Hot Sale YPG -Serie Druckspray Granulation Trockner für organische Katalysatoren

-

Druckspray -Granulationstrockner für organische Katalysatoren ist eine Art von Gerät, das gleichzeitig die Trocknung und Granulation beenden kann. Gemäß den Prozessanforderungen, Sie können den Druck einstellen, Durchflussrate der materiellen Flüssigkeitspumpe und der Größe des Sprühlochs, um die erforderlichen kugelförmigen Partikel in einem bestimmten Größenverhältnis zu erhalten.

Beschreibung

heißer Verkauf YPG-Serie Drucksprühgranulationstrockner für organische Katalysatoren

Drucksprühgranulationstrockner für organische Katalysatoren BESCHREIBUNG

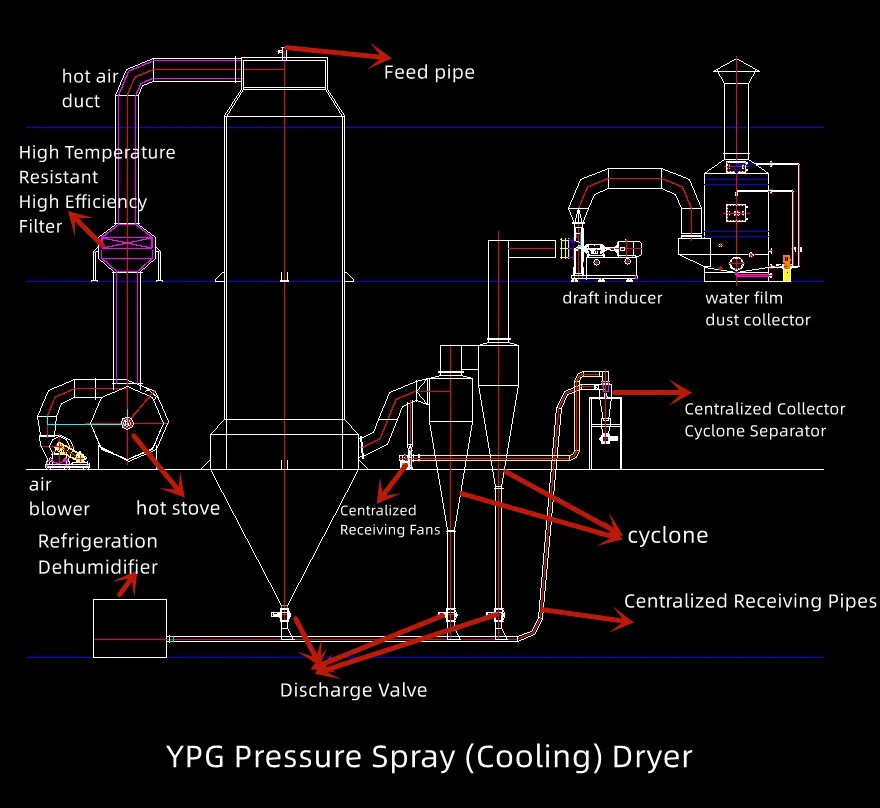

Der Drucktyp der YPG -Serie Spray (Erstarren) Trockner hat ein Gerät, das zusammen trocknen und granulieren kann. Der Sprühdruck, Sprühstrom und die Größe der Sprühdüse der Flüssigmaterialpumpe können entsprechend den Anforderungen eingestellt werden, und die spezifische Größe der Granulatkugeln kann erreicht werden.Drucksprühgranulationstrockner für organische Katalysatoren FUNKTIONSPRINZIP

Das flüssige oder pastöse Rohmaterial wird mithilfe eines Drucksprühers und der Unterstützung durch den Druck einer Membranpumpe in kleine Flüssigkeitstropfen gesprüht, und schnelle Trocknung durch ausreichenden Wärmeaustausch (10-90Sek.).Der Großteil der Pulverkörnchen wird am Auslass am Boden des Trockners gesammelt.Die Abluft und das feine Pulver werden durch den Zyklon getrennt, Die verschwendete Luft wird vom Saugventilator abgegeben, und feines Pulver wird am Boden des Zyklons gesammelt. Am Auslass ist ein Staubwedel zweiter Klasse angebracht; daher, die Rückgewinnungsrate des fertigen Pulvergranulats kann sein 96% Zu 98%.

