Fluidization advantages over other drying methods

Fluidization advantages make fluid bed drying your best choice over other drying methods. You gain faster results and save energy—studies show fluidized bed drying can cut drying time by more than 5 hours and reduce energy use by 35.8%. You enjoy consistent product quality, safe operation, and easy scale-up for large batches. Take a look at the benefits:

Advantage | Description |

|---|---|

Rapid and Uniform Drying | You achieve even moisture removal and efficient heat transfer. |

Gentle Handling | You protect delicate materials from damage. |

Energy Efficiency | You use less energy with shorter drying cycles. |

Easy Scale-up | You expand production smoothly as demand grows. |

Versatility | You process many types of materials with simple adjustments. |

Enhanced Product Quality | You maintain integrity and key product features. |

Key Takeaways

Fluid bed drying significantly reduces drying time by over 5 hours and cuts energy use by 35.8%.

This method ensures uniform drying, preventing wet spots and maintaining product quality.

Fluid bed dryers are versatile, handling various materials with simple adjustments for different products.

The system operates safely with features that reduce dust accumulation and overheating risks.

Low maintenance needs mean less downtime and lower costs, allowing you to focus on production.

Fluidization Overview

Principle

You want a drying method that works fast and keeps your product safe. Fluidization gives you that edge. The core idea behind fluidization is simple but powerful. When you push a gas, usually air, through a bed of solid particles at the right speed, something amazing happens. The gas lifts the particles, making them float and move like a liquid. This state lets each particle move freely. You get better contact between the hot air and every piece of your material.

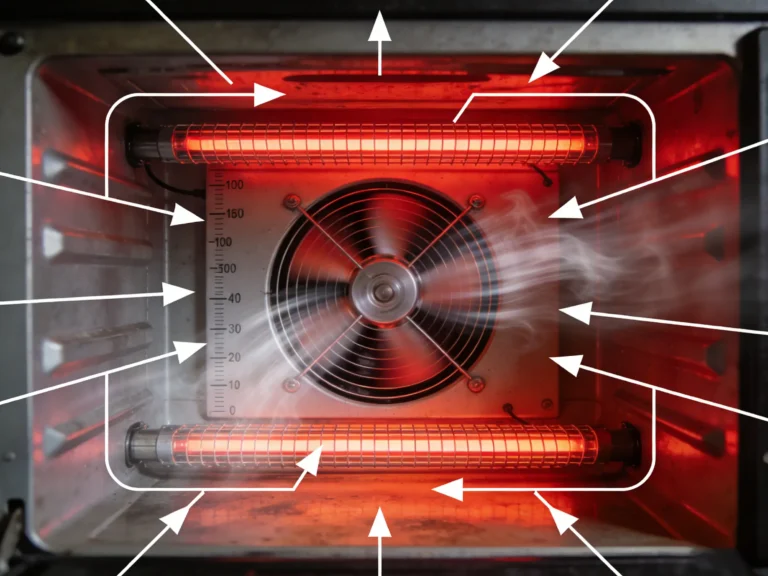

This process is not just about movement. It is about efficiency. The gas creates a drag force that lifts the particles. As a result, you see a huge boost in heat and mass transfer. Your drying process becomes faster and more even. You avoid hot spots and reduce the risk of overheating your product. You keep your product’s quality high and your energy costs low.

Tip: Fluidization helps you dry delicate materials without damaging them. You protect your investment and deliver better results.

