Continuous plate dryer Ideal application on Pesticide production line

Continuous plate dryer

Material Overview:

Pesticide, currently the unified English name is pesticide, which means “killing agent”, but in fact the so-called pesticide refers to the chemical and biological drugs used to control harmful organisms (pests, mites, nematodes, pathogens, weeds and rodents) that endanger agricultural, forestry and animal husbandry production. Later, through the long-term development of production and life, some natural products have the ability to control harmful organisms in agriculture and animal husbandry. Up to 17 categories, etc.) and regulate plant growth. Various additives used for hygiene and improving the physical and chemical properties of active ingredients are usually included.

changshi Continuous plate dryer machine

Continuous plate dryer Ideal application for Pesticide production line

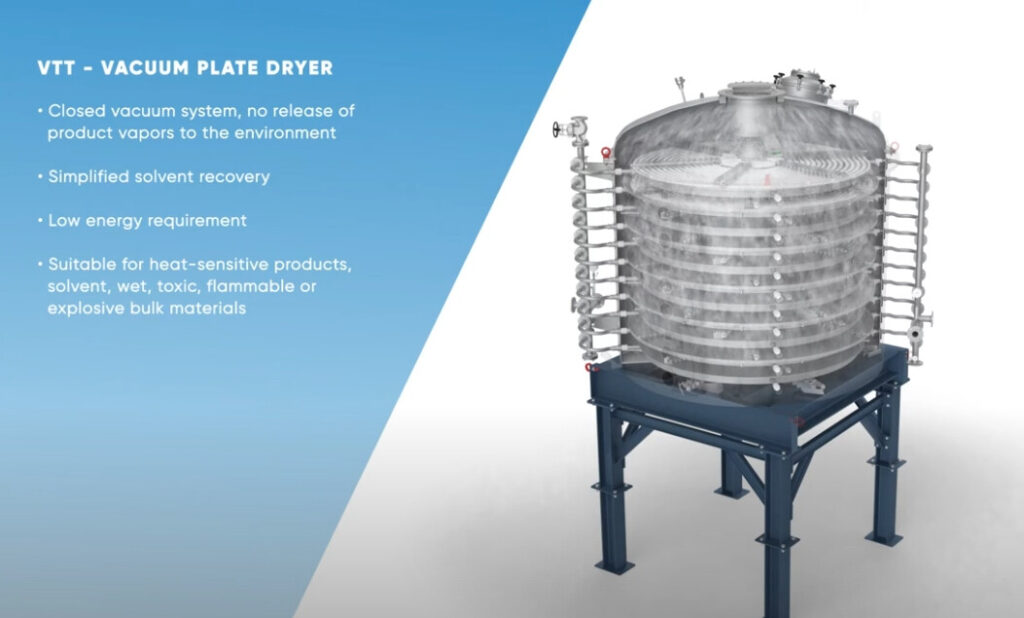

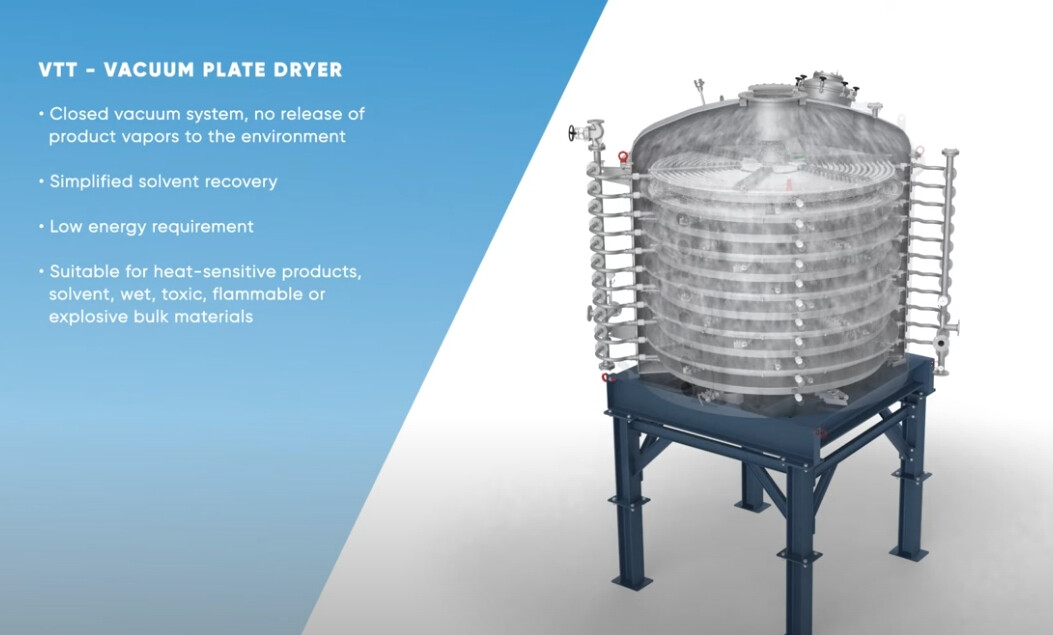

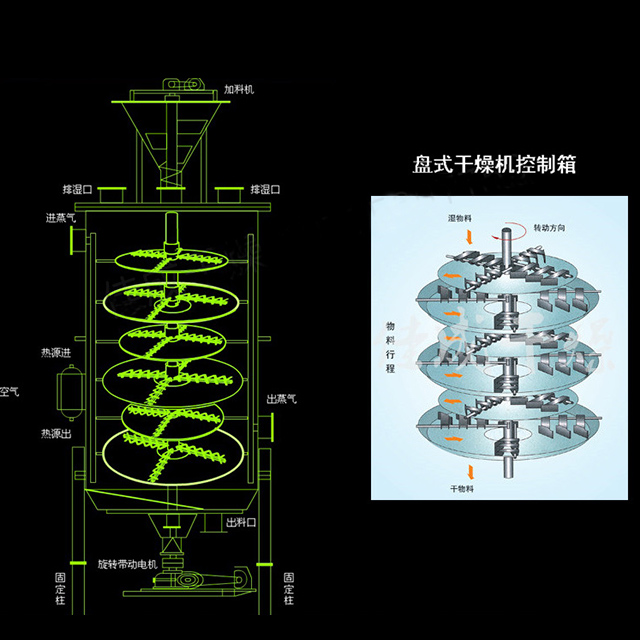

The continuous plate dryer is a highly efficient conduction-type continuous drying equipment. Its unique structure and working principle determine that it has the characteristics of high thermal efficiency, low energy consumption, small footprint, simple configuration, convenient operation and control, and good operating environment. It is widely used in chemical, pharmaceutical, pesticide, food, feed and other industries.

changshi Continuous plate dryer machine adopts interlayer heating and internal stirring at the same time, with a large heat transfer surface and high thermal efficiency. Continuous plate dryer is set to stir, so that the material forms a continuous circulation state in the barrel, further improving the uniformity of the material heating. Continuous plate dryer is set to stir, so that the slurry, paste and paste materials can be dried smoothly.