Drucksprühgranulationstrockner für organische Katalysatoren ANWENDUNG

Chemische Industrie: Natriumfluorid (Kalium ), Alkalischer Farbstoff und Pigment,Farbstoff-Zwischenprodukt, Mn3o4, Verbunddünger, Ameisensäure, Katalysator, Schwefelsäuremittel, Aminosäure,Weißer Kohlenstoff, und etc..

Lebensmittelindustrie: Fettmilchpulver, Protein, Kakaomilchpulver, Milchpulver ersetzen,Eiweiß (Eigelb), Nahrung und Pflanze,Hafer,Hühnersaft, Kaffee, Instant löslicher Tee ,Fleisch würzen,Protein ,Sojabohne,Erdnussprotein, Hydrolysat, Zucker,Maissirup,Maisstärke,Glucose, Pektin,Malzzucker, Sorbinsäure-Kalium, und etc..

Pharmaindustrie: Traditionelle chinesische Medizin, Pestizid, Antibiotikum, Medizinisches Trinkmittel,und etc..

Kunststoffe und Harz: Ab, ABS-Emulsion, Harnsäureharz, Phenolisches Aldehydharz, Harnstoff-Formaldehyd-Harz, Formaldehydharz, Polyethylen, Polychlorpren, Und usw.

Waschmittel: Gewöhnliches Waschpulver,Fortschrittliches Waschpulver,Seifenpulver, Soda-Asche, Emulgator, Aufheller, Orthophosphorsäure, und etc..

Keramik: Aluminiumoxid, Keramikfliesenmaterial, Magnesiumoxid, Talkum, und etc.. Andere: Calmogastrin, Hime-Chlorid , Stearinsäure-Mittel, und etc..

Drucksprühgranulationstrockner für organische Katalysatoren EIGENSCHAFTEN

1. Schnelle Trocknungsgeschwindigkeit. Die Oberfläche des Materials wird stark vergrößert, wenn flüssiges Rohmaterial zerstäubt wird 95% – 98% Wasser kann im heißen Luftstrom sofort verdunsten. Die Trocknungszeit beträgt nur wenige Sekunden. Dieser Trockner eignet sich besonders zum Erhitzen empfindlicher Materialien.

2. Das fertige Produkt ist ein Kugelgranulat mit einheitlicher Größe. Die Fließfähigkeit und Löslichkeit sind gut. Die Qualität und Reinheit des Produkts ist sehr hoch.

3. Abhängig von den Eigenschaften des Rohmaterials, Der Trockner kann Heißluft zum Trocknen oder Kaltluft zum Granulieren verwenden.

4. Einfache und stabile Bedienung. Das Steuerungssystem ist komfortabel und ermöglicht einen einfachen automatischen Betrieb.

Technischer Parameter

| Artikel \ Modell | Einheit | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| Wasserverdunstung- Rationskapazität |

kg | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| Gesamtdimension (Φ×H) |

mm | 1600× 8900 |

2000× 11500 |

2400× 13500 | 2800× 14800 |

3200× 15400 |

3800× 1880 |

4600× 22500 |

| Hochdruck Pumpendruck |

mPa | 2~10 | ||||||

| Leistung | KW | 8.5 | 14 | 22 | 24 | 30 | 82 | 30 |

| Einlassluft Temperatur |

OC | 140~350 | ||||||

| Produktwasser Inhalt |

% | <5(Bis zu 0,5) | ||||||

| Sammelquote | % | >97 | ||||||

| elektrische Heizung | KW | 75 | 120 | 150 | Die Temperatur liegt unter 200 °C Parameter berechnet werden sollen |

|||

| Strom +Dampf |

Mpa+KW | 0.5+54 | 0.6+90 | 0.6+108 | entsprechend den praktischen Gegebenheiten | |||

| Heißluftofen | Kcal/h | 100000 | 150000 | 200000 | 300000 | 400000 | 500000 | 1200000 |

* Das Obige ist die größte Verdunstung.

Rezensionen

Es gibt noch keine Rezensionen.