Spitze 10 Hersteller von Sprühtrocknungssystemen in 2025

GEA-Gruppe

SPX FLOW

BÜCHI Labortechnik

Europäische SprayDry-Technologien (ESDT)

Dedert Corporation

Tetra Pak

Shandong Tianli Trocknungstechnologie

Freund-Vector Corporation

G. Larsson-Stärketechnologie

DryDania

Die Auswahl des richtigen Sprühtrocknungssystems fördert das Marktwachstum und steigert die Produktionseffizienz. Marktführende Lieferanten und Hersteller bieten fortschrittliche Sprühtrocknungssysteme an, was kann die Energieeffizienz um bis zu verbessern 40%. Die besten Hersteller von Sprühtrocknern zeichnen sich durch ihre Technologie aus, breite Produktpalette, starke globale Präsenz, ausgezeichnete Kundenbetreuung, und Ruf. Die Abstimmung der Stärken jedes Herstellers auf spezifische Anforderungen an die Produktionseffizienz gewährleistet eine höhere Produktqualität und eine bessere Marktleistung.

Wichtige Erkenntnisse

Führende Sprühtrocknungshersteller sind mit fortschrittlicher Technologie führend, die die Energieeffizienz und Produktqualität steigert.

Eine breite Produktpalette und ein starker globaler Support helfen Unternehmen dabei, das richtige Sprühtrocknungssystem für ihre Bedürfnisse zu finden.

Die Wahl des richtigen Systems hängt von der passenden Technologie ab, Budget, und After-Sales-Service für spezifische Produktionsziele.

Sprühtrocknung spielt eine Schlüsselrolle in der Ernährung, pharmazeutisch, und chemische Industrie durch Verbesserung der Produktstabilität und -leistung.

Regelmäßige Wartung und Sicherheitskontrollen sichern die langfristige Effizienz und schützen Investitionen in Sprühtrocknungsanlagen.

Auswahlkriterien

Technologie

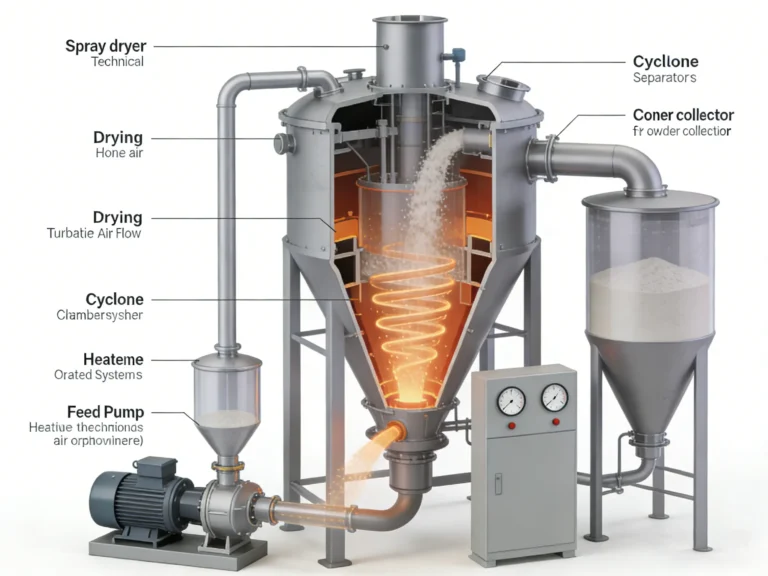

Hersteller erreichen Spitzenplätze, indem sie in fortschrittliche Technologie für Sprühtrocknungsanlagen investieren. Automatisierung und Digitalisierung Fahren Sie nun den Sprühtrocknungsprozess fort, Verbesserung der Effizienz und Kontrolle. Führende Unternehmen nutzen Automatisierung, Steuerungssysteme, und Wärmeübertragungstechnologie, um zuverlässige Ergebnisse zu liefern. Viele Systeme verfügen über eine HEPA-Filtration, Temperaturregelung, und Feuchtigkeitssensoren. Diese Funktionen helfen, die Qualität zu überwachen und Fehler zu reduzieren. Echtzeitüberwachung und fortschrittliche Kontrollstrategien, wie Feed-Forward- und Feedback-Schleifen, unterstützen eine gleichbleibende Produktqualität. Bedienerschulungen und vorbeugende Wartungsprogramme reduzieren mechanische Probleme zusätzlich. Unternehmen, die energieeffizientes Design und nachhaltige Verarbeitungslösungen anbieten, stechen im Markt hervor.

Produktpalette

Eine vielfältige Produktpalette signalisiert die Fähigkeit eines Herstellers, unterschiedliche Branchenanforderungen zu erfüllen. Top-Anbieter bieten Sprühtrocknungsgeräte an Labor, Pilot, und vollständige Produktionsmaßstäbe. Ihre Ausrüstung dient der Pharmaindustrie, Essen und Trinken, und Biotechnologiesektoren. Diese Vielfalt ermöglicht es Kunden, die richtige Lösung für ihre spezifische Anwendung zu finden. Marktdaten zeigen, dass führende Marken Geräte für verschiedene Regionen und Branchen anbieten, mit detailliertem Benchmarking und Marktanteilsanalyse. Diese breite Produktpalette stellt sicher, dass Sprühtrocknungsdienstleistungen sowohl die Forschung im kleinen Maßstab als auch die Produktion im großen Maßstab unterstützen können.

