Wie vibrierende Wirbelschichttrockner funktionieren

Ein vibrierender Wirbelschichttrockner trocknet Materialien, indem er Partikel in einem Heißluftstrom suspendiert, während die Maschine vibriert. Sie sehen, wie die Vibration dabei hilft, die Partikel in Bewegung zu halten, Dadurch kann der Luftstrom jeden Teil des Materials erreichen. Dieser Prozess gibt Ihnen schnell, gleichmäßiges Trocknen, insbesondere für Pulver und Granulate.

Zu den Branchen, die diese Technologie nutzen, gehören::

Lebensmittelverarbeitung (größten Marktanteil)

Chemikalien

Arzneimittel

Keramik

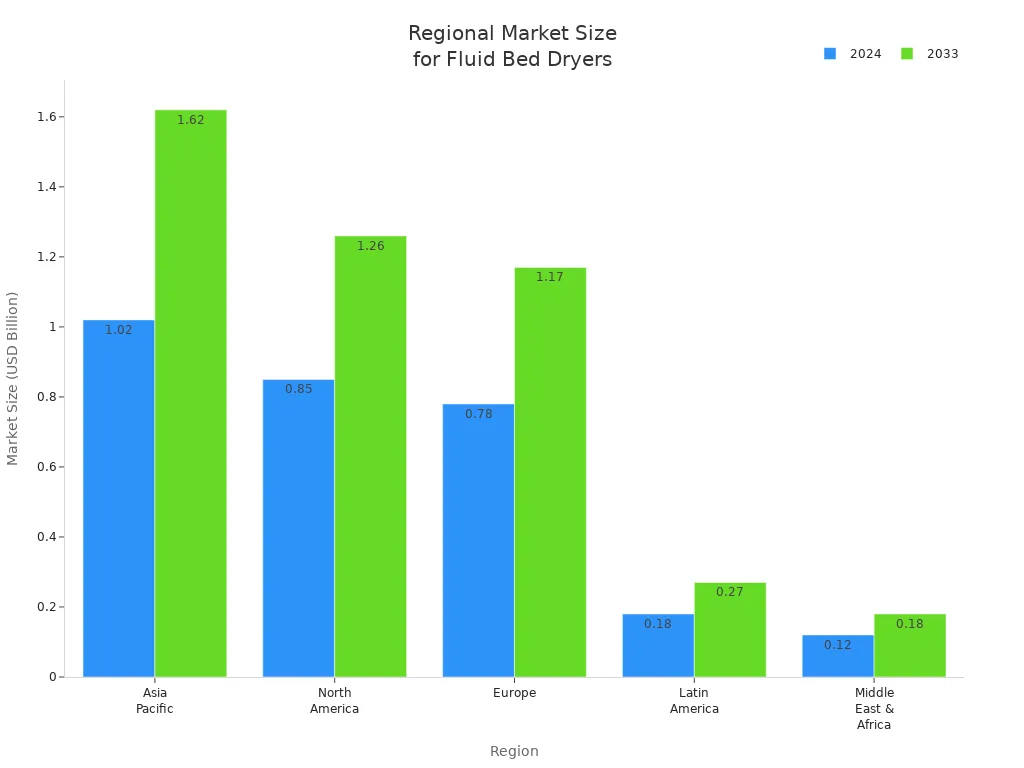

Der Weltmarkt für diese Trockner erreicht $750 Millionen in 2024 und wächst weiter, da Unternehmen nach energieeffizienten Lösungen suchen.

Wichtige Erkenntnisse

Vibrationswirbelschichttrockner nutzen Heißluft und Vibration, um Pulver und Granulate schnell und gleichmäßig zu trocknen.

Vibration hält Partikel in Bewegung, verhindert Klumpenbildung und sorgt dafür, dass heiße Luft jeden Teil des Materials erreichen kann.

Sie können die Temperatur steuern, Luftstrom, und Vibration, um verschiedene Materialien anzupassen und Energie zu sparen.

Diese Trockner eignen sich gut für Lebensmittel, Chemikalie, und Pharmaindustrie für sanfte, gleichmäßige Trocknung.

Die Wartung wird durch Funktionen wie Clean-in-Place-Systeme einfacher, und die Sicherheit wird durch Staubabscheider und Sensoren gewährleistet.

