Neuankömmling niedriger Preis China lieferte vertikale Flüssigkeitsbetttrockner FG -Serie

Merkmale des vertikalen fluidisierten Trockners der FG -Serie

Wegen Pulvergranulation, Die Strömungseigenschaft wird verbessert und der Staub wird verringert.

Ergebnisse 25 – 36 von 88 werden angezeigt

Wegen Pulvergranulation, Die Strömungseigenschaft wird verbessert und der Staub wird verringert.

Granulatortrocknungsgeräte für Pulver

Das Pulverkörnchen im Flüssigkeitsbett erscheint im Zustand der Fluidisierung. Es ist vorgeheizt und mit sauberer und beheizter Luft gemischt. Gleichzeitig wird die Lösung des Klebstoffs in den Behälter gesprüht. Es lässt die Partikel granulieren, die Klebstoff enthält. Unaufhörlich trocken durch heiße Luft zu sein, Die Feuchtigkeit im Granulieren wird verdampft. Der Prozess wird kontinuierlich durchgeführt. Schließlich bildet es ideal, Einheitliches und poröses Granulat.

Hohlpaddel Trockner (Schlammentrocknungsmaschine)

ist ein horizontaler Rühr- und Wärme -Leitungs -Typ Trocknungsausrüstung das kann kontinuierlich funktionieren. Die rührende Klinge ist wie Schiffspaddel, Es heißt also Paddeltrockner. Im Ausland, Es wird auch als Schlitztrockner oder Rührentrockner bezeichnet.

Hohlpaddel -Trockner wird erfolgreich in Foodstuff eingesetzt, Chemikalie, petrochemisch, Farbstoff, Branchenschlammfelder, usw. Die Zeichen der Wärmeübertragung, Kühlung, und rühren lassen die Maschine den folgenden Betrieb erreichen: Kalzinierung (Niedertemperatur), Kühlung, Trocknen (Lösungsmittelwiederherstellung), Heizung (Schmelzen), Reaktion und Sterilisation. Rühre Paddel ist auch Wärmeübertragungsfläche, Dadurch wird die Einheit effizienter Wärmeübertragungsbereich größer, und die Handhabungszeit wird verkürzt. Die Wärmeübertragungsfläche des Keiltyps hat eine SLEF-Reinigungsfunktion. Komprimierung - Expand -Rührfunktion macht das Material gleichmäßig gemischt. Material macht die Kolbenflussbewegung entlang der axialen Richtung, im axialen Richtungsintervall, die Temperatur, Feuchtigkeit und Mischgradient ist sehr niedrig.

YK Swing Granulator ist der spezielle Granulator, der feuchte Pulver durch den Bildschirm und Granulatpartikel unter der Reaktion von im Uhrzeigersinn und gegen den Uhrzeigersinn des Zylinders durchführen kann. Zusätzlich, Es kann das Agglomerationspulver zu den benötigten Größenpartikeln machen. Der Materialkontaktbereich besteht aus Edelstahl. Es ist einfach zu reinigen, Einfacher Betrieb und geringem Energieverbrauch

YPG -Serie organische Katalysatoren Granulationsdruckspray -Trocknungsmaschine : Der Sprühtrocknungsprozess ist der breiteste im Flüssigkeitsformprozess und in der Trocknungsindustrie verwendet. Die Trocknertechnologie eignet sich am besten für Pulver, Partikelprodukte aus Materialien, wie zum Beispiel,Lösung, Emulsion, SC und Pumpable -Pastezustandsmaterial. Aus diesem Grund, Wenn die Partikelgröße und Verteilung des Endprodukts, ihr Restwassergehalt, Die Stapeldichte und die Partikelform müssen den Präzisionsstandard erfüllen, Sprühtrocknungsprozess ist einer der am meisten gewünschten Prozesse.

