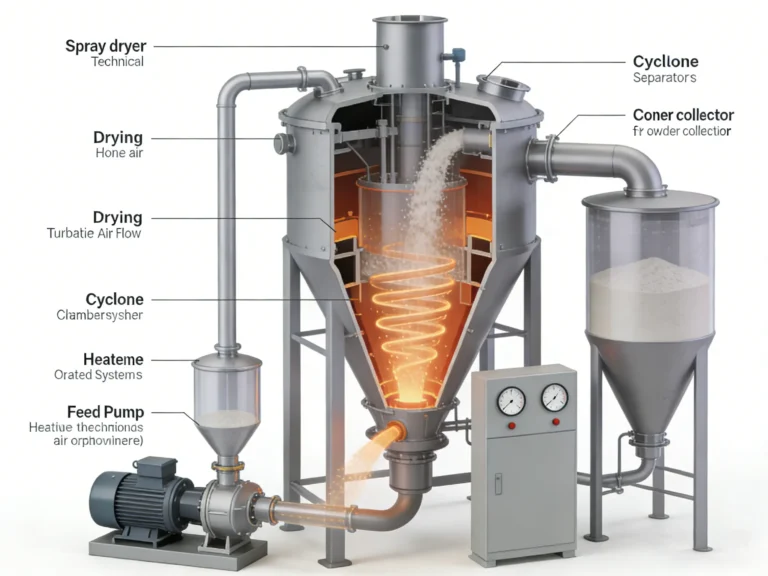

Spray Drying Process Explained Simply for Everyone

The spray drying process turns liquids into powders by atomizing and drying droplets with hot air, ensuring fast, efficient, and consistent results.

The spray drying process turns liquids into powders by atomizing and drying droplets with hot air, ensuring fast, efficient, and consistent results.

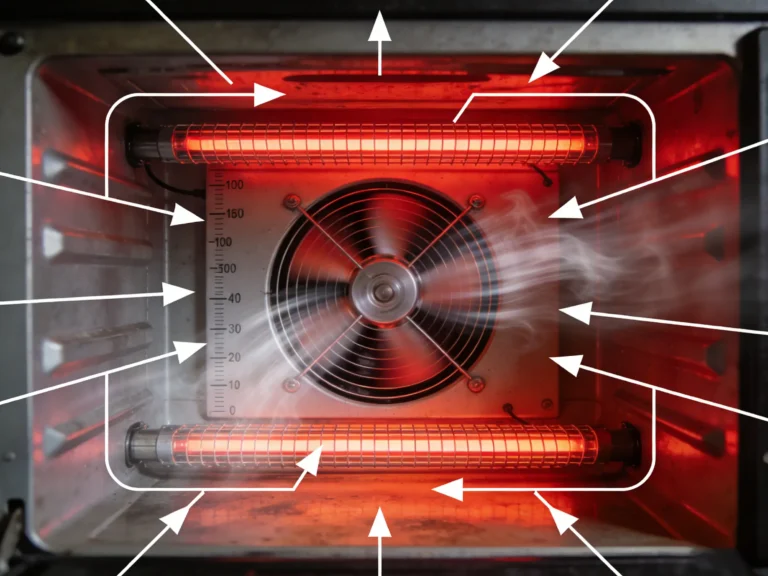

A drying oven in laboratory removes moisture from samples using controlled heat and airflow, ensuring uniform drying and reliable experimental results.

A Hot Air Circulating Oven uses a fan to distribute heat evenly, ensuring fast, energy-efficient drying, sterilizing, and baking for labs and kitchens.

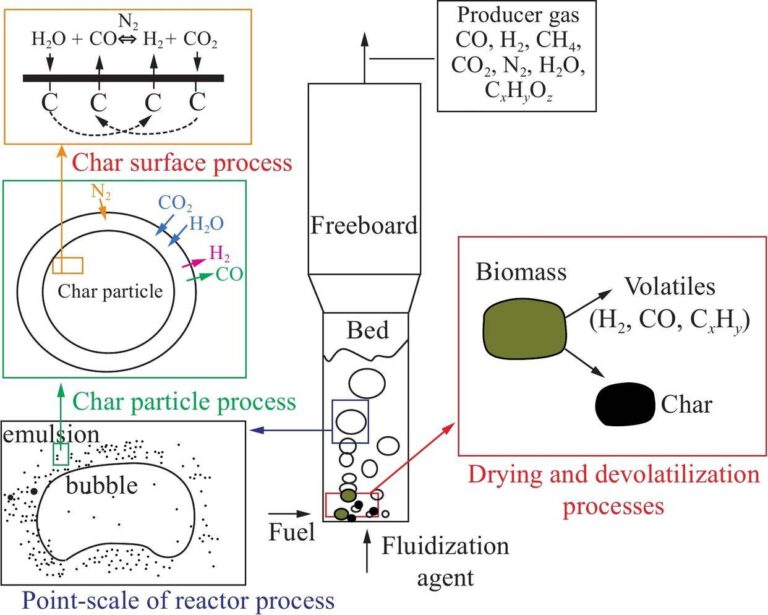

Fluid Bed Drying offers fast, uniform moisture removal for powders, granules, and pellets, improving efficiency and product quality in various industries.

Fluid Bed Drying offers fast, uniform drying for pharmaceuticals, food, chemicals, agriculture, and minerals, improving efficiency and product quality.

Fluidization advantages include faster, uniform drying, energy savings, and gentle handling, making it superior to other drying methods for many industries.

The basic principle of fluidization involves balancing upward fluid force with particle weight, enabling efficient mixing and heat transfer in industry.

A spray dry tower turns liquid or slurry into dry powder by atomizing droplets and drying them with hot air, ideal for heat-sensitive products.

Compare experimental and computational methods for spray dryer design calculations to determine the most accurate and scalable approach for your process.

A spray dryer como funciona by atomizing liquid into droplets, drying them with hot air, and collecting powder for efficient industrial production.