Unterstützung

Starke Supportleistungen zeichnen die besten Hersteller aus. Unternehmen mit globaler Reichweite bieten Sprühtrocknungsdienstleistungen wie Schulungen an, Ersatzteillogistik, und Leistungsprüfungen. Technische Zertifizierungen und Remote-Service-Plattformen Stärkung der After-Sales-Netzwerke und Steigerung der Kundenbindung. Partnerschaften mit Forschungseinrichtungen tragen dazu bei, neue Technologien schnell auf den Markt zu bringen. Hersteller mit robusten Sprühtrocknungsdiensten gewährleisten die Widerstandsfähigkeit der Lieferkette und die Einhaltung internationaler Standards. Ihr Engagement für Sicherheit, Zertifizierungen, und ihr Ruf machen sie zu zuverlässigen Partnern für Kunden weltweit.

Führende Hersteller von Sprühtrocknern

GEA-Gruppe

Die GEA Group gilt als weltweit führender Hersteller von Sprühtrocknern. Das Unternehmen bietet eine breite Palette an Sprühtrocknungsausrüstung, einschließlich der Systeme NIRO Minor und NIRO Mobile Minor. Diese Systeme unterstützen das Labor, Pilot, und Produktion im industriellen Maßstab. Die Technologie von GEA ermöglicht eine präzise Steuerung der Trocknungsparameter, Dies hilft, Ausbeute und Pulverqualität zu optimieren. Zum Beispiel, Das NIRO Minor-System hat eine hohe Effizienz bei der Trocknung pflanzlicher Getränke bewiesen, erreichen Erträge bis zu 59.2% mit Prozessmodifikationen wie der Sprühtrocknung mit entfeuchteter Luft. Mit der Ausrüstung von GEA können Benutzer die Prozessbedingungen anpassen, um Pulver mit spezifischen physikalischen Eigenschaften herzustellen. Diese Flexibilität macht GEA zur bevorzugten Wahl für Lebensmittel, Getränk, und pharmazeutische Anwendungen. Die globale Präsenz und das Engagement des Unternehmens für Innovation gewährleisten eine zuverlässige Unterstützung für Lieferanten und Hersteller weltweit.

SPX FLOW

SPX FLOW gilt als Top-Anbieter von Sprühtrocknungsanlagen, mit einer starken Präsenz in Amerika, Europa, und Asien. Die Produktlinie des Unternehmens umfasst fortschrittliche Sprühtrocknungsgeräte, die auf hohe Effizienz und Nachhaltigkeit ausgelegt sind. SPX FLOW hat seine Marktposition durch strategische Akquisitionen ausgebaut, wie zum Beispiel der Kauf des Industrietrocknungsgeschäfts der GEA Group in 2023. Das Unternehmen berichtet regionales Umsatzwachstum von 20–25 %, Dies spiegelt die starke Nachfrage nach seiner Ausrüstung wider. SPX FLOW konzentriert sich auf die Integration von IIoT-Lösungen, die dazu beitragen, regulatorische Anforderungen in Regionen wie Saudi-Arabien und Malaysia zu erfüllen. Das Engagement des Unternehmens für Nachhaltigkeit und Energieeffizienz verschafft ihm einen Wettbewerbsvorteil. Die Sprühtrocknungsausrüstung von SPX FLOW serviert die Lebensmittel, Getränk, pharmazeutisch, und chemische Industrie, Dies macht es zu einer vielseitigen Wahl für viele Anwendungen.

SPX FLOW ist ein Hauptakteur auf dem Markt für Industrietrockner.

Das Unternehmen setzt auf Nachhaltigkeit und Energieeffizienz.

Das Marktwachstum wird durch die Nachfrage nach Lebensmitteln angetrieben, Getränk, pharmazeutisch, und Chemiesektor.

Die IIoT-fähigen Systeme des Unternehmens erfüllen neue regulatorische Anforderungen.

BÜCHI Labortechnik

BÜCHI Labortechnik ist auf Sprühtrocknungsanlagen im Labormaßstab spezialisiert. Der Mini-Sprühtrockner B-290 und der Nano-Sprühtrockner B-90 des Unternehmens werden häufig in Forschung und Entwicklung eingesetzt. Die Ausrüstung von BÜCHI zeichnet sich durch ihre Fähigkeit aus, hochwertige pharmazeutische Pulver mit verbesserter Löslichkeit und Bioverfügbarkeit herzustellen. Der Das B-290-System verbessert die Löslichkeit des Arzneimittels und die orale Bioverfügbarkeit, während der B-90 die Produktion kleiner Partikel aus minimalen Proben mit hohen Ausbeuten ermöglicht. Die patentierte Technologie von BÜCHI sorgt für reproduzierbare und skalierbare Prozesse, was R reduziert&D Kosten. Die Ausrüstung liefert enge Partikelgrößenverteilungen und eine gute Fließfähigkeit, Damit ist es ideal für pharmazeutische und biotechnologische Anwendungen.

