Der Sprühtrocknungsprozess ist für jedermann einfach erklärt

You might wonder how liquids turn into powders so quickly. The spray drying process helps you achieve this by turning a liquid into tiny droplets, then drying them with hot air to create a fine powder. Many industries use this process, einschließlich food processing, Arzneimittel, Chemikalien, Keramik, and other manufacturing sectors. You see the results in everyday products like milk powder or instant coffee.

Wichtige Erkenntnisse

Spray drying quickly turns liquids into powders using hot air and tiny droplets. This method is efficient and widely used in food and pharmaceutical industries.

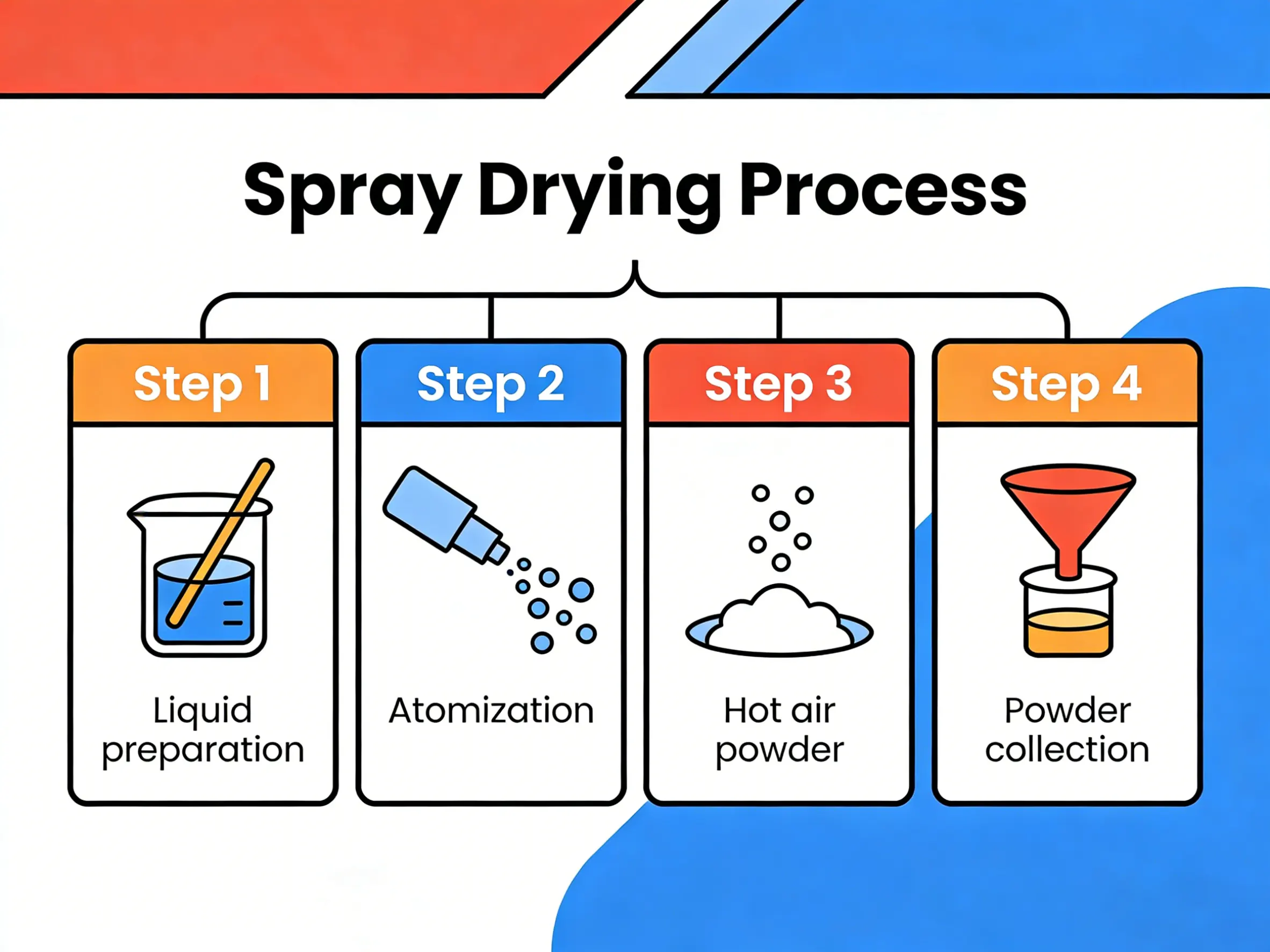

The process involves preparing the liquid, atomizing it into droplets, and rapidly drying it with hot air. Each step is crucial for achieving high-quality powder.

