Comprensión del diagrama esquemático del secador de lecho fluidizado

You use a fluid bed dryer to take water out of powders and granules. Hot air moves through the powders and granules. This helps you dry them evenly in many industries. Jiangsu Changshi Technology makes advanced drying machines. They focus on fluid bed dryers. Knowing the fluid bed dryer schematic diagram helps you use the machine safely. It also helps you fix problems fast. The table below shows how you use a fluid bed dryer for different jobs in each industry.

Industria | Main Functions |

|---|---|

Farmacéutico | Drying Active Pharmaceutical Ingredients, Secado de granulación, Tablet Drying |

Químico | Drying Chemical Powders, Polymer Drying, Chemical Reaction Drying |

Procesamiento de alimentos | Drying Grains and Cereals, Drying Coffee Beans, Drying Fruits and Vegetables |

Mineral Aggregate | Drying Minerals and Ores, De-agglomeration |

Biomass | Drying Biomass for better burning |

Recycling | Drying and handling waste to make new products or fuel |

Control de llave

Fluid bed dryers use hot air to dry powders and granules. This helps them dry evenly. They are important in places like medicine and food factories.

Knowing the fluid bed dryer schematic diagram helps you find parts fast. It also helps you fix problems quickly. This keeps the dryer safe and working well.

The main parts are the air supply, calentador, and dust separation. These parts work together to keep the product good while drying.

You can change the air temperature and flow. This helps you make drying faster or slower. It lets you control how things dry and how good they turn out.

Fluid bed dryers can be used for many things. Ellos save energy and work with different materials. They are good for things that need gentle heat.

What Is a Fluid Bed Dryer?

Definition and Principle

A fluid bed dryer is a machine that dries things like powder and granules. You put the wet material in a chamber with small holes at the bottom. When you start the machine, hot air blows up through the holes. The air lifts the particles and makes them float around. The particles move like a liquid. This is called fluidization.

Here is how fluidization happens in a fluid bed dryer:

The air makes the solid particles float and move like a fluid.

The hot air gives heat to the particles, so water turns into vapor.

You can change the drying time by setting the air and heat.

The moving air stops the particles from sticking together, so they dry evenly.

The air takes the water vapor away, and it leaves as wet exhaust.

The air touches every particle, so drying is fast and even. This way works better than many other drying ways. The fluid bed dryer lets you control the drying, so you get the results you want.

Key Functions

You use a fluid bed dryer to lower water in powders and granules. This helps keep your products safe and good quality. The machine is used in many fields, like medicine and food. Jiangsu Changshi Technology makes special fluid bed dryers for these jobs.

Solicitud | Descripción |

|---|---|

Drying of active pharmaceutical ingredients (API) | You dry them evenly, so they stay strong and good quality. |

Secado de granulación | You use it after making wet granules to get the right size and dryness. |

Tablet drying | You take out water from tablets without breaking them. |

Drying grains and cereals | You make them last longer and stop them from going bad. |

Drying coffee beans | You keep the taste and smell by drying them gently and evenly. |

Drying of fruits and vegetables | You make them last longer by taking out water before packing. |

Jiangsu Changshi Technology can make dryers that fit what you need. You can count on them for good and steady drying.