Leistungsmetrik | Komparativer Vorteil / Notizen | |

|---|---|---|

Drogenbeladung | 76.2% ± 4.6% | Hohe Wirksamkeit bei der Arzneimittelverkapselung (50% Zu 100%) typisch für die Sprühtrocknung, anderen Methoden überlegen |

Renditeprozentsatz | 83% ± 2% | Hohe Ausbeute im Vergleich zu herkömmlichen Partikel-Engineering-Methoden; Verlust hauptsächlich aufgrund der Partikelanhaftung |

Partikelgrößenverteilung | Eng, mittlere Größe ~445 nm (Vildagliptin-Nanosphären) | Eine enge Verteilung ist entscheidend für eine gezielte Abgabe und eine konsistente Bioverfügbarkeit |

Fließfähigkeit | Gutes Fließverhalten, Ruhewinkel <33.5° | Zurückzuführen auf eine kleine und enge Partikelgrößenverteilung (mittlere Größe ~80,9 nm für Gelatine-Nanokügelchen) |

Prozessmerkmale | Patentierte Technologie ermöglicht die Produktion kleiner Partikel aus minimalen Proben | Bietet hohe Erträge, reduziert R&D Kosten, und bietet im Vergleich zu anderen Methoden Reproduzierbarkeit und Skalierbarkeit |

Europäische SprayDry-Technologien (ESDT)

Europäische SprayDry-Technologien (ESDT) bietet maßgeschneiderte Sprühtrocknungsgeräte für eine Vielzahl von Branchen. Das Unternehmen entwirft Systeme für Lebensmittel, Molkerei, Chemikalie, und pharmazeutische Anwendungen. Die Ausrüstung von ESDT unterstützt sowohl die Pilot- als auch die Serienproduktion. Die Stärke des Unternehmens liegt in seiner Fähigkeit, Lösungen auf spezifische Kundenbedürfnisse zuzuschneiden. ESDT bietet einen robusten After-Sales-Support, einschließlich Schulungs- und Wartungsdienstleistungen. Der Fokus des Unternehmens auf Flexibilität und Kundenservice macht es zu einem vertrauenswürdigen Partner für Lieferanten, die spezielle Sprühtrocknungslösungen suchen.

Dedert Corporation

Die Dedert Corporation ist für ihre innovativen Sprühtrocknungssysteme und energieeffizienten Designs bekannt. Das Unternehmen bietet eine Reihe von Geräten für Lebensmittel an, Chemikalie, und Umweltanwendungen. Die Systeme von Dedert verfügen über eine fortschrittliche Zerstäubungstechnologie, was die Trocknungseffizienz und Produktqualität verbessert. Das Unternehmen investiert in Forschung und Entwicklung, um die Prozesskontrolle zu verbessern und den Energieverbrauch zu senken. Das globale Servicenetzwerk von Dedert gewährleistet eine zuverlässige Unterstützung der Kunden. Die Ausrüstung des Unternehmens eignet sich für Anwendungen, die einen hohen Durchsatz und gleichbleibende Pulvereigenschaften erfordern.

