque particule. Vous voyez un séchage uniforme, ce qui signifie que chaque partie de votre produit reçoit le même traitement. Cela vous aide à obtenir des résultats de haute qualité et à éviter des problèmes tels qu'une élimination inégale de l'humidité..

Les séchoirs à lit fluidisé améliorent l’efficacité des processus. Vous pouvez sécher rapidement de grandes quantités, vous économisez donc du temps et de l'énergie. La conception de ces séchoirs vous permet de contrôler la température et le débit d'air. Vous protégez votre produit de la surchauffe et maintenez une qualité élevée. Vous remarquez également des améliorations de la qualité des produits car le mouvement doux évite d'endommager vos matériaux..

Voici quelques avantages clés:

Élimination efficace de l’humidité pour de nombreux types de produits

Meilleure efficacité des processus et réduction de la consommation d’énergie

Produit de haute qualité et moins de rebuts

Séchage rapide et uniforme pour des résultats constants

Conseil: Les séchoirs à lit fluidisé vous aident à répondre aux normes strictes dans des secteurs tels que l'alimentation et la pharmacie..

Limites

Vous pouvez rencontrer certains défis lorsque vous utilisez des séchoirs à lit fluidisé. Tous les matériaux ne fonctionnent pas bien avec cette technologie. Les poudres collantes ou très fines peuvent poser des problèmes lors du traitement. Vous devez vérifier si votre produit convient aux séchoirs à lit fluidisé avant de commencer..

Ces séchoirs nécessitent une configuration minutieuse et des contrôles réguliers. Si vous ne contrôlez pas le débit d'air ou la température, vous pourriez obtenir une mauvaise qualité ou gaspiller de l'énergie. Certains séchoirs peuvent être bruyants ou prendre beaucoup de place dans votre usine. Il faut aussi penser au coût d'achat et d'entretien de ces sécheuses.

Les défis courants incluent:

Adéquation des matériaux pour un séchage efficace

Besoin d’opérateurs qualifiés et d’entretien régulier

Exigences possibles en matière de bruit et d'espace

Investissement initial plus élevé par rapport à certains autres séchoirs

Note: Vous pouvez résoudre bon nombre de ces problèmes en choisissant le bon sèche-linge et en formant votre équipe..

Critères de sélection des séchoirs et des avancées

Choisir le bon sèche-linge

Lorsque vous sélectionnez des séchoirs à lit fluidisé pour votre procédé, vous devez penser à plusieurs facteurs importants. Vous souhaitez adapter le sèche-linge à votre type de matériau, taille du lot, et les objectifs de production. Vous recherchez également un rendement élevé et une efficacité énergétique pour réduire les coûts et protéger l’environnement..

Voici les points clés à considérer:

Type de matériau: Certains séchoirs fonctionnent mieux avec des poudres, granulés, ou des cristaux.

Capacité: Vous avez besoin d'un séchoir adapté à la taille de votre lot ou à vos besoins de production continue.

Efficacité énergétique: Choisissez des sécheuses qui consomment moins d’énergie et réduisez vos factures.

Contrôle de la température: De bons séchoirs vous permettent de régler et de maintenir la bonne température pour votre produit.

Espace: Certains séchoirs ont besoin de plus d'espace dans votre usine.

Vous pouvez comparer différents types de séchoirs à lit fluidisé en utilisant le tableau ci-dessous:

Type de sèche-linge | Caractéristiques de performances | Aptitude aux industries |

|---|---|---|

Lit Fluide Vibrant | Temps de séchage rapides, adapté aux produits sensibles à la chaleur, résultats de séchage constants. | Idéal pour les applications nécessitant un séchage rapide. |

Lit fluidisé par lots | Offre de la flexibilité pour les petits lots, efficace pour divers matériaux. | Convient aux industries avec différentes tailles de lots. |

Lit fluidisé continu | Haut débit, conçu pour les opérations à grande échelle, nécessite plus d'espace au sol. | Idéal pour les besoins de traitement continu de gros volumes. |

Vous voyez que les séchoirs à lit fluidisé vous offrent des options pour chaque secteur. Vous pouvez choisir un séchoir par lots pour les petits travaux ou un séchoir en continu pour les grandes opérations.. Les séchoirs vibrants à lit fluidisé vous aident à sécher rapidement les produits sensibles à la chaleur.