Grundlagen des vibrierenden Wirbelschichttrockners

Definition

Sie können sich einen vibrierenden Wirbelschichttrockner als eine spezielle Maschine vorstellen, die kleine Partikel oder Pulver trocknet. Es nutzt sowohl Vibration als auch Heißluft, um Materialien zu bewegen und zu trocknen. Die folgende Tabelle zeigt die Hauptmerkmale dieses Trockners:

Aspekt | Beschreibung |

|---|---|

Trocknertyp | |

Materialbetttiefe | Seicht (ein paar Zentimeter) |

Materielle Bewegung | Der Vibrationsförderer bewegt das Material mit einem nach oben erhitzten Luftstrom |

Rolle des Luftstroms | Heiße Luft strömt durch eine perforierte Wanne nach oben, um das Material zu trocknen |

Materialflussmuster | Pfropfenströmung, Es gilt also: First-In ist First-Out |

Partikelgrößenbereich | Behandelt Partikel von weniger als 50 Mikrometer bis ca 1/2 Zoll |

Anwendungen | Essen, Chemikalien, Arzneimittel, und mehr |

Vorteile | Reduziert die Kanalisierung, Funktioniert mit vielen Formen, einstellbarer Luftstrom, starke Förderkraft |

Einschränkungen | Benötigt mehr Platz als statische Trockner, mehr bewegliche Teile, Temperaturgrenzen |

Trocknungseffizienz | Trocknet schneller und verbraucht weniger Luft als statische Trockner |

Wartung | Mehr bewegliche Teile bedeuten mehr Wartung |

Umgang mit nassem Material | Sehr nasses Material muss möglicherweise mit trockenem Material gemischt werden |

Mit diesem Design können Sie viele Arten von Materialien schnell und gleichmäßig trocknen.

Zweck

Mit einem vibrierenden Wirbelschichttrockner erreichen Sie mehrere wichtige Ziele:

Erreichen schnelle und gleichmäßige Trocknung für Pulver und Granulate.

Verbessern Sie die Wärme- und Stoffübertragung, indem Sie Partikel in heißer Luft schweben lassen.

Verklumpungen verhindern, Daher trocknet jedes Partikel auf die gleiche Weise.

Sparen Sie Energie mit hoher thermischer Effizienz.

Schützen Sie empfindliche Materialien durch schonende Trocknung.

Behandeln Sie große Materialmengen für die industrielle Produktion.

Verbessern Sie die Produktqualität, indem Sie sicherstellen, dass jede Charge gleich trocknet.

Tipp: Wenn Sie Lebensmittel trocknen möchten, Chemikalien, oder Medizin, Dieser Trockner liefert zuverlässige Ergebnisse und spart Energie.

