Fluid Bed Drying Ultimate Guide

Fluid Bed Drying is a process that uses hot air to dry solid particles by suspending them in a moving stream of air. You can find this technology in many industries because it helps you dry materials quickly and evenly. Companies choose this method for its strong efficiency and ability to handle large volumes.

The global market for fluid bed dryers reached USD 1.2 billion in 2024. Experts predict it will grow to USD 2.5 billion by 2033, with a yearly growth rate of 8.9% from 2026 to 2033.

Here is how Fluid Bed Drying stands out compared to older drying methods:

Advantage | Description |

|---|---|

High Thermal Efficiency | You use heat more effectively. |

Smaller Footprint | You save space in your facility. |

Minimal Maintenance | You lower your operational costs. |

Maximum Gas-to-Solids Contact | You get faster and better drying. |

Key Takeaways

Fluid Bed Drying uses hot air to dry materials quickly and evenly, making it ideal for industries like pharmaceuticals and food processing.

This method offers high thermal efficiency, saving energy and reducing operational costs while ensuring consistent product quality.

Proper control of airflow, temperature, and particle size is crucial for achieving optimal drying results and maintaining product integrity.

Regular maintenance and safety precautions are essential to prevent equipment issues and ensure safe operation during the drying process.

Testing materials before use helps identify suitability for Fluid Bed Drying, avoiding potential problems with sticky or large particles.

Fluid Bed Drying Overview

Definition

You use Fluid Bed Drying to remove moisture from solid particles by suspending them in a stream of heated air. This process helps you dry powders, granules, and pellets quickly and evenly. The air lifts and mixes the particles, so each piece gets exposed to the heat. You find Fluid Bed Drying in many industries, including pharmaceuticals, chemicals, and food processing. Companies rely on this method because it gives you consistent results and supports large-scale production.

Recent years have seen major changes in how you use Fluid Bed Drying. The pharmaceutical sector, for example, has invested $18.7 billion in new equipment and technology upgrades, including advanced drying systems. Chemical manufacturing has increased its investment in process equipment by 28% over the past three years. Food processing companies have adopted Fluid Bed Drying to meet export market requirements and quality standards.

Sector | Investment (USD) | Growth Rate (%) | Notes |

|---|---|---|---|

Pharmaceutical | 18.7 billion | N/A | Significant investment in new equipment and technology upgrades, including drying systems. |

Chemical Manufacturing | N/A | 28 | Increased investment in process equipment over the past three years. |

Food Processing | N/A | N/A | Adoption driven by export market requirements and quality standards. |

The European Commission’s Horizon Europe program has allocated €15 billion for industrial innovation, including energy-efficient drying technologies. Government initiatives now promote sustainable manufacturing practices, which has accelerated the adoption of Fluid Bed Drying systems.

Principle

Fluid Bed Drying works by passing hot air through a perforated bed that holds your material. The air flows upward, lifting and mixing the particles so they float and tumble. You get even heat distribution because the air touches every particle. This movement helps you dry materials faster than older methods like tray drying.

You can see how technology has improved the principle of Fluid Bed Drying:

Advanced fluidized bed designs now give you better drying efficiency than traditional methods.

Spray nozzles let you create porous agglomerates, which help tablets dissolve faster.

Bottom spray technology allows you to coat and layer not just tablets, but also smaller particles like pellets and minitablets.

Multiparticulate dosage forms support individualized medicine, helping patients who have trouble with regular tablets.

Quality by design and process analytical technology (PAT) tools help you monitor and control the drying process for better results.

Pharmaceutical manufacturers must follow strict rules set by the U.S. Food and Drug Administration (FDA). You need precise control over drying to meet Current Good Manufacturing Practices (cGMP). This ensures your products stay safe and effective.

Tip: You can use Fluid Bed Drying to improve product quality and meet regulatory standards, especially in industries where safety and consistency matter most.