Spray drying helps create products like milk powder and inhalable medicines. It ensures these products are easy to store, mix, and use.

Controlling droplet size and air temperature is key to producing consistent powder quality. This prevents clumping and ensures uniformity in the final product.

You benefit from spray drying every day, whether in your coffee or medicine. This process keeps products fresh and effective for longer.

Spray Drying Process Basics

Was ist Sprühtrocknung??

You can think of the spray drying process as a way to turn liquids into powders quickly and efficiently. This method uses a special machine that sprays liquid into tiny droplets. Hot air dries these droplets almost instantly, leaving behind fine powder. The process works by concentrating the liquid first, which means removing some water to make it thicker. Dann, the machine breaks the liquid into small drops, making it easier for the hot air to dry them. You get a powder that is easy to store, mix, and use.

Sprühtrocknung transforms liquid substances into fine powders. The process uses atomization and hot air to evaporate moisture quickly. You see this method used in many industries because it saves time and energy compared to older drying methods.

The spray drying process stands out because:

It creates powders with controlled size and shape.

It works faster than other drying methods like rotary or tray dryers.

Advanced designs help save energy and improve heat transfer.

Purpose and Uses

You find the spray drying process used in many fields. Food companies use it to make products like milk powder, löslicher Kaffee, und Aromen. Pharmaceutical companies rely on it to produce medicines, especially those that need careful handling, such as heat-sensitive drugs and proteins. This process helps create powders for inhalable medicines and vaccines, keeping them stable and effective for longer periods.

Zu den üblichen Verwendungszwecken gehören::

Making powdered foods for easy mixing and long shelf life.

Creating inhalable powders for drug delivery.

Improving drug solubility and absorption in your body.

Developing microcapsules for controlled-release medicines.

You benefit from spray drying every day, whether you drink instant coffee or take medicine. The process helps companies control the quality and safety of their products.

Spray Drying Process Steps

Preparing the Liquid Feed

You start the spray drying process by preparing the liquid feed. This step makes sure the liquid is ready for drying and will turn into a good powder. The liquid can be a solution, a suspension, or an emulsion. You adjust its concentration and thickness so it works well in the machine.

You mix the ingredients to get the right concentration.

You check the thickness, called viscosity, to make sure it flows smoothly.

You filter the liquid to remove any lumps or unwanted particles.

Tipp: A well-prepared liquid feed helps you get a powder with the right texture and quality.

Atomizing into Droplets

Nächste, you use atomization to break the liquid into tiny droplets. This step is important because droplet size affects how fast the liquid dries and what the final powder looks like. You can choose different atomization techniques depending on your needs.

Vorteile | Anwendungen | |

|---|---|---|

Rotationszerstäubung | Produces uniform particles; handles thick liquids | Used for milk powder, Kaffeesahne |

Druckzerstäubung | Macht gut, sogar Tröpfchen; spart Energie | Used for medicines and fine chemical powders |

Two-Fluid Atomization | Creates very fine droplets; präzise Steuerung | Used for pharmaceutical and cosmetic powders |

Ultraschallzerstäubung | Gentle process; very fine droplets | Used for heat-sensitive medicines and coatings |

Smaller droplets dry faster and give you smaller powder particles. You get better mixing and faster dissolving powders when you control droplet size.

Droplet size decides how small the powder particles will be.

Smaller particles dissolve faster and work better in products.

You keep powder quality consistent by controlling droplet size.

Rapid Drying with Hot Air

After atomization, you send the droplets into a chamber filled with hot air. The high temperature makes the water in each droplet evaporate almost instantly. You control the air temperature to protect sensitive ingredients and get the best powder.

Anwendung | Auslasstemperatur (°C) | |

|---|---|---|

Milk Powder | 150–220 | 70–100 |

Special Products | Bis zu 230 | 90–110 |

The hot air quickly removes moisture from the droplets.

You adjust air temperature, Tröpfchengröße, and airflow to get the powder you want.

The spray drying process works fast, so delicate materials do not get damaged.

Notiz: Rapid drying helps you keep vitamins, Proteine, and flavors safe in the final powder.