Process

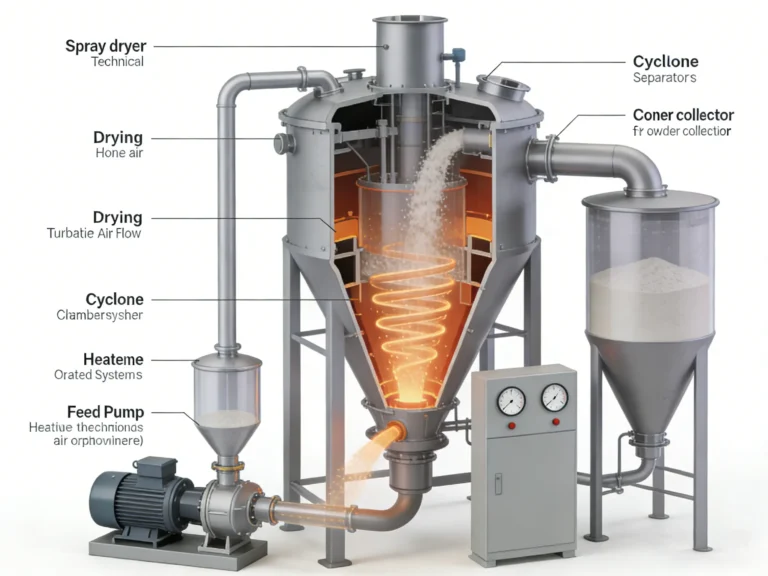

You will find the fluidization process easy to understand and even easier to use. In an industrial dryer, you load your bulk material into a chamber. A stream of hot gas flows upward from the bottom. This gas keeps your material in constant motion, suspending each particle in the air. Every particle gets surrounded by hot gas, so drying happens quickly and evenly.

You can choose between continuous or batch operations. This flexibility means you can scale up or down as your needs change. Modern fluidized bed dryers use smart controls and energy-saving features. You get the best performance with less waste. You can dry, cool, or even coat your products in the same system.

You save time.

You save energy.

You get consistent, high-quality results.

Fluidization puts you in control. You meet your production goals and keep your customers happy.

Fluidization Advantages

Energy Efficiency

You want to save energy and lower your costs. Fluidization advantages give you an edge with energy-efficient operation. Fluid bed drying uses hot air to lift and move particles, so every piece gets exposed to heat quickly. This rapid heat and mass transfer means you dry your product faster and use less energy. You can adjust temperature, humidity, and air flow to match your needs. Higher inlet air temperatures and flow rates can shorten drying times, making your process even more efficient. The preheating phase does use some energy, but the overall savings are clear. You get a system that works smarter, not harder.

Fluid bed drying lets you control energy use with simple adjustments.

You achieve efficient results and keep your energy bills low.

💡 Tip: Choose fluidized bed drying for an energy-efficient operation that supports your bottom line.

Uniform Drying

You need every part of your product to dry evenly. Fluidization advantages shine here. Fluidized bed drying surrounds each particle with hot air, so you avoid uneven moisture. This method ensures all particles reach the same moisture level at the same time. You protect your product’s quality and extend its shelf life. Studies show that fluidized bed drying is preferred for wet granules because of its rapid heat and mass transfer. You also benefit from large capacity and lower capital costs.

Aspect | Description |

|---|---|

Study Type | |

Focus | Segregation and mixing dynamics for binary and ternary solids |

Methodology | Pseudo-2D fluidized bed experiments with particle image velocimetry and infrared thermography |

Findings | Significant hydrodynamic changes observed, correlating bed configurations to local solids drying behavior. |

You get peace of mind knowing your product will not have wet spots or over-dried areas.

Product Quality

You want your product to look good and perform well. Fluidization advantages help you keep product quality high. Fluid bed drying protects the physical and chemical properties of sensitive products. You can control drying time, air temperature, and gas velocity to match your product’s needs. This flexibility lets you adjust the process for different materials, so you avoid damaging delicate items.

Aspect | Findings |

|---|---|

Agglomerate Modifications | Changes in the population of agglomerates were observed during the drying process. |

Drying Time | The duration of the drying process was influenced by operating conditions. |

Residual Humidity | The level of humidity remaining in the product post-drying was affected by the process. |

Operating Conditions | Inlet air temperature and gas velocity significantly impacted thermal efficiency. |

You keep your product’s integrity and deliver consistent results every time.