changshi Continuous plate dryer Performance characteristics

(I) Easy to adjust and strong applicability

◎ The drying process can be optimized by adjusting the material layer thickness, spindle speed, number of rake arms, rake blade type and size.

◎ Each layer of the drying plate can be heated or cooled by the hot medium or cold medium alone, and the material temperature can be accurately and easily controlled.

◎ The residence time of the material can be accurately adjusted.

◎ The flow direction of the material is single, there is no back-mixing phenomenon, the drying is uniform, the quality is stable, and no re-mixing is required.

(II) Simple and easy operation

◎ The start-up and shutdown operations of the dryer are very simple.

◎ After stopping the feeding, the conveying material dirt rake blade can quickly empty the material in the dryer.

◎ Through the special large inspection door mirror, the equipment can be carefully cleaned and observed.

(III) Low energy consumption

◎ The material layer is very thin, the spindle speed is low, the material conveying system requires small power and low power consumption.

◎ Drying is carried out by heat conduction, with high thermal efficiency and low energy consumption.

(IV) Good operating environment, solvent can be recovered, and dust emission meets the requirements

◎ Normal pressure type: Due to the low air flow velocity in the equipment and the high-up and low-down distribution of humidity in the equipment, it is difficult for dust to float to the top of the equipment, so the exhaust gas discharged from the top dehumidification port contains almost no dust.

