3 Key Fluid Bed Dryer Specification Facts You Need

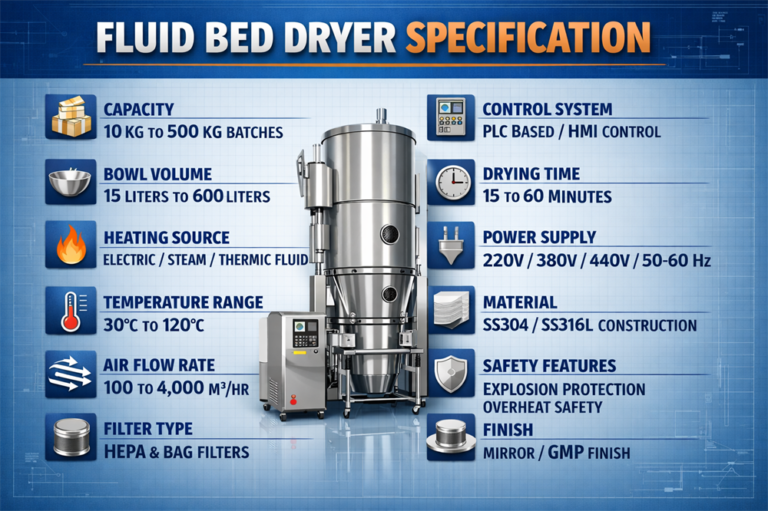

Understand fluid bed dryer specification: airflow, temperature control, and batch size for optimal drying performance and consistent product quality.

Your blog category

Understand fluid bed dryer specification: airflow, temperature control, and batch size for optimal drying performance and consistent product quality.

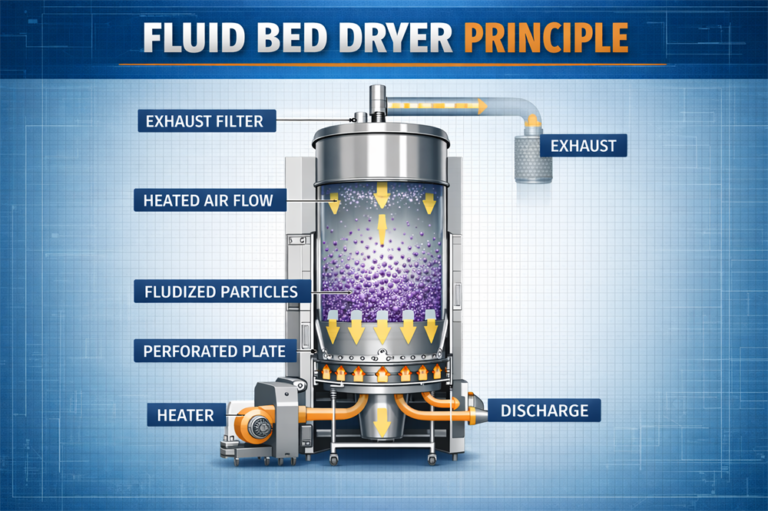

Fluid bed dryer principle: Hot air fluidizes particles, ensuring rapid, uniform drying by maximizing heat and moisture transfer for powders and granules.

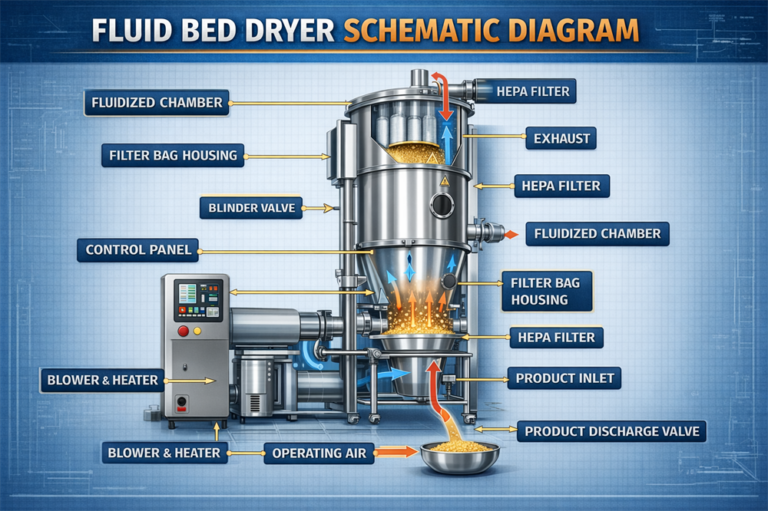

A fluid bed dryer schematic diagram shows how hot air fluidizes and dries powders, highlighting key components and airflow for efficient, even drying.

A secador spray industrial turns liquids into powders by atomizing feed and drying droplets with hot air, ideal for food, pharma, and chemical industries.

Compare types of spray dryer, including rotary, nozzle, and hybrid systems, to find the best fit for your product and industry needs.

Find out how to choose the best egg powder making machine for your business, considering capacity, features, certifications, and long-term costs.

A hot air oven sterilizes lab items using dry heat and convection, ensuring even, safe heating for glassware, metals, powders, and oils.

A spray dryer como funciona by atomizing liquid into droplets, drying them with hot air, and producing uniform powder for industrial use.

Follow this step-by-step guide for accurate spray dryer calculations, covering key data, formulas, and tips to determine dryer capacity.

Spray dryer design calculations Excel tools help you organize data, run mass and energy balances, and optimize your process for accurate, fast results.