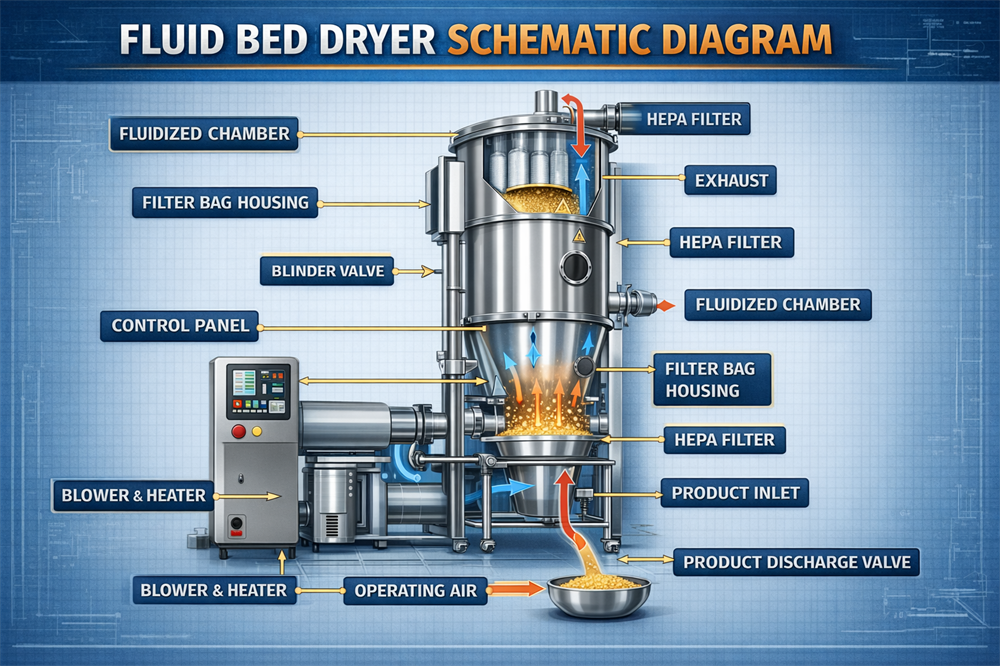

Fluid Bed Dryer Schematic Diagram

When you look at the fluid bed dryer schematic diagram, you can see how the machine works. The diagram helps you learn how air moves and how materials travel inside. It also shows how each part connects to another part. If you study the diagram, you can find problems fast. You can also make good choices when you use or fix the machine. The diagram shows where air and material go, so you know where to look if something is wrong.

Componentes principales

A fluid bed dryer schematic diagram has many parts. Each part does something important to help the dryer work. Here are the main parts you will see:

Air supply: Brings in new air.

Calentador: Makes the air hot before it goes in.

Air distributor plate: Spreads the air under the material.

Feed supply: Puts wet powder or granules into the chamber.

Dust separation: Stops dust from getting out.

Collection and control panel: Lets you watch and change how the dryer works.

Spray manifolds (optional): Add liquid for special drying jobs.

Dehumidifiers (optional): Take out extra water from the air.

External and internal agitation: Use motors or agitators to keep things moving.

Exhaust outlet: Lets wet air leave the chamber.

Fluid bed processor: This is where the drying happens.

Gyratory motors: Shake the chamber to mix better.

Spacer frame: Holds the parts in place.

Expansion chamber: Gives more room for air and material to move.

Material discharge spout: Sends dry material out of the dryer.

Blower or supply fan: Pushes air through the dryer.

Heater/cooler moisturizer: Changes the air’s heat and moisture.

Air inlet: Where air comes in.

Cyclone separator: Takes fine particles out of the exhaust.

Vibratory or auger discharge conveyor: Moves dry material out.

Sistema de control: Lets you set and change how the dryer works.

Consejo: When you look at the fluid bed dryer schematic diagram, pay close attention to the air distribution system. The air distributor plate spreads air so every particle gets dry. Some plates make the air swirl, which saves energy and dries things faster.

How to Read the Diagram

To read a fluid bed dryer diagram, follow the path of air and material. Start at the air inlet. Air goes through the heater and then into the chamber under the distributor plate. The plate spreads the air so the material floats and dries. Wet air leaves through the exhaust outlet. You can see where dust separation and cyclone separators keep the air clean. The control panel lets you change the heat and air flow.

You will also see that batch and continuous fluid bed dryer diagrams look different. Batch models dry one load at a time. Continuous models keep material moving and drying all the time. The table below shows how these two types are different:

Característica | Secador de lecho fluido por lotes | Secador de lecho fluido continuo |

|---|---|---|

Operation | Dries material in batches | Dries material all the time |

Design | Uses a disc with holes for air | Uses heated air through a plate |

Movimiento material | Loads, se seca, and empties in batches | Moves from one chamber to the next |

Discharge Mechanism | Uses a stream or hopper to empty | Lets material out all the time |

Heat Transfer Systems | Changes by design | Can use different heat units |

When you look at the fluid bed dryer schematic diagram, you see how all the parts work together. You can follow the arrows and lines to learn how drying happens. You use the diagram to check the main parts and make sure the dryer works right. If you want to know more, you can ask Jiangsu Changshi Technology for special diagrams that fit what you need.

Fluid Bed Dryer Operation

Drying Process Steps

You can understand how a fluid bed dryer works by following each step in the drying process. The machine uses hot air to dry materials like powder. Here is a simple way to see the main steps:

Loading: You place the material to be dried into the chamber. This can be powder or granules.

Air Flow: Hot air enters through a perforated plate at the bottom. The air lifts the particles and creates a fluidized bed. You see the answer to how does a fluid bed dryer work in this step.

El secado: The hot air touches every particle. Moisture evaporates and leaves the material. This step is important for drying powders quickly and evenly.

