Secadores por pulverización con atomizador rotatorio versus atomizadores de boquilla para uso industrial

Decision-makers often ask which atomizer spray dryer best suits industrial needs. Rotary atomizers and nozzle atomizers both deliver robust performance and reliability in large-scale production. Rotary atomizers offer continuous processing and handle high flow rates, making them popular in Europe. Atomizadores de boquilla, favored in the US, excel in producing finer droplets that can enhance product quality. Each atomization technology supports process efficiency and safety. The right choice depends on feed properties, tamaño de partícula deseado, and operational priorities.

Control de llave

Atomizadores rotativos handle thick, high-viscosity feeds well and resist clogging, making them ideal for large-scale, producción continua.

Atomizadores de boquilla produce finer, more uniform droplets, which improves product quality and suits industries needing precision and hygiene.

Rotary atomizers use less energy and have higher throughput but require more maintenance and can cause more downtime than nozzles.

Choosing the right atomizer depends on feed properties, tamaño de partícula deseado, maintenance limits, and cost considerations.

Regular cleaning, operator training, and smart controls help maintain efficiency and extend the life of both atomizer types.

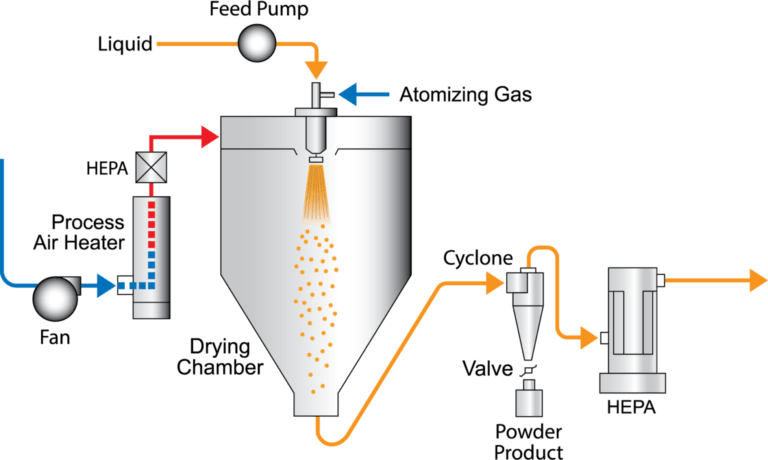

Atomizer Spray Dryer Basics

Atomizadores rotativos

Atomizadores rotativos play a central role in many industrial atomizer spray dryer systems. These atomizers use a rapidly spinning wheel to break up liquid feed into fine droplets. The droplets then enter a hot air stream, where they dry quickly. Rotary atomizers handle a wide range of feed viscosities and can process large volumes, making them ideal for continuous production.

Recent industrial studies show that rotary atomizers can achieve high performance even in harsh environments like mining and construction. Por ejemplo, advanced designs using 3D printing have improved durability and chemical resistance. Researchers have also used high-speed imaging and modeling to study how the liquid forms droplets. They found that the thickness of the liquid jet at the exit of the atomizer affects droplet size. By adjusting the speed and design, operators can control the spray pattern and improve energy efficiency.

Rotary atomizers offer flexibility and reliability, especially when processing feeds with varying properties.

Atomizadores de boquilla

Nozzles are another key technology in atomizer spray dryer systems. These atomizers use pressure nozzles or two-fluid nozzles to create fine sprays. Pressure nozzles force liquid through a small opening at high pressure, often up to 300 bar. Two-fluid nozzles mix liquid with compressed air, generalmente entre 4 y 10 bar, to form droplets.

Nozzles can produce very fine droplets, which helps create powders with uniform particle size and consistent quality.

The design of the nozzle, including its angle and internal structure, affects the spray pattern and droplet size.

Pressure nozzles work well for low to medium viscosity feeds and are common in food, farmacéutico, e industrias químicas.

Numerical simulations and experiments show that adjusting spray pressure changes droplet size and dust reduction performance.

Nozzles can face challenges with clogging, especially when handling thicker feeds.

Atomizer spray dryer systems that use nozzles offer precise control over product quality. Sin embargo, operators must consider the limitations of pressure nozzles, such as sensitivity to feed properties and the need for regular maintenance.

Diferencias clave

Control del tamaño de las gotas

Droplet size control stands as a critical factor in secado por aerosol. Operators rely on precise droplet size to influence powder quality, velocidad de secado, and product consistency. Rotary atomizers use a spinning disc to fling liquid outward, romperlo en gotas. The speed of the disc and the properties of the liquid, such as viscosity and surface tension, determine the resulting droplet size. By adjusting the disc speed, operators can shift the average droplet size, but the range of sizes often remains broad.

