3 Datos clave sobre las especificaciones del secador de lecho fluidizado que necesita

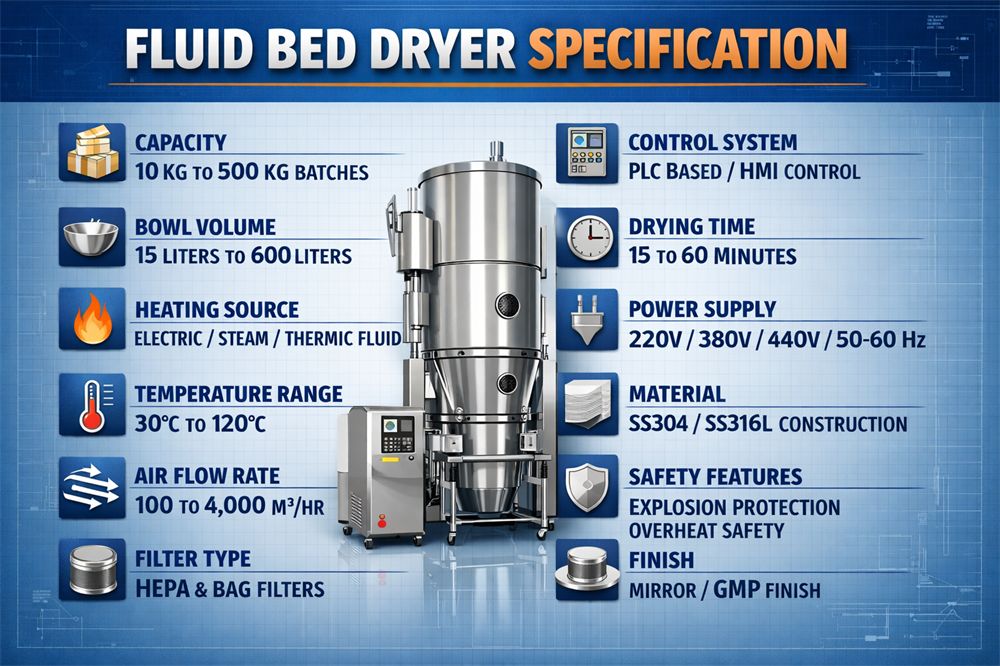

When you choose a fluid bed dryer, it’s essential to consider three main factors: airflow capacity, temperature control range, and batch size or volume. These fluid bed dryer specifications determine how the dryer operates and whether it meets your specific needs. Airflow capacity influences the speed and efficiency of the drying process. The temperature control range affects the rate at which moisture is removed from the material. Batch size indicates the quantity you can dry in a single operation. The table below illustrates how these specifications impact the performance of the dryer:

Variable | Impact on Performance |

|---|---|

Airflow Capacity | Enhances drying speed and allows for larger drying volumes |

Temperature Control Range | Accelerates drying and reduces energy consumption |

Batch Size | Affects the movement and drying efficiency of the material |

Jiangsu Changshi Technology employs innovative designs and custom solutions to ensure you maximize the benefits of every fluid bed dryer.

Control de llave

Pensar en airflow capacity to make drying faster and better. Good airflow helps heat materials evenly.

Check the temperature control range for your drying needs. This stops damage and keeps results the same each time.

Pick the right batch size for your production goals. The right batch size makes work faster and improves quality.

Find safety features like sensors and automation in the dryer. These features make the dryer safer and easier to use.

Talk to experts like Jiangsu Changshi Technology for custom solutions. Custom designs can make your drying process better.

Fluid Bed Dryer Airflow Specification

What Is Airflow in Fluid Bed Dryer Design

Airflow is very important in fluid bed dryer specification. It means how fast hot air moves inside the dryer. This moving air lifts and holds up the particles. The particles act like a liquid when this happens. In fluid bed dryer design, you measure airflow by how fast it goes. The right airflow makes sure every particle gets heated. This helps the dryer work well. Si quieres secar la comida, you might see airflow capacity numbers like these:

Industria | |

|---|---|

Industria de alimentos | 10–30 |

Industria química | N / A |

Jiangsu Changshi Technology uses special distributor plates and airflow controls. These tools help you set the airflow for your material and process.

Eficiencia & Quality Impact

How you set airflow in your dryer changes drying speed and product quality. When you control airflow, you get even drying and keep your product good. The fluidization process helps heat and mass move better. This means moisture leaves faster and more evenly. Look at how airflow rates connect to drying results:

Aspecto | Descripción |

|---|---|

Airflow Rates | Controlled airflow is key for even drying and keeping product safe. |

Eficiencia de secado | The fluidization process helps heat and mass move, so moisture leaves quickly. |

Calidad del producto | Steady drying keeps the product good and stops over-drying or under-drying. |

The right airflow helps you stop problems like too much or too little drying. This matters for industries with strict quality rules.