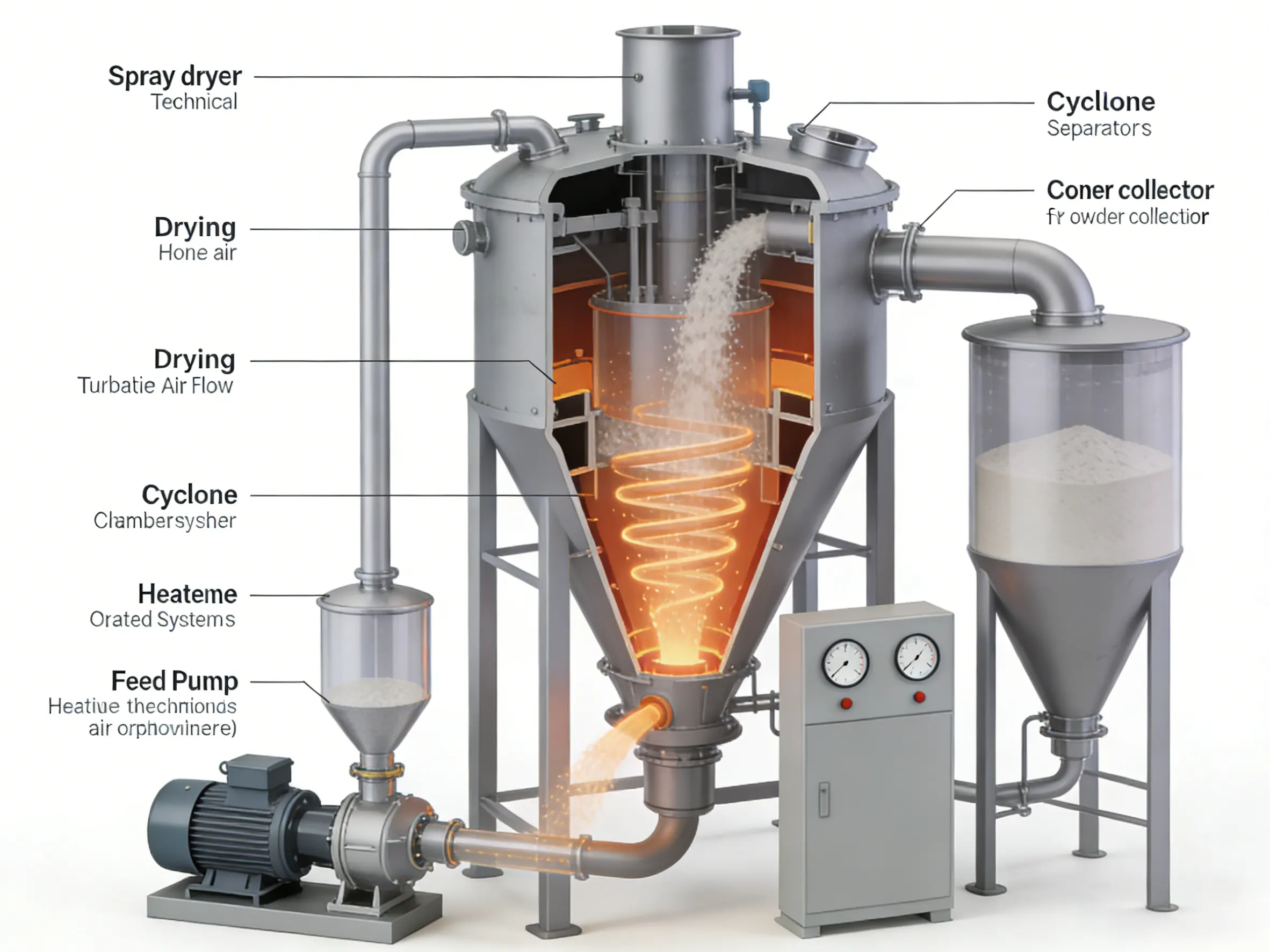

Collecting the Powder

When the droplets dry, they turn into powder particles. You need to collect these particles safely and keep them pure. You use different machines to separate the powder from the air.

Beschreibung | Anwendungen | |

|---|---|---|

Cyclone Separators | Spins air to drop powder into a hopper | Good for large amounts; may lose some fine particles |

Bag Filters | Traps powder in fabric bags | Works well for fine powders; needs regular cleaning |

Electrostatic Precipitators | Uses electric charges to catch powder on plates | Best for pure and sticky powders; more complex |

You can also use sieving, air classification, and extra purification steps to improve powder quality. You store the powder in clean containers and test it to make sure it meets safety standards.

Tipp: Careful collection and storage keep your powder fresh and safe for use.

The spray drying process often runs continuously in factories. You get high production rates and uniform powders. You control particle size and moisture to match your product needs.

Benefits of Spray Drying Process

Fast and Efficient Drying

You get fast results with the spray drying process. The machine turns liquid into powder in seconds. This speed helps you produce large amounts of powder quickly. Industries choose spray drying because it works much faster than freeze drying or drum drying. You can see the difference in the table below:

Vorteil | Sprühtrocknung | Gefriertrocknung | Trommeltrocknung |

|---|---|---|---|

Trocknungsgeschwindigkeit | Very fast | Langsam | Mäßig |

Produktionsrate | Hoch | Niedrig | Medium |

You control the drying by adjusting droplet size, Lufttemperatur, and air speed. Smaller droplets dry faster. Higher temperatures and faster air movement help remove moisture quickly. You save energy by using advanced techniques like superheated steam and AI optimization. These methods lower energy use and keep the process efficient.