Nozzles, por otro lado, use pressure or air to force liquid through a small opening. This process creates droplets by breaking up the liquid stream. Nozzles offer more direct control over droplet size by changing the pressure or the gas-to-liquid ratio. Higher pressure in nozzles usually leads to smaller droplets. Two-fluid nozzles, which mix air and liquid, allow for even finer adjustments. Operators can fine-tune the droplet size by changing air pressure or nozzle geometry. This level of control helps produce powders with very uniform characteristics.

Consejo: For applications that demand tight control over droplet size and minimal variation, nozzles provide a clear advantage.

Distribución del tamaño de partículas

Particle size distribution describes how many particles fall into each size range after drying. This property affects flowability, solubilidad, and the final use of the powder. Rotary atomizers tend to produce a broader particle size distribution. The spinning disc creates droplets of many sizes, especially when processing feeds with higher viscosity. This flexibility allows rotary atomizers to handle a wide range of feed properties, but it can result in powders with mixed particle sizes.

Nozzles, especially blade-designed and two-fluid types, generate a more uniform particle size distribution in certain regions. The design of the nozzle and the operating pressure play a major role. Por ejemplo, increasing air pressure in twin-fluid nozzles reduces the number of large droplets, leading to a tighter distribution. Computational studies and experiments show that nozzle design affects how the liquid and gas mix, which shapes the final particle size distribution.

The following table summarizes key statistical comparisons between rotary atomizers and nozzles:

Métrico / Aspecto | Atomizadores rotativos (Spinning Disc) | Atomizadores de boquilla (Conventional & Blade-designed) |

|---|---|---|

Key Metrics | VMD-NMD ratio, Coefficient of Variation, Relative Span Factor (RSF), Rosin-Rammler (RR) distribution | Sauter Mean Diameter (SMD), Distribution fitting (RR, MRR), Coefficient of Variation |

Droplet Size Distribution | Broader distribution with more large droplets; influenced by disc speed, flow rate, and liquid properties | More uniform distribution in certain regions, influenced by nozzle design and operating parameters (e.g., gas-to-liquid ratio, presión de aire) |

Uniformidad | Evaluated via VMD-NMD ratio and RSF; uniformity improves with increased Reynolds number and disc speed | Blade-designed nozzles reduce velocity stratification, enhancing uniformity; air pressure dominates droplet size in twin-fluid nozzles |

Spray Formation Modes | Transition from direct drop to ligament and sheet formation with increasing flow rate; mixed modes observed | Primary and secondary breakup regions identified; breakup morphology changes with pressure and gas velocity |

Influencing Factors | Disc speed, flow rate, surface tension, liquid viscosity | Presión del aire, liquid velocity, viscosidad, surface tension, nozzle geometry |

Statistical Distribution Models | Rosin-Rammler (RR) and Modified Rosin-Rammler (MRR) distributions fit experimental data well | Maximum entropy method, discrete probability function (DPF), empirical approaches used for modeling droplet size |

Nozzles excel in producing consistent droplet size and a narrow particle size distribution. Atomizadores rotativos, while less precise, offer greater flexibility for feeds with higher viscosity or variable properties. The choice between these atomization methods depends on the desired powder quality and the nature of the feed material.

Performance Factors

Eficiencia

Industrial operators often evaluate atomizer spray dryers by how well they convert liquid feed into dry powder. Several metrics help measure this process:

Coverage: Measures how much area the spray reaches, which affects uniformity.

Particle Distribution: Shows how evenly droplets spread, influencing mixing and drying.

Penetrability: Tells how well droplets reach target surfaces, which is important for product quality.

Propeller-atomizer distance: Impacts spraying efficiency, as shown by smoke and laser tests.

Researchers use advanced tools like dimensional analysis and symbolic regression to predict droplet size and spreading. These methods help operators achieve accurate control over droplet size, with errors as low as ±15%. The Rosin-Rammler distribution function often models droplet size in industrial settings. Operators rely on these tools to maintain high efficiency in spray drying.

