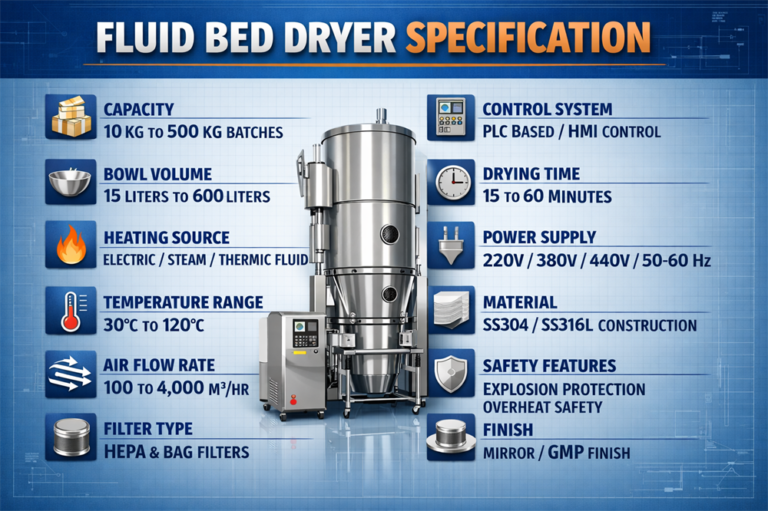

3 Datos clave sobre las especificaciones del secador de lecho fluidizado que necesita

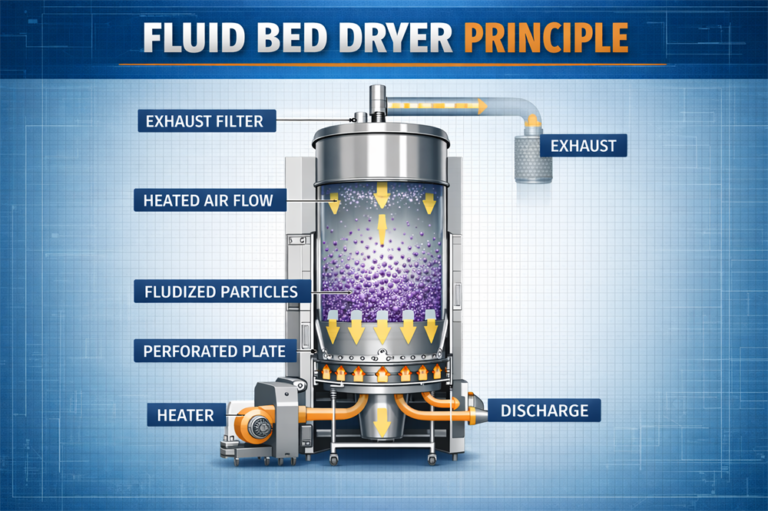

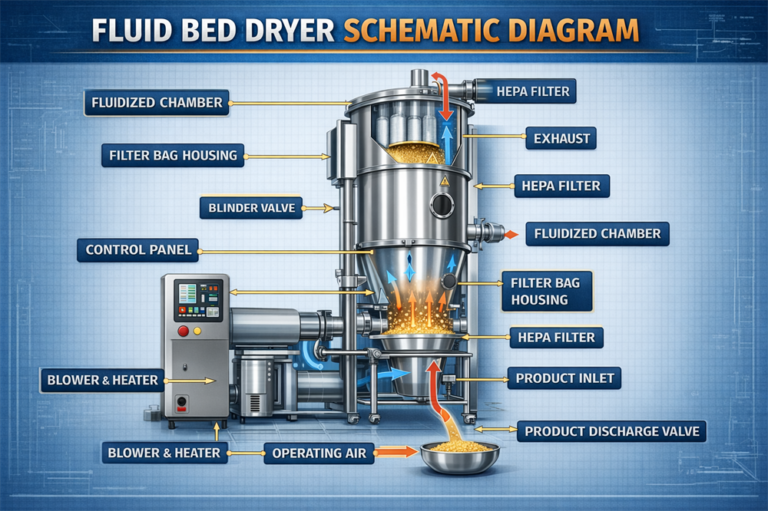

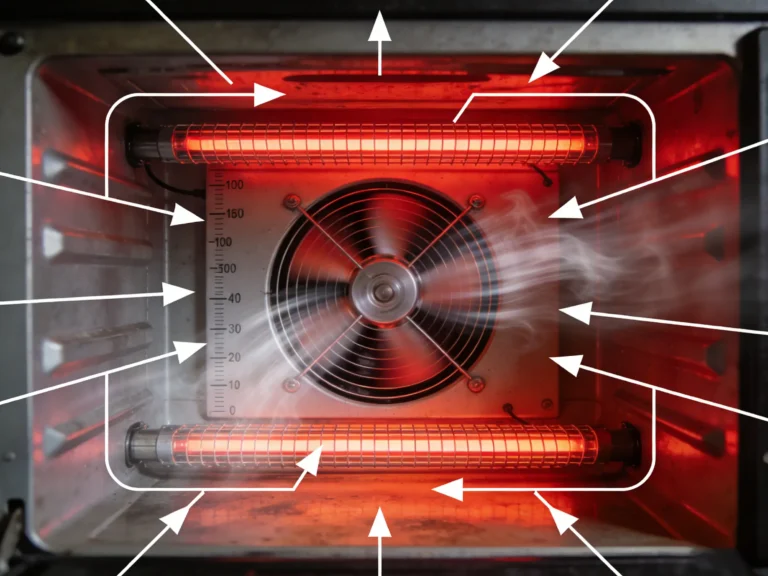

Comprender las especificaciones del secador de lecho fluido: flujo de aire, control de temperatura, y tamaño del lote para un rendimiento de secado óptimo y una calidad constante del producto.