Secador por pulverización centrífugo de alta velocidad, secador por pulverización de café instantáneo, máquina de secado por pulverización de leche en polvo

Descripción

Secador por pulverización centrífugo de alta velocidad, secador por pulverización de café instantáneo, máquina de secado por pulverización de leche en polvo

LPG Descripción del secador centrífugo de spray

La tecnología de secado en spray es la más amplia utilizada en la tecnología de conformación líquida y en la industria de secado. Es más adecuado para producir polvo, partícula, o bloquear productos sólidos de materiales de solución, emulsión, estados de pasta soliquoides y bombeables. Por lo tanto, El secado por pulverización es una de las tecnologías más deseadas cuando el tamaño de partícula y la distribución de los productos finales, su contenido de agua residual, y la densidad de almacenamiento y la forma de las partículas pueden cumplir con los estándares de precisión.

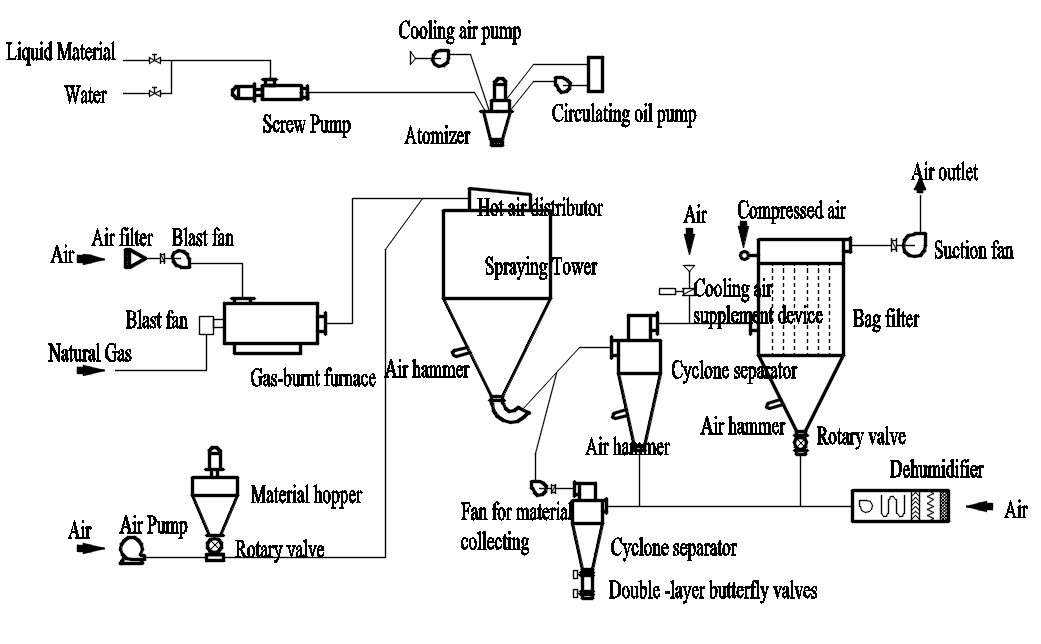

GLPG Centrifugal Spray Secador Principio de trabajo

El aire entra en el distribuidor de aire que en la parte superior del secador después de filtrar y calentar. El aire caliente en forma espiral entra de manera adecuada en la sala de secado. Cuando la materia prima líquida pasa a través del rociador centrífugo de alta velocidad en la parte superior de la torre, se girará y rociará en las cuentas líquidas de niebla extremadamente fina.. La materia prima se puede secar a los productos finales al instante mientras se pone en contacto con el aire con calefacción. Los productos terminados se descargan continuamente desde la parte inferior de la torre de secado y segregador de ciclones. El gas residual se descarga del soplador.

Características del secador de spray centrífugo de GLPG

1.La velocidad de secado es rápida. Cuando la materia prima líquida se atomiza, La superficie del material se ampliará enormemente. 95% – 98% de agua se puede evaporar instantáneamente en el flujo de aire caliente y el secado es solo unos segundos. Esta secadora es especialmente adecuada para secar el material sensible al calor..

2.La uniformidad, capacidad de flujo & La solubilidad de la secadora es muy buena. Los productos terminados tienen alta calidad y alta pureza.

3.Operación simple y estable, Control y depuración convenientes, Operación automática fácil de lograr.

4.El proceso de producción es simple, La secadora puede secar el material líquido que contiene 40%-60%(90% Para materiales especiales) de humedad en polvo a la vez. No hay necesidad de aplastar o tamizar después del secado para que el entorno operativo esté limpio y en condiciones saludables, También puede evitar volar en polvo en el aire durante el proceso de secado.