Throughput

Throughput describes how much product an atomizer can process in a given time. Rotary and nozzle atomizers show clear differences in this area. The table below compares typical performance data:

Métrico | Atomizador de boquilla (Snow Cannon) | |

|---|---|---|

Power Consumption | 9.7 kilovatios/h | 160 kilovatios/h (pump) + 75 kilovatios (motor) |

Typical Water Throughput | ~80 GPM | ~54 GPM |

Evaporation Efficiency | Más alto (~80% <150 micrones) | Más bajo (~14% evaporation) |

Droplet Size Distribution | 50-120 micrones (80% <150 micrones) | 500-600 microns average |

Operational Challenges | No clogging | Frequent clogging, overspray |

Evaporation Cost Efficiency | Lower cost per 1,000 gallons | Higher operational expense |

Rotary atomizers produce smaller droplets, which increases surface area and speeds up evaporation. They also avoid clogging and allow for steady flow. Nozzle atomizers create larger droplets that often fall back, reducing evaporation and raising costs. Rotary atomizers handle higher throughput with less energy, making them a strong choice for large-scale operations.

Feed Handling

Viscosity and Solids

Feed viscosity and solids content play a major role in atomizer spray dryer performance. Rotary atomizers handle a wide range of viscosities and high solids content with ease. Their spinning disc design allows thick or concentrated feeds to spread evenly, which helps maintain consistent droplet formation. In contrast, nozzle atomizers often work best with low to medium viscosity feeds. High viscosity or high solids can cause pressure drops and uneven spray patterns.

Pharmaceutical spray drying research shows that feed concentration directly affects droplet size y, in turn, the aerodynamic diameter of dried particles. This relationship impacts product quality and process efficiency. Studies on fluidized bed nozzles reveal that feed composition influences agglomerate size and liquid film thickness, which can change how well heat and mass transfer occur. Por ejemplo, an Air-Core-Liquid-Ring (ACLR) nozzle can handle feeds with viscosities up to 3 Pa·s and dry-matter contents up to 57% by weight. Sin embargo, higher viscosity leads to internal flow instabilities and a wider range of droplet sizes, sometimes producing droplets larger than 500 micrones. These findings confirm that viscosity and solids content are critical factors in atomizer selection and operation.

Operators should always match atomizer type to the feed’s viscosity and solids content to ensure stable performance and high product quality.

Clogging Resistance

Clogging can disrupt spray drying operations and reduce efficiency. Rotary atomizers have an open structure that resists clogging, even when processing feeds with suspended solids or high viscosity. This design advantage allows for longer run times and less frequent cleaning. Experimental studies highlight that rotary atomizers maintain narrow droplet size distributions while avoiding blockages.

Nozzle atomizers show more variation in clogging resistance. Tangential full cone nozzles, which lack internal vanes, resist clogging better than axial designs with swirl inserts. Pneumatic nozzles also differ: external mixing types keep liquid and gas streams separate, making them less likely to clog. Internal mixing nozzles, while effective at atomization, are more prone to blockages.

Atomizer Type | Clogging Resistance | Key Design Feature |

|---|---|---|

Atomizador rotatorio | Alto | Open spinning disc |

Tangential Nozzle | Moderate-High | No internal vanes |

Axial Nozzle | Moderate-Low | Swirl inserts |

Neumático (External) | Alto | Separate liquid/gas streams |

Neumático (Internal) | Bajo | Mixed liquid/gas inside nozzle |

Operators should consider clogging risk when choosing an atomizer, especially for feeds with high solids or viscosity. Selecting the right design reduces downtime and maintenance costs.

Maintenance Needs

Cleaning

Proper cleaning of atomizer spray dryers ensures consistent product quality and extends equipment life. Operators must remove soil and residue from both rotary and nozzle atomizers to prevent contamination and maintain efficiency. El EPA manual on precision cleaning outlines several effective strategies. It recommends regular maintenance routines that include washing, rinsing, and drying stages. Operators often use immersion tanks, hand-held spray washers, or forced air drying to clean atomizer components.

Case studies from industries such as electronics manufacturing show that automated jet spray cleaning systems work well for atomizers. These systems use programmable nozzles to target specific areas, reducing the need for manual labor and increasing repeatability. Companies like Digital Equipment Corporation have adopted aqueous cleaning methods in cleanroom environments, which help maintain high standards of cleanliness. Operator training also plays a key role. Well-trained staff can monitor cleaning solutions, adjust cleaning cycles, and respond quickly to any issues.

Regular cleaning and operator training help prevent buildup and keep atomizers running smoothly.