Komponenten

Luftsystem

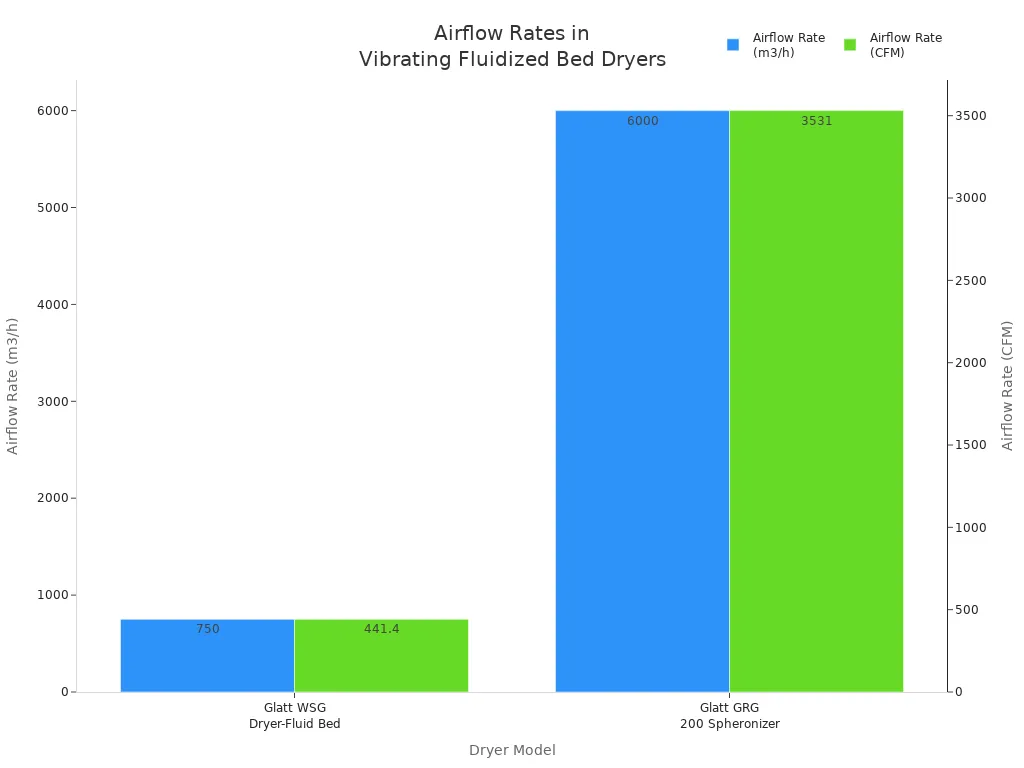

Sie verlassen sich darauf, dass das Luftsystem Wärme liefert, Druckluft durch das Partikelbett strömen lassen. Diese Luft hebt die Partikel an und trennt sie, Trocknung möglich machen. Die meisten Systeme verwenden eine perforierte oder poröse Platte, um die Luft gleichmäßig zu verteilen. Die Luftstromrate hängt vom Trocknermodell und Ihren Prozessanforderungen ab. Zum Beispiel, das Glatt WSG-Modell verwendet 750 m³/h Luft bei 3 Bar, während die Glatt GRG 200 erreichen kann 6,000 m³/h bei 0.5 Bar. Den Vergleich der Luftstromraten können Sie in der folgenden Tabelle sehen:

Trocknermodell | Hersteller | Luftsystemtyp | Luftstromrate (m³/h) | Luftstromrate (CFM) | Betriebsdruck (Bar) | Notizen |

|---|---|---|---|---|---|---|

Glatt WSG Trockner-Fließbett | Glatt | Erhitzt, Druckluft durch perforiertes Wirbelbett mit Vibration | 750 | 441.4 | 3 | Batch-Betrieb, Luft auf 70°C erhitzt, nutzt Druckluft bei 3 Bar |

Glücklich GRG 200 Sphäronisator | Glatt | Erhitzt, Druckluft durch perforiertes Wirbelbett | 6000 | 3531 | 0.5 | Batch-Betrieb, Luft auf 60°C erhitzt, niedrigerer Druck als WSG |

Niro Trockner-Fließbett | Niro | Kontinuierlich vibrierendes Wirbelbett mit perforiertem Wirbelbett | N / A | N / A | N / A | Dauerbetrieb, Spezifische Luftstromraten sind nicht angegeben |

Witte Vibrationsfließbetttrockner | Witte | Erhitzte Luft strömt unter Vibration durch die poröse Förderoberfläche | Variable (Hunderte bis Tausende) | N / A | N / A | Luftstromraten und -größen variieren je nach Anwendung, Produktfeuchtigkeit, Durchsatz, Temperatur |

Notiz: Sie können den Luftstrom an Ihr Material und Ihre Trocknungsbedürfnisse anpassen.