Process

Equipment

You use several main parts when you set up a Fluid Bed Drying system. Each part works together to help you dry materials quickly and safely. Here is a table that shows the key components and what they do:

Component | Function |

|---|---|

Base part | Connects to the air handling unit and moves air into the main tower. |

Product container | Holds the wet material and lets you move it easily to other machines. |

Distributor Plates | Spreads air evenly around the product and keeps the material in place. |

Process chamber | Where fluidization happens as air enters the main tower. |

Expansion chamber | Contains filter bags that stop fine particles from escaping during drying. |

Exhaust piping connections | Directs air to the blower and uses dampers to control airflow. |

Draught fan/blower | Creates airflow by spinning impellers to make pressure. |

Control Panel | Lets you set and manage drying settings for better control. |

You need each part to work well so you get even drying and keep your product safe. The control panel helps you adjust settings like temperature and airflow. The distributor plates make sure air reaches every particle. The expansion chamber keeps small particles from leaving the system.

You also need to watch several important settings when you run Fluid Bed Drying equipment. These settings help you get the best results and protect your product. Here is a table that explains the main operational parameters:

Parameter | Description |

|---|---|

Airflow Rate | You must set this so particles float but do not break apart. |

Temperature | You control this to stop overheating and keep your product from getting damaged. |

Particle Size | Smaller particles need less air to float; larger ones need more. |

Bed Height | This affects how long particles stay in the dryer and how well they dry. |

Tip: You should check these settings often. Good control helps you get dry, safe, and high-quality products.

Phases

You follow three main steps when you use Fluid Bed Drying. Each phase helps you prepare, dry, and finish your product.

Preheating

You start by warming up the air and the equipment. This step helps you reach the right temperature before you add your wet material. Preheating makes sure you get even drying from the start.Drying

You add your wet material to the product container. Hot air flows through the distributor plates and lifts the particles. The particles move and tumble in the air stream. This movement lets every piece touch the hot air, so you get fast and even drying. You watch the temperature and airflow to keep your product safe.Cooling

You finish by cooling down the dried material. You lower the temperature and slow the airflow. Cooling helps you handle the product safely and keeps it from sticking together or breaking apart.

Note: You should follow each phase carefully. Skipping a step can lead to uneven drying or damaged products.

You see how Fluid Bed Drying uses smart equipment and clear steps to help you dry materials quickly and safely. You get better control, higher quality, and safer products when you follow the right process.

Advantages

Even Drying

You get more even drying when you use this technology. The system lifts and mixes particles in a stream of hot air. Each piece receives the same amount of heat, so you avoid wet spots and over-dried areas. Uniform drying helps you keep product quality high and reduces waste.

Here is a table that shows how different drying methods compare:

Drying Method | Even Drying | Product Quality | Notes |

|---|---|---|---|

Fluidized Bed Drying (FBD) | Yes | High | Enhanced by technologies for uniform drying. |

Traditional Drying Methods | No | Variable | Less uniform drying compared to FBD. |

Microwave-Assisted FBD | Yes | High | Requires different steps; further research needed. |

Far Infrared Assisted FBD | Yes | High | Can control quality components during drying stages. |

Tip: You can improve your results by choosing a system that gives you even drying. This helps you meet strict quality standards.

Energy Efficiency

You save energy when you use this drying method. The system uses hot air more effectively, so you need less energy to dry each batch. You also finish drying faster, which lowers your energy bills.

See how energy use compares in the table below:

Drying Technology | Energy Consumption (kW/m³ wet product) | Drying Time Reduction (%) | Energy Efficiency (%) |

|---|---|---|---|

Fluid Bed Drying (FBD) | 1006 | > 5 hrs | 25-50 |

Oven Drying | N/A | N/A | N/A |

Note: You can cut costs and help the environment by using a more efficient drying process.

Material Handling

You make material handling easier with this drying system. Uniform drying stops clumping and keeps materials flowing smoothly. You can process and package products faster. You also protect fragile materials from damage because the system dries gently.

Here are some ways this technology helps you:

Restores flowability for processing and packaging.

Allows for gentle drying, preventing damage to fragile materials.

Enhances efficiency by speeding up production and reducing delays.

Callout: You can boost your productivity and keep your products safe by using a system that handles materials well.