Tetra Pak

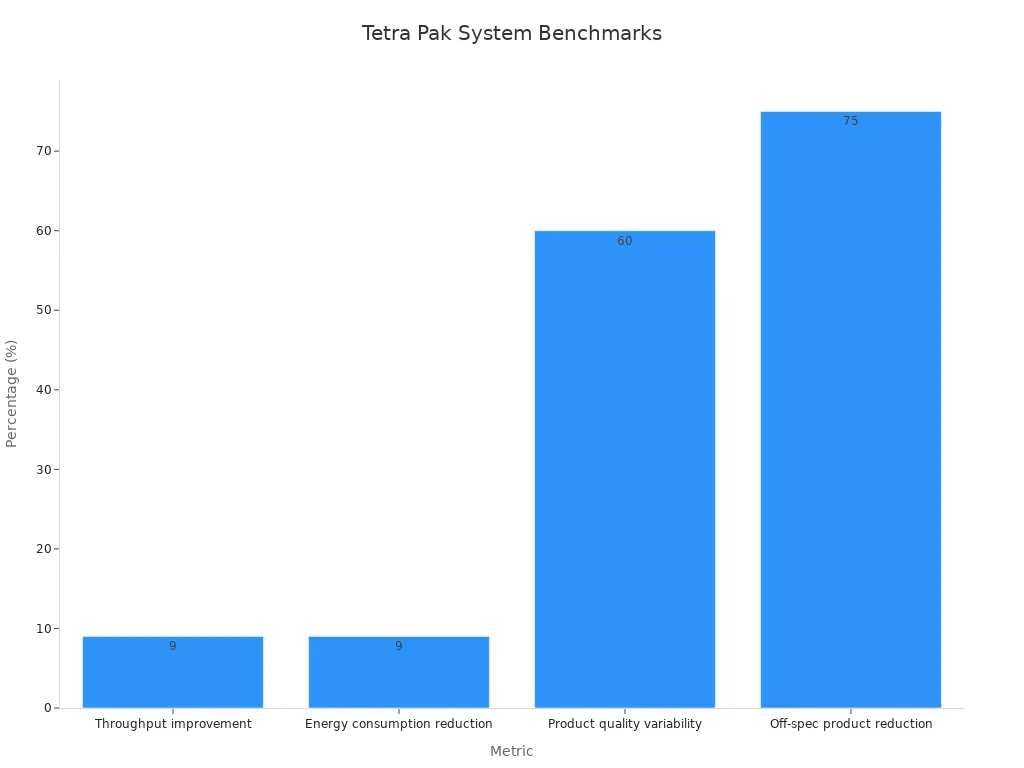

Tetra Pak ist ein führender Anbieter von Sprühtrocknungsanlagen für die Lebensmittel- und Milchindustrie. Die des Unternehmens Pflanzenverstärker in Pulverform™ nutzt fortschrittliche Prozesskontrolltechnologien, wie Model Predictive Control und Pavilion8-Software. Diese Technologien verbessern den Durchsatz um bis zu 9% und reduzieren den Energieverbrauch pro Einheit um bis zu 9%. Die Systeme von Tetra Pak reduzieren außerdem die Schwankung der Produktqualität um bis zu 60% und Off-Spec-Produkt um bis zu 75%. Der Fokus des Unternehmens auf Automatisierung und Prozessoptimierung hilft Herstellern, eine gleichbleibende Produktqualität und niedrigere Betriebskosten zu erreichen.

Die Ausrüstung von Tetra Pak wird häufig für Milchpulver verwendet, Säuglingsnahrung, und Herstellung von Ernährungsprodukten.

Shandong Tianli Trocknungstechnologie

Shandong Tianli Drying Technology hat für seine hocheffizienten Sprühtrocknungsanlagen Anerkennung gefunden. Das Unternehmen erhielt die 2024 Erster Preis des Technology Progress Award der Shandong Equipment Manufacturing Association für sein Gerät zur Trocknung mit geschlossenem Kreislauf. Dieses System erreicht a thermischer Wirkungsgrad von 81.62% und reduziert die Abgasemissionen auf knapp 1% im Vergleich zur konventionellen Technik. Die Ausrüstung von Shandong Tianli wird in neuen Energiematerialien eingesetzt, Hochleistungsmaterialien, Chemikalie, und petrochemische Industrie. Der Fokus des Unternehmens auf Energieeinsparungen und Emissionsreduzierung macht es zu einem starken Wettbewerber auf dem Weltmarkt.

Beweistyp | Einzelheiten |

|---|---|

Branchenpreis | 2024 Technology Progress Award Erster Preis der Shandong Equipment Manufacturing Association |

Ausgezeichnetes Projekt | Geschlossenes Umlauftrocknungsgerät und industrielle Anwendung |

Thermische Effizienz des Systems | 81.62% |

Reduzierung der Abgasemissionen | Reduziert auf 1% im Vergleich zur herkömmlichen Trocknungstechnik |

Technologieniveau | Anerkannt als „international führendes Niveau“ |

Anwendungsbranchen | Neue Energiematerialien, Hochleistungsmaterialien, Chemikalie, petrochemisch, und andere |

Auswirkungen auf den Markt | Starke Wettbewerbsfähigkeit, energiesparende Weiterentwicklung, reduzierte Investitions- und Betriebskosten |

Freund-Vector Corporation

Die Freund-Vector Corporation ist auf Sprühtrocknungsgeräte für die pharmazeutische und nutrazeutische Industrie spezialisiert. Die Systeme des Unternehmens unterstützen die Granulierung, Beschichtung, und Trocknungsprozesse. Die Geräte von Freund-Vector zeichnen sich durch eine präzise Kontrolle der Partikelgröße und des Feuchtigkeitsgehalts aus, was eine gleichbleibende Pulverqualität gewährleistet. Das Unternehmen bietet sowohl Lösungen im Labor- als auch im Produktionsmaßstab an. Das Engagement von Freund-Vector für Innovation und Kundenbetreuung macht es zu einem zuverlässigen Partner für Hersteller, die fortschrittliche Sprühtrocknungstechnologie suchen.