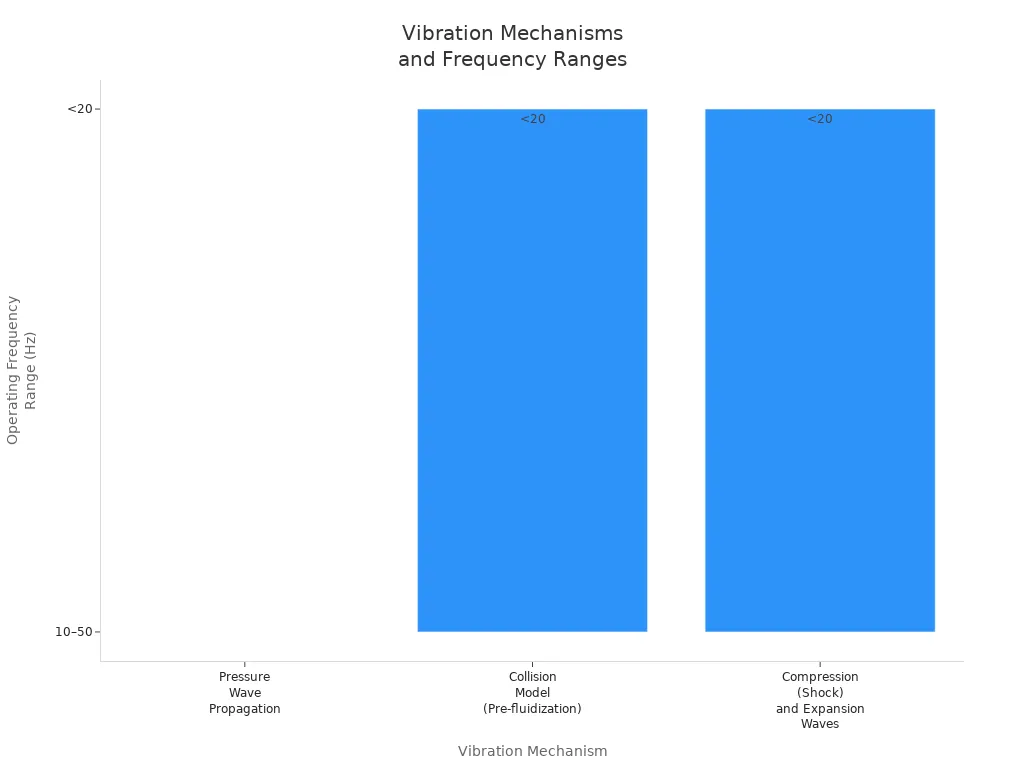

Vibrationsmechanismus

Der Vibrationsmechanismus hält die Partikel in Bewegung und sorgt dafür, dass die Luft jeden Teil des Materials erreicht. In diesen Trocknern finden Sie verschiedene Arten von Vibrationen. Manche nutzen Druckwellen, während andere Kollisions- oder Kompressionswellen verwenden. Die meisten Trockner arbeiten zwischen 10 Und 50 Hz. Niedrigere Frequenzen, unten 20 Hz, eignen sich gut für größere Partikel oder schwere Lasten. Die folgende Tabelle zeigt gängige Vibrationsarten und ihre Frequenzbereiche:

Vibrationsmechanismus | Beschreibung | Betriebsfrequenzbereich (Hz) |

|---|---|---|

Druckwellenausbreitung | Druckwellen von einer vibrierenden Basis übertragen Energie durch das Bett. | 10–50 (üblicherweise 10–25, ~30) |

Kollisionsmodell (Vorverflüssigung) | Energie bewegt sich durch Kollisionen zwischen der Basis und den Teilchen, dann durch Teilchenkollisionen. | Unten 20 |

Kompression (Schock) und Expansionswellen | Gepulster Gasfluss und Wellenausbreitung über das Bett bei niedriger Frequenz und hoher Amplitude. | Unten 20, Amplitude > 10 mm |

Tipp: Sie können die Trocknung verbessern, indem Sie die Vibrationsamplitude um ca. einstellen 3 mm.

Bettstruktur

Die Bettstruktur hält das Material und steuert die Bewegung von Luft und Partikeln. Normalerweise sehen Sie unten eine perforierte oder poröse Platte. Diese Platte verteilt die Luft gleichmäßig und stützt das Material. Auch die Form des Behälters spielt eine Rolle. Ringförmig (ringförmig) Betten liefern oft bessere Ergebnisse bei gleichmäßiger Trocknung. Die folgende Tabelle erläutert, wie sich verschiedene Teile der Bettstruktur auf die Trocknung auswirken:

Bettstrukturelement | Auswirkung auf Trocknungseffizienz und Gleichmäßigkeit |

|---|---|

Die richtige Positionierung gewährleistet den gewünschten Luftstrom und die gewünschte Temperatur, Dadurch werden die Luftstrommuster und die Gleichmäßigkeit des Endprodukts gesteuert. | |

Form des Produktbehälters | Unterschiedliche Formen beeinflussen die Partikelhaltung und die Temperatur-/Geschwindigkeitsverteilung; Ringförmige Designs liefern oft bessere Ergebnisse. |

Notiz: Ein gutes Bettdesign sorgt für eine gleichmäßige Trocknung und hohe Effizienz.

Entladung

Das getrocknete Produkt entnehmen Sie über ein Austragssystem am Ende des Bettes. Dieses System kann eine einfache Rutsche oder ein gesteuertes Ventil sein. Sie können die Austragsrate an Ihre Prozessgeschwindigkeit anpassen. Dieser Schritt stellt sicher, dass Sie einen gleichmäßigen Fluss an getrocknetem Material erhalten, bereit zur Verpackung oder Weiterverarbeitung.