Exhaust: Moist air exits the chamber through filters or a cyclone separator. The system keeps the air clean and removes water vapor.

Discharging: You remove the dried product from the dryer. The material is now ready for the next step in your process.

Consejo: If you want to get the best results, make sure you load the right amount of material and set the correct air temperature.

Reference Points in the Diagram

When you look at the schematic diagram, you find several control points that help you run the fluid bed dryer safely and efficiently. These points show you how does a fluid bed dryer work and where you can check or adjust the process.

Inlet-Air Temperature: You set and monitor the temperature of the air entering the dryer.

Out-Air Temperature: You check the temperature of the air leaving the chamber.

Product Temperature: You watch the temperature of the material inside the dryer.

Fan Motor Speed: You control how fast the fan moves air through the system.

Loss On Drying (LOD): You measure how much moisture leaves the material.

These reference points help you keep the drying process stable. You can use the diagram to find each point and make changes if needed. The fluid bed dryer gives you control over every step, so you get high-quality dried products every time.

Advantages and Applications

Benefits of Fluid Bed Dryers

Secadores de cama fluida give you many benefits in production. The machine dries every particle at the same speed. This helps your product quality stay high. The dryer keeps the temperature steady and stops overheating. The process is quick, así ahorrarás tiempo y energía. You can use it for many powders and granules. It works well even for materials that are sensitive to heat.

Here is a table that shows the main benefits of fluid bed dryers compared to older drying machines:

Ventaja | Descripción |

|---|---|

Efficient Drying | Heat spreads evenly and removes moisture from all particles. |

Fast Process | It dries things faster than older machines. |

Versatilidad | You can dry many materials, even those that need gentle heat. |

Energy-Efficient | It uses less energy because heat moves well. |

Escalabilidad | You can get small or big dryers for labs or factories. |

The air touches every particle, so heat and mass transfer work well. This means you dry things quickly and keep them good quality. In medicine, you control drying steps closely to meet strict rules. En comida, you keep taste and safety while making products last longer.

Consejo: Jiangsu Changshi Technology can make special dryers for you. Their team helps you pick the right dryer and checks quality at every step.

Typical Uses in Industry

Secadores de cama fluida are used in many industries. More than half of medicine companies use these dryers for drying and granulation. Food factories use them to dry fruits, verduras, granos, y hierbas. Chemical plants use them to dry compounds and colors. You also see them in detergent making, mining, and farming for drying seeds and coffee beans.

Here are some common ways people use fluid bed dryers:

Farmacéuticos: Dry powders, gránulos, y tabletas with careful control.

Procesamiento de alimentos: Dry fruits, verduras, granos, and herbs and keep them good.

Químicos: Dry chemical compounds and colors.

Detergentes: Dry detergent powders and cleaning products.

Minerales: Dry mineral ores and aggregates.

Agricultura: Dry seeds, granos, and coffee beans.

Jiangsu Changshi Technology makes advanced dryers for many jobs. Their custom designs and quality checks help you get great results for your products.

When you know how to read the fluid bed dryer schematic diagram, you get many benefits.

You can see how air and water move during drying.

You learn how air temperature and Adiabatic Saturation Ratio help remove water.

You make the process better by picking the right dryer and getting your material ready.

If you pick new machines from Jiangsu Changshi Technology, you can work faster and save time. For the best results, ask experts for help with custom drying.

Factor | Explicación |

|---|---|

Material properties | You pick the best dryer by knowing tamaño de partícula and water amount. |

Capacidad | You choose drying speed to fit your production. |

Eficiencia energética | You save money by using heat and air in a smart way. |

Integration | You make sure your dryer works with your other machines. |

Specific challenges | You get special advice for your own process problems. |

Preguntas más frecuentes

What materials can you dry in a fluid bed dryer?

Puede polvos secos, gránulos, granos, semillas, and even some small crystals. This machine works well for food, medicamento, quimicos, y minerales.

How do you clean a fluid bed dryer?

You should turn off the machine and let it cool. Remove leftover material. Use a soft brush or vacuum. Wipe surfaces with a damp cloth. Always follow safety rules.

Why does air temperature matter in drying?

Air temperature controls how fast water leaves your material. If you set it too high, you may damage your product. If it is too low, drying takes longer.

Can you adjust the drying time?

Sí, you can change the drying time. You do this by setting the air speed, temperatura, and how much material you load. The control panel helps you make these changes.

What safety steps should you follow?

Always check that all parts work before you start. Wear safety gear. Never open the chamber while the machine runs. Follow the instructions from your manufacturer.