G. Larsson-Stärketechnologie

G. Larsson Starch Technology konzentriert sich auf Sprühtrocknungsanlagen für die Stärke- und Lebensmittelindustrie. Die Systeme des Unternehmens sind auf hohe Effizienz und Produktkonsistenz ausgelegt. G. Die Ausrüstung von Larsson unterstützt die Produktion von Pulvern auf Stärkebasis und anderen Lebensmittelzutaten. Die verfahrenstechnische Kompetenz des Unternehmens hilft Kunden dabei, eine optimale Trocknungsleistung zu erzielen. G. Das globale Servicenetzwerk von Larsson bietet technischen Support und Wartung, Gewährleistung eines zuverlässigen Betriebs für Lieferanten und Hersteller.

DryDania

SiccaDania bietet ein umfassendes Sortiment an Sprühtrocknungsgeräten für die Molkerei, Essen, und Biotechnologiesektoren. Die Systeme des Unternehmens sind für ihren modularen Aufbau und ihre Skalierbarkeit bekannt. Die Ausrüstung von SiccaDania unterstützt sowohl die Pilot- als auch die Serienproduktion, wodurch es für ein breites Anwendungsspektrum geeignet ist. Das Unternehmen legt Wert auf Energieeffizienz und Prozessflexibilität. Zu den After-Sales-Services von SiccaDania gehört auch Schulung, Ersatzteile, und technischer Support. Der Fokus des Unternehmens auf Kundenzufriedenheit und Innovation macht es zu einem führenden Anbieter in der Sprühtrocknungsbranche.

Der globale Markt für Sprühtrocknungsgeräte ist erreicht USD 3.36 Milliarden in 2024 und soll voraussichtlich auf USD wachsen 5.0 Milliarden von 2035, mit einer CAGR von 3.69%. Führende Unternehmen wie SPX FLOW, GEA-Gruppe, und Tetra Pak treiben dieses Wachstum durch technologische Fortschritte voran, strategische Akquisitionen, und ein Fokus auf Nachhaltigkeit. Das Essen und Trinken, pharmazeutisch, und Chemiesektor bleiben die Haupttreiber der Marktexpansion.

Vergleich von Sprühtrocknungssystemen

Merkmale

Die Top-Sprühtrocknungssysteme führender Hersteller bieten eine Reihe von Funktionen, die Anwendern dabei helfen, qualitativ hochwertige Ergebnisse zu erzielen. Jedes Unternehmen entwirft seine Sprühtrocknungsausrüstung, um den spezifischen Branchenanforderungen gerecht zu werden. Die folgende Tabelle vergleicht die wichtigsten Funktionen der Top-Marken:

Hersteller | Technologieniveau | Anpassungsoptionen | Support-Dienste |

|---|---|---|---|

GEA-Gruppe | Erweiterte Automatisierung | Hoch | Global, starkes Training |

SPX FLOW | IIoT-Integration | Medium | Regional, reaktionsschnell |

BÜCHI Labortechnik | Präzision im Labormaßstab | Hoch | R&D-Unterstützung, Ausbildung |

ESDT | Kundenspezifisches Engineering | Sehr hoch | Flexibel, Wartung |

Dedert Corporation | Energieeffizienz | Medium | Global, technische Hilfe |

Tetra Pak | Prozessoptimierung | Medium | Milchorientiert, Prüfungen |

Shandong Tianli | Trocknung im geschlossenen Kreislauf | Medium | Lokal, preisgekrönt |

Freund-Vektor | Pharma-Fokus | Hoch | Pharmaunterstützung, Ausbildung |

G. Larsson | Kompetenz im Bereich Stärke | Medium | Unterstützung der Lebensmittelindustrie |

DryDania | Modularer Aufbau | Hoch | Ausbildung, Ersatzteile |

Notiz: Anpassungs- und Supportniveaus können Einfluss darauf haben, wie gut Sprühtrocknungssysteme den individuellen Produktionsanforderungen entsprechen.

Für und Wider

Die Sprühtrocknungsausrüstung jedes Herstellers hat Stärken und Schwächen. Die folgende Liste hebt die wichtigsten Vor- und Nachteile hervor:

GEA-Gruppe:

✅ Zuverlässig, fortgeschrittene Automatisierung

❌ Höhere AnfangsinvestitionSPX FLOW:

✅ Starke IIoT-Funktionen

❌ Begrenzte Anpassungsmöglichkeiten für NischenanwendungenBÜCHI Labortechnik:

✅ Hervorragend geeignet für R im Labormaßstab&D

❌ Nicht ideal für die MassenproduktionESDT:

✅ Hochgradig anpassbare Lösungen

❌ Kleinere globale PräsenzDedert Corporation:

✅ Konzentrieren Sie sich auf Energieeinsparungen

❌ Weniger Optionen für KleinanwenderTetra Pak:

✅ Optimiert für Milchprodukte und Lebensmittel

❌ Weniger Flexibilität für andere SektorenShandong Tianli:

✅ Preisgekrönte Energieeffizienz

❌ Unterstützung hauptsächlich in AsienFreund-Vektor:

✅ Starke pharmazeutische Expertise

❌ Begrenzt außerhalb des PharmasektorsG. Larsson:

✅ Spezialisierung auf Stärke und Lebensmittel

❌ Engerer AnwendungsbereichDryDania:

✅ Modular, skalierbare Ausrüstung

❌ Neuere Marke, weniger globale Reichweite

Sprühtrocknungssysteme unterscheiden sich in der Technik, Anpassung, und Unterstützung. Um die besten Ergebnisse zu erzielen, sollten Benutzer ihre Bedürfnisse mit der richtigen Sprühtrocknungsausrüstung abstimmen.