Downtime

Downtime affects productivity and costs in industrial spray drying. Rotary atomizers often require more maintenance due to their moving parts. Operators report frequent unplanned shutdowns caused by mechanical failures, hopper wetting, and scaling. Tasks such as balancing the atomizer wheel, monitoring slurry flow, and maintaining gearboxes add to the workload. These issues can lead to unstable temperatures and moisture problems in the system, sometimes forcing operators to reduce production rates.

Atomizadores de boquilla, which have no moving parts, generally offer greater reliability. After switching from rotary to nozzle atomizers, many facilities see fewer shutdowns and more stable operation. Nozzle systems allow for better spray pattern control and redundancy, which helps prevent wetting and moisture issues. Operators also notice lower flow rates for cooling gases, which means the system runs more efficiently.

Atomizadores rotativos: Higher maintenance, more frequent downtime

Atomizadores de boquilla: Lower maintenance, improved reliability, less downtime

Choosing the right atomizer can reduce maintenance needs and keep production lines running efficiently.

Cost Considerations

Initial Investment

Industrial atomizer spray dryers require a significant upfront investment. The type of atomizer chosen can greatly affect the initial cost. Rotary atomizers usually have a moderate purchase price. Nozzle atomizers often cost less to install, especially for smaller systems. Gas atomizers, used in specialized applications, have the highest initial investment. Their price ranges from $100,000 to several million dollars, depending on size and features.

Aspecto | Detalles |

|---|---|

Initial Investment Cost | Gas atomizers: $100,000 to several million dollars |

Costos operativos | High gas use, skilled maintenance required |

Ventajas | High purity, tamaño de partícula uniforme, scalability, eficiencia |

Limitaciones | High initial cost, complex operation, regular maintenance, material limits |

Water metal atomizers also come with high production and purchase costs. These costs can discourage companies from choosing them, especially when other atomizer types offer similar performance at a lower price. The need for frequent cleaning and maintenance adds to the financial burden.

Nota: Companies should compare the total initial investment for each atomizer type, not just the purchase price. Instalación, setup, and training can add to the total cost.

Operating Costs

Operating costs include energy use, mantenimiento, cleaning, y mano de obra. Rotary atomizers often require more maintenance due to moving parts. This can lead to higher ongoing expenses. Atomizadores de boquilla, with fewer moving parts, usually have lower maintenance costs. Sin embargo, they may need more frequent cleaning if the feed contains solids or is prone to clogging.

Gas atomizers consume large amounts of gas, which increases operational expenses. They also need skilled operators and regular upkeep. Water metal atomizers require frequent cleaning to maintain performance, which raises labor and downtime costs.

Atomizadores rotativos: Higher maintenance, moderate energy use

Atomizadores de boquilla: Lower maintenance, possible cleaning costs

Gas atomizers: High energy and maintenance costs

Water metal atomizers: High cleaning and labor costs

Companies should consider both initial and ongoing costs when selecting an atomizer. The right choice balances purchase price, maintenance needs, and daily operating expenses.

Ajuste de la aplicación

Industrial Uses for Rotary Atomizers

Atomizadores rotativos serve as the backbone in many large-scale industrial spray drying operations. Companies in the dairy industry use rotary atomizers to produce milk powder and whey protein. These atomizers handle high-viscosity feeds and large volumes, which makes them ideal for continuous production. Detergent manufacturers rely on rotary atomizers to create uniform granules that dissolve quickly in water. In the ceramics sector, rotary atomizers help form powders for tiles and advanced ceramics. Operators in the chemical industry choose rotary atomizers for their ability to process slurries with high solids content. Rotary atomizers also play a role in environmental applications, such as flue gas desulfurization, where they treat emissions by spraying absorbent slurries. Con el tiempo, industries have favored rotary atomizers for their flexibility and resistance to clogging, especially when processing challenging materials.

Industrial Uses for Nozzle Atomizers

Nozzles find their place in industries that demand precision and product consistency. The automotive sector uses nozzles for high-volume painting and coating, where a fine, even spray ensures a smooth finish. Pharmaceutical and cosmetic manufacturers depend on nozzles for sterile processing and precision spraying, which supports strict hygiene standards. Electronics companies use nozzles for coating and cleaning delicate components. In the food and beverage industry, nozzles deliver hygiene-sensitive spraying, meeting safety regulations. Aerospace manufacturers apply nozzles for coating and surface treatments, where durability and quality matter. The chemical industry uses nozzles for applying coatings and cleaning, often choosing designs that resist corrosion and handle various viscosities.