Aplicación de secador de spray centrífugo de GLPG

Industria química: Fluoruro de sodio (potasio), Tintes básicos & Pigmentos, Intermedios de tintes, Fertilizante, Ácido silícico fórmico, Catalizador, Agente de ácido sulfúrico, Aminoácidos, Negro de carbono blanco, y etc.

Resina de plástico: AB, Emulsión ABS, Resinas de urea-formaldehído, Resinas fenólicas, Resinas de formaldehído de urea, Polietileno, Cloruro de polivinilo, y etc.

Industria de alimentos: Leche rica en lípidos, Proteína de axila, Leche en polvo de cacao, Leche sustituta, Comida de sangre de caza, Clara de huevo (Amarillo), Jugo De Pollo, Café, Té instantáneo, Condimentar Carne, Proteína, Haba de soja, Proteína de maní, Hidrolizar, y etc.

Azúcar: Jarabe de maíz, Maicena, Glucosa, Pectina, Maltosa, Sorbato de potasio, y etc.

GLPG Centrifugal Spray Secador Parámetros técnicos

| Dimensión / Modelo | 5 | 25 | 50 | 150 | 200-2000 |

| Temperatura de entrada ° C | 140-350 control automático | ||||

| Temperatura de salida ° C | 80-90 | ||||

| máx.. Capacidad de evaporación (kg/hora) | 5 | 25 | 50 | 150 | 200-2000 |

| Método de atomización | transmisión de aire comprimido | tracción mecánica | |||

| Revolución (R.P.M) | 25000 | 18000 | 18000 | 15000 | 8000-15000 |

| Revolución (R.P.M) Diámetro de disco atomizante (milímetros) |

50 | 120 | 120 | 150 | 180-240 |

| Fuente de calor | electricidad | vapor+electricidad | vapor+electricidad, aceite, combustible de aceite, horno de aire caliente | ||

| máx.. Potencia de calefacción (kilovatios) | 9 | 36 | 72 | 99 | |

| Dimensiones generales (L × W × H)(metro) | 1.8× 0.93 × 2.2 | 3× 2.7 × 4.26 | 3.5× 3.5 × 4.8 | 5.5× 4 × 7 | Depende de la situación real |

| Tasa de restauración de polvo seco (%) | ≥95 | ||||

Notas: La cantidad evaporada de agua está relacionada con las características de las materias primas y la temperatura del aire de entrada y el aire de salida. Cuando la temperatura del aire de salida es de 90 ° C, La curva con clasificación de Evapo de agua se enumera en la tabla anterior (Solo como referencia). Si el producto ha sido mejorado o actualizado por una nueva tecnología, Los parámetros relacionados se cambiarán en consecuencia!

Atención al orden

◎ Nombre y propiedad líquida: Contenido sólido(o contenido de agua), viscosidad , tensión superficial y valor de pH.

◎ Contenido de agua residual de densidad de polvo seco permitido, tamaño de partícula, y la temperatura máxima permitida.

◎ Salida: Tiempo de cambio diario .

◎ Energía que se puede suministrar: presión de vapor, Electricidad correctamente , combustible de carbón, petróleo y gas natural .

◎ Requisito de control: Si las temperaturas de entrada y salida deben controlarse o no.

◎ Requisito de recolección de polvo: Si es necesario usar lter de bolsa de tela y el requisito del entorno del gas agotado .

◎ Otros requisitos especiales.

GLPG Centrifugal Spray Secador Parámetro técnico

| Tamaño | A | B | C | D | E1 | E2 | F | GRAMO | H | I |

| GLP-25 | 1290 | 3410 | 4260 | 1800 | 1200 | 1200 | 1000 | 1700 | 1300 | 1550 |

| GLP-50 | 1730 | 4245 | 5100 | 2133 | 1640 | 1640 | 1250 | 1750 | 1800 | 1600 |

| GLP-100 | 2500 | 5300 | 6000 | 2560 | 2100 | 2100 | 1750 | 1930 | 2600 | 1780 |

| GLP-150 | 2800 | 6000 | 7000 | 2860 | 2180 | 2180 | 1970 | 2080 | 3050 | 1960 |

| LPG-200 | 2800 | 6600 | 7300 | 3200 | 2300 | 2300 | 2210 | 2250 | 3050 | 2100 |

| LPG-300 | 2800 | 8000 | 8700 | 3700 | 2800 | 2800 | 2520 | 2400 | 3040 | 2250 |

Reseñas

Aún no hay reseñas.