Applications

Pharmaceuticals

You find Fluid Bed Drying in many pharmaceutical plants. This technology helps you dry powders and granules for tablets and capsules. You can control moisture levels, which keeps your medicine stable and safe. The process also lets you mix and coat particles, so you can make products that dissolve faster or taste better. You meet strict quality standards because Fluid Bed Drying gives you even results every time.

You can improve patient safety and product quality by using this drying method in pharmaceutical production.

Food

You use Fluid Bed Drying to process food products like grains, coffee beans, fruits, and vegetables. This method helps you remove moisture quickly and gently, which keeps flavors and nutrients in your food. You also extend shelf life and prevent spoilage.

Here is a table that shows how different foods benefit from this technology:

Product | Benefit |

|---|---|

Grains and Cereals | |

Coffee Beans | Gentle and uniform drying preserves flavor and aroma. |

Fruits and Vegetables | Moisture removal extends shelf life before processing or packaging. |

Tip: You can keep your food fresh and safe by choosing a drying system that works fast and evenly.

Chemicals

You use Fluid Bed Drying to process many types of chemicals. This technology works well for bulk solids, powders, and granules. You get gentle treatment, which protects sensitive materials from damage. You also handle different chemicals efficiently, so you can meet production goals and keep quality high. The versatility of Fluid Bed Drying makes it a top choice for chemical manufacturers who need reliable and consistent drying.

Plastics

You rely on Fluid Bed Drying to prepare plastic powders, granules, and pellets. This method gives you fast and even drying, which helps you make high-quality plastic products. You also save energy and can use the system for many types of materials.

See the table below for the main advantages:

Advantage | Description |

|---|---|

Ensures rapid and consistent drying of materials. | |

Uniform Drying | All particles dry evenly, leading to consistent quality in plastic products. |

Energy Efficiency | Consumes less energy compared to traditional drying methods. |

Versatility | Suitable for various materials including powders, granules, and pellets. |

Note: You can boost your production and lower costs by using a drying system that works for many plastic materials.

Limitations

Material Suitability

You need to check if your material fits fluid bed drying before you start. Not every product works well in this system. Some materials have special needs or react badly to the process. For example, sticky powders can clump together and block airflow. Large, heavy particles may not lift or move in the air stream. Fine powders might escape through filters or cause dust problems.

Here is a table to help you see which materials work best:

Material Type | Fluid Bed Drying Suitability | Notes |

|---|---|---|

Free-flowing Granules | ✅ Good | Dry evenly and quickly |

Sticky Powders | ❌ Poor | May clump and block airflow |

Large Particles | ⚠️ Limited | May not fluidize well |

Fine Powders | ⚠️ Limited | Risk of dust and loss |

Tip: Always test your material in a small batch first. This helps you avoid problems and saves time.

Particle Disintegration

You may notice that some particles break apart during fluid bed drying. The strong air flow lifts and tumbles the material. Fragile or soft particles can chip, crack, or turn into dust. This can lower your product quality and create waste.

You can spot signs of particle disintegration by checking for:

More dust in your filters

Smaller particle size after drying

Uneven product texture

If you work with delicate materials, you should use lower air speeds or shorter drying times. You can also try using a gentler drying method for sensitive products.

Note: Protect your product by adjusting the process or choosing a different drying method if you see too much breakage.

Fluid bed drying gives you many benefits, but you must know its limits. You get the best results when you match the process to your material’s needs.

Fluid Bed Drying vs. Other Methods

Tray Drying

You may know tray drying as one of the oldest drying methods. You spread your material on trays and let hot air pass over it. This process takes more time because heat does not reach every particle evenly. Fluid bed drying works much faster. You get better product quality because the hot air lifts and mixes your material, so each piece dries at the same rate. You also save energy since fluid bed dryers have a compact design that keeps heat inside.

Fluid bed drying gives you faster results than tray drying.

You get more uniform drying and consistent moisture levels with fluid bed dryers.

The compact design of fluid bed dryers helps you minimize heat loss and improve energy efficiency.

Tip: If you want to dry large batches quickly and keep quality high, fluid bed drying is a better choice than tray drying.