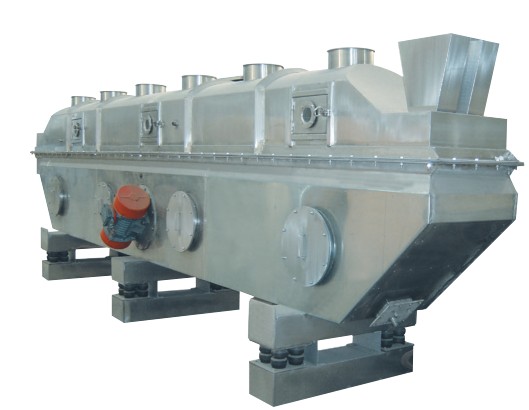

Versatility

You need a drying system that adapts to your changing needs. Fluidization advantages include unmatched flexibility. Fluid bed drying works for many types of products, from seeds and food additives to pressed fruits and vegetables. You can switch between products with simple adjustments. This versatility means you can handle new projects or scale up production without buying new equipment.

Product Type | Description |

|---|---|

Seeds | Fluidized bed dryers gently dry seeds, preserving their quality. |

Food Additives | Ideal for drying delicate food additives uniformly. |

Pressed Fruits | Enhances the quality of dried pressed fruits and vegetables. |

You process seeds, food additives, pressed fruits, and vegetables with ease.

You enjoy flexibility and efficient operation in one system.

Safety

You want a safe workplace. Fluidization advantages make fluid bed drying a safer choice. The design of fluidized bed dryers reduces dust accumulation and self-heating, which lowers the risk of fire or explosion. You get better airflow and temperature control, so you avoid dangerous hot spots. Built-in safety features like proper ventilation, explosion-proof equipment, and automatic temperature controls protect your team and your facility.

Safety Feature | Description |

|---|---|

Routine checks to identify wear and tear, ensuring all components function correctly. | |

Proper Ventilation | Prevents dust accumulation and reduces explosion risks through adequate airflow. |

Use of Explosion-Proof Equipment | Essential for operations with combustible materials to contain potential explosions. |

Temperature Control Systems | Helps prevent overheating with automatic shut-off features to mitigate fire risks. |

Training and Safety Drills | Ensures employees are familiar with safety protocols and can respond effectively in emergencies. |

You create a safer environment and reduce operational risks.

Low Maintenance

You want to spend less time and money on repairs. Fluidization advantages include low maintenance needs. Fluid bed dryers have no moving parts, so you avoid the breakdowns common in other systems. Most maintenance involves simple checks on fans or combustion systems. You do not need to worry about complex machinery or frequent repairs. This simplicity keeps your operation running smoothly and your costs down.

Fluid bed drying systems are simpler than rotary or tray dryers.

You focus on production, not on fixing equipment.

Gentle Handling

You need to protect delicate products. Fluidization advantages give you gentle handling. Fluid bed drying minimizes contact with fragile materials, so you avoid breakage or loss of quality. Controlled vibration and fluidization ensure even drying without burning or over-drying. This method works well for sensitive items like milk powder, bread crumbs, and natural foods.

Industry | Product Examples |

|---|---|

Pharmaceuticals | Sensitive materials requiring integrity |

Food Processing | Natural foods maintaining taste and texture |

You maintain product integrity and natural qualities.

You deliver products that look and taste their best.

✅ Note: Fluid bed drying gives you efficient, safe, and flexible solutions for all your drying needs.

Fluid Bed Dryers vs. Other Methods

Rotary Dryers

You may consider rotary dryers for drying bulk materials. These dryers use a rotating drum to tumble your product while hot air passes through. Rotary dryers work well for large, coarse particles and can handle high moisture loads. However, you face challenges with heat-sensitive products. The tumbling action and high temperatures can damage delicate materials. You may see uneven drying and risk thermal degradation. Fluid bed dryers give you a clear advantage here. You get gentle handling and better temperature control. You protect your product’s quality, especially for sensitive items.