Sector Industrial | Key Applications/Processes | Reasons for Optimal Performance |

|---|---|---|

Automotive | High-volume painting and coating | Precise, efficient spray; supports automation |

Farmacéutico & Cosmético | Sterile processing, precision spray | High precision and hygiene; specialized designs |

Electronics | Coating and cleaning | Precise atomization; material compatibility |

Alimento & Beverage | Hygiene-sensitive spraying | Hygiene standards; material compatibility |

Aerospace | Coating and surface treatment | High-quality finishes; durabilidad |

Químico | Coatings and cleaning | Handles viscosities; corrosion resistance |

Nozzles have evolved with technology. Manufacturers now use smart nozzles and additive manufacturing to improve precision and efficiency. Environmental regulations have also shaped nozzle design, leading to more water-based and low-VOC coatings. Over the years, industries have shifted toward nozzles when they need accuracy, hygiene, and adaptability to new materials.

Energy and Reliability

Power Use

Industrial atomizer spray dryers require significant energy to operate. Rotary atomizers use electric motors to spin discs at high speeds. This design allows for efficient droplet formation and steady evaporation efficiency. Operators often choose rotary atomizers for large-scale production because they handle high flow rates with moderate power consumption. Nozzle atomizers rely on pumps or compressed air to create sprays. Pressure nozzles need strong pumps, while two-fluid nozzles use both air and liquid pressure. These systems can consume more energy, especially when producing very fine droplets.

Automatización systems help manage energy use. Sensors monitor temperature, presión, and humidity in real time. Operators can adjust settings to optimize performance and reduce waste. Advanced control systems also help maintain consistent product quality. By using automation, companies lower their energy bills and improve process stability.

Atomizer Type | Main Power Source | Typical Energy Use | Energy Optimization Features |

|---|---|---|---|

Atomizador rotatorio | Electric motor | Moderado | Variable speed control, automation |

Atomizador de boquilla | Pump or compressed air | Más alto (for fine spray) | Pressure regulation, automation |

Consejo: Regular monitoring and smart controls help keep energy use in check and support reliable operation.

Long-Term Durability

Industrial atomizers must withstand harsh conditions. Manufacturers use strong materials like stainless steel, cerámica, and special alloys. These materials resist high temperatures and corrosion, which extends equipment life. Design features such as reinforced frames and protective coatings add extra strength. Modular components make repairs and maintenance easier.

Modern atomizer systems include automation and control technology. These systems track equipment health and process parameters. Operators receive alerts when maintenance is needed, que reduce el tiempo de inactividad. Automation also improves safety and reduces human error. Companies see more consistent operation and fewer unexpected shutdowns.

Durable materials protect against wear and corrosion.

Reinforced frames and coatings increase lifespan.

Modular parts simplify maintenance.

Automation enables real-time monitoring and proactive care.

IoT and AI technologies are making predictive maintenance possible.

Emerging technologies continue to improve reliability. IoT sensors and AI tools predict problems before they cause failures. This approach keeps atomizer spray dryers running smoothly for years.

Atomizadores rotativos excel in high-volume, high-viscosity, and clog-resistant applications. Nozzle atomizers deliver precise particle size and suit industries needing hygiene and accuracy. Matching atomizer type to product, alimentar, and process priorities ensures optimal results.

Checklist for Choosing an Atomizer:

Identify feed viscosity and solids content

Define required particle size and distribution

Consider maintenance and downtime limits

Evaluate energy and cost constraints

Para soluciones personalizadas, companies should consult equipment suppliers or process engineers.

Preguntas más frecuentes

What is the main advantage of rotary atomizers in industrial spray drying?

Atomizadores rotativos handle high-viscosity feeds and large volumes. They resist clogging and support continuous production. Many industries choose rotary atomizers for their flexibility and reliability.

How do nozzle atomizers improve product quality?

Atomizadores de boquilla create fine, gotitas uniformes. This control leads to powders with consistent particle size. Industries needing precise quality, como los productos farmacéuticos, often select nozzle atomizers.

Which atomizer type requires less maintenance?

Nozzle atomizers have fewer moving parts. They usually need less maintenance than rotary atomizers. Operators report fewer unplanned shutdowns and more stable operation with nozzle systems.

Can both atomizer types process high-solids feeds?

Atomizer Type | High-Solids Feed Handling |

|---|---|

Atomizador rotatorio | Excellent |

Atomizador de boquilla | Moderado |

Rotary atomizers excel with high-solids feeds. Nozzle atomizers may clog or lose efficiency with thick materials.