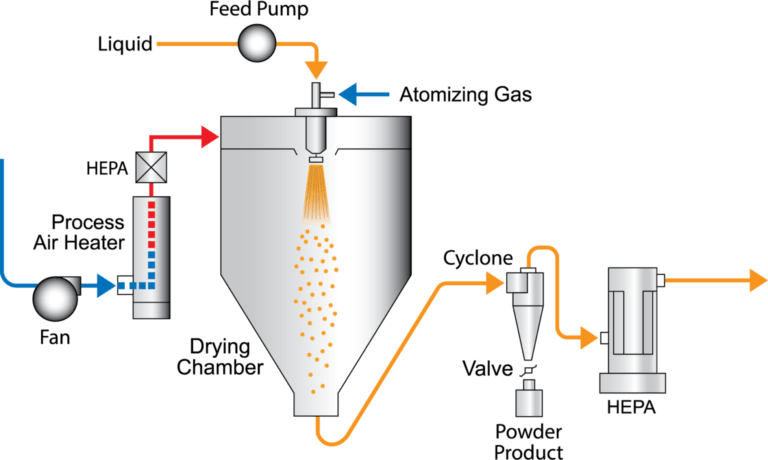

Spray Drying

Spray drying uses a different approach. You turn your liquid or slurry into fine droplets and dry them with hot air. This method works well for products like milk powder or instant coffee. Spray drying uses less energy because moisture evaporates quickly from small droplets. Modern spray dryers use heat recovery systems and precise temperature controls to save even more energy. Fluid bed drying usually needs more energy since you must keep the particles floating and dry them for longer periods. New designs, such as vibration fluid bed dryers, help you use less air and energy.

Spray drying is more energy efficient because moisture leaves the droplets quickly.

You can find heat recovery systems and temperature controls in modern spray dryers.

Fluid bed drying uses more energy due to longer drying times and the need to keep particles moving.

Vibration fluid bed dryers help you save energy by improving particle movement.

Note: Choose spray drying for liquids and fluid bed drying for solids. Each method fits different types of products.

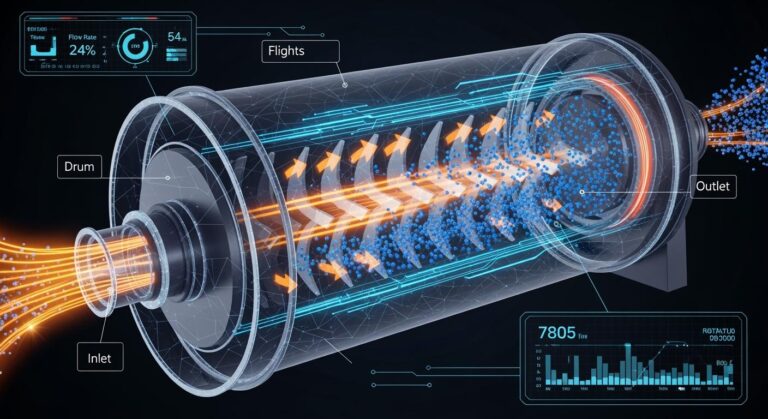

Rotary Drying

Rotary dryers handle bulk materials well. You place your material in a rotating drum and let hot air dry it as the drum turns. Rotary dryers work with many types of feedstock and do not need much supervision. Fluid bed dryers need your material to stay consistent and require careful control of settings. You get better energy efficiency with fluid bed dryers because the fluidization effect spreads heat evenly. Rotary dryers use less energy when you process smaller batches.

Rotary dryers adapt to changes in feedstock and need less supervision.

Fluid bed dryers work best when your material stays consistent.

You get thermal efficiency with fluid bed dryers, but rotary dryers use less energy at lower capacities.

Callout: Use rotary drying for tough, variable materials. Use fluid bed drying for high efficiency and uniform results with consistent materials.

Considerations

Material Properties

You need to know how your material behaves before you start fluid bed drying. The size and shape of each particle affect how well the air can lift and dry them. Moisture content also plays a big role. If your material holds a lot of water, it will take longer to dry. Some materials cannot handle high heat and may break down or lose quality. You should always check these properties first.