Fluid bed dryers suit heat-sensitive materials.

Rotary dryers may cause thermal damage.

You achieve more uniform drying with fluid bed dryers.

Tip: Choose fluid bed dryers when you need to maintain product integrity and avoid overheating.

Fluid-bed dryers are generally more favorable for heat-sensitive materials due to their gentle handling capabilities.

Rotary dryers may present challenges in maintaining product quality for heat-sensitive materials due to potential thermal degradation.

Both dryer types require careful consideration of temperature control and retention time to optimize product quality.

Flash Dryers

You might look at flash dryers for rapid drying of fine, wet materials. Flash dryers use a stream of hot air to suspend and dry particles almost instantly. This method works best for very small particles and sticky or wet materials. However, flash dryers do not prevent hot or cold spots. You may see uneven drying and risk losing product quality. Fluid bed dryers, on the other hand, surround each particle with hot air. You get even drying and better control over the process.

Here is a quick comparison between fluid bed dryers and flash dryers:

Consideration | Fluidized Bed Drying | Flash Drying |

|---|---|---|

Typical material examples | Chemicals, pharmaceutical ingredients, dairy products, dyes and pigments, food ingredients, metallurgical materials | High-moisture food ingredients, ceramics, chemicals, starches, effluents, organic salts, sugar, dyes and pigments |

Prevents hot/cold spots | Yes | No |

Suited for particle sizes below 50 microns | No | Yes |

Potential product loss | Higher | Lower |

Good for sticky or very wet materials | No | Yes |

You also want to think about maintenance and energy use. Fluid bed dryers have fewer moving parts, so you spend less time on repairs. Flash dryers have more moving components and may need more attention. Flash dryers can use 15-30% less energy than some older technologies, but fluid bed dryers still offer strong energy efficiency and lower maintenance.

Consideration | Fluidized Bed Drying | Flash Drying |

|---|---|---|

Maintenance Requirements | Lower due to fewer moving parts | Moderate due to moving components |

Energy Consumption | Not specified | 15-30% less than conventional technologies |

✅ Note: Fluid bed dryers give you even drying and simple maintenance. Flash dryers work best for very fine, sticky materials.

Tray Dryers

You may have used tray dryers for small batches or specialty products. Tray dryers hold your material on trays inside a heated chamber. You get simple operation and low upfront costs. However, you face slow drying times and uneven results. You must load and unload trays by hand, which takes time and increases labor costs. Fluid bed dryers solve these problems. You get faster drying, better uniformity, and easy scale-up for larger production. You also reduce manual handling, which lowers the risk of contamination.

Fluid bed dryers speed up your process.

Tray dryers require more labor and time.

You achieve higher product quality and consistency with fluid bed dryers.

💡 Tip: Upgrade to fluid bed dryers for higher efficiency and less manual work.

Comparison Table

You want a clear view of how these drying methods stack up. Here is a side-by-side comparison to help you choose the best option for your needs:

Feature / Method | Fluid Bed Dryers | Rotary Dryers | Flash Dryers | Tray Dryers |

|---|---|---|---|---|

Drying Speed | Fast | Moderate | Very Fast | Slow |

Product Quality | High, gentle handling | Risk of thermal damage | Can be uneven | Risk of uneven drying |

Energy Efficiency | High | Moderate | High | Low |

Maintenance | Low, few moving parts | Moderate, moving parts | Moderate | Moderate |

Scale-up | Easy, continuous | Easy for bulk | Good for fine powders | Difficult, batch only |

Labor Requirement | Low | Moderate | Moderate | High |

Best For | Heat-sensitive, uniform drying | Bulk, coarse materials | Fine, sticky materials | Small batches, specialty |

🚀 Choose fluid bed dryers to boost your efficiency, protect your product, and simplify your operation. You get the best results for heat-sensitive and high-quality products. You also save time and money on maintenance and labor.