Advanced Airflow Features

Modern fluid bed dryers have new airflow features. These features help you get better results. Here are some benefits you can get:

Even drying lowers moisture differences by heating each particle.

Faster drying times remove moisture quicker than old dryers.

Energy efficiency saves energy for each batch.

Gentle handling is good for materials that are sensitive to heat, Como comida y medicina.

Jiangsu Changshi Technology gives custom airflow solutions in their fluidized bed dryer designs. You can work with their team to set airflow for your material and needs. This focus on design and quality helps you get good drying and top product quality every time.

Fluid Bed Dryer Design: Control de temperatura

Temperature Range Explained

It is important to know how temperature control works in fluid bed dryer design. El temperature range is a big part of fluid bed dryer specification. This lets you dry many materials, like food or chemicals. The dryer can get very hot for hard jobs. It can also stay cool for things that need gentle drying. The table below shows how these dryers can be used in different ways:

Característica | Descripción |

|---|---|

Rango de temperatura | Made for many temperatures so you can use it for lots of things. |

Application Flexibility | Can dry materials that need careful temperature control. |

High-Temperature Drying | Can dry things that need high heat to remove water. |

Low Residual Moisture Levels | Helps get very low moisture by drying slowly and carefully. |

You can control the heat and airflow very well. This helps stop burning or not drying enough. The design lets you set different temperatures in heating and cooling areas. This makes the fluidized bed dryer design very useful.

Material Sensitivity & Results

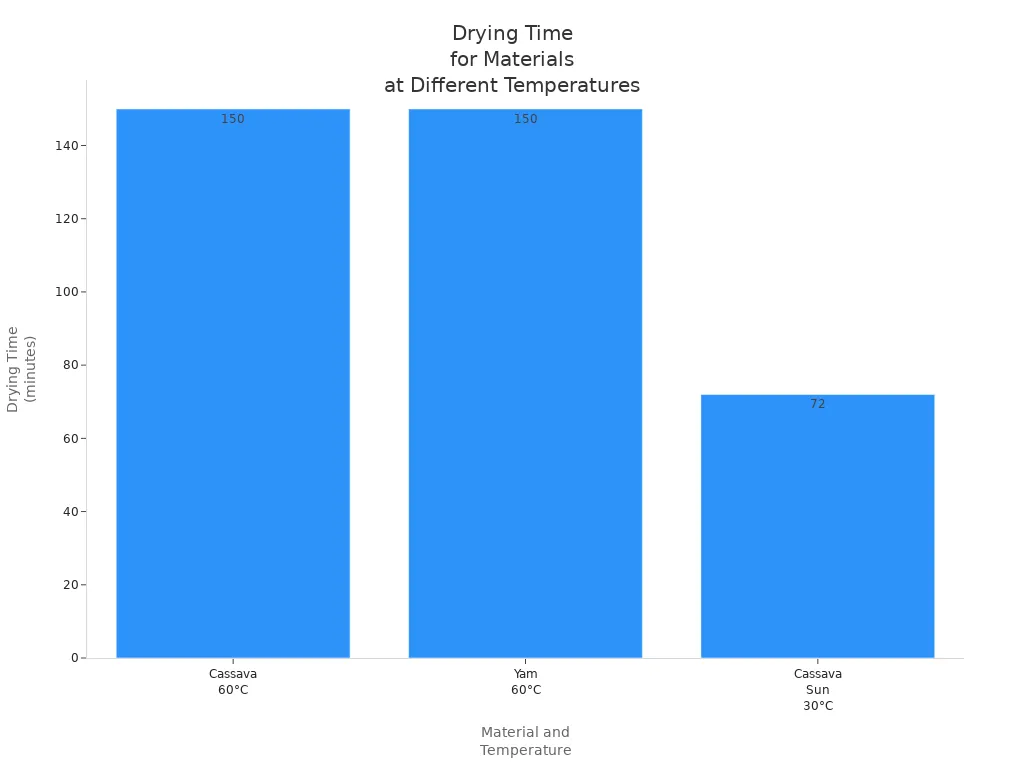

Different materials act in their own way when heated. Some need soft drying to keep them good. Por ejemplo, medicine often needs low heat. Foods like maize or cassava also need careful drying. The table below shows how temperature changes drying for different things:

Material | Initial Moisture Content (%) | Final Moisture Content (%) | Tiempo de secado (minutos) | |

|---|---|---|---|---|

Cassava | 60 | 75.4 | 11 | 150 |

Yam | 60 | 75.4 | 11 | 150 |

Maize | 40 | 75.4 | 11 | N / A |

Cassava (Secado al sol) | 30 | 75.4 | 11 | 72 |

You can see that lower heat takes more time but keeps the product safe. Good temperature control in fluid bed dryer design helps you dry things well and get the same results each time. You also stop problems like damage from too much heat or color changes.