◎ Closed type: Equipped with a solvent recovery device, it can easily recover organic solvents in the wet gas. The solvent recovery device is simple and has a high recovery rate. For flammable, explosive, toxic and easily oxidized materials, nitrogen can be used as a wet gas for closed-loop circulation to make it safe to operate. It is particularly suitable for drying flammable, explosive and toxic materials.

◎ Vacuum type: A disc dryer operated under vacuum is particularly suitable for drying heat-sensitive materials.

(V) Easy installation and small footprint

◎ The dryer is shipped as a whole and transported as a whole. It only needs to be hoisted in place, and installation and positioning are very easy.

◎ Due to the layered layout and vertical installation of the drying disc, even if the drying area is large, the footprint is small.

Applicable materials

Drying, pyrolysis, combustion, cooling, reaction, sublimation

◎Organic chemical products◎Inorganic chemical products◎Medicine, food◎Feed, fertilizer

changshi Continuous plate dryer machine Application:

● Drying of the following materials in the pharmaceutical, food, chemical and other industries.

● Suitable for slurry, paste, and powder materials.

● Heat-sensitive materials that require low-temperature drying.

● Oxidizable, explosive, highly irritating, and highly toxic materials.

● Materials that require the recovery of organic solvents.

changshi Continuous plate dryer machine Technical parameter table:

| Item \ type | Diamter (mm) | High (mm) | Area of dry (m2) | Power (Kw) |

| 1200/4 | Φ1850 | 2718 | 3.3 | 1 |

| 1200/6 | 3138 | 4.9 | ||

| 1200/8 | 3558 | 6.6 | 1.5 | |

| 1200/10 | 3978 | 8.2 | ||

| 1200/12 | 4398 | 9.9 | 2.2 | |

| 1500/6 | Φ2100 | 3022 | 8.0 | |

| 1500/8 | 3442 | 10.7 | ||

| 1500/10 | 3862 | 13.4 | ||

| 1500/12 | 4282 | 16.1 | 3.0 | |

| 1500/14 | 4702 | 18.8 | ||

| 1500/16 | 5122 | 21.5 | ||

| 2200/6 | Φ2900 | 3319 | 18.5 | |

| 2200/8 | 3739 | 24.6 | ||

| 2200/10 | 4159 | 30.8 | 4.0 | |

| 2200/12 | 4579 | 36.9 | ||

| 2200/14 | 4999 | 43.1 | 5.5 | |

| 2200/16 | 5419 | 19.3 | ||

| 2200/18 | 5839 | 55.4 | 7.5 | |

| 2200/20 | 6259 | 61.6 | ||

| 2200/22 | 6679 | 67.7 | 11 | |

| 2200/24 | 7099 | 73.9 | ||

| 2200/26 | 7519 | 80.0 |

| Item \ type | Diamter (mm) | High (mm) | Area of dry (m2) | Power (Kw) |

| 2500/6 | Φ3150 | 3319 | 26.3 | 4 |

| 2500/8 | 3739 | 35 | ||

| 2500/10 | 4159 | 43.8 | 5.5 | |

| 2500/12 | 4579 | 52.5 | ||

| 2500/14 | 4999 | 61.3 | 7.5 | |

| 2500/16 | 5419 | 70 | ||

| 2500/18 | 5839 | 78.8 | 11 | |

| 2500/20 | 6259 | 87.5 | ||

| 2500/22 | 6679 | 96.3 | ||

| 2500/24 | 7099 | 105 | 13 | |

| 2500/26 | 7519 | 113.8 | ||

| 3000/8 | Φ3800 | 4050 | 48 | 11 |

| 3000/10 | 4650 | 60 | ||

| 3000/12 | 5250 | 72 | ||

| 3000/14 | 5850 | 84 | ||

| 3000/16 | 6450 | 96 | ||

| 3000/18 | 7050 | 108 | 13 | |

| 3000/20 | 7650 | 120 | ||

| 3000/22 | 8250 | 132 | ||

| 3000/24 | 8850 | 144 | ||

| 3000/26 | 9450 | 156 | 15 |

Related Products

more about changshi companyhttps://jscstech.cn/