Applications

Pharmaceuticals

You want to deliver safe, effective medicines every time. Fluidized bed drying gives you the control you need for pharmaceutical production. You can dry powders, granules, and pellets without damaging their structure. This method keeps active ingredients stable and ensures each batch meets strict quality standards. You avoid overheating, so sensitive compounds stay potent. You also reduce contamination risks because the system uses closed chambers and filtered air. When you need to scale up, fluidized bed dryers handle large volumes with ease. For pharmaceutical companies, this technology stands out as one of the ideal applications for consistent, high-quality results.

💊 Tip: Use fluidized bed drying to protect your product and meet regulatory demands.

Food Processing

You want food that looks good, tastes great, and lasts longer. Fluidized bed dryers help you reach these goals. This technology keeps the bed temperature steady and extends the constant drying rate period. You prevent moisture variation and avoid damaging your product. You get high heat and mass transfer efficiency, uniform moisture reduction, and faster drying times. You can make real-time adjustments to the process, so you minimize waste and boost product quality. These features make fluidized bed drying one of the ideal applications for food processing, especially when you need to deliver safe, appealing products to your customers.

High heat and mass transfer efficiency

Uniform moisture reduction

Reduced drying time and increased drying rate

🍎 Note: Choose fluidized bed drying to keep your food products fresh and appealing.

Chemicals and Minerals

You need a drying solution that works for a wide range of materials. Fluidized bed dryers handle everything from plastic pellets and fertilizers to minerals, ores, and catalysts. You can process coal, salt, pet foods, rubber, foundry sand, biomass, and even recycled glass. This flexibility means you can switch between products quickly and efficiently. You get even drying, low maintenance, and safe operation for all your chemical and mineral needs. Fluidized bed drying supports large-scale production and helps you meet market demands without sacrificing quality.

Common Materials Dried |

|---|

Plastic Pellets |

Fertilizer |

Minerals & Ores |

Chemical Compounds |

Catalysts |

Salt |

Biomass & Wood |

Frac Sand & Aggregates |

🏭 Alert: Fluidized bed dryers give you the power to handle many materials with one reliable system.

You want the best results for your drying process. Fluidized bed drying gives you rapid, uniform results, gentle handling, and high energy efficiency. You can scale up production easily and maintain top product quality. The table below shows why this method stands out:

Advantage | Benefit |

|---|---|

Rapid, uniform drying | Consistent moisture removal and faster processing |

Gentle handling | Protects delicate materials |

Energy efficiency | Cuts energy use and costs |

Easy scale-up | Grows with your business |

Versatility | Adapts to many products |

Enhanced quality | Keeps your product at its best |

🚀 Choose fluidized bed drying to boost efficiency and deliver superior products every time.

FAQ

What makes fluidized bed drying better than other drying methods?

You get faster drying, lower energy costs, and higher product quality. Fluidized bed drying gives you even results and protects delicate materials. You can scale up production easily and keep maintenance simple.

Can you use fluidized bed dryers for different products?

Yes, you can adjust settings for many materials. Fluidized bed dryers work for food, pharmaceuticals, chemicals, and minerals. You get customizable drying methods that fit your needs.

Is fluidized bed drying safe for your workplace?

You reduce risks with better airflow and temperature control. Fluidized bed dryers have safety features like automatic shut-off and explosion-proof equipment. You create a safer environment for your team.

How does fluidized bed drying help you save money?

You use less energy and spend less on repairs. Fluidized bed dryers have fewer moving parts, so you avoid costly breakdowns. You get efficient operation and lower bills.

Why should you choose fluidized bed drying for sensitive products?

You protect fragile items with gentle handling. Fluidized bed drying keeps product integrity and avoids overheating. You deliver high-quality results every time.