Auswahl eines Sprühtrocknungssystems

Anwendungsanforderungen

Das Richtige auswählen Sprühtrocknungssystem beginnt mit dem Verständnis der Produkt- und Branchenanforderungen. Jede Anwendung stellt besondere Anforderungen an die Pulverqualität, Feuchtigkeitsgehalt, und Partikelgröße. Unternehmen sollten nach Sprühtrocknungsdiensten suchen, die dies anbieten:

Echtzeitüberwachung mit Sensoren für Temperatur, Luftfeuchtigkeit, und Luftstrom

Fortschrittliche Zerstäubungstechnologien für gleichmäßige Produktqualität

Dynamische Luftstromsteuerung durch Lüfter mit variabler Geschwindigkeit

Regelmäßige Wartung und geplante Inspektionen zur Vermeidung von Ausfallzeiten

Energieeffizienzmaßnahmen wie Wärmerückgewinnung und Isolierung

Die Produktionseffizienz verbessert sich, wenn das System dem entspricht Produktionsvolumen und Produktspezifikationen. Unternehmen, die Sprühtrocknungsdienste mit fortschrittlichen Steuerungssystemen nutzen, können die Einlass- und Auslasstemperaturen optimieren. Dieser Ansatz maximiert die Trocknungseffizienz und verhindert eine Produktverschlechterung. Zuverlässige Betriebszeit und gleichbleibende Qualität hängen sowohl von der Technologie als auch vom Support ab.

Budget und ROI

Bei der Auswahl einer Sprühtrocknungsanlage spielt die Budgetanalyse eine entscheidende Rolle. Unternehmen sollten die Kapitalkosten vergleichen, Betriebskosten, und Wartungsgebühren. Sprühtrocknungsdienste bieten oft langfristige Einsparungen. Zum Beispiel, einige Systeme bieten 20-30% geringere Gesamtkosten über eine 35-jährige Anlagenlebensdauer im Vergleich zu herkömmlichen nassen Kalksteinwäschern. Energieeinsparungen ergeben sich aus reduziertem Pumpenaufwand und dem Wegfall der Rauchgasnacherwärmung. Auch standortspezifische Faktoren und der Technologiereifegrad wirken sich auf die Kosteneffizienz aus. Unternehmen sollten die Kosten für die Abfallentsorgung und die Verfügbarkeit von Reagenzien berücksichtigen. Der langfristige ROI hängt von den geschätzten Kosteneinsparungen ab, Energieverbrauch, und die Zuverlässigkeit der Sprühtrocknungsdienste.

Kundendienst

Der Kundendienst stellt sicher, dass das Sprühtrocknungssystem weiterhin eine hohe Produktionseffizienz liefert. Führend Sprühtrocknungsdienste enthalten:

Umfassende Wartung und Support zur Minimierung von Ausfallzeiten

Schneller Zugriff auf Ersatzteile für schnelle Reparaturen

Automatisierungs- und Steuerungssysteme für vorausschauende Wartung

Schulungsprogramme für Bediener

Unternehmen, die in einen starken Kundendienst investieren, schützen ihre Ausrüstung und sorgen für eine hohe Produktionseffizienz. Zuverlässige Sprühtrocknungsdienste helfen Unternehmen, sich an veränderte Produktionsanforderungen und Industriestandards anzupassen.

Anwendungen von Sprühtrocknungsgeräten

Essen und Trinken

Sprühtrocknung spielt eine wichtige Rolle in der Lebensmittel- und Getränkeindustrie. Unternehmen nutzen diese Technologie, um flüssige Zutaten in Pulver umzuwandeln. Dieser Prozess hilft, den Geschmack zu bewahren, Farbe, und Nährstoffe. Lebensmittelhersteller setzen bei Produkten wie Milchpulver auf die Sprühtrocknung, löslicher Kaffee, und Fruchtsaftpulver. Getränkehersteller nutzen die Sprühtrocknung, um lösliche Getränkemischungen und Aromen herzustellen. Die Technologie unterstützt die Verarbeitung von Lebensmittelzutaten durch die Herstellung stabiler Pulver, die sich schnell in Wasser auflösen. Sprühtrocknung trägt außerdem dazu bei, die Haltbarkeit zu verlängern und die Transportkosten zu senken. Viele Lebensmittel- und Getränkehersteller entscheiden sich für die Sprühtrocknung, weil sie eine gleichbleibende Qualität liefert und strenge Sicherheitsstandards erfüllt. Der Prozess unterstützt sowohl die Lebensmittelproduktion im großen Maßstab als auch die Entwicklung spezieller Zutaten.

