The basic principle of fluidization

Fluidization happens when you pass a gas or liquid upward through fine solid particles at a speed that makes them behave like a fluid.

The basic principle involves the upward force from the fluid balancing the weight of the particles, causing them to lift and mix rapidly.

You see the state of fluidization when the bed of solids expands and bubbles form, much like boiling water.

The principle of fluidization allows you to achieve excellent mixing, heat transfer, and chemical reactions.

Many industries depend on this process for efficient operations.

Key Takeaways

Fluidization occurs when gas or liquid moves upward through solid particles, making them behave like a fluid. This process enhances mixing and heat transfer.

Understanding the factors affecting fluidization, such as particle size and density, helps improve efficiency in industrial applications.

Fluidized bed reactors are widely used in industries like chemical manufacturing and energy production for their ability to mix solids and fluids effectively.

Using fluidization offers advantages over traditional methods, including better moisture control and faster drying times for various materials.

Monitoring temperature and airflow is crucial for safe and efficient operation of fluidized beds, ensuring optimal performance.

Basic Principle

Fluidization Explained

You can understand the basic principle of fluidization by looking at how fine solid particles behave when you pass a gas or liquid through them. The basic principle starts with the fluid moving upward. This movement creates a force that lifts the particles. When the upward force matches the weight of the particles, the bed of solids begins to expand. You see bubbles form, and the particles mix quickly. The bed acts like a boiling liquid.

The onset of incipient instability in a particle bed is preceded by stable gas diffusion in the interstices and is caused by a critical momentum force that may overcome the inertia of the particles. The critical momentum force is provided by the critical superficial gas velocity Uc in the form of critical mass flux of diffusion. It is found that the first movement of particles may be predicted by a critical transient Rayleigh number determined by a critical superficial velocity equals to the minimum fluidization velocity, Umf. The onset of incipient fluidization was found to occur at a critical transient Rayleigh number of 3.1, which is close to the lowest theoretical value for buoyancy convection in a porous medium bounded by free surfaces.

You need to pay attention to several important factors that affect the basic principle. These include particle density, size, shape, and how the particles are packed together. The way the fluid moves through the bed also matters. You can see how these factors work together in the table below:

Aspect | Findings |

|---|---|

Particle Density Influence | Higher particle density leads to poorer fluidization performance during initial stages. |

Hydrodynamics | Significant effects on hydrodynamics observed, with errors in predictions for high-density particles. |

Fluidization Stages | Three distinct fluidization stages identified, influenced by particle size distribution. |

Particle Size Distribution | Narrow PSD leads to better flowability and lower minimum fluidization velocity (U*mf). |

Group C Particles | Wider PSD results in higher bed expansion and improved gas-solid contact. |

Nano-modulation | Enhances fluidization quality of Group C powders, indicating the importance of size and distribution. |

You can see different behaviors in the fluidization process depending on the type of particles. For example:

Geldart B/D particles form bubbles easily, but the bed does not expand much.

Geldart A particles expand evenly, which makes the bed more stable.

Shock and continuity waves move through the bed during gas flow, showing how the basic principle works in real time.

The basic principle of fluidization helps you achieve better mixing and heat transfer. You can use this process in many industries, such as chemical manufacturing and energy production.

Two-Phase Theory

You can explore the two-phase theory to understand the basic principle of fluidization more deeply. This theory says that the bed contains two main phases: the solid particles and the fluid (gas or liquid). The fluid supports the particles by pushing them upward. The particles move and mix because of the drag force and buoyancy from the fluid.

The geometrical, physical and aerodynamical properties of particulate solid materials all affect the onset of fluidization, and the characteristics, behavior and the main parameters of fluidized beds. The most important solid properties are: particle density, skeletal (true) density, bulk density, porosity, mean equivalent particle diameter, particle shape, particle size distribution, and free fall (or terminal) velocity.

You can see how the two-phase theory developed over time:

Stage | Description | Time Period |

|---|---|---|

1 | Early 1940s | |

2 | Introduction of two phase theory | Early 1950s |

3 | Bubble hydrodynamics studies | Early 1960s |

4 | General understanding of suspension structures | Turn of the century |

The two-phase theory helps you predict how the bed will behave. You can see dense and dilute regions in the bed. The fluid and solid phases interact, which leads to different flow patterns. The table below shows how scientists study these patterns:

Aspect | Details |

|---|---|

Study Focus | |

Operating Conditions | Superficial gas velocity: 15.5 m/s; Solid flux: 140 kg/m²s; Geldart B particles (sand) |

Key Findings | Axial solid concentration distribution shows dilute and dense regions. Core-annulus structure and back-mixing near the wall observed. |

Drag Force Model | Revised drag force coefficient based on the EMMS model was proposed and used in CFD simulations. |

Validation Method | Comparison of experimental results with CFD simulations to assess flow structure and pressure drop. |

Conclusion | EMMS drag model showed better agreement with experimental data, validating its use in simulations. |

In the two-phase theory, you see the solid phase supported by the fluid phase. The fluidization process depends on how well the fluid can lift and mix the particles. You can use this basic principle to improve chemical reactions and heat transfer in reactors.