Influence on Drying Effectiveness | |

|---|---|

Particle Size and Shape | Affects fluidization behavior and drying speed. |

Moisture Content | Changes drying time and moisture removal ability. |

Heat Sensitivity | Sets the safe drying temperature to avoid damage. |

Tip: Test a small batch to see how your material reacts in the dryer.

Cost

You must plan your budget when choosing a fluid bed dryer. The price depends on the size, features, and brand. Advanced models with automation or energy-saving designs may cost more at first but can save money over time. You can buy new or used equipment. Used dryers cost less, but you need to check their condition. Lab-scale units are cheaper and work well for testing. Industrial units cost more but handle bigger jobs.

Cost Factor | Description |

|---|---|

Size and Capacity | Match the dryer to your production needs. |

Manufacturer Reputation | Trusted brands may offer better quality and support. |

Advanced Features | Automation and energy-saving options can lower long-term costs. |

New vs. Used Equipment | Used dryers save money but may need repairs. |

Price Range for Lab Units | |

Price Range for Industrial | $50,000–$200,000+ |

Used Equipment Pricing | $10,000–$150,000, depending on age and condition. |

Maintenance

You should keep your dryer clean and check it often. Dust and leftover material can block airflow and lower efficiency. Replace filters and inspect moving parts to prevent breakdowns. Regular maintenance helps you avoid costly repairs and keeps your dryer running smoothly. Make a checklist for daily, weekly, and monthly tasks. This simple habit can extend the life of your equipment.

Clean distributor plates and filters regularly.

Check for worn parts and replace them as needed.

Keep a log of all maintenance activities.

Note: Good maintenance saves you time and money in the long run.

Safety

You must follow safety rules when using a fluid bed dryer. Some materials can catch fire or explode if they get too hot. Drying chemicals may release harmful gases or dust. Overheating can cause materials to ignite on their own. The dryer may also release air pollution, such as smoke or harmful gases. Always use proper ventilation and monitor temperature closely.

Safety Concern | Description |

|---|---|

Flammable materials can ignite during drying. | |

Explosion hazards | High heat may cause pressure build-up and explosions. |

Chemical hazards | Harmful gases may escape during unloading. |

Overheating | Materials can heat up and catch fire by themselves. |

Air pollution hazards | Drying can release dust and harmful gases into the air. |

⚠️ Always train your team and use safety equipment to protect everyone in your facility.

You see fluid bed drying as a fast and versatile way to dry many products. The process gives you uniform results and saves energy. You can use it for pharmaceuticals, pressed fruits, and vegetables. The system fits both small and large production needs.

Advantage | Description |

|---|---|

Efficiency | Rapid, uniform drying |

Versatility | Handles many materials |

Product Quality | Gentle, preserves integrity |

Scalability | Fits any production size |

You should check your product’s sensitivity to heat and control settings for best results. Talk to experts before you choose this method.

FAQ

What materials can you dry with a fluid bed dryer?

You can dry powders, granules, pellets, and some crystals. Free-flowing materials work best. Sticky or very fine powders may cause problems. Always test your material first to see if it fits the process.

How do you control the drying temperature?

You set the temperature using the control panel. Sensors watch the heat level. You adjust the settings to keep your product safe. Lower temperatures help protect heat-sensitive materials.

Tip: Check the temperature often to avoid overheating your product.

Is fluid bed drying safe for food and medicine?

Yes, you can use fluid bed drying for food and medicine. The process meets strict safety standards. You control moisture and temperature to keep products safe and high quality.

How often should you clean a fluid bed dryer?

You should clean the dryer after each batch. Dust and leftover material can block airflow. Regular cleaning keeps your equipment working well and helps you avoid contamination.

Task | Frequency |

|---|---|

Clean filters | After each use |

Check plates | Weekly |

Inspect parts | Monthly |

Can you save energy with fluid bed drying?

Yes, you save energy because the system uses hot air efficiently. You finish drying faster than with older methods. Energy-saving models help you lower costs even more.

⚡ Choose a dryer with energy-saving features for best results.