Seguridad & Automation Features

Safety is very important in fluidized bed dryer design. New dryers use sensors and valves to keep things safe. Automatización lets you check and change heat and airflow easily. You can use a control panel to set what you want and see data right away. Some dryers use AI and IoT to watch temperature and moisture all the time. These features help you keep your product good and save energy. The table below lists some safety and automation características:

Característica | Descripción |

|---|---|

Automatización | Computers help control the dryer for safety and better work. |

AI and IoT Integration | Always checks and changes things by itself. |

Control Panel | Lets you set heat and airflow and see data as it happens. |

Continuous Monitoring | Watches heat, humedad, and airflow to keep things safe and save energy. |

Jiangsu Changshi Technology uses smart design and checks for quality to give you safe and strong dryers. You can ask for special temperature control for your material and process. This focus on design and settings helps you get great results every time.

Key Parameters in Fluidized Bed Dryer Design: Batch Size & Volumen

Batch Size Specification

When you think about fluid bed dryer specification, batch size is very important. Batch size means how much material you can dry at once. You should pick a batch size that fits your needs. Por ejemplo, a fluid bed dryer that holds 120-150 kg uses a container that is 200 litros. Some dryers can dry 100 a 300 kg in one batch, and their containers can be as big as 670 litros. The table below shows how batch size and volume are different for each dryer type:

Tipo de secadora | Batch Size (kg) | Volumen (l) |

|---|---|---|

Lab-Scale Fluid Bed Dryer | 0.5 – 5 | N / A |

Fluid Bed Dryer 120kg | N / A | 200 |

Batch Powder Fluid Bed Dryer | 100 – 300 | 670 |

Throughput & Production Needs

Batch size is linked to how much you can make and how fast. If you use a dryer with a bigger batch size, you can dry more material at one time. This helps you dry things faster and reach your goals. In medicine, alimento, and chemical work, batch sizes can be from 5 a 1500 kg. You need to pick the right batch size to get the best results. Companies use special models to find the best settings and keep the product good. When you choose the right fluidized bed dryer, you can make more and work better.

Área de aplicación | Batch Size Range (kg) |

|---|---|

Farmacéutico | 5 a 1500 |

Alimento | 5 a 1500 |

Chemical Processing | 5 a 1500 |

Customization & Application Matching

Sometimes you need a dryer made just for your process. Jiangsu Changshi Technology can make special dryers to fit your batch size and volume. Custom dryers help you reach your goals and keep your product good. You can pick special spray nozzle systems or designs for your material and how much you make. This makes sure your product is always good and dries well. Por ejemplo, Jiangsu Changshi Technology has models like JCT-C-I and JCT-C-II. These can dry 100 kg and 200 kg in one batch. You get a dryer that fits your work and helps you make more.

Customization Aspect | Beneficio |

|---|---|

Tailored Solutions | Meets specific production needs |

Improved Efficiency | Enhances overall process performance |

Consistent Quality | Ensures uniform product characteristics |

Consejo: Always look at the main parameters in fluidized bed dryer design before you choose. The right batch size and volume help you get good results and high product quality.

When picking a fluid bed dryer, you should look at three things: flujo de aire, control de temperatura, and batch size. These choices help you get good drying and keep your product safe. The table below shows how each part helps your work and product:

Especificación | Impact on Performance |

|---|---|

flujo de aire | Makes drying even and quicker |

Control de temperatura | Gives better drying and keeps products safe |

Batch Size | Helps you make more at once |

Always check these features before buying a dryer.

Jiangsu Changshi Technology can make dryers that fit what you need.

Think about safety, easy controls, and if the dryer works with your material for the best results.

Preguntas más frecuentes

What is the main purpose of a fluid bed dryer?

You use a fluid bed dryer to remove moisture from powders or granules. El design lifts and mixes particles with hot air. This process dries materials quickly and evenly.

How does the design of a fluid bed dryer affect drying results?

The design controls airflow and temperature. You get even drying and protect your product. Good design also helps you save energy and improve quality.

Can you customize the design for different materials?

Sí, you can match the design to your material. You choose airflow, temperatura, and batch size. This helps you get the best results for your process.

What safety features should you look for in a dryer?

You should look for sensors, control panels, and automatic shut-off. These design features keep your dryer safe and easy to use.

How do you choose the right dryer for your needs?

You check the design, tamaño del lote, and temperature range. You also think about your material and production goals. The right dryer helps you work faster and get better results.