Avancées récentes

Vous remarquez de nombreuses nouvelles tendances dans les séchoirs à lit fluidisé. Les entreprises veulent une meilleure efficacité et efficacité énergétique. Vous voyez plus d’automatisation et de commandes intelligentes dans les séchoirs modernes. Ces fonctionnalités vous aident à économiser de l'énergie et à améliorer la qualité des produits.

Voici quelques tendances du marché qui façonnent les séchoirs à lit fluidisé:

Demande croissante de solutions de séchage efficaces

Avancées dans la technologie de séchage et l’automatisation

Croissance des industries pharmaceutiques et chimiques

Besoin croissant d’équipements économes en énergie

Les secteurs agroalimentaire et agricole continuent de croître. De plus en plus de séchoirs à lit fluidisé sont utilisés pour répondre au besoin d'un séchage rapide et fiable.. Ces séchoirs traitent de gros volumes et vous donnent des résultats uniformes. Vous bénéficiez d’une meilleure efficacité et de coûts réduits.

Les séchoirs à lit fluidisé modernes utilisent des capteurs et des panneaux de commande pour vous aider à ajuster les paramètres.. Vous obtenez un contrôle précis de la température et pouvez surveiller les niveaux d’humidité. L'automatisation vous permet de faire fonctionner les séchoirs avec moins de travail manuel et moins d'erreurs. Vous constatez des améliorations en matière de sécurité et de qualité des produits.

Conseil: Lorsque vous investissez dans des séchoirs à lit fluidisé avancés, vous obtenez une meilleure efficacité, consommation d'énergie réduite, et une qualité de produit supérieure.

Vous considérez le séchage sur lit fluidisé comme un moyen moderne de sécher les matériaux rapidement et uniformément.. Cette méthode utilise un flux d'air ascendant pour soulever les particules, rendant les séchoirs essentiels dans de nombreuses industries. Vous bénéficiez d’un séchage plus rapide, meilleure qualité du produit, et une consommation d'énergie réduite. Quand vous choisissez des sèche-linge, vous devez considérer le type de produit, efficacité, et l'espace.

Réglementations gouvernementales et normes de l'industrie vous pousse à utiliser des sèche-linge de haute qualité.

Des règles strictes de la FDA et de l'EMA vous poussent à adopter des séchoirs avancés.

Vous constatez que les sèche-linge économes en énergie vous aident à atteindre vos objectifs de développement durable.

Vous pouvez vous attendre à ce que les séchoirs continuent de s'améliorer à mesure que le marché se développe et que la technologie progresse..

FAQ

Quels matériaux pouvez-vous sécher avec un sèche-linge fluide?

Vous pouvez sécher les poudres, granulés, cristaux, graines, grains, et minéraux. Les séchoirs à lit fluidisé fonctionnent mieux avec des matériaux à écoulement libre. Les poudres collantes ou très fines peuvent nécessiter une manipulation particulière.

Comment contrôlez-vous la température de séchage?

Vous définissez la température à l'aide du panneau de commande. Les séchoirs modernes utilisent des capteurs pour maintenir la température stable. Cela vous aide à protéger les produits sensibles de la surchauffe.

Pourquoi choisissez-vous le séchage sur lit fluidisé plutôt que les méthodes traditionnelles?

Vous obtenez un séchage plus rapide, meilleure qualité du produit, et une consommation d'énergie réduite. Les séchoirs à lit fluidisé vous permettent d’éliminer uniformément l’humidité. Vous évitez des problèmes tels qu'un séchage inégal ou des dommages au produit.

Pouvez-vous utiliser des séchoirs à lit fluidisé pour la sécurité alimentaire?

Oui. Les séchoirs à lit fluidisé vous aident à éliminer rapidement l’humidité. Vous réduisez le risque de moisissures et de bactéries. Vous préservez la sécurité des aliments et améliorez la durée de conservation.

De quel entretien les séchoirs à lit fluidisé ont-ils besoin?

Vous nettoyez la chambre de séchage et vérifiez souvent le système d'alimentation en air. Vous inspectez les capteurs et les panneaux de contrôle. Un entretien régulier vous aide à éviter les pannes et à maintenir le bon fonctionnement du sèche-linge.