So funktioniert ein vibrierender Wirbelschichttrockner

Materialzuführung

Sie starten den Trocknungsprozess, indem Sie Ihr Material dem vibrierenden Wirbelschichttrockner zuführen. Sie können a verwenden Schneckenförderer, Fließband, oder sogar manuelles Laden, Abhängig von Ihrem Setup. Der Feeder verteilt das Material gleichmäßig auf dem Bett. Diese gleichmäßige Verteilung ist wichtig, da dadurch jedes Partikel die gleiche Chance zum Trocknen erhält. Die Vibration des Trocknerkörpers fördert den Materialvorschub und unterstützt den Beginn der Fluidisierung. You can adjust the feeding rate to match your production needs.

Tipp: A steady, uniform feed keeps the drying process stable and prevents clumping at the start.

Fluidization by Airflow

Once the material enters the dryer, hot air flows upward through a perforated plate at the bottom of the bed. This air comes from a blower or supply fan and is heated to the right temperature for your product. The air lifts the particles, making them float and move freely. This floating state is called „fluidization.“ You control the air temperature and humidity to match your material. Zum Beispiel, you might use air at 70°C to 120°C for fertilizers, or lower temperatures for sensitive products. The perforated plate spreads the air evenly, so every particle gets the same amount of heat.

The air system also includes filters and dust collectors to keep the process clean and safe.

You can adjust the airflow to change how much the particles move and how fast they dry.

Vibration Effects

Vibration is what makes this dryer special. Der vibrating motor shakes the bed, causing the particles to jump and move in random directions. This movement keeps the particles from sticking together or settling in one spot. You get better mixing, which means the hot air can reach every surface of every particle. Vibration also helps prevent dead zones and clumps, so you avoid uneven drying. The combination of vibration and airflow turns the material from a static pile into a dynamic, moving layer. This dynamic state improves both heat and mass transfer, making drying faster and more uniform.

Vibration reduces friction between particles, so they move smoothly across the bed.

The gentle shaking protects delicate materials from breaking apart.

Trocknungsprozess

As the particles float and move, the hot air removes moisture from them. The heat from the air transfers to the wet material, causing water to evaporate. The moving particles expose new surfaces to the air all the time, so erfolgt die Trocknung schnell und gleichmäßig. You can control the temperature and humidity of the air to fit your product. Zum Beispiel, you might start with lower temperatures for very wet materials and increase the heat as drying continues. The control system lets you adjust fan speeds, Luftdruck, and vibration strength to get the best results.

Notiz: The dryer collects dust and fine particles using cyclone separators and filters, keeping the air clean before it leaves the system.

Product Movement

The vibration not only mixes the particles but also moves them forward along the bed. As the material travels, it spends enough time in the hot air to dry completely. The horizontal movement prevents particles from staying in one place too long or escaping too soon. This steady flow keeps the bed depth even and ensures that every batch dries the same way. At the end of the bed, the dried product leaves through a discharge spout or valve. Sie können die Austragsrate an Ihre Prozessgeschwindigkeit anpassen.

The horizontal transport avoids dead zones and blow-through, so you get uniform drying.

The system recovers dust and keeps the environment safe.

In summary, the vibrating fluidized bed dryer uses a careful balance of feeding, Luftstrom, vibration, and movement to turn wet material into a dry, uniform product. You get fast, efficient drying with less risk of clumping or uneven results.

Features and Advantages

Energieeffizienz

You can achieve impressive energy savings with a vibrating fluidized bed dryer. Der vibratory motion improves heat transfer and keeps particles moving, so you use less drying air. This system dries materials faster than conventional dryers. You also get schonende Handhabung, which protects your product and keeps moisture levels even. When you operate near the system’s natural frequency, du kannst boost energy efficiency by 5% Zu 15%. The dryer uses less energy while still giving you high drying rates and quality results. You can control the air temperature and vibration to match your needs, which helps you avoid wasting energy.

Tipp: Lower drying temperatures and the right vibration settings can help you save even more energy.

Process Control

You have strong control over the drying process. Real-time monitoring lets you adjust temperature, Luftstrom, and humidity as needed. Vibration helps you move even tough materials, so you avoid hot spots and uneven drying. You can use zoning to create different drying stages in one machine. Adjusting the vibration angle lets you control how long the material stays in the dryer. Plug flow design ensures that the first material in is the first out, so you get consistent results every time.

You prevent under-drying or over-drying by adjusting settings on the fly.

Consistent drying improves product quality and safety.

Vielseitigkeit

A vibrating fluidized bed dryer works with many types of materials. Du kannst dry powders, Granulat, fibers, and even small particles. This dryer is common in the food, Chemikalie, and pharmaceutical industries. You can handle grains, cereals, fruits, Polymere, und Katalysatoren. If you need to dry materials with different particle sizes, you can adjust the vibration and airflow. You should check the moisture content before drying, since too much moisture can cause problems like bed stall. Breaking up large lumps before drying helps you get better results.