Arzneimittel

Für die präzise Pulververarbeitung ist die Pharmaindustrie auf die Sprühtrocknung angewiesen. Hersteller nutzen die Sprühtrocknung, um pharmazeutische Wirkstoffe in Pulverform zu überführen. Diese Methode verbessert die Löslichkeit und Bioverfügbarkeit von Arzneimitteln. Pharmaunternehmen entscheiden sich häufig für die Sprühtrocknung, um inhalierbare Arzneimittel herzustellen, orale Tabletten, und Formulierungen mit kontrollierter Freisetzung. Die Technologie ermöglicht eine genaue Kontrolle der Partikelgröße und des Feuchtigkeitsgehalts. Sprühtrocknung trägt auch dazu bei, empfindliche pharmazeutische Verbindungen während der Verarbeitung zu schützen. Viele pharmazeutische Produkte erfordern eine strenge Qualitätskontrolle, und Sprühtrocknungssysteme liefern die für die behördliche Zulassung erforderliche Konsistenz. Die Pharmabranche schätzt die Sprühtrocknung wegen ihrer Fähigkeit, ein breites Spektrum an pharmazeutischen Verbindungen und Formulierungen zu verarbeiten.

Sprühtrocknung unterstützt die Entwicklung neuer pharmazeutischer Produkte, indem sie ein schnelles Scale-up vom Labor zur Produktion ermöglicht.

Chemikalien

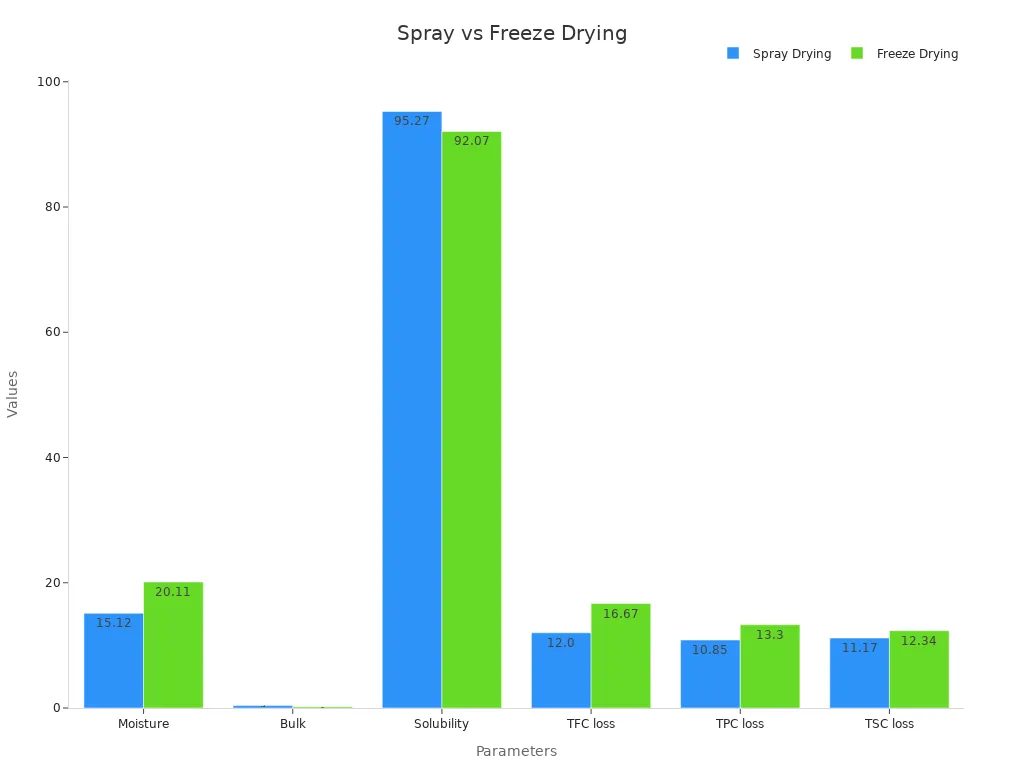

Die Sprühtrocknungstechnologie bietet in der chemischen Industrie viele Vorteile. Unternehmen nutzen die Sprühtrocknung zur Herstellung von Mikrokapseln, Katalysatoren, und Spezialchemikalien. Das Verfahren erzeugt Pulver mit niedrigem Feuchtigkeitsgehalt und hoher Schüttdichte, was die Lagerung und Handhabung verbessert. Die folgende Tabelle vergleicht Sprühtrocknung mit Gefriertrocknung für die chemische Verarbeitung:

Parameter | Sprühtrocknung (SDMCs) | Gefriertrocknung (FDMCs) | Vergleichende Einsicht |

|---|---|---|---|

Feuchtigkeitsgehalt / Hygroskopizität (g/100g) | 15.12% Feuchtigkeitsaufnahme | 20.11% Feuchtigkeitsaufnahme | Sprühtrocknung führt zu einem geringeren Feuchtigkeitsgehalt und einer geringeren Hygroskopizität, Verbesserung der Lagerstabilität. |