Fluidized Bed

How a Fluidized Bed Works

You can see how a fluidized bed operates by watching what happens when you introduce air or liquid from below a bed of solid particles. The upward flow lifts the particles, causing them to move and mix. This movement creates a dynamic system where the particles behave almost like a liquid. You notice different flow regimes as the speed of the fluid changes. The table below shows how the bed changes with each regime:

Flow Regime Type | Description |

|---|---|

Fixed Bed | The initial state where particles are stationary and not fluidized. |

Bubbling Fluidization | Bubbles form within the bed, and particles interact more actively. |

Slugging Fluidization | Large bubbles appear, causing irregular movement of particles. |

Turbulent Fluidization | The flow becomes vigorous, and particles mix rapidly. |

Dilute-Phase Transport | Particles disperse in the gas phase, and concentration drops. |

Fast Fluidization | The bed acts like a fluid, with strong gas and particle interactions. |

Slug/Bubbly Flow | Both slugs and bubbles exist, creating mixed movement. |

Bubble-Free Dense-Phase Flow | The bed stays dense, and gas flow remains low. |

Packed Bed Flow | Particles pack tightly, and fluid movement is minimal. |

You can suspend solid particles in a continuous liquid phase using gas sparging. The liquid enters from the top and moves against the gas flow. The design of the gas distributor lets liquid exit from the bottom without carrying particles away. This mechanism allows you to use fine or low-density particles in a continuous flow reactor.

Uniform mixing happens when you introduce air from below the powder bed. The air lifts and agitates the particles, turning the dense powder into a fluid-like state. You can spray a liquid binding solution onto the fluidized particles to help granules grow and improve mixing.

Key Features

You will find several features that make a fluidized bed unique. The table below highlights these important aspects:

Key Feature | Description |

|---|---|

High surface area contact | You get a large contact area between fluid and particles in each bed volume. |

High relative velocities | The fluid and particles move quickly compared to each other. |

Intermixing | Particles mix thoroughly throughout the bed. |

Collisions | Frequent collisions happen between particles and with the walls. |

You need to consider design factors when building a fluidized bed. Particle size distribution affects how much air flow you need. Rounded particles behave differently than oblong ones, which changes drying uniformity. Bulk density influences the minimum velocity needed for fluidization and helps prevent material loss. Specific heat tells you how much energy you need to heat the particles. Fragile particles may need gentle fluidization to avoid breaking. Chemical composition can cause problems like stickiness or heat sensitivity. Inlet air temperature must match what the particles can handle. Air flow velocity controls the fluidization regime and heat transfer. Retention time depends on air flow and weir height, which helps you reach the right moisture level.

Temperature and pressure also affect how the fluidized bed works. Bubble movement controls the flow structure at lower temperatures. At higher temperatures, the way particles stick together becomes more important. Ultra-high temperatures increase interparticle forces, which can change how the particles behave.

Fluidized Bed Reactor

Industrial Applications

You can find fluidized bed reactors in many industries. These reactors help you handle chemical reactions and material processing more efficiently. You see them used in oil refining, chemical production, and energy generation. The design of these reactors lets you mix solids and fluids quickly, which improves the process.

Here are the main types of fluidized bed reactors you might encounter:

Type of Reactor | Description |

|---|---|

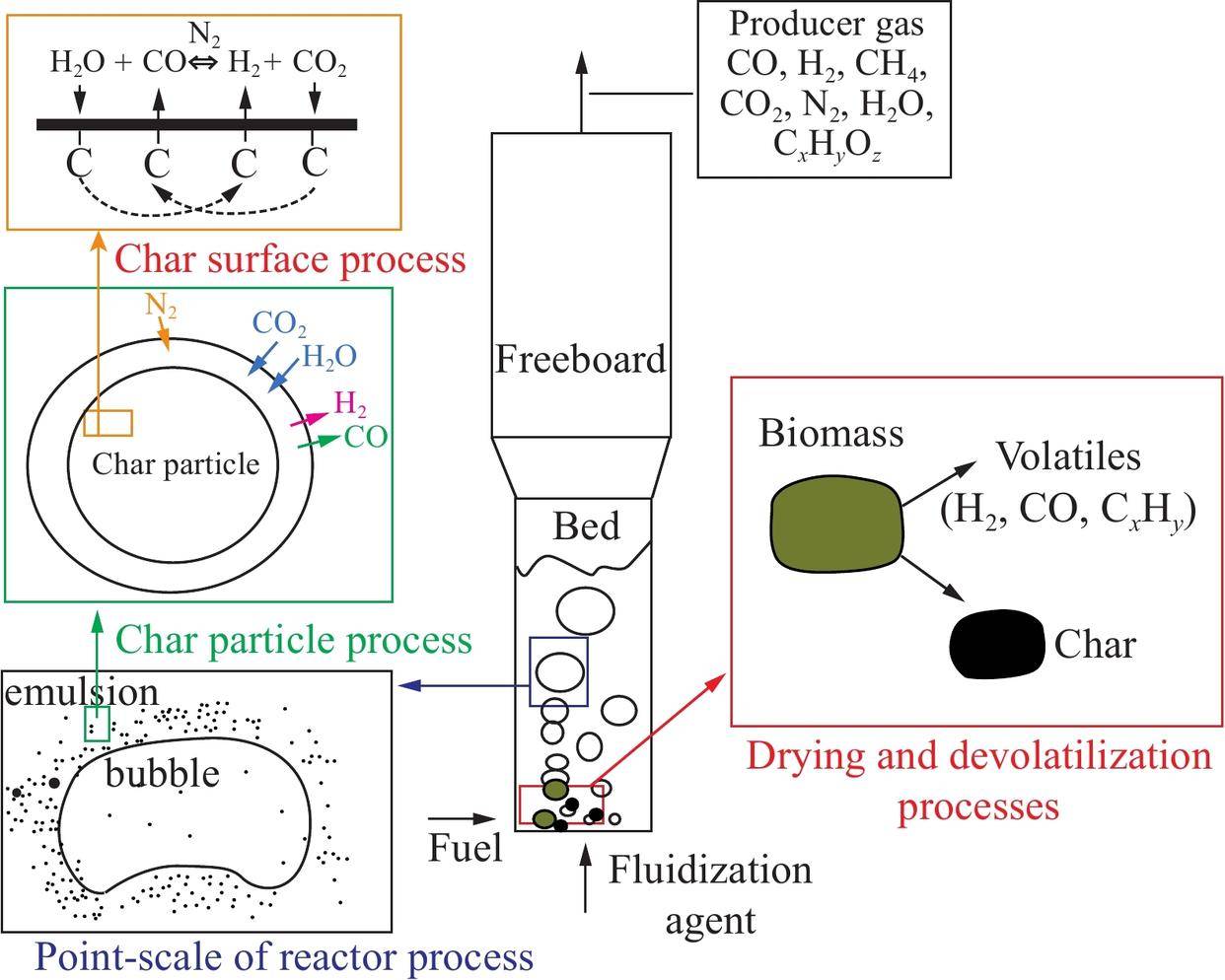

BFB (Bubbling Fluidized Bed) | Simple design with a reactor column, distributor, biomass screw feeding system, and cyclone for fine particle removal. |

CFB (Circulating Fluidized Bed) | Consists of a reaction column, multiple cyclones, and a biomass screw feeding system; captures and recirculates coarse and fine particles. |

Entrained Fluid Bed | Uses high gas velocities to keep particles suspended. |

Fluidized bed reactors play a key role in several industrial applications:

Application Type | Description |

|---|---|

Oil and Chemical Processing | Used for continuous feeding and production of bio-oil. |

Synthesis of Acrylonitrile | Employed in the production of acrylonitrile. |

Catalytic Cracking | Utilized in petrochemical industries for catalytic processes. |

Heat Transfer | Efficient heat transfer with uniform bed temperatures. |

You also see these reactors in pharmaceutical manufacturing. They help you dry powders, coat tablets, and mix ingredients. The market for fluidized bed reactors keeps growing. In 2024, the market reached USD 3.5 billion. Experts expect it to rise to USD 5.9 billion by 2033, with a steady growth rate.

Benefits

Fluidized bed reactors offer many advantages for industrial processes. You get better mixing and faster reactions. The design lets you control temperature and material flow easily. You can use these reactors for chemical synthesis, pollution reduction, and material processing.