Vibrierende fließende Betttrocknermaschine

Vibrierender fließendes Bett, ist eine neue Art von fließenden und effizienten Trocknungsgeräten, die zum Trocknen von körnigen und pudrigen Materialien geeignet sind. Es hat die Vorteile eines einfachen Betriebs, Energieeinsparung und Umweltschutz. Das vibrierende fließende Bett ist eine neue Art von Geräten, die in den letzten zehn Jahren allmählich entwickelt und erweitert wurde, und wird zunehmend zum Hauptmodell für Trocknungsgeräte. Das vibrierende fluidisierte Bett ist ein neues Trocknungsgerät, das spezifische erforderliche Schwingungsquellen auf gewöhnliche flüssige Betttrockner anwendet. Diese Schwingungsquelle kann in Elektromotor -Methoden unterteilt werden, Elektromagnetische Induktionsmethode, Kurbelwelle oder exzentrische Methode, pneumatische oder hydraulische Methode gemäß seiner Anregungsmethode.

XSG -Serie Rotary Blitztrockner (Siliziumkarbidblitzverdampfung Trockner) ist eine neue Art von Trocknungsgeräten, die von unserer Fabrik auf der Grundlage der Einführung und Absorption fortschrittlicher Fremdtechnologie entwickelt wurde. Die Maschine hat fortschrittliche Technologie, angemessenes Design, Kompaktstruktur, breiter Anwendungsbereich, große Produktionskapazität, Gute Produktqualität, hohe Effizienz, und Energieeinsparung. Trocknen, zerquetschen, und das Screening werden gleichzeitig in einem Gerät abgeschlossen, Beseitigung der Umweltverschmutzung, und die Leistung der gesamten Maschine erreicht das internationale fortschrittliche Technologieebene.

Bananen-Heißluftumlaufofen eignen sich für das Material und das Produkt heißer Verfestigung und Trockenentwicklung im Arzneimittel, Chemikalie, Essen, Landwirtschaft, Nebenprodukt, Wasserprodukt, Lichtindustrie, Schwerindustrie und andere Industrien. Wie zum Beispiel: Rohstoffmedizin, Rohdroge, Vorbereitete Kräutermedizin der chinesischen traditionellen Medizin, Gips, Pulver, Teilchen, Trinkvermittler, Pille, Packflasche, Pigment, Farbstoff, Entwässerung von Gemüse, getrocknetes Fruchtstück, Wurst, Kunststoff, Harz, Elektrische Komponente, Backlack und etc.

XSG Chlortetracyclin -Blitzdampfverdampfer wird häufig zum Trocknen von Materialien wie Paste verwendet, Kuchenform, Pulver, Granulatmaterial, usw. Es handelt.

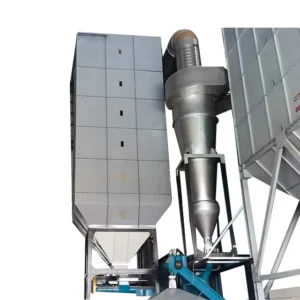

Natriumchlorid Horizontaler Flüssigkeitsbetttrockner wird ebenfalls als fluidisiertes Bett bezeichnet. Es besteht aus Luftfilter, Heizung, Hauptbett-Hauptmaschine, Feeder, Zyklonabscheider, Stoffbeutel Duster, Hochdruckzentrifugenlüfter, und Betriebstabelle. Der Staubsammler muss gemäß den Eigenschaften von Rohstoffen ausgestattet sein. Sie können den Zyklonabscheider oder Stoffbeutel nach den Materialmerkmalen verwenden, Der Zyklonabscheider wird hauptsächlich für Materialien mit hohem spezifischen Schwerkraft verwendet und der Stoffbeutel Duster wird hauptsächlich für Pulver- und kleine Granulatmaterialien verwendet. Der Luftversorgungsgerät und der Gürtelförderer sind optional. Die Wärmequelle kann Dampf verwenden, Strom, Heißluftofen gemäß den Kundenanforderungen.

Werkseitig Direktverkauf Plastik Erdnussöl Flüssige Wäscherei Seide Pfeffer Mist Mango Spin -Bildschirm Protein Futtermittelblitzverdampfung XSG Serie Spin Blitztrockner XSG Spin Blitztrockner wird häufig zum Trocknen von Materialien wie Paste verwendet, Kuchenform, Pulver, Granulatmaterial, usw. Es ist ein neuer Typ mit hoher Trocknungseffizienz und geringem Energieverbrauch…

Natriumsulfat vibrierende fluidisierte Betttrockner anwendbare Materialien

Borsäure, Borax, Dihydroxybenzol, Malinsäure, Maleinsäure, Monosatriumglutamat, Oxalat, Kalium, Permanganat, Sesam, Pentaerythritol, HPAM, Hyphenprotein, Natriumsulfat, Natriumborat, Plastikarchon, Katalysator, Backpulver, Waschmittel, Quarzsand, Bohnenpulpe, Essbarer Zucker, Salz verfeinern, Bohne, Samen, Bergbauschlacke, Aktivierter Ton, Verbunddünger, und etc..