Schüttdichte (g/cm³) | 0.39 | 0.21 | Durch Sprühtrocknung entstehen Mikrokapseln mit einer um ca. 85,7 % höheren Schüttdichte, was auf eine bessere Verpackung hinweist. |

Löslichkeit (%) | 95.27% | 92.07% | Sprühtrocknung erhöht die Löslichkeit um ~3,5 %, wahrscheinlich aufgrund von Maillard-Reaktionseffekten bei höheren Temperaturen. |

Erhaltung des gesamten Flavonoidgehalts (TFC) nach 60 Tage | 12.00% Verlust | 16.67% Verlust | Sprühtrocknung zeigt eine hervorragende Retention von Flavonoiden während der Lagerung, was auf eine bessere Stabilität hinweist. |

Beibehaltung des gesamten Phenolgehalts (TPC) nach 60 Tage | 10.85% Verlust | 13.30% Verlust | Durch Sprühtrocknung bleiben Phenolverbindungen im Laufe der Zeit besser erhalten. |

Beibehaltung des gesamten löslichen Inhalts (TSC) nach 60 Tage | 11.17% Verlust | 12.34% Verlust | Die Sprühtrocknung übertrifft die Gefriertrocknung bei der Beibehaltung des löslichen Gehalts geringfügig. |

Kapselungseffizienz (EE) | >80% gesamt; 66.07%-85.46% für einige Flavonoide | >80% gesamt; >90% für einige Flavonoide | Beide Methoden erzielen einen hohen EE, Aber durch Gefriertrocknung bleiben hitzeempfindliche Flavonoide besser erhalten. |

Durch Sprühtrocknung entstehen Pulver, die sich leicht lagern und transportieren lassen. Chemieunternehmen schätzen diese Methode wegen ihrer Schnelligkeit und Fähigkeit, qualitativ hochwertige Produkte herzustellen. Das Verfahren unterstützt die Herstellung stabiler Mikrokapseln und Spezialchemikalien für viele industrielle Anwendungen.

Top-Hersteller von Sprühtrocknern zeichnen sich durch fortschrittliche Technologie aus, starke Unterstützung, und spezialisierte Produktsortimente. Um in einem wachsenden Markt die besten Ergebnisse zu erzielen, sollten Unternehmen die Systemfunktionen an die Projektanforderungen anpassen. Regelmäßige Sicherheitskontrollen, Hygienisches Design, und eine präzise Prozessüberwachung tragen zur Aufrechterhaltung hoher Standards bei.

Testen Sie stets Sicherheitssysteme und überwachen Sie den Staubgehalt.

Sicherstellen Die Geräte erfüllen strenge Hygienestandards und unterstützt eine einfache Reinigung.

Nutzen Sie zuverlässige Instrumente, um die Trocknung zu optimieren und die Produktqualität zu verbessern.

Sorgfältige Auswahl und laufende Wartung schützen Investitionen und unterstützen den langfristigen Markterfolg. Für maßgeschneiderte Lösungen, Wenden Sie sich für eine ausführliche Beratung an die Hersteller.

FAQ

Wozu dient die Sprühtrocknung??

Durch Sprühtrocknung werden Flüssigkeiten zu Pulvern. Unternehmen verwenden es in Lebensmitteln, Arzneimittel, und Chemikalien. Dieser Prozess trägt zur Konservierung der Produkte bei, Haltbarkeit verbessern, und erleichtern die Lagerung und den Transport von Pulvern.

Wie wählen Unternehmen den richtigen Sprühtrocknerhersteller aus??

Sie schauen auf Technologie, Produktpalette, Unterstützung, und Ruf. Unternehmen gleichen ihre Bedürfnisse mit den Stärken jedes Herstellers ab. Sie prüfen auch Zertifizierungen und Kundendienst.

Was sind die Hauptvorteile von Sprühtrocknungssystemen??

Sprühtrocknungssysteme bieten eine schnelle Trocknung, gleichbleibende Pulverqualität, und Energieeffizienz. Diese Systeme helfen Unternehmen, Kosten zu sparen und die Produktsicherheit zu verbessern. Viele Systeme unterstützen zudem eine einfache Reinigung und Wartung.

Wie oft sollten Sprühtrocknungsgeräte gewartet werden??

Hersteller empfehlen eine regelmäßige Wartung. Die meisten Unternehmen planen alle paar Monate Kontrollen. Regelmäßige Inspektionen tragen dazu bei, Ausfälle zu verhindern und den reibungslosen Betrieb des Systems sicherzustellen.

Können Sprühtrocknungssysteme empfindliche Produkte verarbeiten??

Ja. Viele Sprühtrocknungssysteme verwenden fortschrittliche Steuerungen, um empfindliche Inhaltsstoffe zu schützen. Diese Systeme halten Temperatur und Feuchtigkeit stabil, Dies trägt zur Erhaltung der Produktqualität bei.