Tipp: Quick drying protects sensitive ingredients like vitamins and proteins, so your powder stays nutritious.

Consistent Powder Quality

You get uniform powder every time. The spray drying process lets you control particle size and moisture. You adjust the machine settings to keep the powder consistent. Quality control measures help you check air supply, liquid feed, and atomization. You can see some key controls in the table below:

Quality Control Measure | What You Control |

|---|---|

Air Supply | Luftstrom, Temperatur, Luftfeuchtigkeit |

Liquid Supply | Solids content, Vorschubgeschwindigkeit |

Zerstäubung | Droplet size, nozzle speed |

You avoid common problems like clumping or uneven particles by using better nozzle designs and cleaning systems. These improvements help you keep the powder safe and easy to use.

Wide Industry Use

You find spray drying in many industries. Lebensmittelunternehmen verwenden es für Milchpulver, löslicher Kaffee, und Säuglingsnahrung. Pharmaceutical companies rely on it for inhalable medicines and protein powders. Chemical and consumer product makers use it for detergents, Enzyme, and specialty cleaners.

Arzneimittel: Inhalable powders, Mikrokapseln

Chemikalien: Technical powders for various uses

Consumer Products: Reinigungsmittel, cleaners, enzyme granules

You benefit from spray drying every day. The process helps companies make finished, packaged powders that last longer and stay fresh. You get products that are easy to store, mix, and use.

Everyday Products

You see the results of the spray drying process in many products you use every day. This method helps companies create powders that are easy to store, mix, and use. Let’s look at some familiar examples.

Food Powders

You find spray-dried powders in your kitchen. Milchpulver is a popular example. Companies use the spray drying process because it works quickly and makes large amounts of powder. Jedoch, high temperatures can change the proteins and reduce some nutrients. Freeze drying keeps more nutrients but costs more and takes longer. You also see instant coffee, tea powders, fruit and vegetable powders, and protein supplements made this way.

Milchpulver

Instant coffee and tea

Obst- und Gemüsepulver

Proteinpulver und Nahrungsergänzungsmittel

Aromen und Gewürze

Tipp: Spray-dried food powders dissolve easily in water, making them perfect for quick drinks and recipes.

Arzneimittel

You benefit from spray-dried medicines. This process helps make powders for inhalers and nasal sprays. It also improves how well your body absorbs some drugs. You get medicines that last longer and work better because of this technology.

Solid dispersion systems to help drugs dissolve

Modified release medicines for steady effects

Stable powders for biologic drugs

Aspekt | Explanation |

|---|---|

Amorphous Solid Dispersions | Sprühtrocknung converts drugs into forms your body absorbs better. |

Crystallisation Risk | Some powders can change over time, so companies choose special ingredients to keep them stable. |

Moisture Sensitivity | Powders can absorb water, so packaging keeps them dry and safe. |

Other Common Goods

You use many other products made with spray drying. This process helps create powders for cleaning, Ernährung, and flavor.

Detergents and cleaning powders

Enzyme granules for laundry

Specialty chemicals for industry

Notiz: The spray drying process helps companies make products that stay fresh and work well for you.

You now know that spray drying turns liquids into powders quickly and safely. This process keeps your food and medicine fresh, easy to use, and long-lasting. You see its results in milk powder, löslicher Kaffee, and many health products.

Beschreibung | |

|---|---|

Reduced Water Activity | Increases shelf life and keeps products safe. |

Improved Powder Quality | Prevents clumping and keeps powders easy to use. |

Consistent Product Quality | Ensures you get the same quality every time. |

If you want to learn more, explore how spray drying shapes the products you use every day! 😊

FAQ

What is the main purpose of spray drying?

You use spray drying to turn liquids into powders quickly. This process helps you make products that last longer and are easy to store or mix.

Can spray drying change the taste or nutrition of food?

You may notice a slight change in taste or nutrition. High heat can affect some vitamins or flavors. Most companies control the process to keep food quality high.

Is spray drying safe for making medicines?

You can trust spray drying for medicines. The process keeps drugs stable and pure. Companies use strict safety checks to protect your health.

What types of products can you make with spray drying?

You can make milk powder, löslicher Kaffee, protein supplements, Medikamente, Reinigungsmittel, and even some cosmetics. Many everyday items start as a liquid and become powder through spray drying.