Benefit/Application | Description |

|---|---|

Chemical Synthesis | Used for synthesizing key plastics like polyethylene and polypropylene, and producing monomers. |

Pollution Reduction | Generates less pollution by using sorbents to capture sulfur and operates at lower temperatures. |

Material and Heat Transfer | Facilitates efficient coating, drying of pharmaceuticals, and quick freezing of food products. |

You notice that heat and mass transfer rates in fluidized beds are much higher than in fixed bed reactors. This makes them ideal for reactions that need efficient heat and mass transfer. You can maintain uniform temperature distribution, which helps with heat transfer. The technology also allows you to regenerate catalysts often without stopping the process.

Fluidized bed reactors help you improve product quality in pharmaceutical manufacturing. You can dry and coat pharmaceutical powders evenly. You also reduce pollution and energy use, which benefits both the environment and your business.

Comparison

Traditional Methods

When you use traditional methods to handle fine solids, you often face many challenges. These methods include free solids splashing, directed gas injection, slugging, and solids entrainment. Each method has its own transport rate and energy efficiency. You can see the differences in the table below:

Method | Transport Rate (kg/m²·s) | Energy Efficiency |

|---|---|---|

Free Solids Splashing | 5 × 10⁻²–2 × 10³ | Highest |

Directed Gas Injection | 1.9–4.3 m/s | Intermediate |

Slugging | N/A | Intermediate |

Confined Solids Splashing | N/A | Lowest |

Solids Entrainment | N/A | Lowest |

You may notice that these methods do not always provide high efficiency, especially when you need to control moisture or achieve uniform mixing. Traditional systems often struggle with removing small trash, which can clog pumps and cause scum to build up. Heavy debris can damage equipment, so you need extra screening devices. When you handle high-solids loads, you must use fine screens and grinders to remove debris. These steps lower the overall efficiency and make it hard to control moisture levels.

Limitation | Impact on Operations |

|---|---|

Causes clogging of pumps and scum accumulation in digesters. | |

Damage from heavy debris | Necessitates additional screening devices to prevent equipment overload. |

Inability to handle high-solids loads | Requires a fine screen coupled with a grinder for effective debris removal in high-solids situations. |

Advantages of Fluidization

When you use fluidization, you gain several advantages over traditional methods. The working principle of fluidization lets you achieve higher efficiency in mixing, heat transfer, and moisture control. You can process a wide range of materials, from grains and spices to chemicals and pharmaceuticals, without changing your equipment. This flexibility means you can dry products with different moisture levels and reach a faster drying time.

Fluidized bed drying adapts to many food products, such as grains, snacks, and spices.

You can use the same equipment in different industries, including pharmaceuticals and chemicals.

The working principle allows you to process materials with various moisture contents, showing great operational flexibility.

You also get better process control and mixing. The working principle of fluidization, especially when combined with vibration, reduces the strong forces between fine particles. This makes it easier to mix and fluidize even the smallest particles. You achieve more even moisture removal and higher efficiency in drying and processing.

Fluidization with vibration breaks up clumps and improves mixing.

You can handle fine particles that are hard to process with traditional methods.

The process gives you more control, leading to better efficiency and more uniform moisture content.

Tip: When you need to dry products quickly and evenly, fluidization gives you a faster drying time and helps you reach the desired moisture level with less energy.

You have learned that fluidization turns solid particles into a fluid-like state, which helps you mix, heat, and process materials more efficiently. Fluidized beds and reactors play a key role in many industries. The table below shows some important benefits:

Application Area | Benefits |

|---|---|

Enhances charging and discharging in solar power plant energy storage systems. | |

Industrial Processes | Increases heat and mass transfer efficiency in various industrial applications. |

High Temperature Energy Storage | Improves power output in sensible and phase-change energy storage systems. |

Research into new fluidization methods, like Fluidized Bed Fenton technology, can help you treat wastewater better and reduce pollution. You can explore these advances to improve your own work or studies.

FAQ

What is fluidization used for in industry?

You use fluidization to improve mixing, drying, and chemical reactions. Many industries rely on this process to boost energy efficiency and product quality. You often see it in food, chemical, and pharmaceutical manufacturing.

How do you control a fluidized bed?

You control a fluidized bed by adjusting the flow rate of gas or liquid. This lets you manage temperature, mixing, and particle movement. Good control helps you achieve better results and maintain energy efficiency.

Why does fluidization improve energy efficiency?

Fluidization improves energy efficiency because it increases contact between particles and fluids. You get faster heat transfer and better mixing. This means you use less energy to reach the same results.

Can you use fluidization for small particles?

Yes, you can use fluidization for small particles. You may need special equipment to control the process. This helps you avoid particle loss and maintain stable operation.

What safety tips should you follow with fluidized beds?

You should monitor temperature and pressure closely. Always control the airflow to prevent overheating or blockages. Regular checks keep your system safe and efficient.