Auswahl der Jiangsu Changshi -Technologie bedeutet, einen erfahrenen Partner mit einer Vielzahl von Produkten auszuwählen, Anpassungsfunktionen, und ein engagiertes Team, das Sie bei jedem Schritt unterstützt.

Zu maßgeschneiderte Trocknungslösungen, die Ihren spezifischen Projektanforderungen entsprechen.

Engagierte Verkäufe, Technologie, und After-Sales-Teams, um einen nahtlosen Service zu gewährleisten.

Zuverlässig, Hochleistungs-Trocknungsmaschinen erfüllen strenge Branchenstandards.

Das aktive Suchen und Einbinden von Kundenfeedback ermöglicht es uns, sich anzupassen und zu verbessern, Stellen Sie sicher, dass unsere Produkte nicht nur den Kundenerwartungen in Bezug auf Qualität und Leistung erfüllen, sondern die Kundenerwartungen übertreffen

Unser Unternehmen hat seit vielen Jahren den Kunden vor dem Verkauf und den After-Sales-Service für Kunden beachtet, Um den Benutzern zufriedenstellende Lösungen zu bieten, hochwertige Produkte, Perfekt nach dem Verkauf, ist unsere konsequente Verpflichtung, die Zufriedenheit jedes Kunden zu gewinnen.

Umarmen Sie das Kundenfeedback als wertvolle Ressource, Wir verwenden es, um die kontinuierliche Verbesserung unserer Produkte und Dienstleistungen voranzutreiben, Gewährleistung eines sich ständig weiterentwickelnden kundenorientierten Ansatzes.

„Die Jiangsu Changshi -Technologie hört nicht nur zu, sondern wirkt sich umgehend auf das Kundenfeedback aus. Ihr Engagement für Verbesserungen zeigt sich in der verbesserten Qualität und Leistung ihrer Produkte.“

„Die Feedback -Schleife mit der Jiangsu Changshi -Technologie ist wirklich kollaborativ. Sie schätzen unsere Erkenntnisse und arbeiten darauf hin, Bedenken auszuräumen, Schaffung einer Partnerschaft, die sich eher wie eine gemeinsame Reise in Richtung Exzellenz anfühlt.“

„Ihre Aufnahmefähigkeit für Feedback unterscheidet sie. Es geht nicht nur darum, ein Produkt zu liefern; Es geht darum, eine Erfahrung zu schaffen, Und sie stellen sicher, dass die Stimme des Kunden nicht nur gehört wird, sondern in ihre laufenden Innovationen einbezogen wird.“

Ja, um Ihnen zu helfen, besser zu helfen, Wir empfehlen Ihnen, den Namen des Rohstoffs anzugeben, den Sie verarbeiten möchten.

Ja, Natürlich. Wir können Extraktionstests durchführen und Videos senden und Berichte für Ihre Referenz testen.

Ja, wir werden, Solange Sie uns Ihre Zeichnungen und detaillierten Anforderungen zur Verfügung stellen.

Sie können zum Flughafen Changzhou fliegen, oder wenn Sie in Shanghai ankommen, Sie können uns Ihren speziellen Standort mitteilen. Wir werden einen Fahrer arrangieren, um Sie abzuholen.

Wir wählen normalerweise den Seetransport. Labormodelle können gemäß den Kundenanforderungen von AIR verschickt werden.

Die Ausrüstungsspannung beträgt 110 V ~ 380 V, Die Spezifikation kann gemäß dem Spannungsstandard des Landes angepasst werden, in dem Ihre Ausrüstung verwendet wird.

Unser Unternehmen hat seit vielen Jahren den Kunden vor dem Verkauf und den After-Sales-Service für Kunden beachtet, Um den Benutzern zufriedenstellende Lösungen zu bieten, hochwertige Produkte, Perfekt nach dem Verkauf, ist unsere konsequente Verpflichtung, die Zufriedenheit jedes Kunden zu gewinnen.