Material Type | Example Products | Industrie |

|---|---|---|

Powders/Granules | Arzneimittel, grains | Pharma, Essen |

Fibers | Cellulose, plant fibers | Chemikalien, Essen |

Small Particles | Katalysatoren, Polymere | Chemikalien |

Wartung

You will find maintenance easier with a vibrating fluidized bed dryer, especially if you use a circular design. These dryers often have features like internal vibration cancellation, clean-in-place nozzles, and removable hoods. You can clean and set up the dryer quickly, was Ausfallzeiten reduziert. You do not need to worry about belt tension or cleaning under belts, as you would with belt dryers. The risk of dust explosions is lower, and you avoid problems like uneven drying or burning. If you use a rectangular unit, you may need more time for cleaning, but overall, maintenance is simpler than with many other drying systems.

Notiz: Regular cleaning and inspection help you keep your dryer running smoothly and safely.

Anwendungen

Lebensmittelindustrie

You often see these dryers in food processing plants. They help you dry products like Salz, Milchpulver, Semmelbrösel, potato granules, powdered sauces, instant foods, soybeans, rice, Gewürze, nuts, and cheese. The table below shows some common food products and the benefits you get from using this drying method:

Food Products Dried | Vorteile |

|---|---|

Salz, Milk Powder, Bread Crumbs, Potato Granules, Powdered Sauces, Instant Foods, Soybeans, Rice, Spices, Nüsse, Cheese | – Consistent drying |

Multi-zone dryers let you control temperature and airflow in each zone. Sie können trocknen, roast, sterilize, and cool in one system. This setup protects fragile foods and keeps quality high.

Chemicals and Pharmaceuticals

You use these dryers to handle chemicals and pharmaceutical products with high moisture or poor flow. Vibration keeps materials from sticking together and helps you dry sticky or hard-to-move powders. The table below explains how these dryers work in these industries:

Aspekt | Beschreibung |

|---|---|

Use Case | |

Vibrationsmechanismus | Uses controlled vibration for gentle movement |

Heating Methods | Direct or indirect heating, heat recovery, high-temp heat pumps |

Process Control | Vibration controls drying time and mixing |

Vorteile | Even drying, Energieeinsparungen, improved product handling |

You can monitor moisture with advanced sensors. This helps you keep every batch safe and consistent. You also save energy because the system uses less air and lower pressure.

Other Uses

You find these dryers in many other industries. They help you dry minerals, Düngemittel, Kunststoff, Reinigungsmittel, and even pet food. You can use them for cooling, roasting, or sterilizing as well. The gentle movement and even airflow protect delicate materials and prevent dust problems.

You can dry a wide range of particle sizes.

You can combine several steps, like drying and cooling, in one machine.

You get reliable results for both bulk and specialty products.

Tipp: If you need to dry sensitive or fragile materials, this technology gives you control and efficiency.

You achieve efficient drying by following clear steps: feed your material, use hot air to fluidize particles, apply vibration for even movement, and collect the dried product. Vibration and airflow work together to give you uniform results and protect product quality.

Key benefits include:

Easy cleaning and maintenance

Precise control for consistent drying

Versatility for many materials

As demand grows in food, Chemikalie, and pharmaceutical industries, you can trust this method for reliable, high-quality drying.

FAQ

What materials can you dry in a vibrating fluidized bed dryer?

Sie können Pulver trocknen, Granulat, crystals, and small particles. Common products include salt, Zucker, grains, Chemikalien, and pharmaceuticals. This dryer works well for materials that flow easily and do not stick together.

How does vibration improve the drying process?

Vibration hält Partikel in Bewegung. You get better mixing and avoid clumping. The hot air reaches every surface, so drying happens faster and more evenly. You also reduce the risk of dead zones.

Can you adjust the drying temperature and airflow?

Ja, you can control both temperature and airflow. This helps you match the drying process to your material. You protect sensitive products and save energy by using only what you need.

Is cleaning and maintenance easy?

You will find cleaning and maintenance simple. Many dryers have removable parts and clean-in-place systems. Regular checks keep your dryer running safely and efficiently.

What safety features do these dryers have?

Most dryers include dust collectors, filters, and explosion vents. You protect your workplace from dust and overheating. Sensors help you monitor temperature and airflow for safe operation.